Isuzu D-Max / Isuzu Rodeo (TFR/TFS). Manual — part 1783

ON-VEHICLE SERVICE (JR405E) 7A3-21

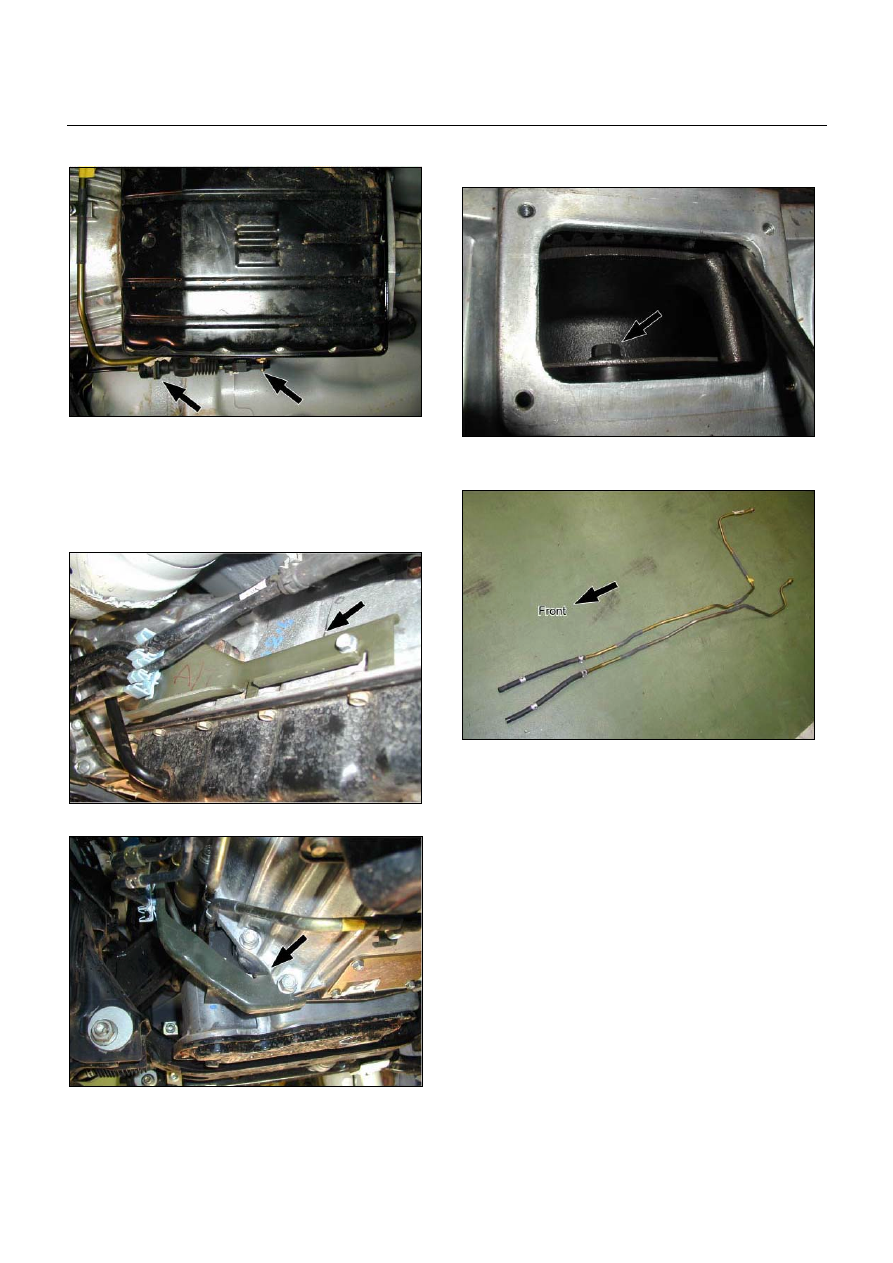

4. Remove the shift cable from the transmission.

P1010068

5. Remove the rear propeller shaft assembly.

6. Loosen (do not remove) the nuts securing the

exhaust manifold and the exhaust pipe.

7.

Disconnect the harness connectors from the

transmission.

8. Remove the fuel pipe bracket.

P1010013

P1010014

9. Remove the ATF level dipstick and tube.

10. Remove the undercover.

11.

Rotate the ring gear and remove the 6 torque

converter bolts.

P1010016

12.

Remove the automatic transmission fluid cooling

pipe.

P1010060

13. Place a jack beneath the engine to support it.

14. Remove the 3rd crossmember.

15. Remove the transmission mount.

16. Lower the jack beneath the engine slightly to tilt the

engine and transmission. Do not allow the radiator

and air conditioner hoses to stretch.

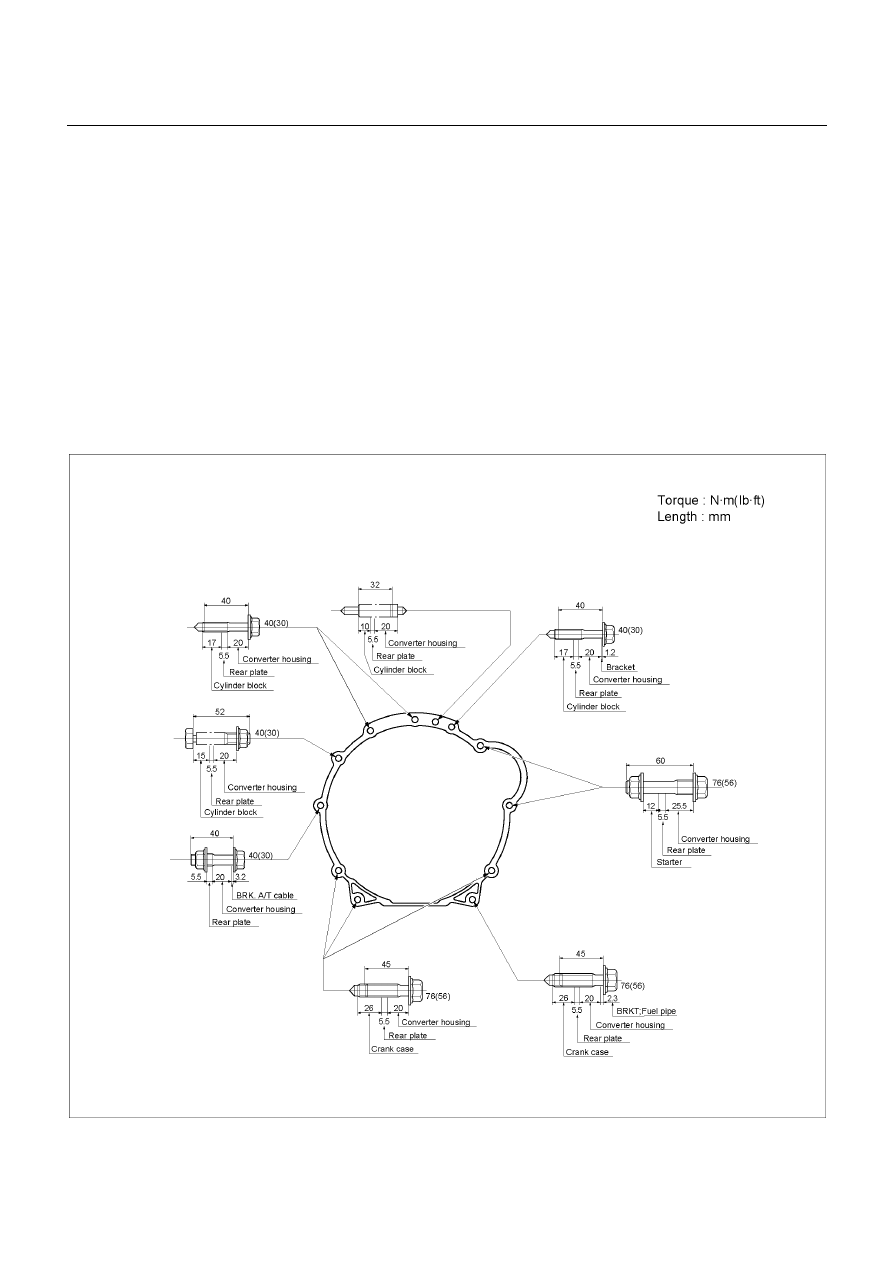

17. Remove the bolts attaching the transmission to the

engine.

18.

Lower the transmission from beneath the vehicle.

Take care not to damage the breathers.

Install or Connect

1. Install the transmission to the engine and tighten the

bolts.

Bolt torque : M10 40 N·m (30 lb·ft)

M12

76

N·m (56 lb·ft)

2. Install the cable bracket to the transmission.

3. Connect the engine harness connectors.

7A3-22 ON-VEHICLE SERVICE (JR405E)

4. Install the 3rd crossmember.

Bolt and Nut torque : 67 N·m (49 lb·ft)

Bolt torque : 50 N·m (37 lb·ft)

5. Install the automatic transmission fluid cooling pipe.

6. Install the torque converter bolts.

Bolt torque : 29 N·m (22 lb·ft)

7. Install the undercover.

Bolt torque : 9 N·m (78 lb·in)

8. Install the ATF level dipstick and tube.

9. Install the fuel hose bracket.

Bolt torque : 6 N·m (52 lb·in)

10. Tighten the nuts securing the exhaust manifold and

the exhaust pipe.

Bolt torque : 43 N·m (32 lb·ft)

11. Install the rear propeller shaft assembly.

Flange bolt torque : 63 N·m (46 lb·ft)

Center bearing bracket bolt torque :

69

N·m (51 lb·ft)

12. Install the shift cable.

13. Connect the negative battery cable.

14. Remove the safety stands.

15. Remove the wheels blocks.

Torque Specifications

RTW37ALF001501

UNIT REPAIR (JR405E) 7A4-1

SECTION 7A4

UNIT REPAIR (JR405E)

TABLE OF CONTENTS

PAGE

Automatic Transmission Disassembly . . . . . . . . . . . . . . . . . . 7A4 - 2

Control Valve Assembly . . . . . . . . . . . . . . . . . . . . . . . 7A4 - 11

Control Valve Upper Body . . . . . . . . . . . . . . . . . . . . . . 7A4 - 18

Control Valve Lower Body . . . . . . . . . . . . . . . . . . . . . . 7A4 - 23

Oil Pump Assembly . . . . . . . . . . . . . . . . . . . . . . . . ... 7A4 - 28

Clutch Pack (Reverse and High Clutch Assembly) . . . . . . . . . . . . . 7A4 - 33

Carrier and Low Clutch Assembly . . . . . . . . . . . . . . . . . . ... 7A4 - 41

Transmission Case . . . . . . . . . . . . . . . . . . . . . . . . . 7A4 - 54

Bearing and Bearing Race Installation Position . . . . . . . . . . . . . . 7A4 - 66

Automatic Transmission Reassembly . . . . . . . . . . . . . . . . . . 7A4 - 69

Service Standard . . . . . . . . . . . . . . . . . . . . . . . . . ... 7A4 - 83

Special Service Tool . . . . . . . . . . . . . . . . . . . . . . . . .. 7A4 - 85

7A4-2 UNIT REPAIR (JR405E)

AUTOMATIC TRANSMISSION

DISASSEMBLY

Cleaning the automatic transmission

1. Use compressed steam and /or cleaning oil to thoroughly

clean the outside of the transmission before disassembly.

CAUTION:

Steam under high pressure may cause dirt particles

adhering to the transmission to fly through the air at great

speed. These particles can cause serious eye injury. Wear

protective goggles when steam-cleaning the outside of

the transmission.

2. During disassembly, clean the removed parts with cleaning

oil. Dry the parts with compressed air.

Use Compressed air to clean the transmission oil holes

and oil passages.

Automatic transmission disassembly cautions

•

Perform the disassembly procedure in a dust-free

environment to prevent the entry of foreign material into

the transmission.

•

Inspect each transmission part as you remove it.

•

Carefully check the oil pan and the magnet for foreign

material. This is a good way to estimate transmission

condition.

•

Use your bare hands or vinyl gloves to disassemble the

transmission. Do not use ordinary work gloves (loose

threads from the gloves may fall into the transmission and

cause problems).

•

Use a plastic hammer to loosen the transmission case

and other aluminum parts during disassembly. Strike

around the parts lightly with the hammer. Do not pry

aluminum parts away from each other with a screwdriver

or similar object.

•

Arrange the disassembled parts neatly in the order they

were removed. Cover the parts with a plastic sheet or

similar object to protect them from dust.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст