Isuzu D-Max / Isuzu Rodeo (TFR/TFS). Manual — part 553

6A – 50 ENGINE MECHANICAL

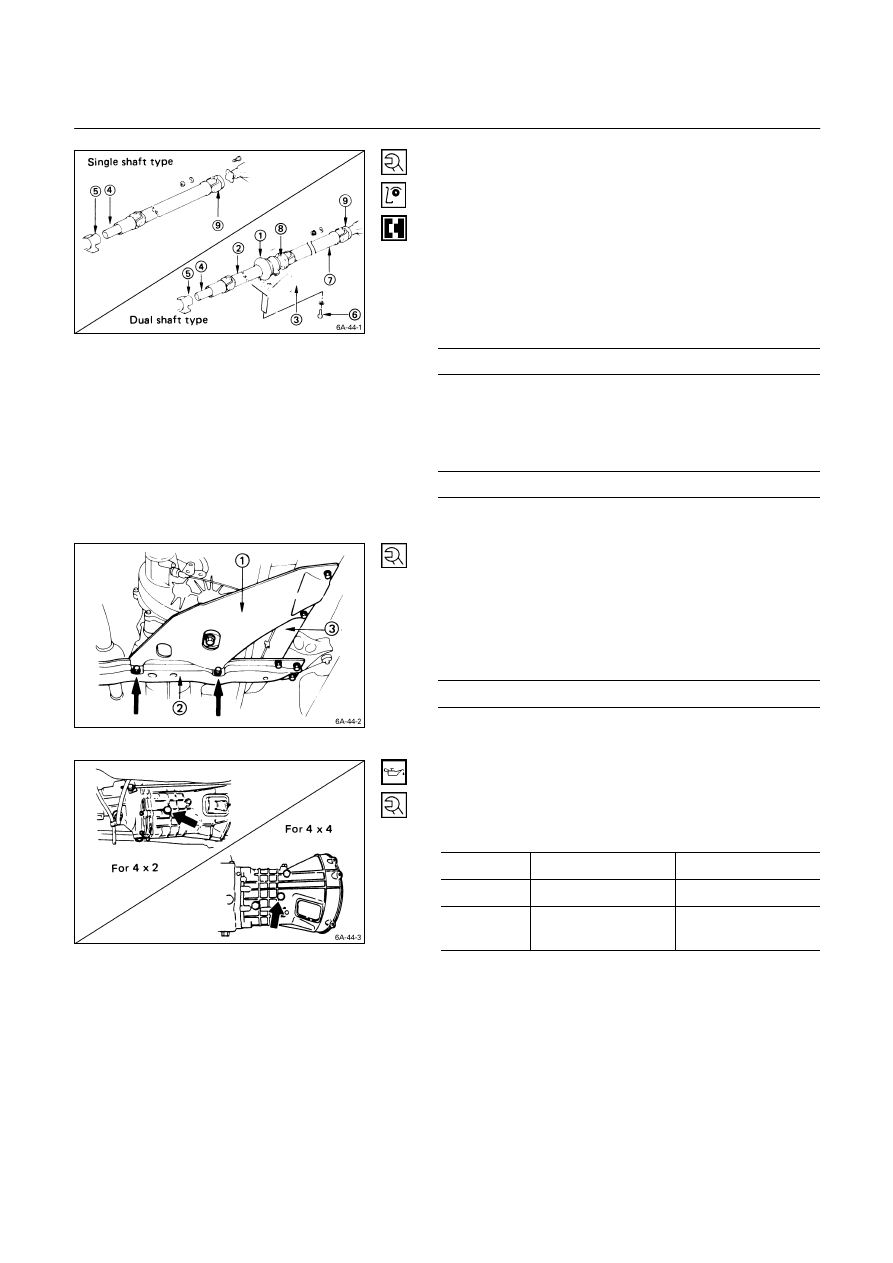

Rear Propeller Shaft

1. Place the center bearing and retainer

Q

together with

the 1st propeller shaft

R

on the No. 4 crossmember

S

.

2. Insert the splined yoke

T

into the transmission main

shaft spline

U

.

3. Tighten the center bearing retainer bolts

V

to the

specified torque.

Center Bearing Retainer Bolt Torque

kg·m (lb.ft/N·m)

6.2

± 0.2 (44.8 ± 1.5/60.8 ± 2.0)

4. Connect the 2nd propeller shaft

W

center coupling

side

X

and drive pinion side

Y

.

Propeller Shaft Flange Yoke Bolt

Torque kg·m

(lb.ft/N·m)

3.6

± 0.3 (26.0 ± 2.2/35.3 ± 2.9)

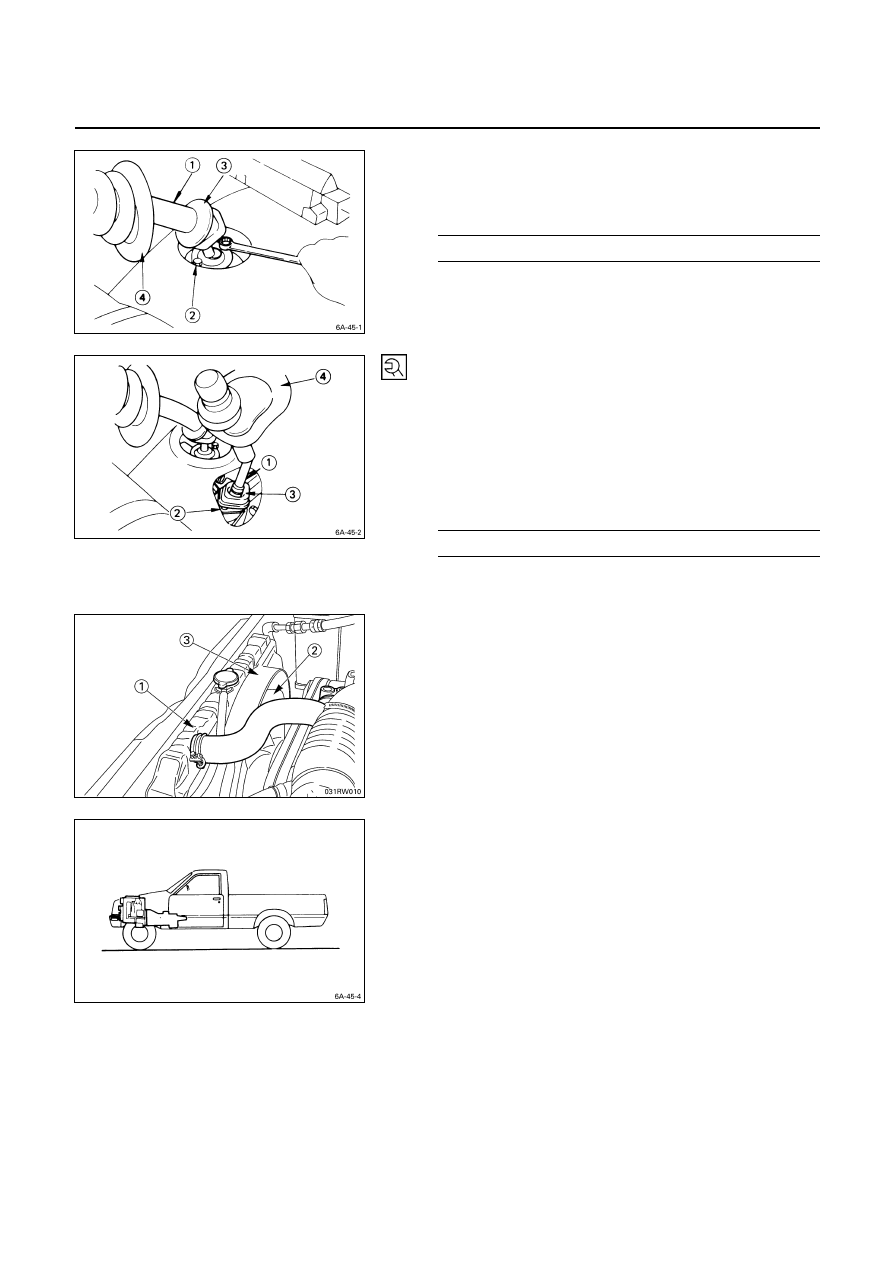

Transfer Case Protector (For 4

×××× 4)

1. Install the transfer case protector

Q

to the mounting

member

R

and the sidemembers

S

.

2. Tighten the transfer case protector bolts to the

specified torque.

Transfer Case Protector Bolt Torque

kg·m (lb.ft/N·m)

3.7

± 1.0 (26.8 ± 7.2/36.3 ± 9.8)

Gear Shift Lever

1. Replenish the transmission case and the transfer case

with the specified engine oil.

Transmission and Transfer Case Oil

lit (US/UK gal)

4

× 2

4

× 4

MSG

1.55 (0.41/0.34)

4.40 (1.16/0.97)

MUA 2.95

(0.65/0.54)

2.95 (T/M)

1.45 (Transter)

2. Install the quadrant box to the transmission rear cover.

ENGINE MECHANICAL 6A – 51

3. Install the gear shift lever

Q

to the transmission case.

4. Tighten the gear shift lever cover

R

bolts to the

specified torque.

Shift Lever Cover Bolt Torque

kg·m (lb.ft/N·m)

2.0

± 0.2 (14.5 ± 1.5/19.6 ± 2.0)

5. Install the dust cover

S

and the grommet

T

.

Transfer Change Lever (For 4

×××× 4)

1. Insert the transfer change lever

Q

into the transfer

side case.

2. Install the ball seat cover along with the change lever

retainer

R

.

3. Tighten the change lever retainer bolts to the specified

torque.

Change Lever Retainer Bolt Torque

kg·m (lb.ft/N·m)

2.0

± 0.2 (14.5 ± 1.5/19.6 ± 2.0)

4. Install the dust cover

S

and the grommet

T

.

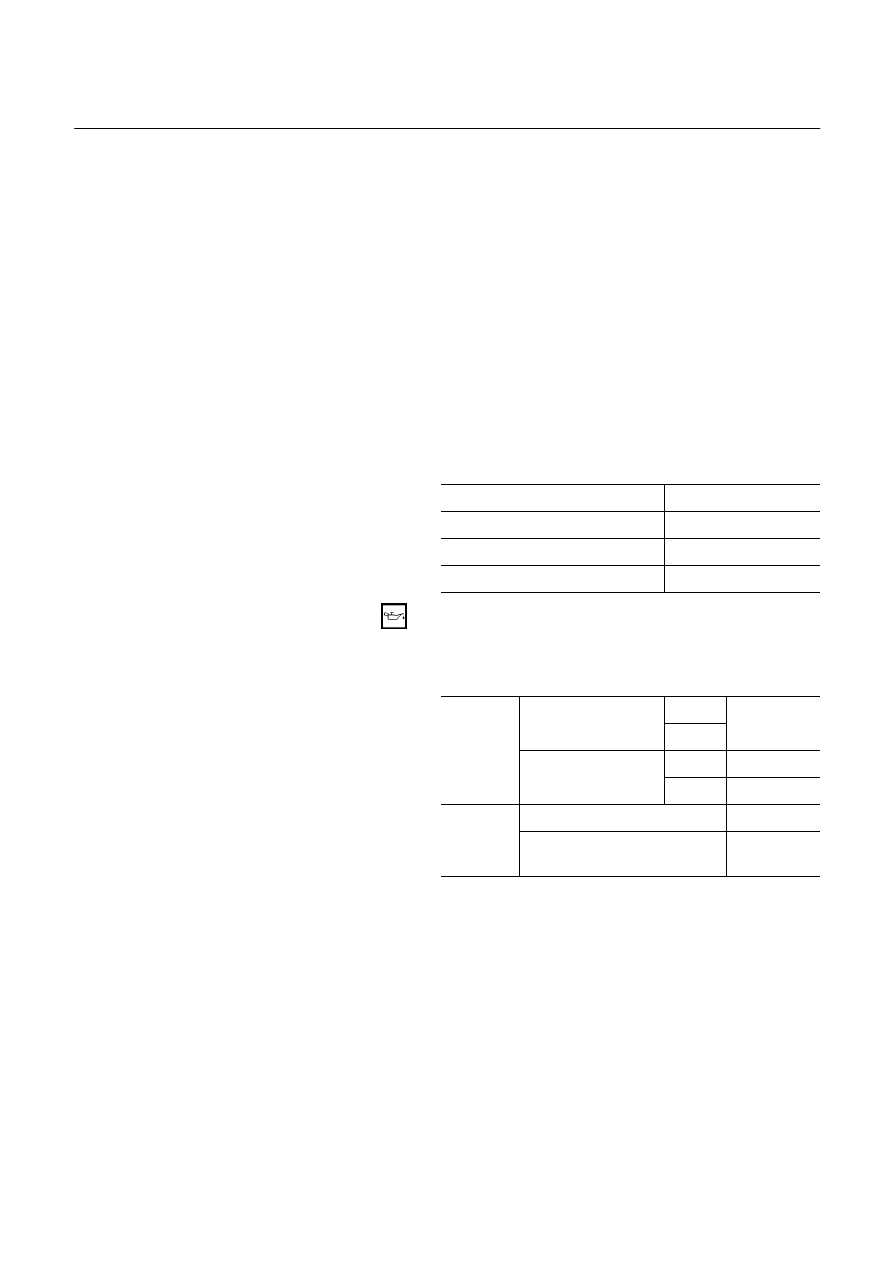

Radiator

1. Install

the

radiator

Q

.

Be careful not to damage the radiator core.

2. Install the cooling fan

R

and the fan shroud

S

.

3. Connect the radiator upper and lower hoses.

4. Install the radiator undercover to the chassis frame.

5. Install the radiator grill to the deflector panel.

Lowering the Vehicle

1. Install the wheels to the vehicle.

2. Place a jack beneath the vehicle.

3. Raise the jack to remove the chassis stands.

4. Lower the vehicle to the ground.

6A – 52 ENGINE MECHANICAL

Coolant Replenishment

Replenish the cooling system with coolant.

When radiator is emptied (for coolant change, etc.):

After filling with coolant up to the inlet port level, put the

radiator cap on and idle the engine for 5 to 6 consecutive

minute. Then remove the radiator cap and check and see

the coolant level. If the coolant is short, add to the radiator

as well as to the reserve tank.

If the reserve tank coolant level is lower than MIN,

replenish coolant to the reserve tank only.

In case there is no coolant in the reserve tank, make sure

of a drop in coolant temperature and add coolant through

the radiator inlet port. Then remove the cap and check the

coolant level after idling the engine for 5 to 6 consecutive

minutes.

Then add coolant into reserve tank fill up to full level.

Coolant Capacity

lit (US/UK gal)

4JA1, 4JA1T

7.0 (1.8/1.5)

4JB1 with turbo engine

9.5 (2.5/2.1)

4JG2T 8.6

(2.3/1.9)

4JA1-TC, 4JH1TC

8.4 (2.2/1.8)

Engine Oil Replenishment

1. Fill the engine through the filler port with new engine

oil of the specified grade.

Engine Oil Capacity and Grade

lit (US/UK gal)

4

× 2

4JA1, 4JA1T, 4JB1T

4

× 4

6.5 (1.7/1.4)

4

× 2

6.5 (1.7/1.4)

Capacity

4JG2T, 4JA1TC,

4JH1TC

4

× 4

7.3 (1.9/1.6)

For 4JA1

CC or CD

Grade

For 4JB1T, 4JG2T, 4JA1T,

4JA1TC, 4JH1TC

CD

2. Start the engine and allow it to idle for several

minutes.

3. Stop the engine and wait five minutes for the oil to

settle.

4. Recheck the oil level and replenish if necessary.

ENGINE MECHANICAL 6A – 53

Engine Hood

Align the setting marks (applied at removal) on the engine

hood

Q

and the engine hood hinges

R

to install the

engine hood.

Battery

1. Check the battery fluid level and the specific gravity.

2. Secure the battery with the battery clamp.

Do not overtighten the battery clamp.

3. Connect the battery cable

R

and the ground cable

S

to the battery.

4. Connect the battery cable to the starter motor and the

ground cable to the cylinder body.

5. Apply grease to the battery terminals.

6. Install the battery clamp

Q.

Take care not to accidentally short the battery with the

spanner or some other tool.

Engine Warm-Up

After completing the required maintenance procedures,

start the engine and allow it to idle until it is warm.

Check the following:

1. Engine idling speed

Refer to “SERVICING” for the idle speed adjustment

procedure.

2. Engine noise level.

3. Engine lubricating system and cooling system

Carefully check for oil and coolant leakage.

4. Engine control cable operation

5. Clutch

engagement

6. Indicator warning light operation

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст