Isuzu D-Max / Isuzu Rodeo (TFR/TFS). Manual — part 222

ENGINE DRIVEABILITY AND EMISSIONS

6E–129

Diagnostic Trouble Code (DTC) P0117

Engine Coolant Temperature Sensor Low Input

Step

Action

Value(s)

Yes

No

1

Was the “On-Board Diagnostic (OBD) System Check”

performed?

—

Go to Step 2

Go to On Board

Diagnostic

(OBD) System

Check

2

1. Connect the Tech 2.

2. Review and record the failure information.

3. Select “F0: Read DTC Infor By Priority” in “F0:

Diagnostic Trouble Code”.

Is the DTC P0117 stored as “Present Failure”?

—

Go to Step 3

Refer to

Diagnostic Aids

and Go to Step

3

3

1. Using the Tech2, ignition “On” and engine “Off”.

2. Select “Clear DTC Information” with the Tech2 and

clear the DTC information.

3. Operate the vehicle and monitor the “F5: Failed

This Ignition” in “F2: DTC Information”.

Was the DTC P0117 stored in this ignition cycle?

—

Go to Step 4

Refer to

Diagnostic Aids

and Go to Step

4

4

Check for poor/faulty connection at the ECT sensor or

ECM connector. If a poor/faulty connection is found,

repair as necessary.

Was the problem found?

—

Verify repair

Go to Step 5

5

Visually check the ECT sensor.

Was the problem found?

—

Go to Step 8

Go to Step 6

6

Using the DVM and check the ECT sensor.

1. Ignition “Off”, engine “Off”.

2. Disconnect ECT sensor connector.

3. Measure the resistance of ECT sensor.

Does the tester indicate standard resistance as shown

in the following table?

Standard

resistance

Go to Step 7

Go to Step 8

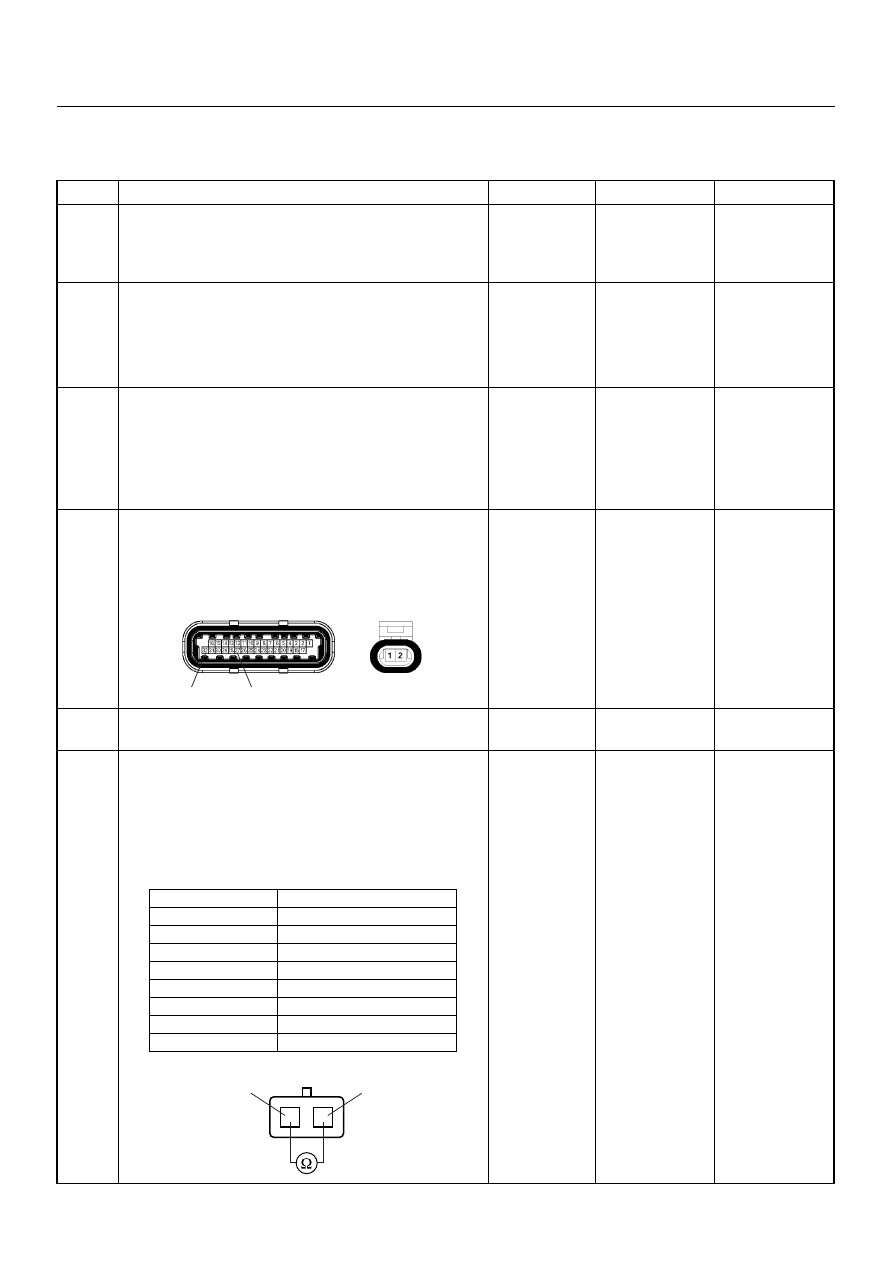

E60(J1)

E69

32

27

Temperature (°C)

Resistance (

Ω) (Approximately)

-20

32040

0

9788

20

3516

40

1439

60

656

80

327

100

175

120

100

ECT Sensor

1

1

2

2

6E–130

ENGINE DRIVEABILITY AND EMISSIONS

7

Using the DVM and check the ECT sensor signal

circuit.

Breaker box is available:

1. Ignition “Off”, engine “Off”.

2. Install the breaker box as type A. (ECM

disconnected) Ref. 6E-80.

3. Disconnect the ECT sensor connector.

4. Check the circuit for short to sensor ground or

ground circuit.

Was the problem found?

Breaker box is not available:

1. Ignition “Off”, engine “Off”.

2. Disconnect the ECT sensor connector.

3. Check the circuit for short to sensor ground or

ground circuit.

Was the problem found?

—

Repair faulty

harness and

verify repair

Go to Step 10

8

Substitute a known good ECT sensor assembly and

recheck.

Was the problem solved?

—

Go to Step 9

Go to Step 10

9

Replace the ECT sensor.

Is the action complete?

—

Verify repair

—

10

Is the ECM programmed with the latest software

release?

If not, download the latest software to the ECM using

the “SPS (Service Programming System)”.

Was the problem solved?

—

Verify repair

Go to Step 11

11

Replace the ECM.

Is the action complete?

IMPORTANT: The replacement ECM must be

programmed. Refer to section of the Service

Programming System (SPS) in this manual.

Following ECM programming, the immobiliser system

(if equipped) must be linked to the ECM. Refer to

section 11 “Immobiliser System-ECM replacement” for

the ECM/Immobiliser linking procedure.

—

Verify repair

—

Step

Action

Value(s)

Yes

No

27

32

E60(J1)

27

32

ENGINE DRIVEABILITY AND EMISSIONS

6E–131

DIAGNOSTIC TROUBLE CODE (DTC) P0118 ENGINE COOLANT

TEMPERATURE SENSOR HIGH INPUT

Condition for setting the DTC and action taken when the DTC sets

Circuit Description

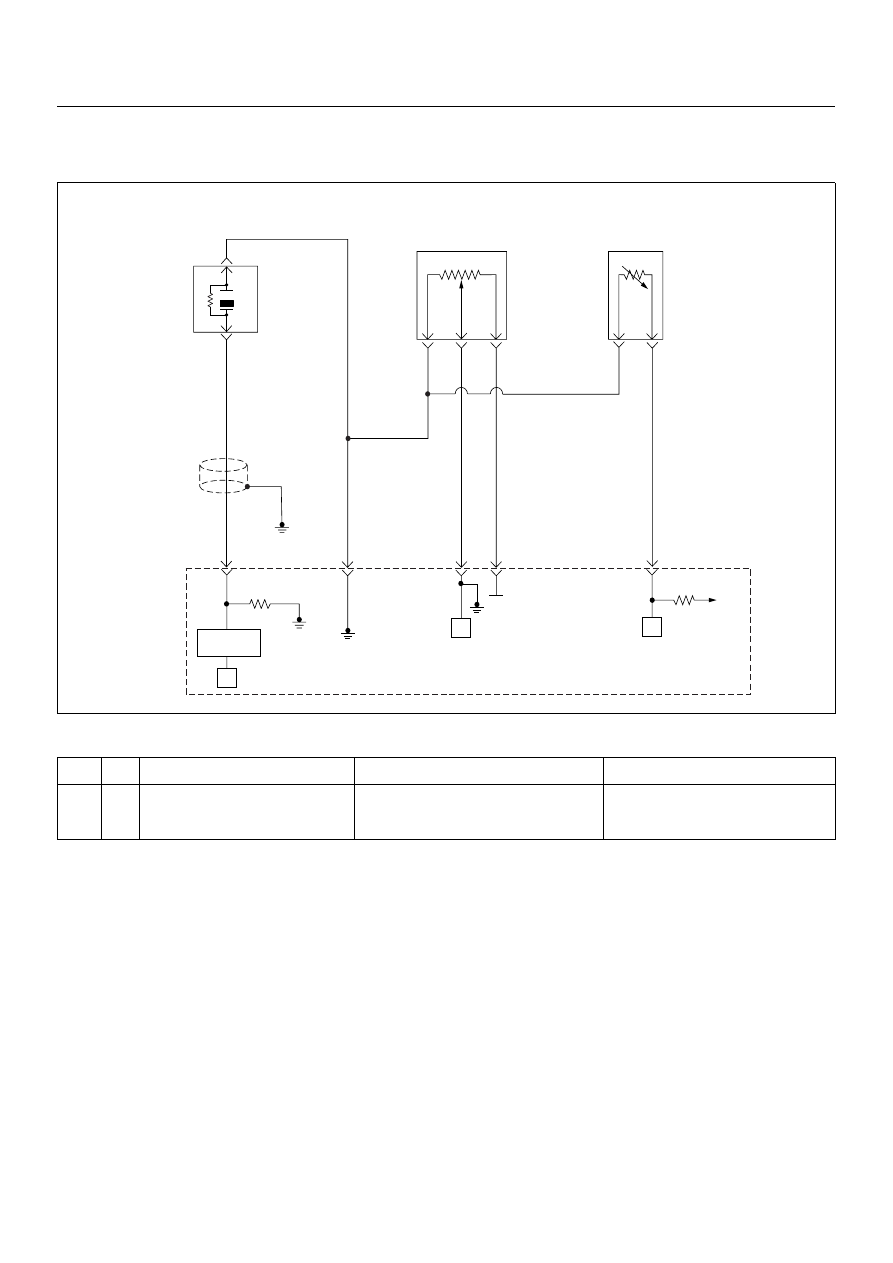

The engine coolant temperature (ECT) sensor is a

thermistor mounted in the engine coolant stream. The

engine control module (ECM) applies a voltage (about 5

volts) through a pull-up resistor to the ECT signal circuit.

When the engine coolant is cold, the sensor (thermistor)

resistance is high, therefore the ECM will measure a

high signal voltage. As the engine coolant warms, the

sensor resistance becomes less, and the ECT signal

voltage measured at the ECM drops. Diagnostic Trouble

code P0118 set when the ECM detects an excessively

high signal voltage on the engine coolant temperature

sensor signal circuit.

Diagnostic Aids

Check for the following conditions:

• Poor connection at ECM - Inspect harness

connectors for backed-out terminals, improper

mating, broken locks, improperly formed or damaged

terminals, and poor terminal-to-wire connection.

• Damaged harness - Inspect the wiring harness for

damage, short to ground, short to battery positive,

and open circuit. If the harness appears to be OK,

observe the ECT display on the Tech 2 while moving

connectors and wiring harnesses related to the ECT

sensor. A change in the ECT display will indicate the

location of the fault.

Code

Type

DTC Name

DTC Setting Condition

Fail-Safe (Back Up)

P0118

A

Engine Coolant Temperature Sensor

High Input

1. Engine run time is longer than 120 sec-

onds.

2. ECT sensor output is below -38°C.

The ECM uses default engine coolant

temperature value based on intake air

temperature and engine run time.

µP

0.5

GRY

J1-27

+5V

µP

µP

5Volts

Reference

Knock

Sensor

0.5

YEL

0.5

WHT/

BLU

J1-7

0.5

BLU/

PNK

J1-32

0.5

BLK/

YEL

J1-15

J1-3

Engine

Coolant

Temperature(ECT)

Sensor

Throttle

Position Sensor

Knock Filter

Module

Engine

Control

Module

(ECM)

6E–132

ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0118

Engine Coolant Temperature Sensor High Input

Step

Action

Value(s)

Yes

No

1

Was the “On-Board Diagnostic (OBD) System Check”

performed?

—

Go to Step 2

Go to On Board

Diagnostic

(OBD) System

Check

2

1. Connect the Tech 2.

2. Review and record the failure information.

3. Select “F0: Read DTC Infor By Priority” in “F0:

Diagnostic Trouble Code”.

Is the DTC P0118 stored as “Present Failure”?

—

Go to Step 3

Refer to

Diagnostic Aids

and Go to Step

3

3

1. Using the Tech2, ignition “On” and engine “Off”.

2. Select “Clear DTC Information” with the Tech2 and

clear the DTC information.

3. Operate the vehicle and monitor the “F5: Failed

This Ignition” in “F2: DTC Information”.

Was the DTC P0118 stored in this ignition cycle?

—

Go to Step 4

Refer to

Diagnostic Aids

and Go to Step

4

4

Check for poor/faulty connection at the ECT sensor or

ECM connector. If a poor/faulty connection is found,

repair as necessary.

Was the problem found?

—

Verify repair

Go to Step 5

5

Visually check the ECT sensor.

Was the problem found?

—

Go to Step 12

Go to Step 6

6

Using the DVM and check the ECT sensor.

1. Ignition “Off”, engine “Off”.

2. Disconnect ECT sensor connector.

3. Measure the resistance of ECT sensor.

Does the tester indicate standard resistance as shown

in the following table?

Standard

resistance

Go to Step 7

Go to Step 12

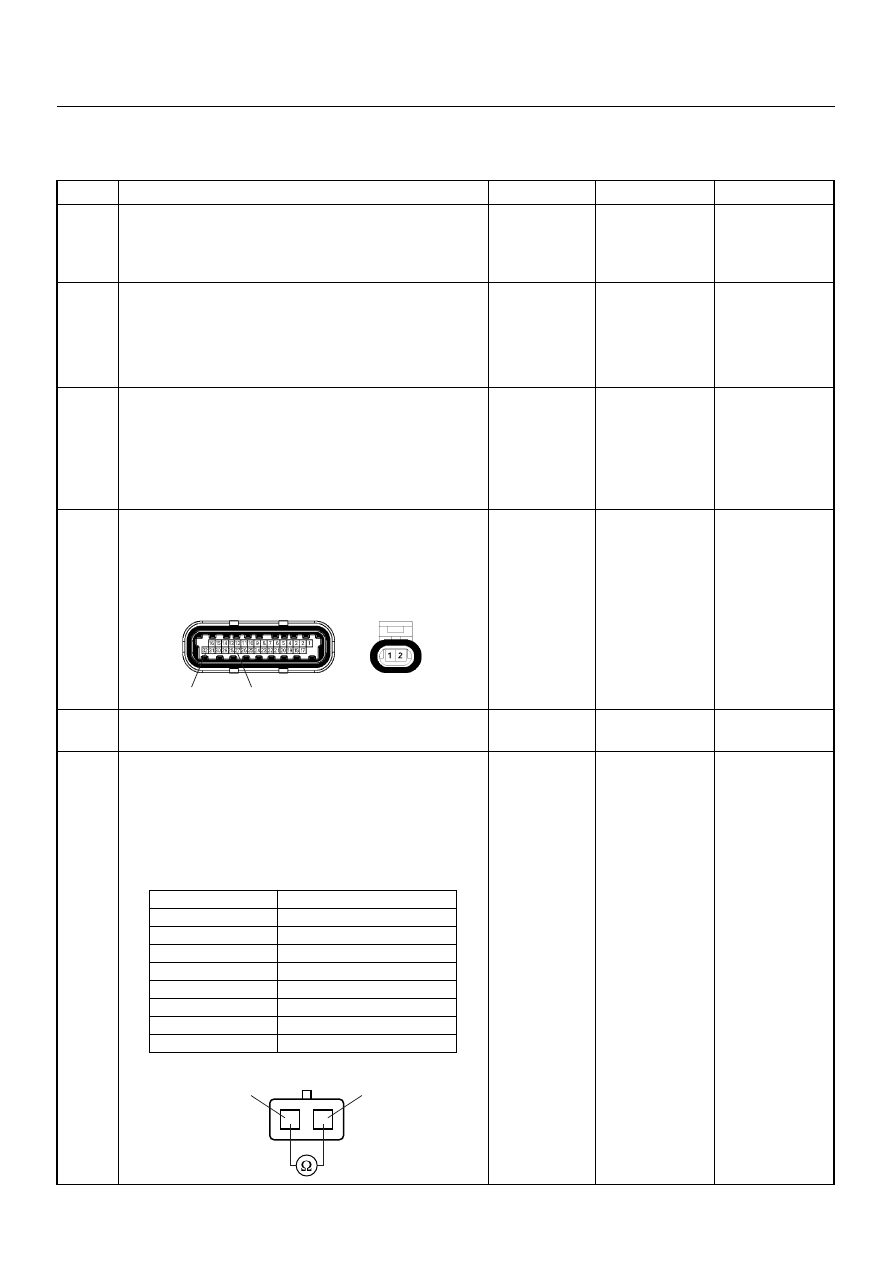

E60(J1)

E69

32

27

Temperature (°C)

Resistance (

Ω) (Approximately)

-20

32040

0

9788

20

3516

40

1439

60

656

80

327

100

175

120

100

ECT Sensor

1

1

2

2

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст