Isuzu KB P190. Manual — part 818

Engine Management – V6 – General Information

Page 6C1-1–30

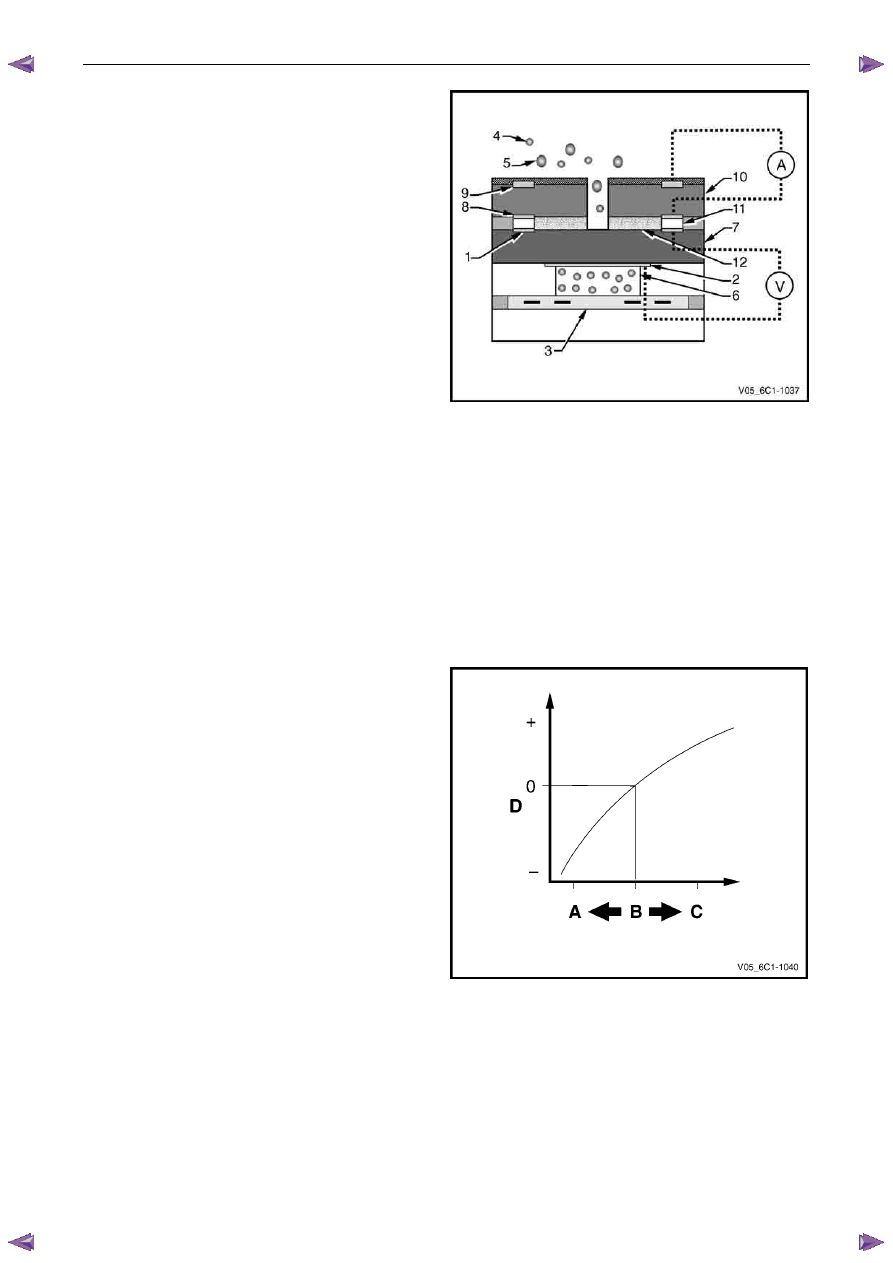

Similar to the two-step HO2S, measurement is achieved by

comparing the oxygen content of the exhaust gas to the

oxygen content of a reference gas. However, the way in

which the ECM calculates the exhaust oxygen content is

different, and results in a continual signal. This allows the

ECM to monitor not only whether the fuel mixture is rich or

lean, but exactly how rich or how lean. The wide-band

HO2S is basically a two-step HO2S with the addition of a

pump cell.

The ECM applies a pump voltage across the pump cell,

which causes oxygen to be pumped from the exhaust gas

into or out of the diffusion gap through the diffusion barrier.

While monitoring the Nernst cell, the ECM varies the pump

current so the gas in the diffusion gap remains constant at

an A/F ratio of 14.7:1 (Nernst cell output of 450 mV).

Legend

1 Outer

Electrode

2 Inner

Electrode

3 Heater

Element

4

Oxygen Molecule (in exhaust stream)

5

Other Molecules (in exhaust stream)

6

Reference Gas (outside air)

7 Nernst

Cell

8

Pump Cell Electrode

9

Pump Cell Electrode

10

Pump Cell

11 Diffusion

Gap

12

Porous Diffusion Barrier

A Pump

Current

V

Nernst Cell Voltage

Figure 6C1-1 – 36

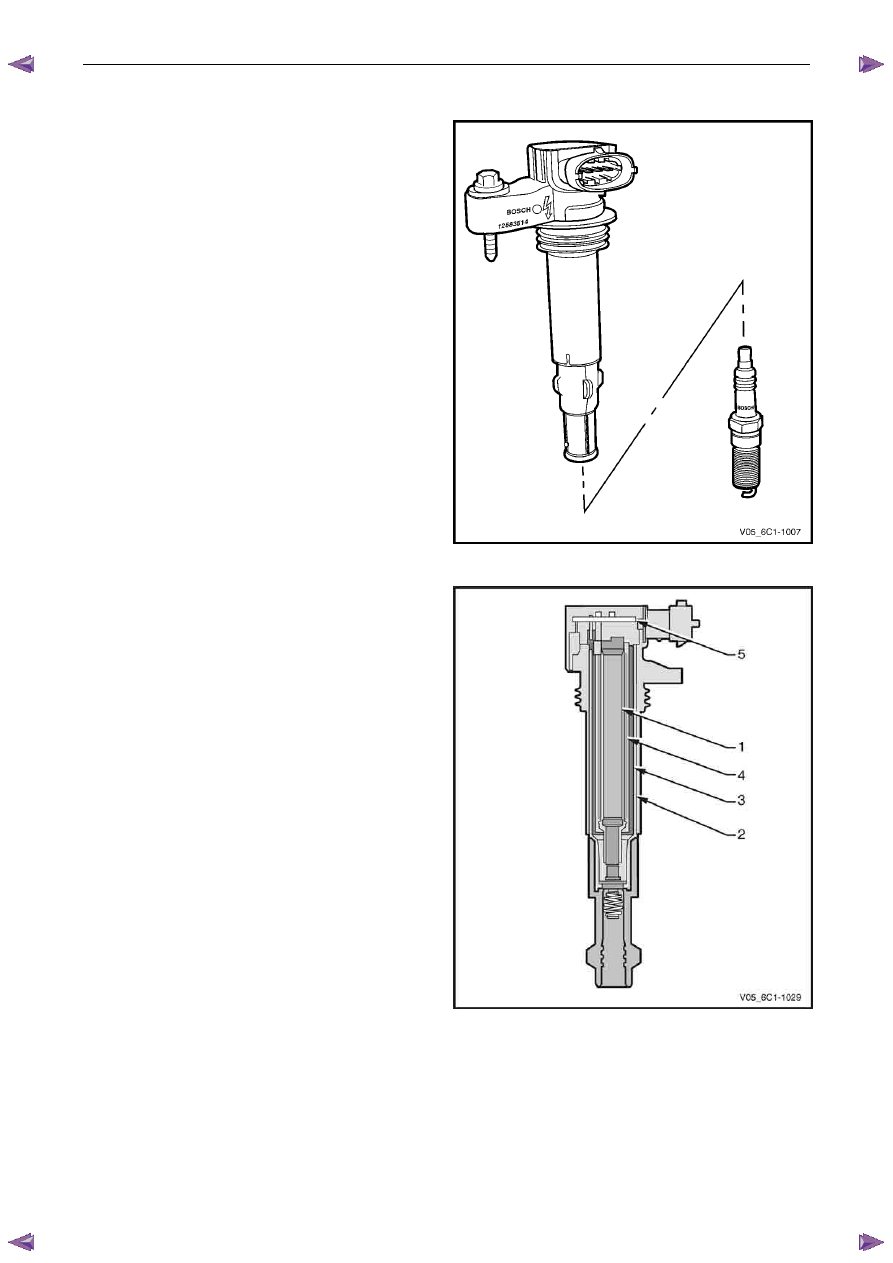

If the exhaust gas is lean, the pump cell pumps oxygen to

the outside (positive pump current). If the exhaust gas is

rich, oxygen is pumped from the exhaust gas into the

diffusion gap (negative pump current). By monitoring how

much it has to vary the pumping current, the ECM

determines the exact A/F ratio.

Legend

A Rich

Mixture

B

A/F Ratio 14.7:1 (Lambda = 1)

C Lean

Mixture

D Sensor

Current

Figure 6C1-1 – 37

Engine Management – V6 – General Information

Page 6C1-1–31

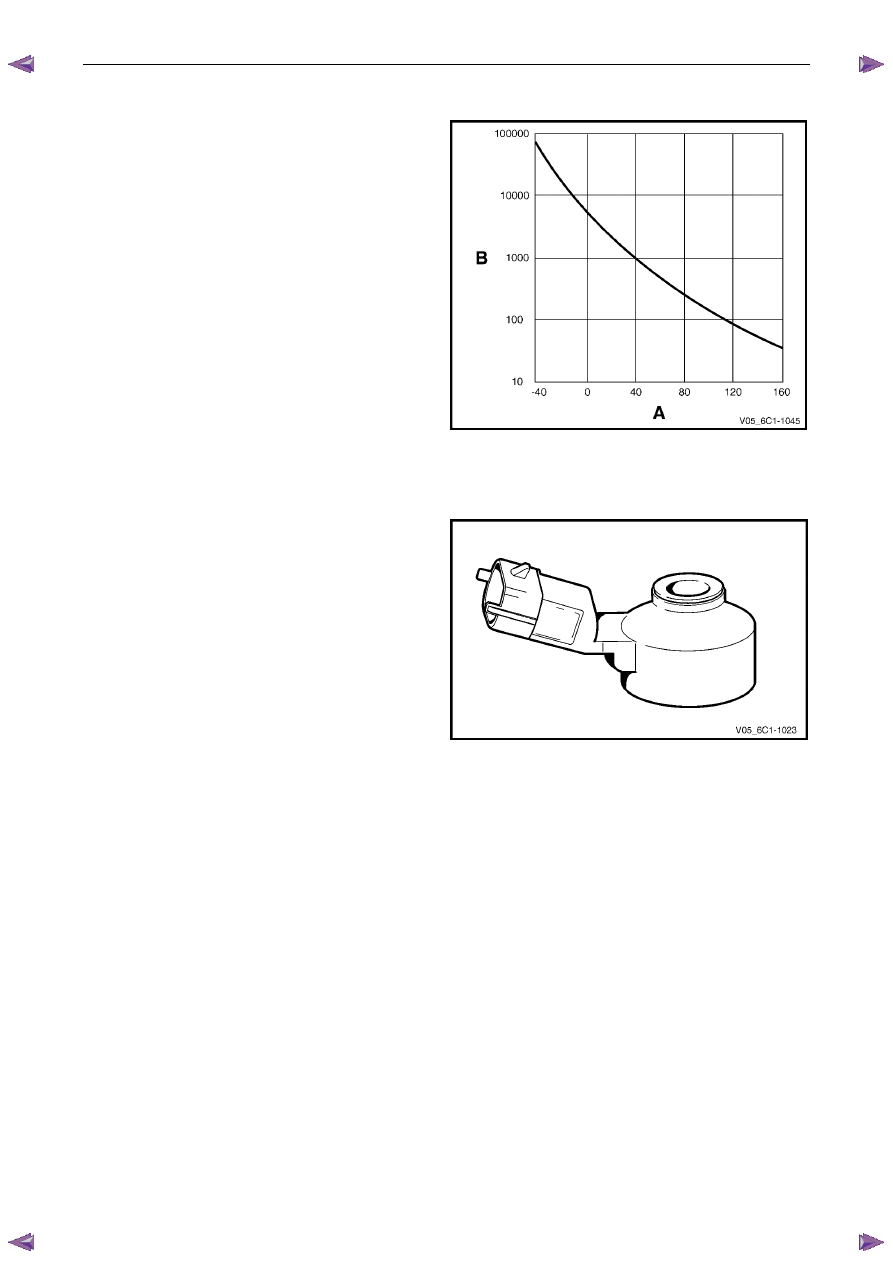

4.15 Ignition Coil and Spark Plug

Long-life platinum tip spark plugs are used which, along with

the ignition coil spark plug boot and spring, require

replacement at 100,000 kilometre service intervals. The

spark plugs, featuring a J-gap and a conical seat, do not

require inspection between services, and must not be re-

gapped.

Individual pencil-type ignition coils, one for each cylinder, are

mounted in the centre of the camshaft covers, and have

short boots connecting the coils directly to the spark plugs.

The pencil coil makes use of the space available in the spark

plug cavity in the cylinder head and camshaft cover. As a

pencil coil is always mounted directly on to the spark plug,

no high-tension ignition leads are required, further enhancing

reliability.

Figure 6C1-1 – 38

Pencil coils operate similarly to other compact coils, however

due to their shape, the structure differs considerably.

The central rod core (1) consists of laminations of varying

widths, stacked in packs that are nearly spherical. A yoke

plate (2), made from layered electrical sheet steel, provides

the magnetic circuit. The primary winding (3) is located

around the secondary winding (4), which supports the core.

A printed circuit board, or driver module, (5) is located at the

top of the coil and controls the firing of the coil based on

input from the ECM.

The ECM is responsible for maintaining correct spark timing

and dwell for all driving conditions. The ECM calculates the

optimum spark parameters from information received from

the various sensors, and triggers the appropriate ignition

module which then operates the coil.

The ignition coil / modules are supplied with the following

circuits:

•

Ignition feed circuit.

•

Ground circuit.

•

Ignition control circuit.

•

Reference low circuit.

Figure 6C1-1 – 39

Engine Management – V6 – General Information

Page 6C1-1–32

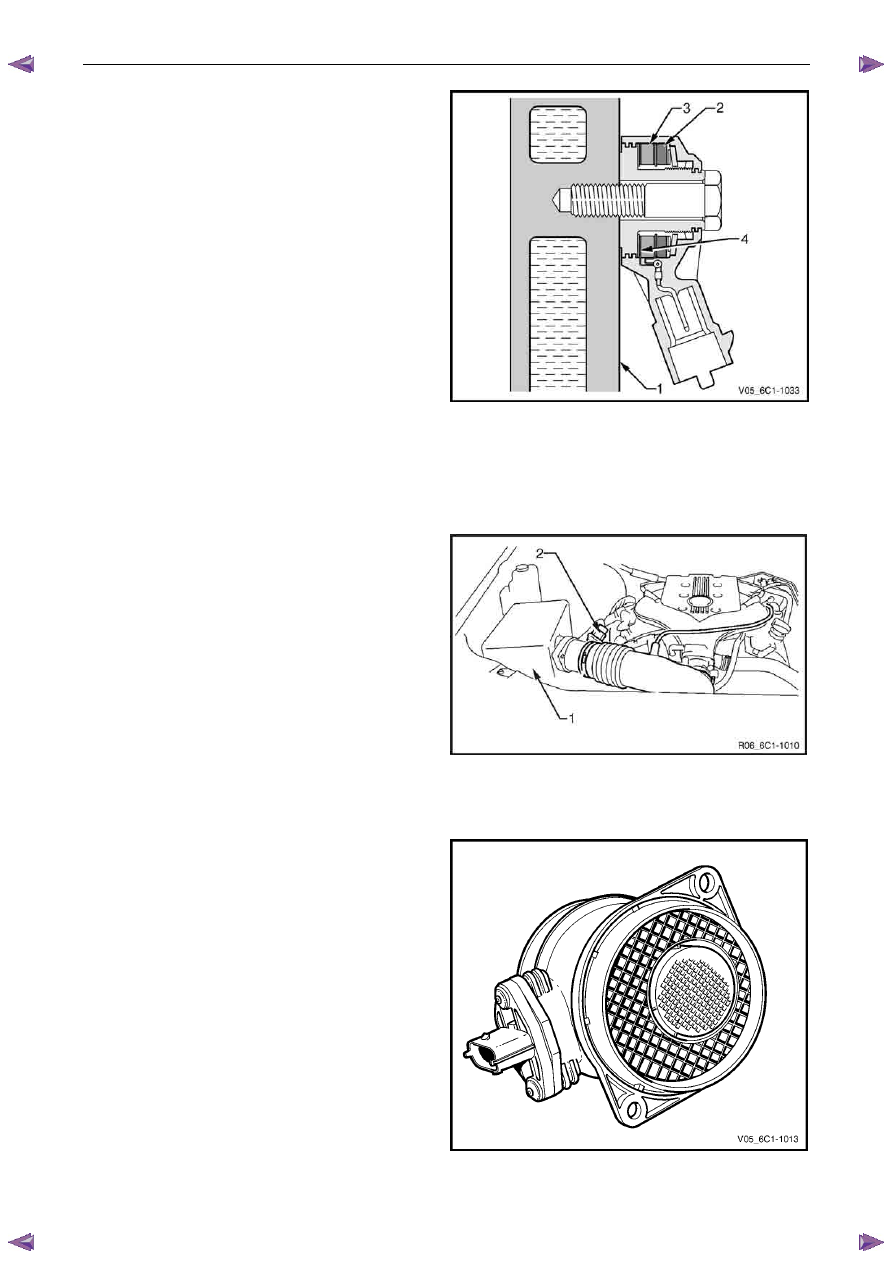

4.16 Intake Air Temperature Sensor

The intake air temperature (IAT) sensor is a thermistor,

which is a resistor that changes it’s resistance value based

on temperature.

The IAT sensor is part of the air mass sensor and is not a

serviceable item. The sensor is a negative temperature

coefficient (NTC) type, intake air temperature produces a

high sensor resistance while high engine coolant

temperature causes low sensor resistance.

Legend

A Temperature

B Resistance

The ECM provides a 5 V reference signal to the IAT and

monitors the return signal which enables it to calculate the

intake air temperature.

The ECM uses this signal to make corrections to the

operating parameters of the system based on changes in air

intake temperature.

Figure 6C1-1 – 40

4.17 Knock

Sensor

The knock sensor (KS) signal is used by the ECM to provide

optimum ignition timing while minimising engine knock or

detonation.

The ECM monitors the voltage of the left-hand (Bank 2)

sensor during the 45 degrees after cylinder 2, 4, or 6 has

fired and the voltage of the right-hand (Bank 1) sensor

during the 45 degrees after cylinder 1, 3, or 5 has fired.

If knock occurs in any of the cylinders, the ignition will be

retarded by three degrees for that particular cylinder. If the

knocking then stops, the ignition will be restored to what it

was before in steps of 0.75 degrees.

Should knocking continue in the same cylinder despite of

the ignition being retarded, the ECM will retard the ignition

an additional step of three degrees, and so on, up to a

maximum of 12.75 degrees. The ignition will also be

retarded at high ambient temperatures to counteract

knocking tendencies provoked by high intake air

temperatures.

Should either Bank 1 or Bank 2 sensor fail to work, or

should an open circuit occur, the ignition timing will then be

set at a default strategy that will retard the ignition much

more than normal.

Figure 6C1-1 – 41

Engine Management – V6 – General Information

Page 6C1-1–33

The knock sensor is tuned to detect the frequency of the

vibration created by combustion knock. The vibration is

transferred to the knock sensor through the cylinder

block (1).

Inside the sensor is a mass (2) that is excited by this

vibration, and the mass exerts a compressive force onto a

piezo-ceramic element (3). The compressive force causes a

charge transfer inside the element, so that an AC voltage

appears across the two outer faces (4) of the element. The

amount of the AC voltage produced is proportional to the

amount of knock.

Figure 6C1-1 – 42

4.18 Mass Air Flow Sensor

Air Intake System

The air intake system draws outside air through an air

cleaner assembly (1). The air is then routed through a mass

air flow (MAF) sensor (2) and into the throttle body and

intake manifold. The air is then directed into the intake

manifold runners, through the cylinder heads and into the

cylinders.

An arrow marked on the body of the MAF sensor indicates

correct air flow direction. The arrow must point toward the

engine.

Figure 6C1-1 – 43

Mass Air Flow Sensor

A hot film type mass air flow (MAF) sensor is used which

measures the air mass inducted into the engine, regardless

of the engine’s operating state. The MAF precisely

measures a portion of the total airflow and takes into

account the pulsation and reverse flows generated by the

engine’s inlet and exhaust valves.

Changes in intake air temperature have no effect on

measuring accuracy.

Figure 6C1-1 – 44

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст