Isuzu KB P190. Manual — part 774

Engine Mechanical – V6

Page 6A1–319

Page 6A1–319

12

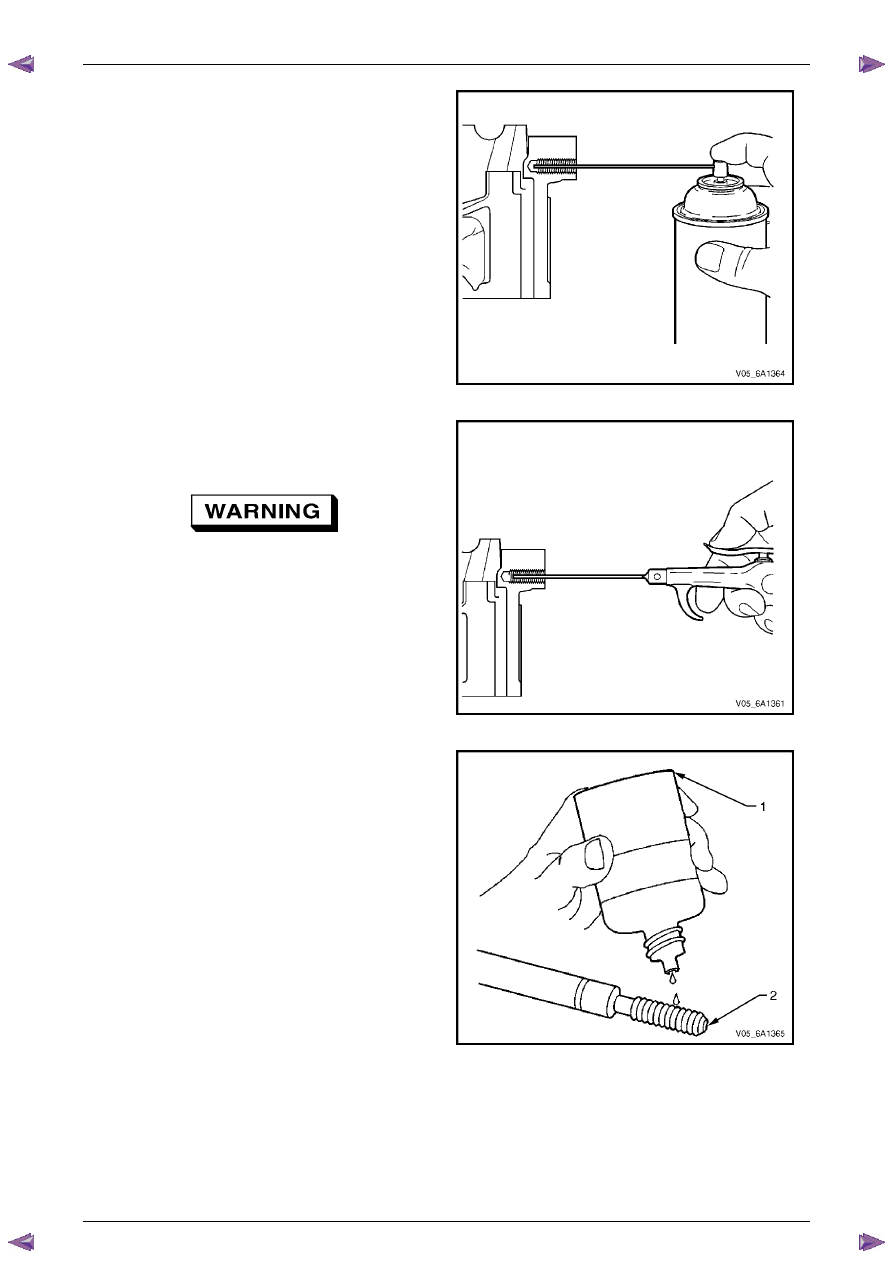

Spray a commercially available thread cleaner into

the tapped hole.

Figure 6A1 – 597

N O T E

All swarf must be removed from the tapped hole

prior to insert installation.

Safety glasses must be worn when using

compressed air.

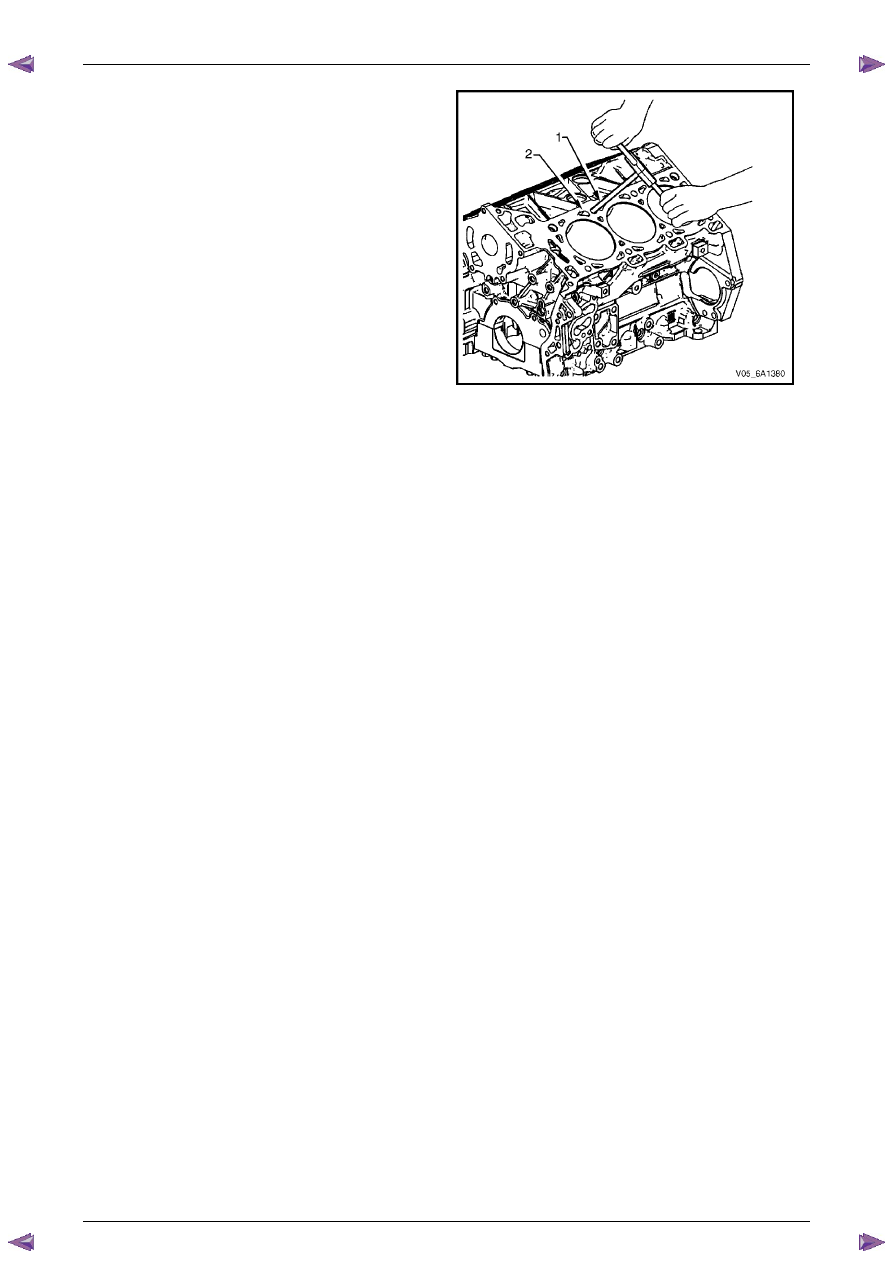

13

Using compressed air, clean out any swarf.

Figure 6A1 – 598

N O T E

Do not allow oil or other foreign material to

contact the outside diameter (OD) of the insert.

14

Lubricate the threads of the driver installation tool (2)

with the driver oil (1).

Figure 6A1 – 599

Engine Mechanical – V6

Page 6A1–320

Page 6A1–320

15

Install the insert (2) onto the driver installation tool (1).

Figure 6A1 – 600

16

Apply thread lock sealant (1) such as Loctite 277® or

equivalent to the insert OD threads (2).

Figure 6A1 – 601

17

Install the insert and installation driver (1) into the

tapped hole by hand only.

18

Start the insert into the threaded hole.

CAUTION

If the insert will not thread down until the

flange contacts the counter-bored surface,

remove the insert immediately with a screw

extracting tool and inspect the tapped hole

for any remaining swarf and/or incorrect

tapping.

19

Install the insert until the flange of the insert contacts

the counter-bored surface.

N O T E

The driver installation tool will tighten up before

cutting completely through the insert. This is

acceptable. The threads at the bottom of the

insert are being formed and the insert is

mechanically locking the insert into the base

material threads.

20

Continue to rotate the driver installation tool through

the insert.

Figure 6A1 – 602

Engine Mechanical – V6

Page 6A1–321

Page 6A1–321

21

In order to completely form the new threads in the

insert, rotate the driver installation tool through the

insert until the mark on the driver installation tool (1)

aligns with the surface of the engine block deck (2).

22

Inspect the insert for correct installation into the

tapped hole.

Figure 6A1 – 603

Engine Mechanical – V6

Page 6A1–322

Page 6A1–322

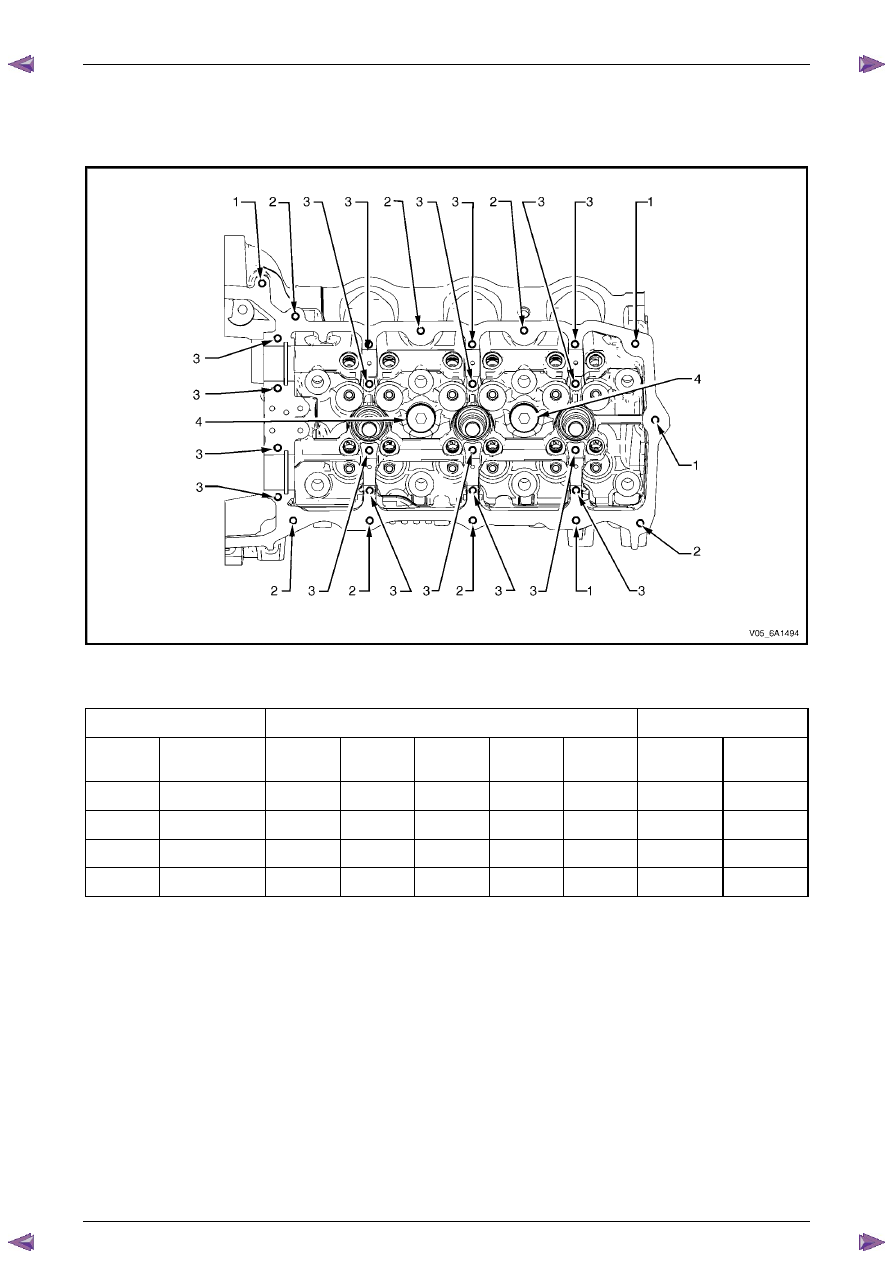

4.9

Thread Repair Specifications

Left-hand Cylinder Head Camshaft Cover Face

Figure 6A1 – 604

Legend

Hole

Tool Number J 42385

Max. Depth in mm

Number Thread

Size Drill

Counter-

bore

Tap Driver

Insert Drill

Tap

1

M6 x 1.0

201

202

203

204

205

22.5

18.0

2

M6 x 1.0

201

202

203

204

205

Thru

Thru

3

M6 x 1.0

701

n/a

203

204

205

28.5

24.0

4

M20 x 1.5

715

716

717

718

719

25.0

17.0

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст