Isuzu KB P190. Manual — part 803

Fuel System – V6

Page 6C – 10

After relieving the fuel system pressure, a

small amount of fuel may be released when

servicing the fuel lines or connections. Cover

the fittings with a shop towel before

disconnecting. This catches any leaking fuel.

Place the soiled towel in an approved

container when disconnection is completed.

3

Wrap a shop towel around the fuel pressure test point to absorb any fuel spillage.

4

Remove the fuel pressure gauge and drain any fuel remaining in the fuel pressure gauge into an approved fuel

container.

5

Remove the soiled shop towel and place in an approved container.

6

Repressurise the fuel system, refer to 3.4

Fuel System Depressurisation.

7

Road-test the vehicle and check for correct operation.

3.3

Fuel Leak Test

After installing any fuel system component

and before starting the engine, check the fuel

system for leaks.

N O T E

For the fuel injector leak-down test (for vehicles

fitted with a V6 engine), refer to 6C1-3 Engine

Management – V6 – Service Operations.

1

Turn the ignition switch on for two seconds.

2

Turn the ignition switch off for 10 seconds.

3

Turn the ignition switch on.

4

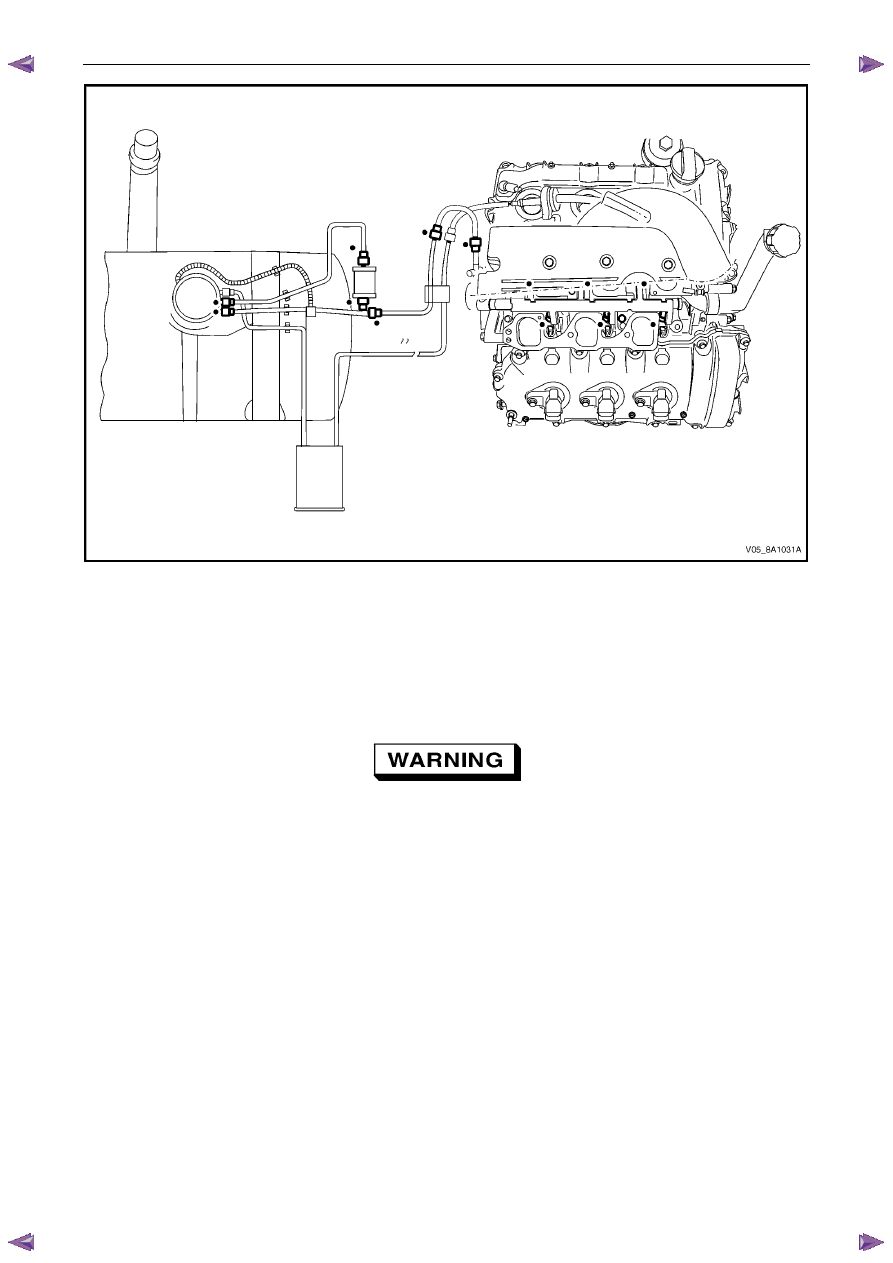

Check for fuel leaks, particularly at points marked

z (that is, quick-connect fittings, fuel rails, fuel injectors,

Schrader valve and evaporative emission control canister purge solenoid, refer to Figure 6C – 6.

Fuel System – V6

Page 6C – 11

Figure 6C – 6

5

Replace any faulty components and repeat step 2 to step 5 inclusive.

6

Replace all engine components removed to perform the fuel leak test, refer to 6C1-3 Engine Management – V6 –

Service Operations.

3.4

Fuel System Depressurisation

To reduce the risk of fire or personal injury,

depressurise the fuel system before servicing

any fuel system components.

1

Turn the ignition switch off.

2

Remove the fuel pump fuse and fuel pump relay, refer to 8A Electrical Body and Chassis.

3

Loosen the fuel filler cap to relieve the fuel tank vapour pressure.

4

With the throttle closed, crank the engine.

N O T E

The engine may start and operate until the fuel

remaining in the fuel delivery system depletes.

5

When the engine stops, crank the engine for another 10 seconds to ensure the fuel feed line pressure has been

fully relieved.

6

Clean the area around the fuel pressure test point.

Fuel System – V6

Page 6C – 12

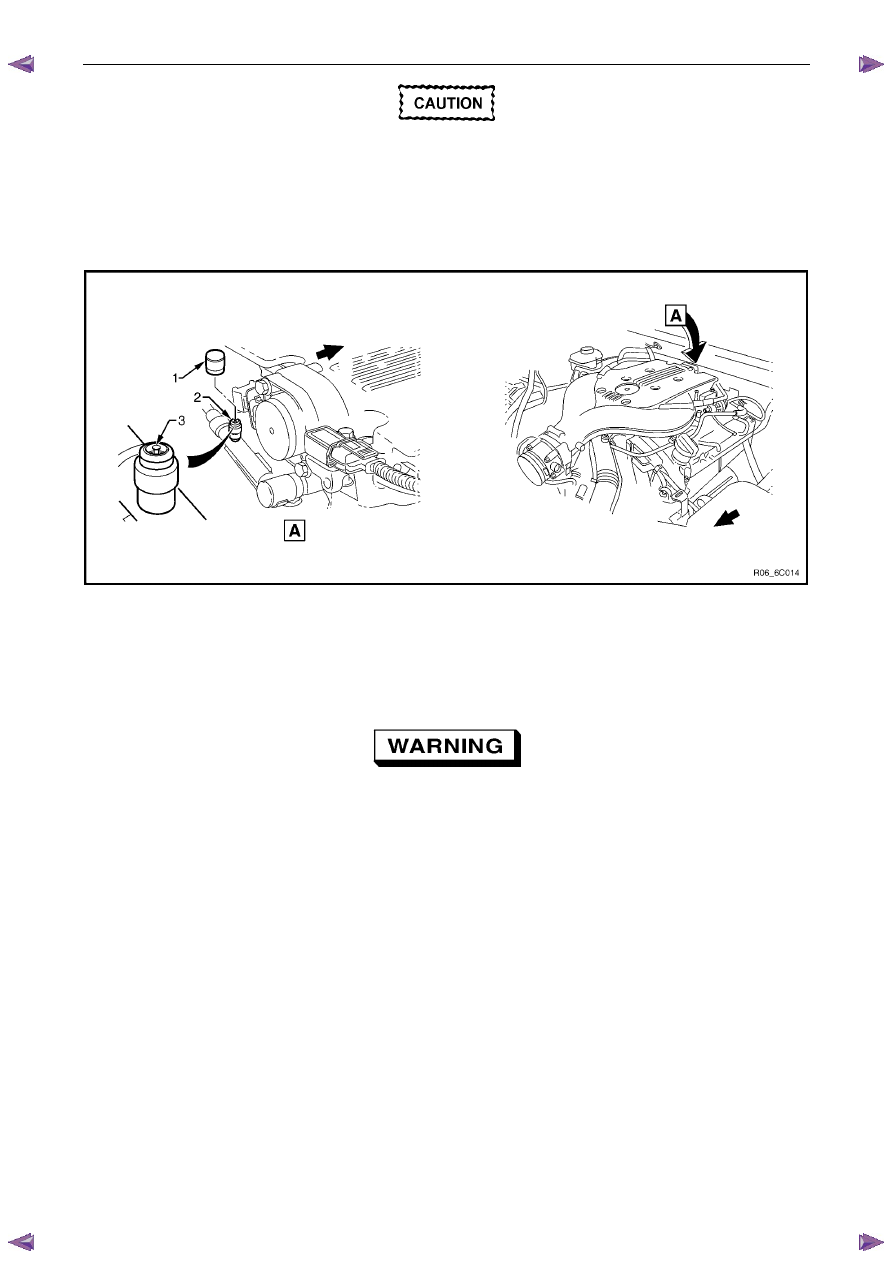

A small amount of fuel may be released when

pressing on the Schrader valve. Cover the

fitting with a shop towel to absorb any fuel

spillage before removing the Schrader valve

sealing cap. Place the soiled towel in an

approved container for disposal.

7

At the fuel pressure test point (2), remove the Schrader valve sealing cap (1), refer to Figure 6C – 7.

Figure 6C – 7

Legend

1

Schrader Valve Sealing Cap

2

Pressure Test Point

3 Schrader

Valve

Wear safety glasses when performing the fuel

pressure relief procedure.

8

Place a shop towel around the Schrader valve to soak up the expelled petrol.

9

Use a small screwdriver to press the Schrader valve down (3).

10

Remove the soiled shop towel and place in an approved container.

Repressurise

1

Reinstall the fuel pump relay and fuel pump fuse.

2

Perform the following procedure to inspect for leaks at the fuel pressure test point:

a

Turn the ignition switch on for two seconds.

b

Turn the ignition switch off for 10 seconds.

c

Turn the ignition switch on.

d

Check for leaks at the fuel pressure test point.

3

Tighten the fuel filler cap.

4

Start the engine and recheck for leaks.

5

Reinstall the Schrader valve sealing cap.

Fuel System – V6

Page 6C – 13

4 Service

Operations

4.1

Fuel Lines And Quick Connect Fittings

Description

The fuel line connector fittings contain the following

components:

1 O-rings

2

Fuel line port

3 Connector

4

Plastic fuel line tube

Figure 6C – 8

Leak Test and Inspection

1.

Turn the ignition key to the ON position and ensure the fuel pump runs for a short time by listening for the pump

start up sound. The fuel pressure will increase when the fuel pump is actuated.

2

Perform a preliminary check of the system by inspecting the system for any leaks around the connections and

fittings.

3

Perform steps 1 and 2 several times.

4

If the preliminary check of the system produces no leaks, start the engine and check the system again for any sign

of leaks around the connections and lines.

Ensure all service precautions have been

observed prior to removing any connector

fittings.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст