Isuzu D-Max / Isuzu Rodeo (TFR/TFS). Manual — part 1044

CLUTCH 7C-35

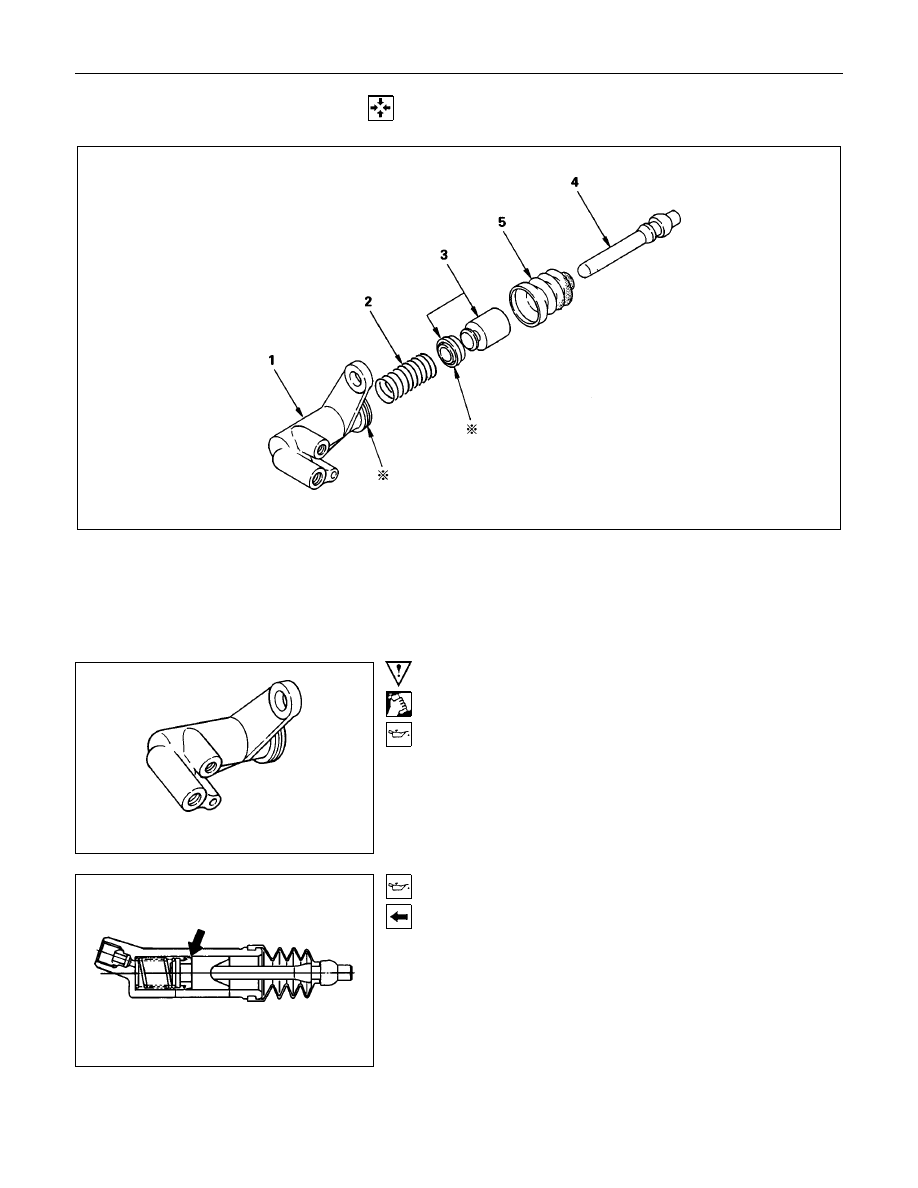

SLAVE CYLINDER (Except 6VD1 Engine)

DISASSEMBLY

Disassembly Steps

▲

1. Boot

2. Push rod

3. Piston and piston cup

4. Spring

5. Cylinder body

6. Solenoid switch

Important Operations

1. Boot

Brake fluid spilled on painted or plastic surfaces will cause

serious damage.

Take care not to spill brake fluid.

7C-36 CLUTCH

INSPECTION AND REPAIR

Make the necessary adjustments, repairs, and part replacements if excessive wear or damage is discovered during

inspection.

Cylinder Body

1. Clean the cylinder body.

2. Check the fluid return port for restrictions and clean it if

necessary.

Cylinder Bore and piston Clearance

1. Clean the cylinder body and the piston.

2. Use an inside dial indicator to measure the cylinder bore.

3. Use a micrometer to measure the piston diameter.

4. Calculate the clearance between the cylinder bore and the

piston diameter.

If the clearance exceeds the limit, the entire slave cylinder

assembly must be replaced.

Cylinder Bore and Piston Clearance

mm(in)

Standard

Limit

0.07 (0.0028)

0.15 (0.006)

Piston and Piston Cup

Visually inspect the disassembled piston and piston cup for

excessive wear and damage.

Replace the inner parts with new parts (Repair kit A) shown in

the illustration.

CLUTCH 7C-37

REASSEMBLY

* Apply grease

(COSMO rubber grease)

Reassembly Steps

▲

1. Cylinder body

2. Spring

▲

3. Piston and piston cup

4. Push rod

5. Boot

6. Solenoid switch

Important Operations

1. Cylinder Body

1) Clean the cylinder body.

2) Apply brake fluid to the cylinder bore.

3. Piston and piston Cup

1) Apply brake fluid to the piston and piston cup.

2) Install the cups to the piston.

Note the installation direction of the piston cups in the

illustration.

3) Install the piston and piston cup to the cylinder body.

7C-38 CLUTCH

SLAVE CYLINDER (6VD1 Engine)

6VD1

Disassembly Steps

1. Boot

2. Push rod

3. Piston and piston cup

4. Spring

5. Cylinder body

Reassembly Steps

To reassemble, follow disassembly steps in

the reverse order.

DISASSEMBLY

1. Boot

2. Push Rod

3. Piston and Piston Cup

4. Spring

5. Cylinder Body

INSPECTION AND REPAIR

Make the necessary adjustments, repairs, and part

replacements if excessive wear or damage is discovered

during inspection.

6VD1

Cylinder body

1) Clean the cylinder body.

2) Check the fluid return port for restrictions and clean it if

necessary.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст