Isuzu KB P190. Manual — part 621

Engine Mechanical – V6

Page 6A1–5

Camshaft Visual Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Camshaft Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Reinstall . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 153

Right-hand Side. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 153

Left-hand Side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

3.20

Rocker Arm. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

Remove . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ... 158

Clean and Inspect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 158

Reinstall . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 159

3.21

Stationary Hydraulic Lash Adjuster . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Remove . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ... 160

Clean and Inspect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 160

Reinstall . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 161

3.22

Cylinder Head Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ... 161

Remove . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ... 161

Right-hand Side (Bank 1) Cylinder Head . . . . . . . . . . . . . . . . . . . . . . . . . ... 161

Left-hand Side (Bank 2) Cylinder Head. . . . . . . . . . . . . . . . . . . . . . . . . . .. 162

Disassemble . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ... 163

Clean . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ... 166

Inspect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Visual Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Cylinder Head Measurement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 167

Valve Spring Inspection and Measurement. . . . . . . . . . . . . . . . . . . . . . . . . 169

Valve and Seat Grinding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

Assemble . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

Reinstall . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 177

Right-hand Side (Bank 1) Cylinder Head . . . . . . . . . . . . . . . . . . . . . . . . . ... 177

Left-hand Side (Bank 2) Cylinder Head. . . . . . . . . . . . . . . . . . . . . . . . . . .. 178

3.23

Engine Mounts and Brackets. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

Remove. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 181

Engine Mount Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

Inspect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

Reinstall . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 183

4

Major Service Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..184

4.1

Engine Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

Remove. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 185

Disassemble. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ... 197

Reassemble . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ... 198

Reinstall . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

4.2

Oil Pan and Oil Pump Suction Pipe Assembly . . . . . . . . . . . . . . . . . . . . . . . . 198

Remove. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 198

Disassemble. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ... 200

Clean. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 200

Inspect. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

Reassemble . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ... 201

Reinstall . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

4.3

Flexplate Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ... 203

Remove . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ... 203

Clean . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ... 204

Inspect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

Reinstall . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 205

4.4

Crankshaft Rear Seal and Plate Assembly . . . . . . . . . . . . . . . . . . . . . . . . . .. 205

Remove . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ... 205

Reinstall . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 207

4.5

Pistons, Pins, Rings, Connecting Rods and Big-end Bearings . . . . . . . . . . . . . . . . . . 208

Remove . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ... 208

Disassemble . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ... 211

Clean and Inspect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 212

Engine Mechanical – V6

Page 6A1–6

Piston Cleaning Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

Piston Inspection Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 213

Piston Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 213

Piston Ring Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 214

Connecting Rod Cleaning Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

Connecting Rod Visual Inspection Procedure . . . . . . . . . . . . . . . . . . . . . . . . 215

Connecting Rod Measurement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . 216

Reassemble . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

Piston and Piston Pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

Piston Ring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

Connecting Rod Bearing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

Reinstall . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 220

Piston Connecting Rod and Connecting Rod Bearing Installation. . . . . . . . . . . . . . . . .. 220

Connecting Rod Bearing Clearance Measurement Procedure. . . . . . . . . . . . . . . . . ... 221

Connecting Rod Final Assembly Procedure. . . . . . . . . . . . . . . . . . . . . . . . ... 222

4.6

Crankshaft and Main Bearings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

Crankshaft End Play Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 223

Remove . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ... 223

Crankshaft Bearing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

Clean and Inspect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 225

Crankshaft and Main Bearing Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . .. 225

Crankshaft and Main Bearing Visual Inspection . . . . . . . . . . . . . . . . . . . . . . . . 226

Crankshaft Main Bearing Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . ... 227

Crankshaft Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ... 228

Reinstall . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 230

Crankshaft Bearing Installation Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . 230

Crankshaft Main Bearing Clearance Measurement. . . . . . . . . . . . . . . . . . . . . . 231

Crankshaft Final Installation Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . .. 233

4.7

Cylinder Block. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

Disassemble . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ... 234

Clean . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ... 238

Inspect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

Visual Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

Measuring Cylinder Bore Diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

Measuring Cylinder Bore Taper. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 239

Measuring Cylinder Bore Out-of-Round . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

Deck Flatness Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ... 240

Reassemble . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

4.8

Thread Repairs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ... 244

General Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ... 244

General Thread Repair. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ... 246

Main Bearing Cap Bolt Hole Thread Repair . . . . . . . . . . . . . . . . . . . . . . . . . . 251

Cylinder Head Bolt Hole Thread Repair . . . . . . . . . . . . . . . . . . . . . . . . . . ... 257

4.9

Thread Repair Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 263

Left-hand Cylinder Head Camshaft Cover Face . . . . . . . . . . . . . . . . . . . . . . . .. 263

Left-hand Cylinder Head Front Face . . . . . . . . . . . . . . . . . . . . . . . . . . . . 264

Left-hand Cylinder Head Intake Face . . . . . . . . . . . . . . . . . . . . . . . . . . . ... 265

Left-hand Cylinder Head Exhaust Face. . . . . . . . . . . . . . . . . . . . . . . . . . . 266

Left-hand Cylinder Head Rear Face . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 267

Right-hand Cylinder Head Camshaft Cover Face . . . . . . . . . . . . . . . . . . . . . . ... 268

Right-hand Cylinder Head Front Face. . . . . . . . . . . . . . . . . . . . . . . . . . . .. 269

Right-hand Cylinder Head Intake Face. . . . . . . . . . . . . . . . . . . . . . . . . . . . 270

Right-hand Cylinder Head Exhaust Face . . . . . . . . . . . . . . . . . . . . . . . . . . . 271

Right-hand Cylinder Head Rear Face . . . . . . . . . . . . . . . . . . . . . . . . . . . ... 272

Engine Block Front . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 273

Engine Block Left-hand Side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 274

Engine Block Right-hand Side. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 275

Engine Block Rear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 276

Engine Block Bottom. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 277

Engine Block Left-hand Deck Face . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 278

Engine Mechanical – V6

Page 6A1–7

Engine Block Right-hand Deck Face. . . . . . . . . . . . . . . . . . . . . . . . . . . . 279

Engine Front Cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 280

Upper Intake Manifold Top . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 281

Upper Intake Manifold Front . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 282

Upper Intake Manifold Rear. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ... 283

Lower Intake Manifold Top. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 284

Oil Pan Front . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 285

Oil Pan Rear. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 286

Oil Pan Bottom . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ... 287

5

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .288

6

Torque Wrench Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . ..292

7

Special Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..294

Engine Mechanical – V6

Page 6A1–8

1 General

Information

The HFV6 engine features a closed vee, deep skirt die cast aluminium cylinder block with cast iron cylinder liners,

internally balanced crankcase, full length water jackets and six bolt main bearing caps.

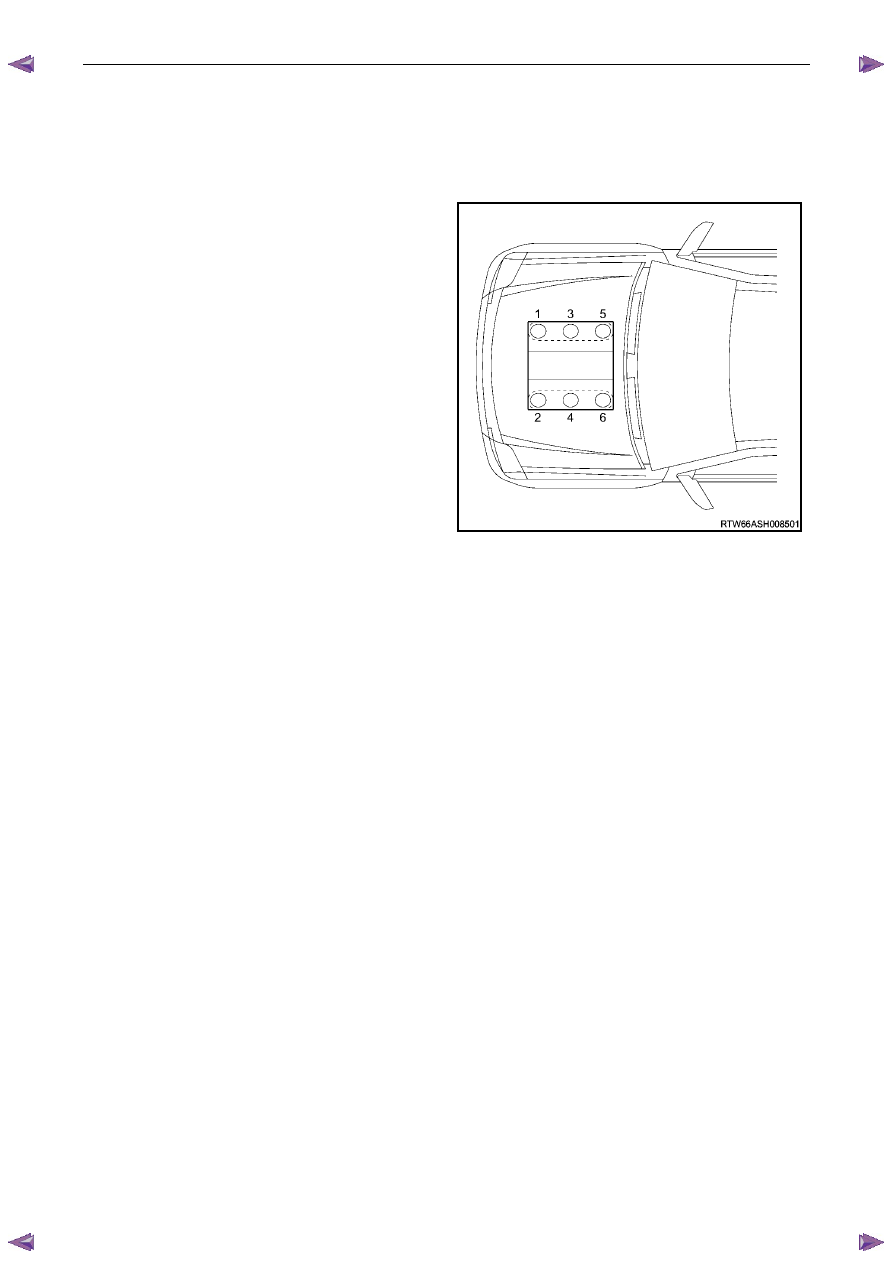

The cylinders are arranged in two banks of three with a 60 degree included angle between the two banks.

The right-hand bank of cylinders consists of number 1-3-5

cylinders and the left-hand bank of cylinders consists of

number 2-4-6.

The engine firing order is 1-2-3-4-5-6.

Each aluminium cylinder head is fitted with hardened valve

seats and four valves per cylinder: two intake and two

exhaust.

The valves are operated by two camshafts (DOHC) per

cylinder bank, one each for intake and exhaust valves.

The crankshaft is manufactured from forged steel. A reluctor

wheel is pressed in place onto the rear of the crankshaft for

the crankshaft position sensor.

The connecting rods are manufactured from powdered

metal and the rod cap is separated during the manufacturing

process using the fractured method. This creates a stronger,

visually seamless rod to cap union.

Figure 6A1 – 1

1.1

WARNING, CAUTION and NOTES

This Section contains various WARNINGS, CAUTIONS and NOTE statements that you must observe carefully to reduce

the risk of death or injury during service, repair procedures or vehicle operation. Incorrect service or repair procedures

may damage the vehicle or cause operational faults. WARNINGS, CAUTION and NOTE statements are not exhaustive.

HOLDEN LTD can not possibly warn of all the potentially hazardous consequences of failure to follow these instructions.

Definition of WARNING, CAUTION and NOTE Statements

Diagnosis and repair procedures in this Section contain both general and specific WARNING, CAUTION and NOTE

statements. HOLDEN LTD is dedicated to the presentation of service information that helps the technician to diagnose

and repair the systems necessary for proper operation of the vehicle. Certain procedures may present a hazard to the

technician if they are not followed in the recommended manner. WARNING, CAUTION and NOTE statements are

designed to help prevent these hazards from occurring, but not all hazards can be foreseen.

WARNING defined

A WARNING statement immediately precedes an operating procedure or maintenance practice which, if not correctly

followed, could result in death or injury. A WARNING statement alerts you to take necessary action or not to take a

prohibited action. If a WARNING statement is ignored, the following consequences may occur:

•

Death or injury to the technician or other personnel working on the vehicle,

•

Death or injury to other people in or near the workplace area, and / or

•

Death or injury to the driver / or passenger(s) of the vehicle or other people, if the vehicle has been improperly

repaired.

CAUTION defined

A CAUTION statement immediately precedes an operating procedure or maintenance practice which, if not correctly

followed, could result in damage to or destruction of equipment, or corruption of data. If a CAUTION statement is ignored,

the following consequences may occur:

•

Damage to the vehicle,

•

Unnecessary vehicle repairs or component replacement,

•

Faulty operation or performance of any system or component being repaired,

•

Damage to any system or components which depend on the proper operation of the system or component being

repaired,

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст