Isuzu KB P190. Manual — part 907

Starting System – V6

Page 6D1-2–20

6

Fit the rear lifting brackets: EN–46114 (1) to the

engine, then hook the chains from the engine hoist

onto the rear lifting bracket.

7

Remove the oil level indicator tube, Refer to 6A1

Engine Mechanical – V6.

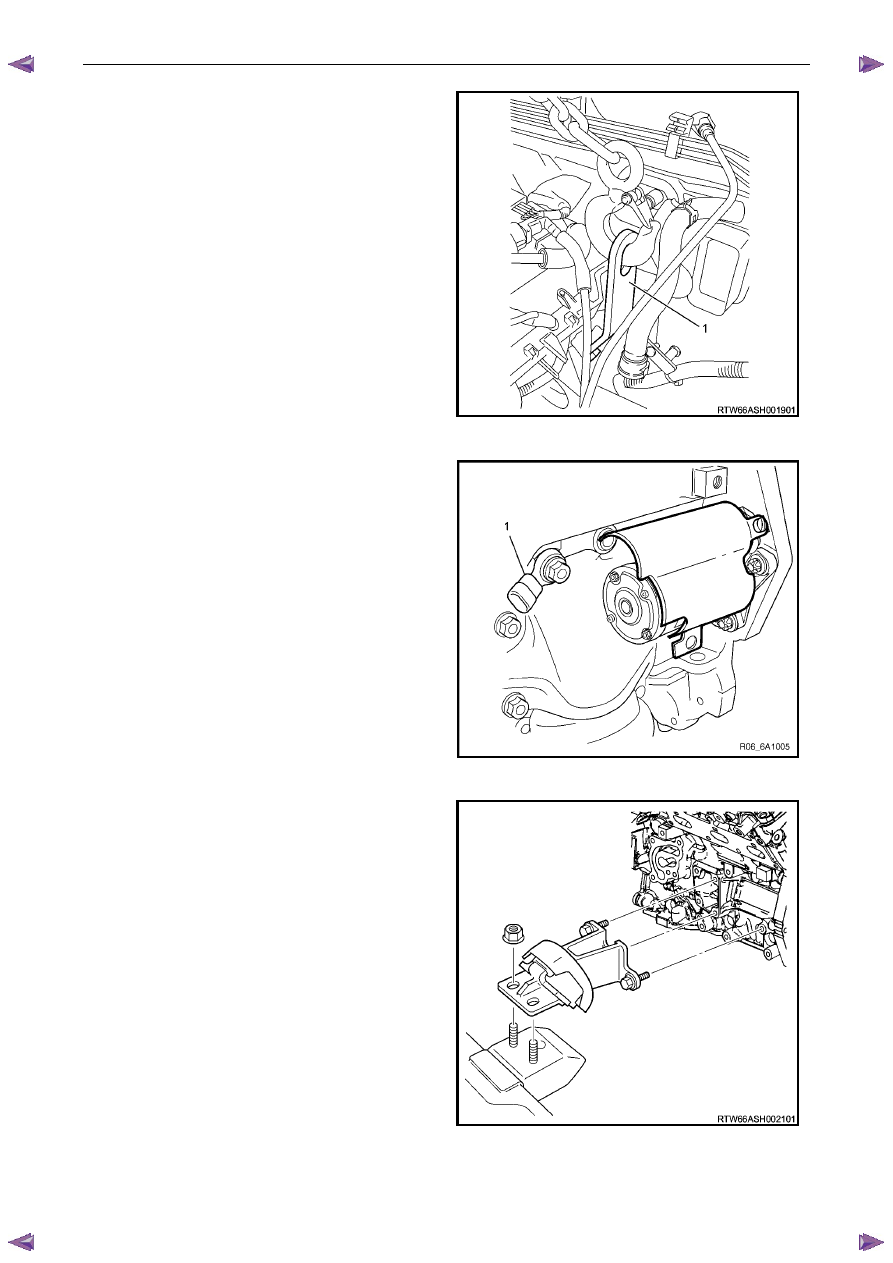

Figure 6D1-2 – 9

8

Remove the left hand side knock sensor (1) from the

engine block.

Figure 6D1-2 – 10

9

Remove the left hand side engine mount, then using

the engine hoist raise the engine to give sufficient

clearance to remove the starter motor.

Figure 6D1-2 – 11

Starting System – V6

Page 6D1-2–21

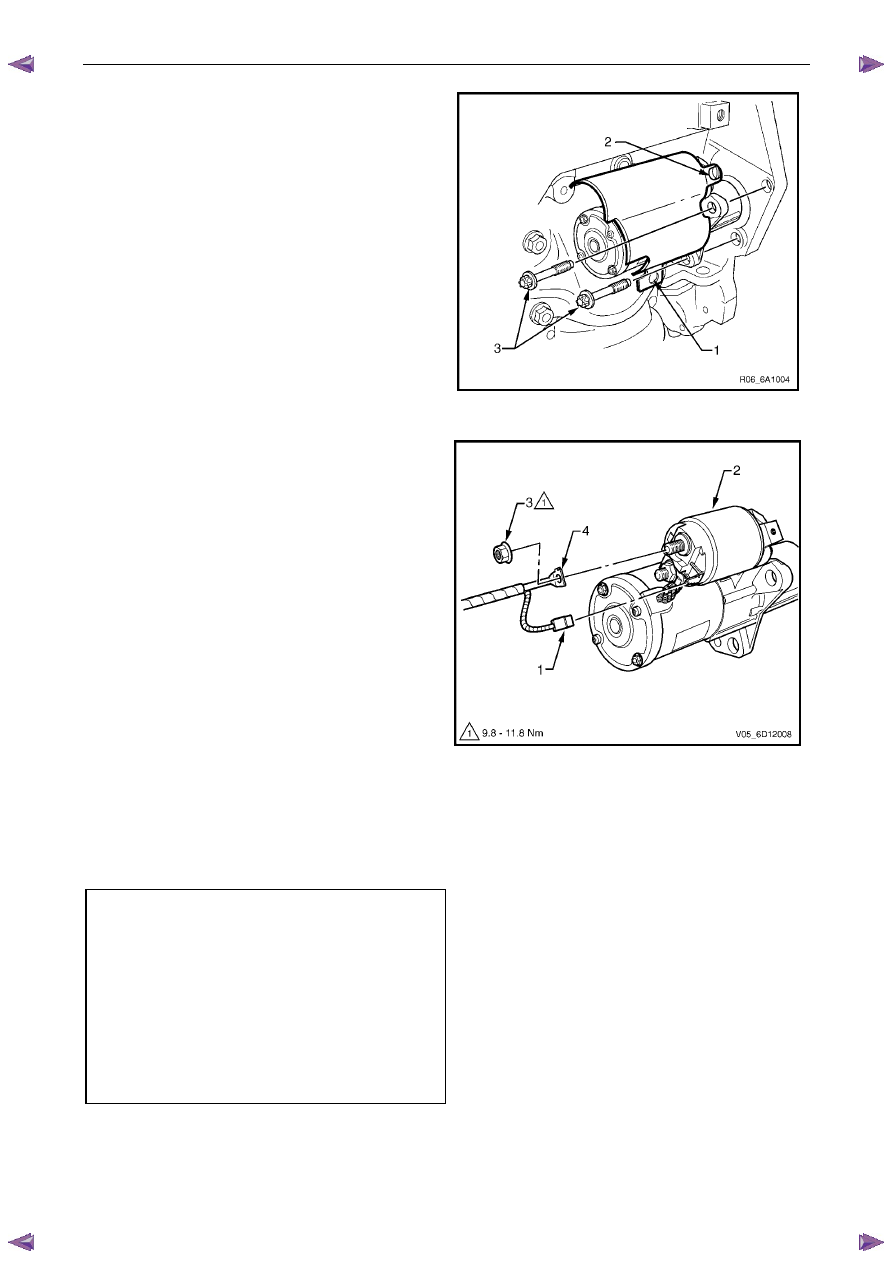

10

Unclip the oil level sensor harness from the heat shield

(1).

11

Remove the heat shield attaching screw (2).

12

Remove the lower starter motor attaching bolt (3).

13

Remove the heat shield.

14

Remove the upper starter motor retaining bolt (3).

15

Remove the starter motor from the engine block and

lower the starter motor as far as possible to gain

access to the wiring harness connections.

Figure 6D1-2 – 12

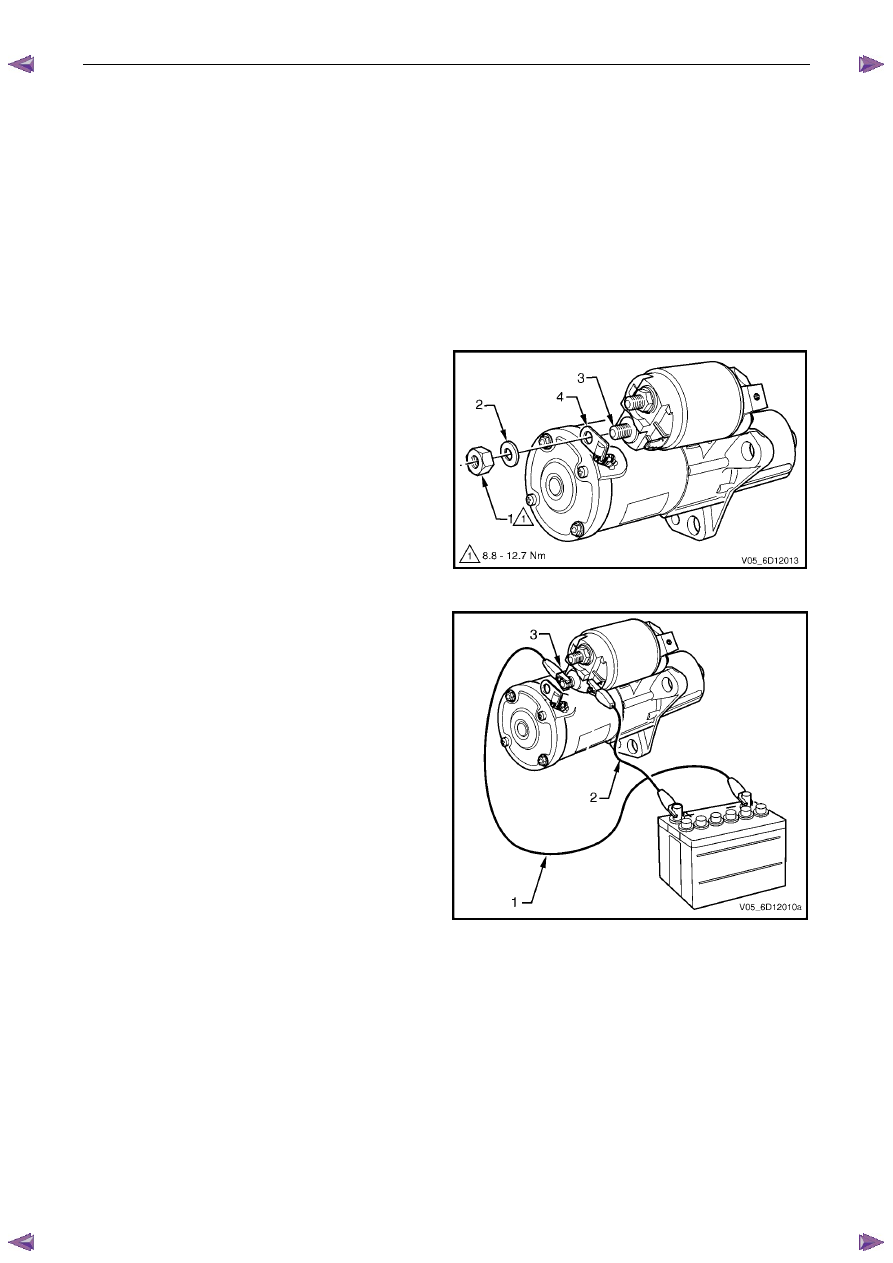

16

Remove the wiring harness connector P – 3 (1) from

the solenoid switch (2).

17

Remove the flange nut (3) and battery connector P – 4

(4) from the solenoid switch.

18

Remove the starter motor from the vehicle.

Figure 6D1-2 – 13

Reinstall

Reinstallation of the starter motor is the reverse of the removal procedure noting the following:

1

Tighten all fasteners to the correct torque specification.

Solenoid switch connector P – 4 nut (B+)

torque specification . . . . . . . . . . . 10.0 Nm

Starter motor heat shield lower bolts

torque specification . . . . . . . . . . . 23.0 Nm

Starter motor heat shield upper screw

torque specification . . . . . . . . . .3.0 – 5.0 Nm

Starter motor mounting bolt

torque specification . . . . . . . . . . . 45.0 Nm

Knock sensor bolt

torque specification . . . . . . . . . . . 23.0 Nm

2

Check the starter motor operates correctly.

Starting System – V6

Page 6D1-2–22

4.3

Starter Motor Bench Tests

Preliminary Checks

1

Check the drive assembly is fully retracted.

2

Check the drive assembly pinion turns freely on the planetary drive shaft.

3

Perform the No Load Test (as outlined in this Section) if the drive assembly is not fully retracted.

4

Disassemble and service the starter motor if it fails the No Load test, refer to 4.4 Starter Motor Disassemble and

Reassemble in this Section.

Pull-in Test

1

Clamp the starter motor, by the mounting lug in the

drive-end housing, in a vice with soft jaws.

2

Remove the nut (1) and washer (2) from the

solenoid switch M terminal (3).

3

Remove the braided cable (4) from the solenoid

switch M terminal.

Figure 6D1-2 – 14

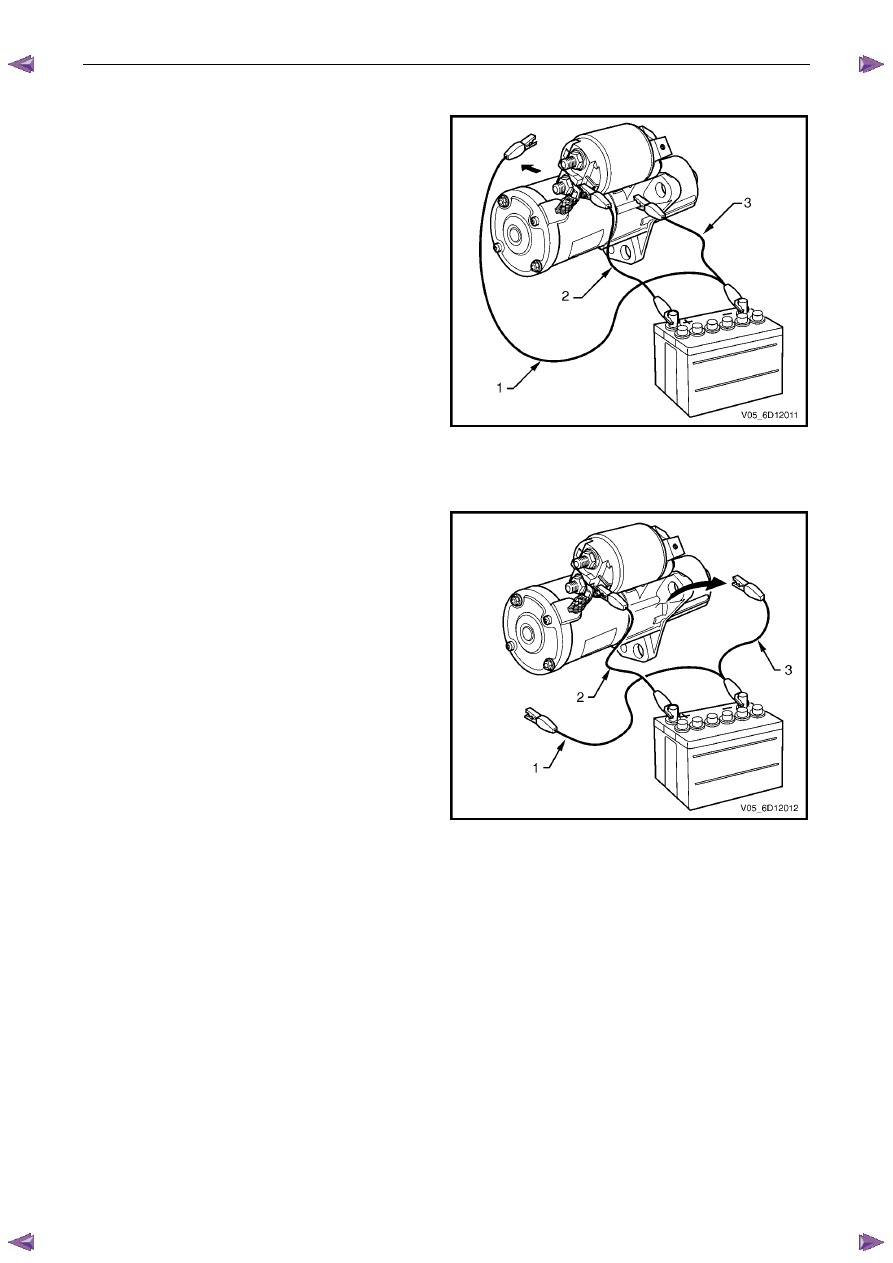

4

Connect the starter motor to an auxiliary battery, as

follows:

a

Connect the test lead (1) between the battery

negative post to the solenoid switch M terminal

(3).

b

Connect the test lead (2) battery positive post.

5

Momentarily hold the free end of test lead (2) to

solenoid switch terminal P – 3.

6

Check the solenoid switch activates and the drive

assembly moves outward.

7

Disassemble and service the starter motor if the

solenoid switch activates but the drive assembly

does not move, refer to 4.4

Starter Motor

Disassemble and Reassemble in this Section.

8

Replace the solenoid switch if it does not activate

(there is no sound or movement).

Figure 6D1-2 – 15

Starting System – V6

Page 6D1-2–23

Hold-in Test

1

Connect the starter motor to an auxiliary battery, as

follows:

a

Connect the test lead (1) between the battery

negative post to the solenoid switch M

terminal.

b

Connect the test lead (2) from the battery

positive post to solenoid switch terminal

P – 3.

c

Connect the test lead (3) to the starter motor

casing.

2

Disconnect the test lead (1) from the M terminal of

the solenoid switch.

3

Check the drive assembly remains extended.

4

Replace the solenoid switch if the drive assembly

returns back into the starter motor.

Figure 6D1-2 – 16

Drive Assembly Return Test

1

Connect the starter motor to an auxiliary battery, as

follows:

a

Connect the test lead (1) between the battery

negative post to the solenoid switch M

terminal.

b

Connect the test lead (2) from the battery

positive post to solenoid switch terminal

P – 3.

c

Connect the test lead (3) to the starter motor

casing.

2

Disconnect the test lead (1) from the M terminal of

the solenoid switch.

3

Disconnect the negative lead (2) from the starter

motor casing.

4

Check the drive assembly returns back into the

starter motor.

5

Replace the solenoid switch if the drive assembly

does not retract.

Figure 6D1-2 – 17

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст