Isuzu KB P190. Manual — part 817

Engine Management – V6 – General Information

Page 6C1-1–26

The EOP sensor provides a voltage signal to the ECM that

is a function of engine oil pressure. It does this through a

series of deformation resistors (1), which change resistance

when a mechanical force is applied. This force is applied to

the resistors by a diaphragm on which the engine oil

pressure acts (2).

The sensor has an internal evaluation circuit (3) and is

provided with a 5 V reference voltage, a ground and a signal

circuit.

Figure 6C1-1 – 28

4.12 Fuel

Injectors

A fuel injector is a solenoid device that is controlled by the

ECM. The six injectors deliver a precise amount of fuel into

each of the intake ports as required by the engine.

Figure 6C1-1 – 29

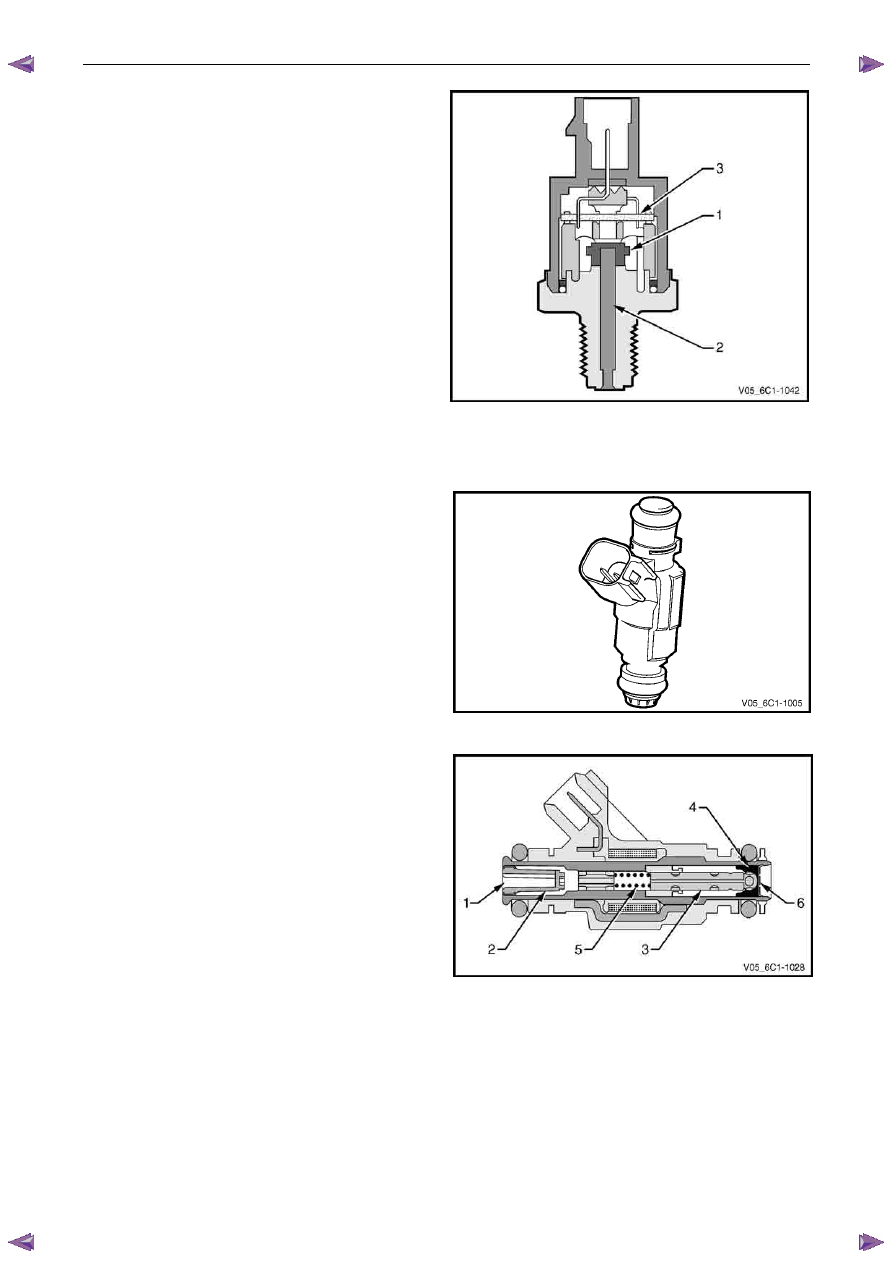

The fuel port (1) connects to the fuel rail. A strainer (2) is

provided in the port to protect the injector from fuel

contamination.

In the de-energised state (no voltage), the valve needle and

sealing ball assembly (3) are held against a cone-shaped

valve seat (4) by spring force (5) and fuel pressure.

When the injector is energised by the ECM, the valve

needle, which has an integral armature, is moved upward by

the injector solenoids magnetic field, un-seating the ball.

An orifice plate (6), located at the base of the injector has

openings that are arranged in such a way that two fuel

sprays emerge from the injector.

Each fuel spray is then directed at one of the intake valves,

causing the fuel to become further vaporised before entering

the combustion chamber.

Figure 6C1-1 – 30

Engine Management – V6 – General Information

Page 6C1-1–27

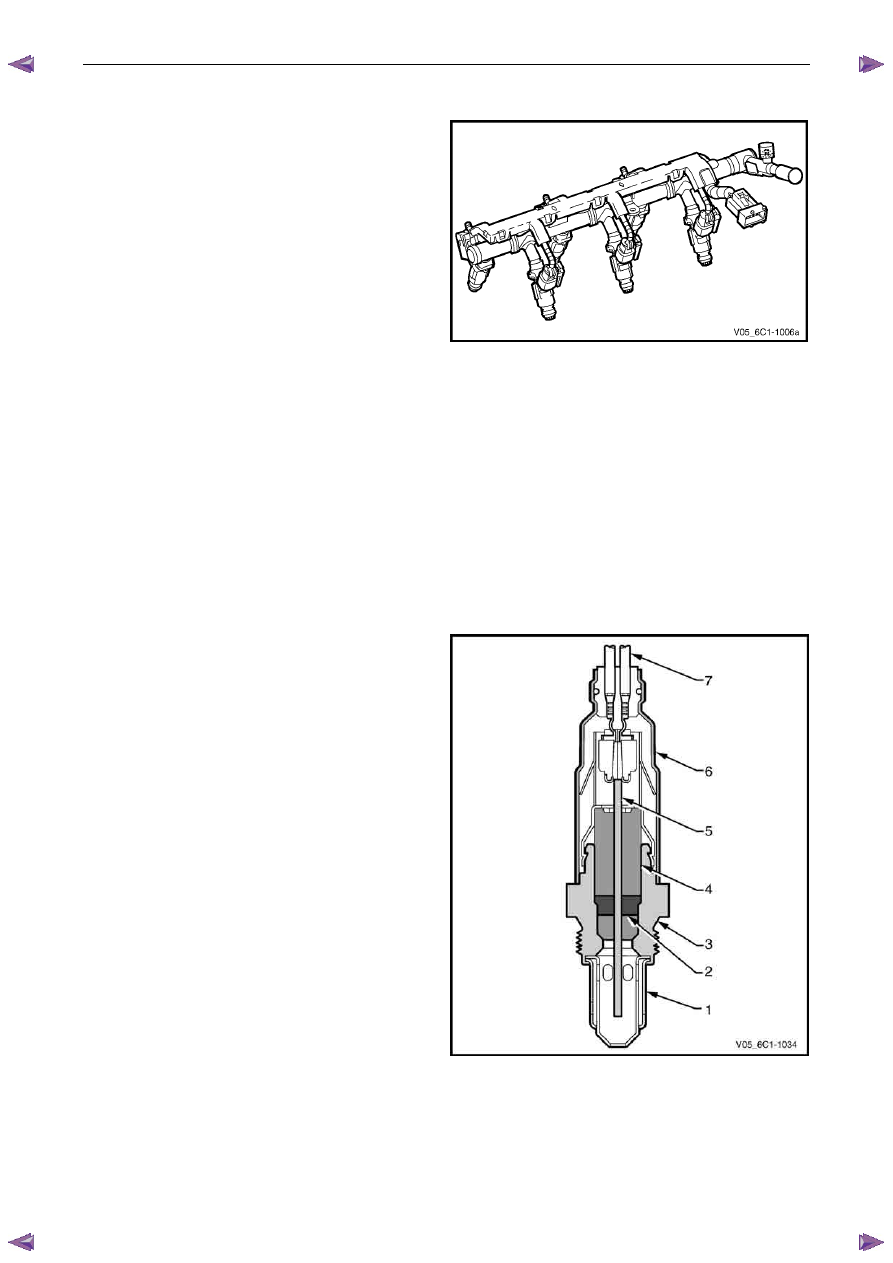

4.13 Fuel Rail Assembly

The fuel rail assembly is mounted on the lower intake

manifold and distributes the fuel to each cylinder through

individual fuel injectors. The fuel rail assembly consists of:

•

the pipe that carries fuel to each injector,

•

a fuel pressure test port,

•

six individual fuel injectors,

•

wiring harness, and

•

wiring harness tray.

Figure 6C1-1 – 31

4.14 Heated Oxygen Sensors

The heated oxygen sensors (HO2S) are mounted in the exhaust system and enable the ECM to measure oxygen

content in the exhaust stream. The ECM uses this information to accurately control the air / fuel ratio, because the

oxygen content in the exhaust gas is indicative of the air / fuel ratio of engine combustion.

When the sensor is cold, it produces little or no signal voltage, therefore the ECM only reads the HO2S signal when the

HO2S sensor is warm. As soon as the HO2S are warm and outputting a usable signal, the ECM begins making fuel

mixture adjustments based on the HO2S signals. This is known as closed loop mode.

The HFV6 engine has four HO2S, one LSU 4.2 wide-band planar type HO2S upstream of the catalytic converter in each

exhaust pipe, and one LSF 4.2 two-step planar type HO2S in each exhaust pipe downstream of the catalytic converter.

LSF 4.2 Two-step Planar Heated Oxygen Sensors

The LSF 4.2 two-step planar heated oxygen sensors have

four wires:

•

The internal heater element supply, which has 12 V

continually applied whenever the ignition is on.

•

Heater element ground – The ECM applies pulse

width modulated (PWM) ground to the HO2S heater

control circuit to control the rate at which the sensor

heats up. This reduces the risk of the sensor being

damaged from heating up too quickly under certain

conditions such as extreme cold temperatures. Once

the sensor has reached the desired operating

temperature, the ECM will monitor and continue to

maintain the sensor temperature.

•

Sensor signal to the ECM.

•

Sensor ground.

Legend

1 Protective

Tube

2

Ceramic Seal Packing

3 Sensor

Housing

4

Ceramic Support Tube

5

Planar Measuring Element

6 Protective

Sleeve

7 Connection

Cable

Figure 6C1-1 – 32

Engine Management – V6 – General Information

Page 6C1-1–28

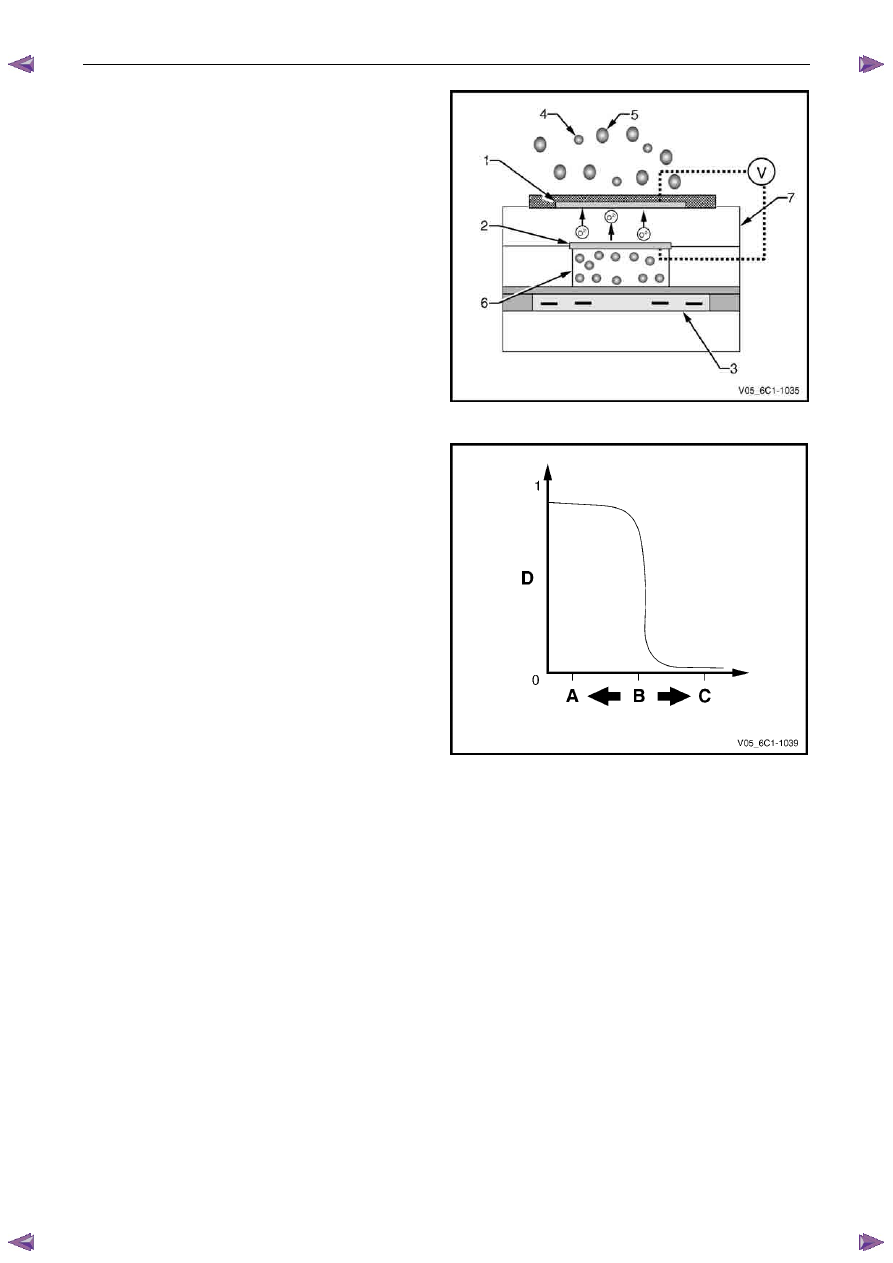

Measurement is achieved by comparing the oxygen content

of the exhaust gas to the oxygen content of a reference gas

(outside air) using the Nernst principle. Oxygen molecules

from the exhaust gas will accumulate on the outer electrode,

while oxygen molecules from the reference gas will

accumulate on the inner electrode. This creates a voltage

difference across the Nernst cell, between the two

electrodes, which is the signal voltage to the ECM.

Legend

1 Outer

Electrode

2 Inner

Electrode

3 Heater

Element

4

Oxygen Molecule (in exhaust stream)

5

Other Molecules (in exhaust stream)

6

Reference Gas (outside air)

7 Nernst

Cell

V Signal

Voltage

Figure 6C1-1 – 33

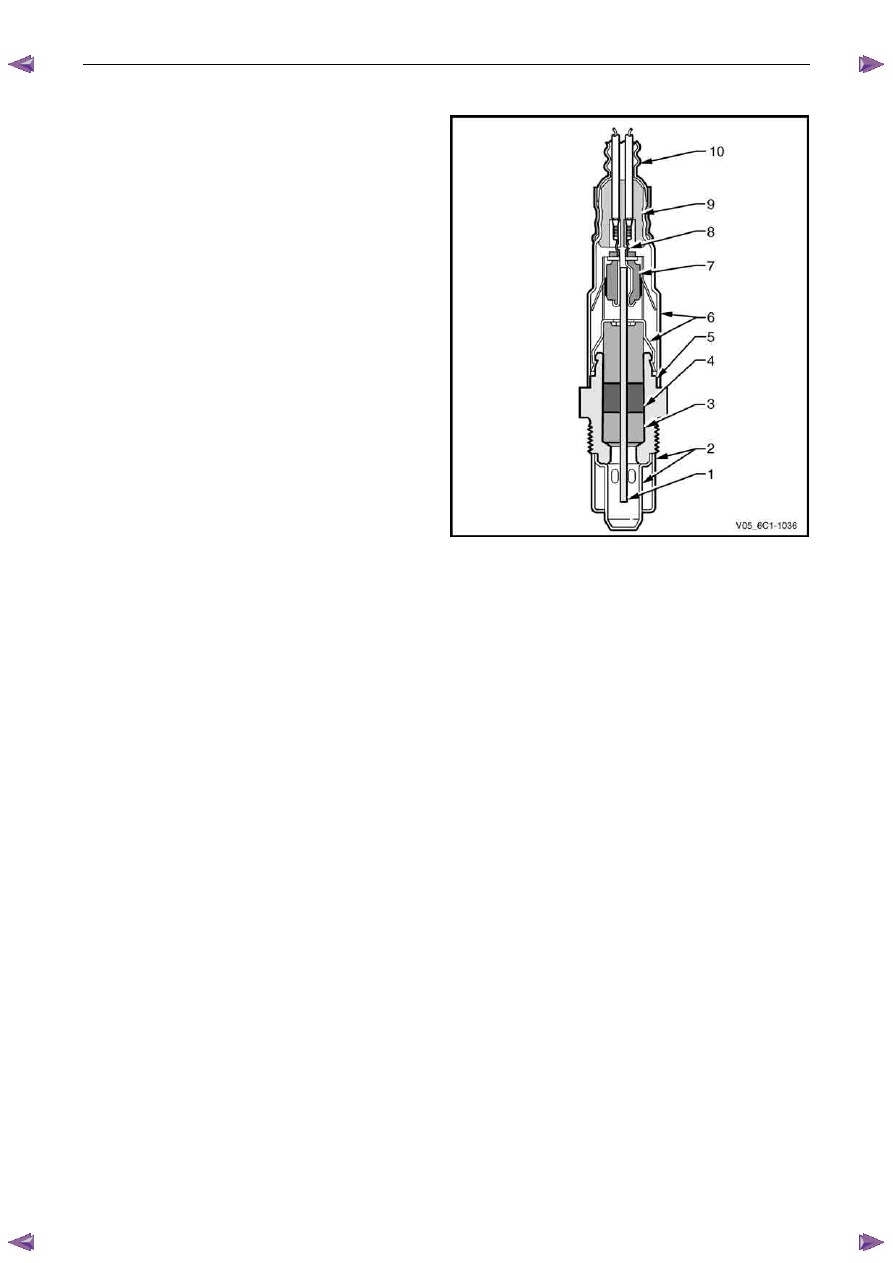

When the fuel system is correctly operating in the closed-

loop mode, the oxygen sensor voltage output is rapidly

changing several times per second, fluctuating from

approximately 100mV (high oxygen content – lean mixture)

to 900mV (low oxygen content – rich mixture). The transition

from rich to lean occurs quickly at about 450-500 mV (air

flow (A/F) ratio 14.7:1, or lambda = 1). Due to this, two-step

HO2S sensors are also known as switching type HO2S

sensors.

Legend

A Rich

Mixture

B

A/F Ratio 14.7:1 (Lambda = 1)

C Lean

Mixture

D Sensor

Voltage

Figure 6C1-1 – 34

Engine Management – V6 – General Information

Page 6C1-1–29

LSU 4.2 Wide-band Planar Heated Oxygen Sensors

The LSU 4.2 wide-band planar heated oxygen sensors have

six wires:

•

The internal heater element supply, which has 12 V

continually applied whenever the ignition is on.

•

Heater element ground – The ECM applies pulse

width modulated (PWM) ground to the HO2S heater

control circuit to control the rate at which the sensor

heats up. This reduces the risk of the sensor being

damaged from heating up too quickly under certain

conditions such as extreme cold temperatures. Once

the sensor has reached the desired operating

temperature, the ECM will monitor and continue to

maintain the sensor temperature.

•

Output voltage.

•

Sensor ground.

•

Trim current.

•

Pumping current.

Legend

1

Measuring Cell (Nernst cell and pump cell)

2

Double Protective Tube

3 Seal

Ring

4 Seal

Packing

5 Sensor

Housing

6 Protective

Sleeve

7 Contact

Holder

8 Contact

Clip

9

PTFE Sleeve (Teflon)

10

PTFE Shaped Sleeve

Figure 6C1-1 – 35

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст