Isuzu KB P190. Manual — part 908

Starting System – V6

Page 6D1-2–24

No Load Test

1

Clamp the starter motor securely to a test bench.

2

Connect the starter motor as shown in Figure 6D1-2 – 18, Close the start switch to activate the starter motor.

4

Record the speed of the planetary drive shaft, current draw and the voltage.

5

Check the readings are within the specifications.

Minimum r.p.m. . . . . . . . . . . . . . ... 2370

Maximum current draw . . . . . . . . . . . 90 A

M Terminal voltage . . . . . . . . . . .12

± 0.1 V

6

Disassemble and service the starter motor if the readings are not within the specifications, refer to 4.4 Starter

Motor Disassemble and Reassemble.

Figure 6D1-2 – 18

Legend

1 Battery

2 Carbon

Pile

3

Shaft Speed Indicator

4

Multimeter set to measure current

5

Multimeter set to measure voltage

6 Start

Switch

7

Solenoid Switch P – 3 pin 1

8

Solenoid Switch P – 4 pin B

9

Solenoid Switch M terminal

Starting System – V6

Page 6D1-2–25

4.4

Starter Motor Disassemble and

Reassemble

Disassemble

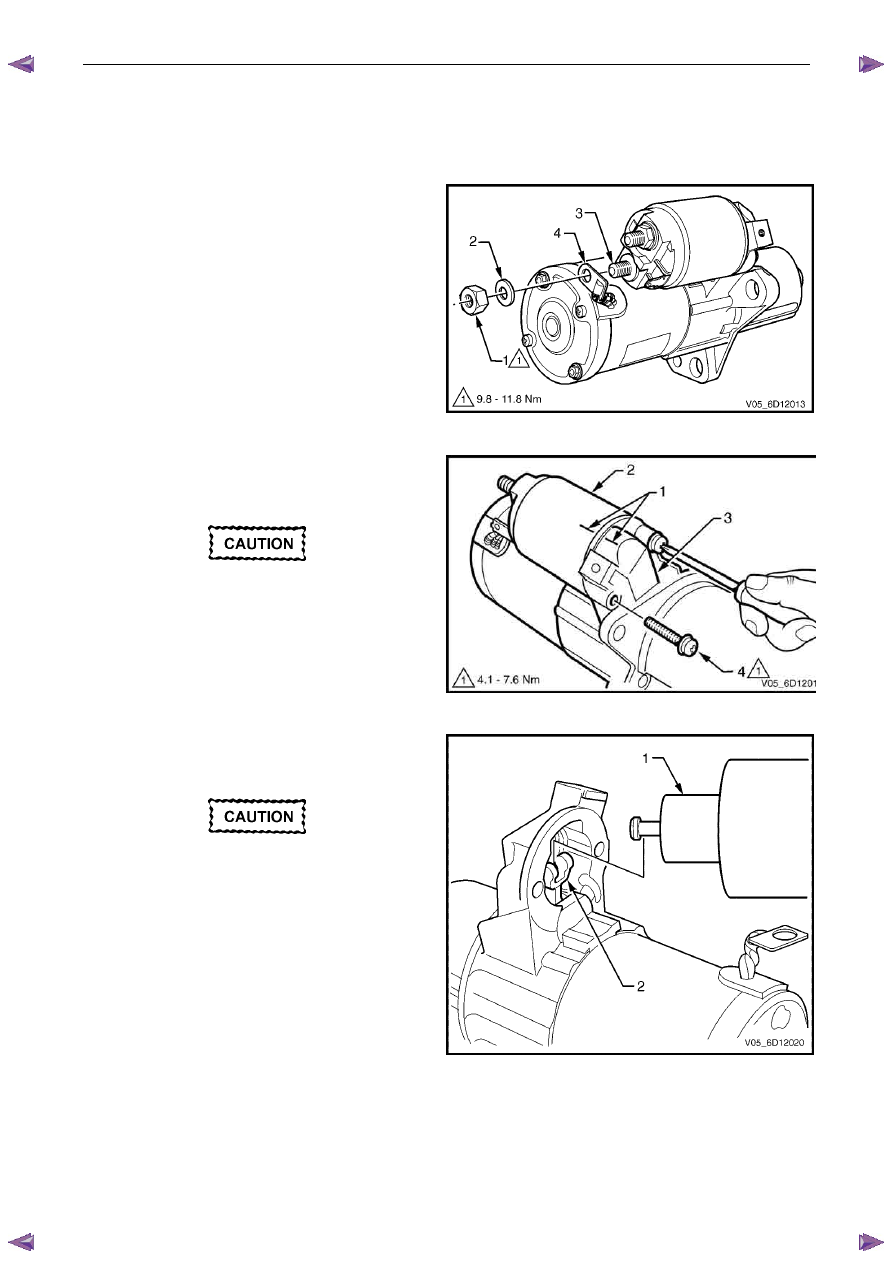

1

Clamp the starter motor, by the mounting lug in the

drive-end housing, in a vice with soft jaws.

2

Remove the nut (1) and washer (2) from the

solenoid switch M terminal (3).

3

Remove the braided cable (4) from the M terminal.

Figure 6D1-2 – 19

4

Scribe aligning marks (1) on the drive-end

housing (2) and the solenoid switch housing (3) to

aid reassembly.

When using an impact driver, avoid

damaging the drive-end housing or

rounding the screw slots of the solenoid

switch mounting screws.

5

Remove the two solenoid switch mounting

screws (4). It may be necessary to loosen the

mounting screws using an impact driver.

Figure 6D1-2 – 20

6

Remove the solenoid switch from the drive-end

housing.

Do not lose the plunger return spring.

7

Unhook and remove the solenoid switch plunger (1)

from the drive assembly fork lever (2).

Figure 6D1-2 – 21

Starting System – V6

Page 6D1-2–26

Reassemble

1

Reassemble the solenoid in the reverse order of the disassembly procedure noting the following points.

Dry all parts thoroughly before assembly,

taking care not to breathe in any vapours.

2

Lightly coat the solenoid switch plunger with 10% molybdenum disulphide grease.

Excess grease can enter the contact chamber

of the solenoid switch and cause contact

problems. Do not use too much grease.

3

Hook the plunger over the fork lever.

4

Insert the return spring into the plunger.

5

Slide solenoid switch over the plunger.

6

Align the solenoid switch with drive-end housing ensuring the solenoid switch terminal P – 4 faces away from the

pole housing.

7

Install and tighten the solenoid switch mounting screws.

Solenoid switch mounting screw

torque specification . . . . . . . . . .4.1 – 7.6 Nm

8

With the starter motor reassembled, perform a No Load Test, refer to 4.3 Starter Motor Bench Tests.

9

If the starter motor fails the No Load Test specification, replace the starter motor.

4.5

Solenoid Switch Tests

Test the Solenoid Switch

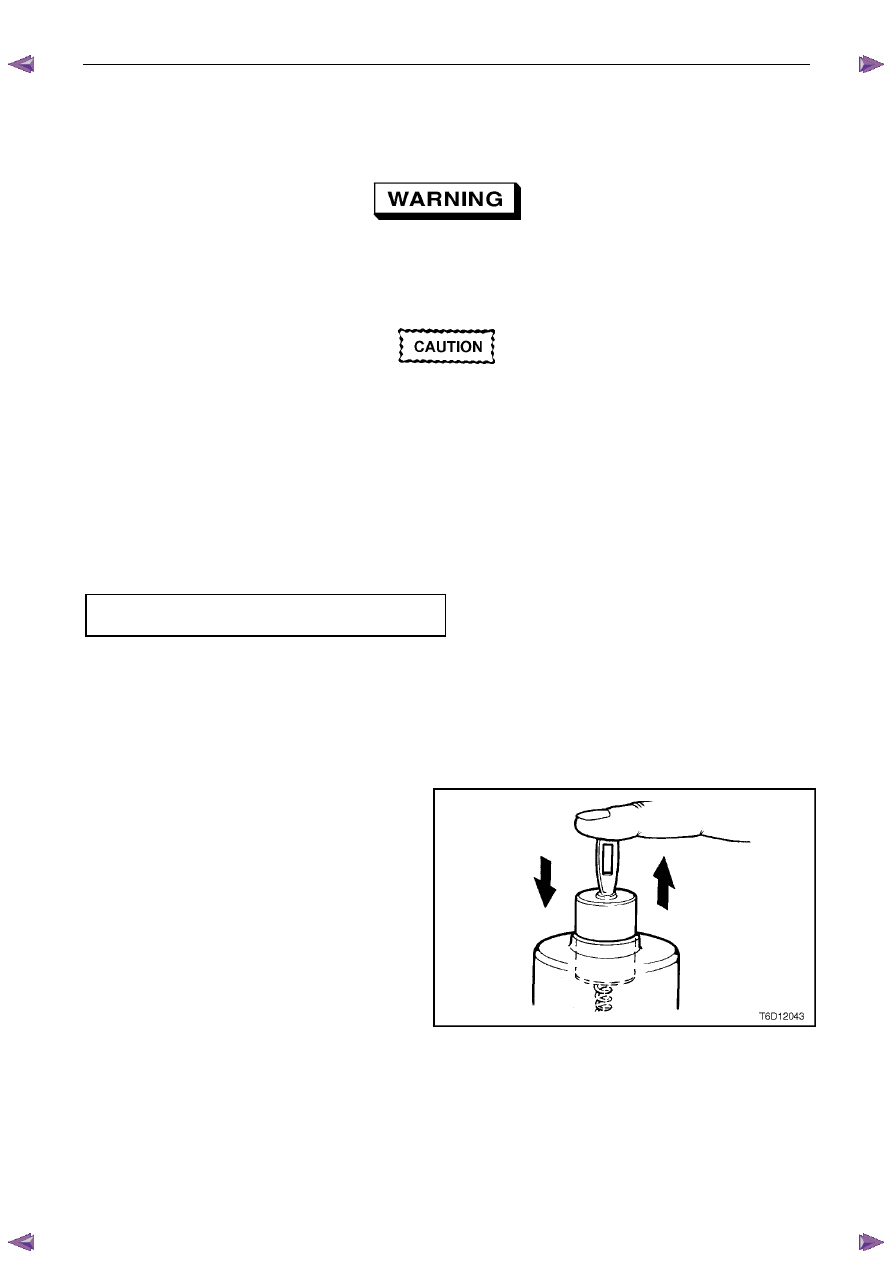

1

Inspect the solenoid switch for any external

damage.

2

Replace the solenoid switch if it displays

significant damage.

3

Install the return spring and plunger into the

solenoid switch.

4

Check the movement of the plunger, as follows:

a

Depress the plunger fully.

b

Release the plunger.

c

If the plunger sticks or binds in the switch

bore, clean or replace the solenoid switch

assembly as required.

Figure 6D1-2 – 22

Starting System – V6

Page 6D1-2–27

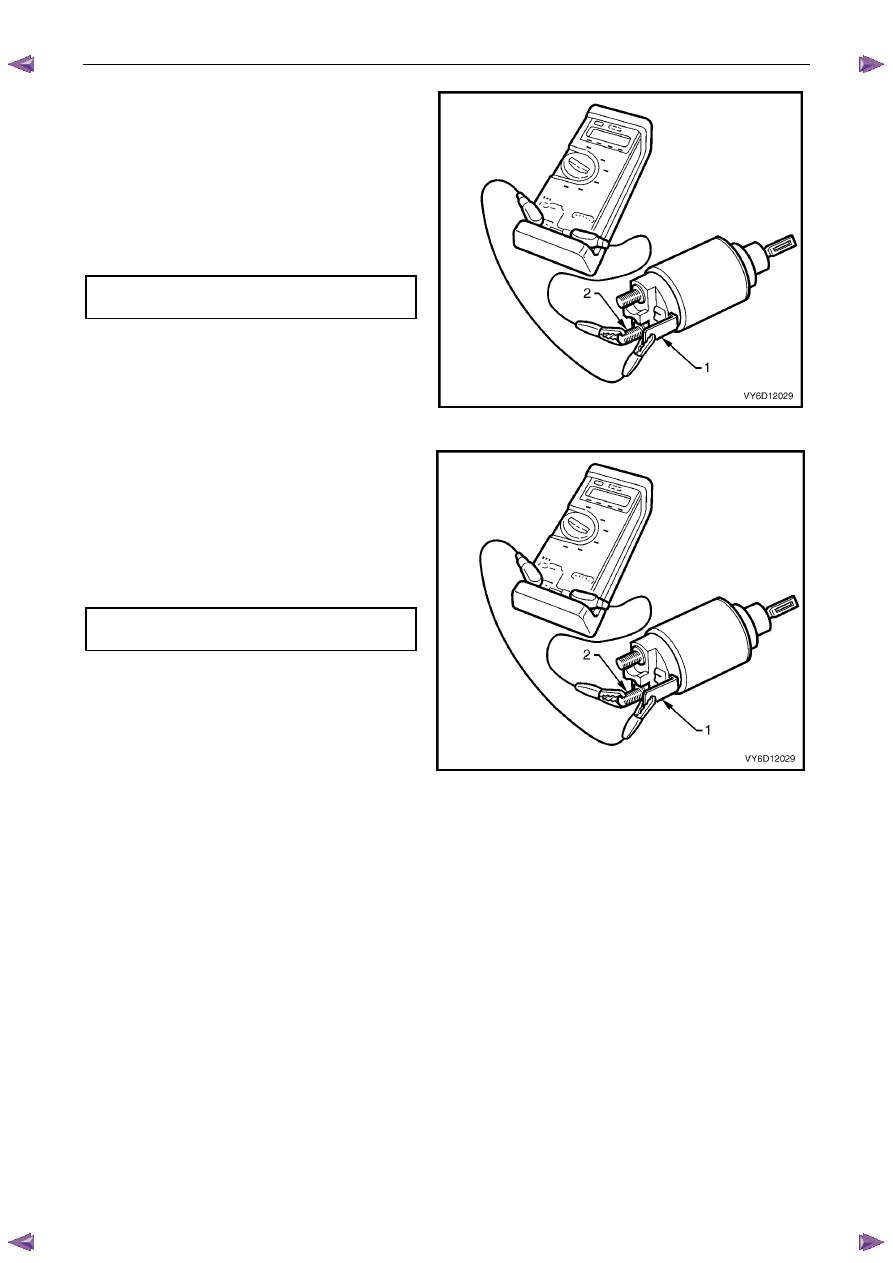

5

Connect a multimeter set to measure resistance

between the solenoid switch M terminal (1) and

the solenoid switch terminal P – 3 (2).

6

Record the resistance reading.

7

Replace the solenoid switch if the resistance is

outside the specification.

Pull-in winding

resistance @ 20

°C. . . . . . . . 0.33 – 0.37 Ω

Figure 6D1-2 – 23

8

Connect a multimeter set to measure resistance

between the solenoid switch housing (1) and the

solenoid switch terminal P – 3 (2).

9

Replace the solenoid switch if the resistance is

outside the specification.

Hold-in winding

resistance @ 20

°. . . . . . . . ..0.75 – 0.87 Ω

Figure 6D1-2 – 24

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст