Isuzu D-Max / Isuzu Rodeo (TFR/TFS). Manual — part 1782

ON-VEHICLE SERVICE (JR405E) 7A3-17

Remove or Disconnect

1. Block the wheels.

2. Disconnect the negative battery cable.

3. Drain the fluid.

Refer

to

“ATF CHANGE” in this section.

4. Remove the 19 bolts and oil pan.

5. Inspect the bottom of the oil pan and strainer netting

for foreign material (clutch facing and metal

shavings).

If there is an excessive accumulation of foreign

material, the oil strainer must be replaced.

Further inspection is required to determine the

source of the foreign material.

6.

Remove the harness assembly (including oil

temperature sensor).

7. Remove the 11 bolts and the solenoid fixing plate.

8. Remove the 6 solenoids and 3 oil pressure switchs.

Inspect

Oil pressure switch

Apply compressed air (392 kPa/4.0 kg/cm

2

) to the oil

pressure switch to check the oil pressure switch

continuity between the connector and screw.

Oil temperature sensor (harness assembly)

Check the oil temperature sensor resistance between

harness terminals 7 and 6 (ground).

Oil temperature sensor resistance:

2,400~2,600

ohms

(20

°°°°

C)

244L300011

Solenoid

Measure the resistance of each solenoid.

Resistance:

Brown connector – 3.0~3.4 ohms (20

°°°°

C)

Gray connector – 12.0~13.2 ohms (20

°°°°

C)

White connector – 12.2~13.4 ohms (20

°°°°

C)

Install or connect

1. Install the O-rings to each of the solenoids.

2. Install the 6 solenoids and 3 oil pressure switchs.

Line pressure solenoid bolt torque:

8

N·m (69 lb·in)

Oil pressure switch bolt torque:

4.4

N·m (39 lb·in)

3. Install the solenoid fixing plate together with the

harness brackets.

Number

Length

(Color)

Solenoid fixing plate bolt

(A)

(B)

4

7

16 mm (0.63 in) (Gold)

45 mm (1.77 in) (Silver)

Bolt torque : 8 N·m (69 lb·in)

4. Install the harness assembly.

5. If removed, install the oil strainer.

Number

Length

(Color)

Oil strainer bolt

(C)

(D)

9

4

13 mm (0.51 in) (Silver)

45 mm (1.77 in) (Silver)

Bolt torque : 8 N·m (69 lb·in)

6. Install the new gasket and oil pan.

Bolt torque : 8 N·m (69 lb·in)

7. Fill the fluid.

Refer

to

“ATF CHANGE” in this section.

8. Connect the negative battery cable.

9. Remove the wheel blocks.

7A3-18 ON-VEHICLE SERVICE (JR405E)

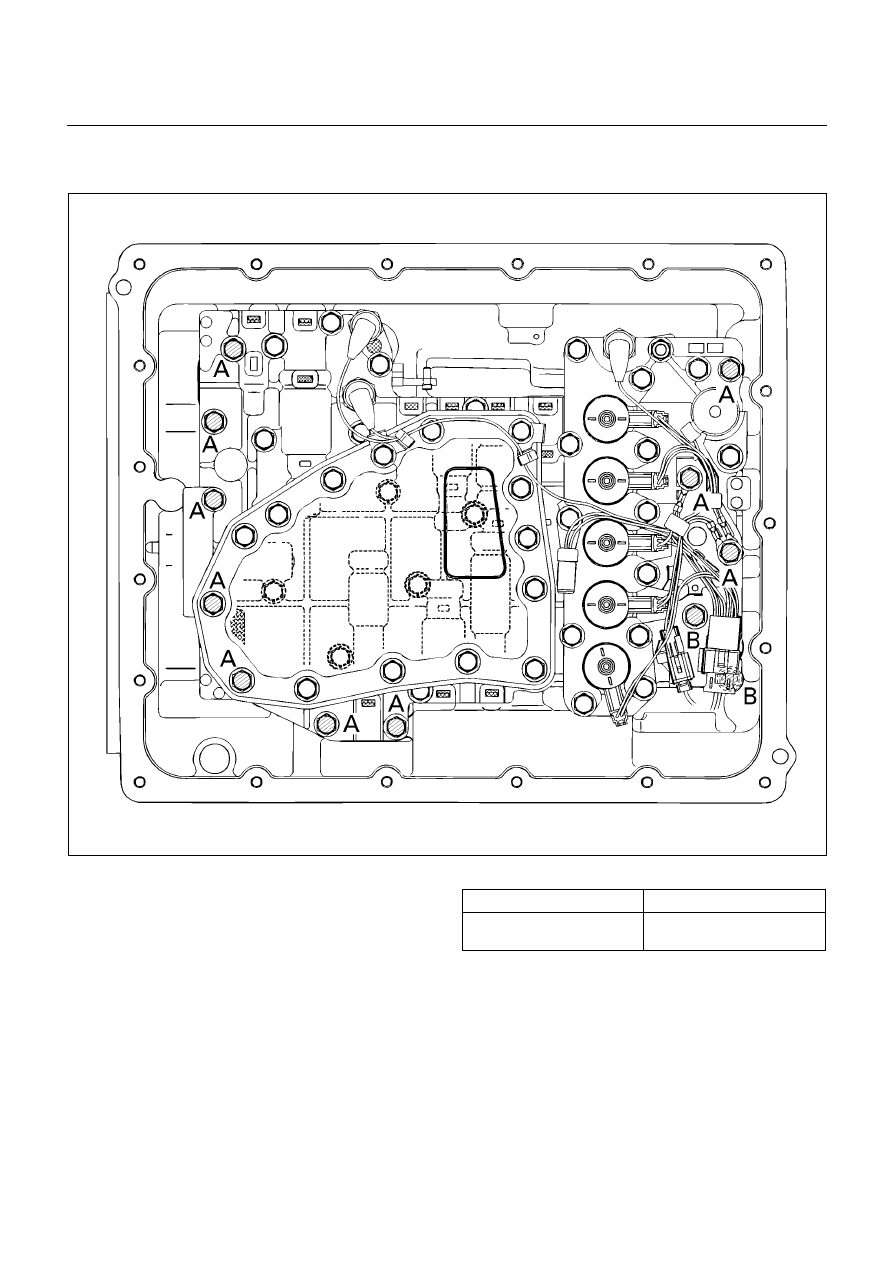

CONTROL VALVE ASSEMBLY

244L300001

Remove or Disconnect

1. Block the wheels.

2. Disconnect the negative battery cable.

3. Drain the fluid.

Refer

to

“ATF CHANGE” in this section.

4. Remove the 19 bolts and oil pan.

5. Inspect the bottom of the oil pan and strainer netting

for foreign material (clutch facing and metal

shavings).

If there is an excessive accumulation of foreign

material, the oil strainer must be replaced.

Further inspection is required to determine the

source of the foreign material.

6. Disconnect the 2 harness connectors leading to the

control valve.

7. Remove the 12 bolts and the control valve assembly.

Number of bolts

Length

10 (A)

2 (B)

40 mm (1.57 in)

30 mm (1.18 in)

Note:

Take care not to disturb the manual valve (inside the

control valve assembly).

Do not allow the pin to fall free (the pin prevents the

valve from turning).

ON-VEHICLE SERVICE (JR405E) 7A3-19

Install or Connect

1. Align the manual valve and the manual plate of the

transmission case.

43ASSY119

2. Install the control valve assembly and tighten the 12

fixing bolts to the specified torque.

Number of bolts

Length

Color

10 (A)

40 mm (1.57 in)

Gold

2 (B)

30 mm (1.18 in)

Gold

Bolt torque : 8 N·m (69 lb·in)

3. Connect the 2 harness connectors.

4. If removed, install the oil strainer.

Refer

to

“Solenoids, Oil Pressure Switch and Oil

Temperature Sensor” previously in this section.

5. Install the new gasket and oil pan.

Bolt torque : 8 N·m (69 lb·in)

6. Fill the fluid.

Refer

to

“ATF CHANGE” in this section.

7. Connect the negative battery cable.

8. Remove the wheel blocks.

FLUSHING THE TRANSMISSION FLUID COOLER AND LINE

The fluid cooler and lines may be flushed under the

following condition. This will help prevent more trouble

after the transmission is repaired.

1. When the abnormal amount of debris are found.

2. When the abnormal wear or chips on gears and

shafts are found while overhauling.

3. When the abnormal clutch facing wear and oil

contamination are found.

Procedures

1. Block the wheels.

2. Disconnect negative battery cable.

3. Raise vehicle and support with suitable safety

stands.

4. Disconnect fluid cooler lines at transmission case

and fluid cooler.

5. Flush and back-flush the fluid cooler and lines using

solvent and compressed air.

Note:

DO NOT exceed 197 kPa (29 psi) air pressure or

damage may result to oil cooler.

6. Remove all remaining solvent from the system with

compressed air.

7. Flush the cooling system again with Automatic

Transmission Fluid (ATF).

After the final flush, connect all lines.

Cooler line joint connector torque :

44

N·m (33 lb·ft)

8. Replenish ATF

9. Start engine to test the system for the free flow of

fluid. If the flow is restricted, the cooler assembly or

lines must be replaced.

Repeated cleaning and flushing may not remove all

debris from the fluid cooler circuit.

Move the select lever through the various ranges and

return to neutral.

Check for fluid level.

If the fluid level is below the specified range, ATF

must be added.

10. Connect negative battery cable.

11. Remove safety stands.

12. Remove wheel blocks.

7A3-20 ON-VEHICLE SERVICE (JR405E)

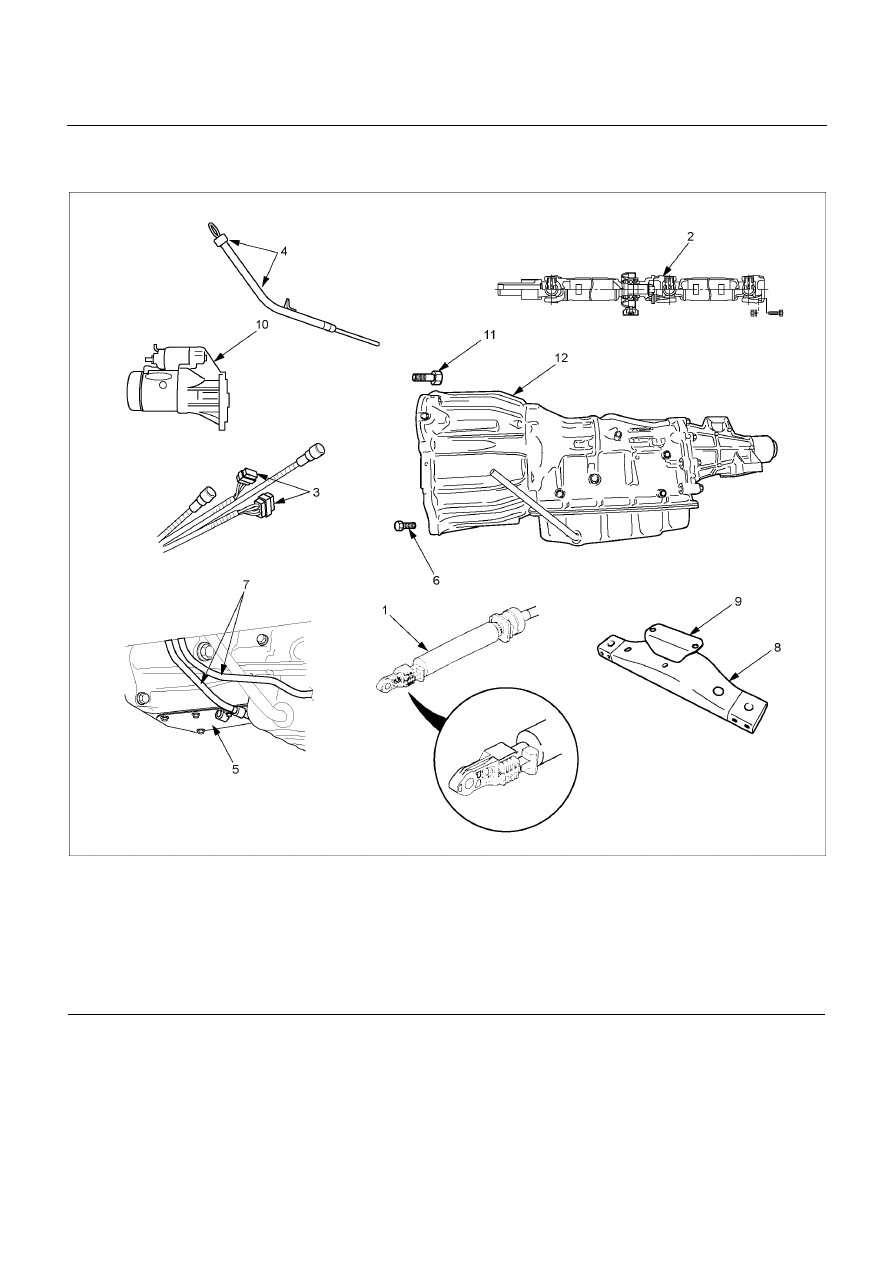

TRANSMISSION ASSEMBLY

RTW37ALF001401

Legend

1. Shift Cable

2. Propeller Shaft

3. Engine Harness

4. ATF Level Dipstick

5. Under Cover

6. Bolt

7. ATF Pipe

8. Crossmember

9. Bracket

10. Starter Motor

11. Bolt

12. Automatic Transmission

Remove or Disconnect

1. Block the wheels.

2. Disconnect the negative battery cable.

3. Raise the vehicle and support with the suitable safety

stands.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст