Isuzu KB P190. Manual — part 909

Starting System – V6

Page 6D1-2–28

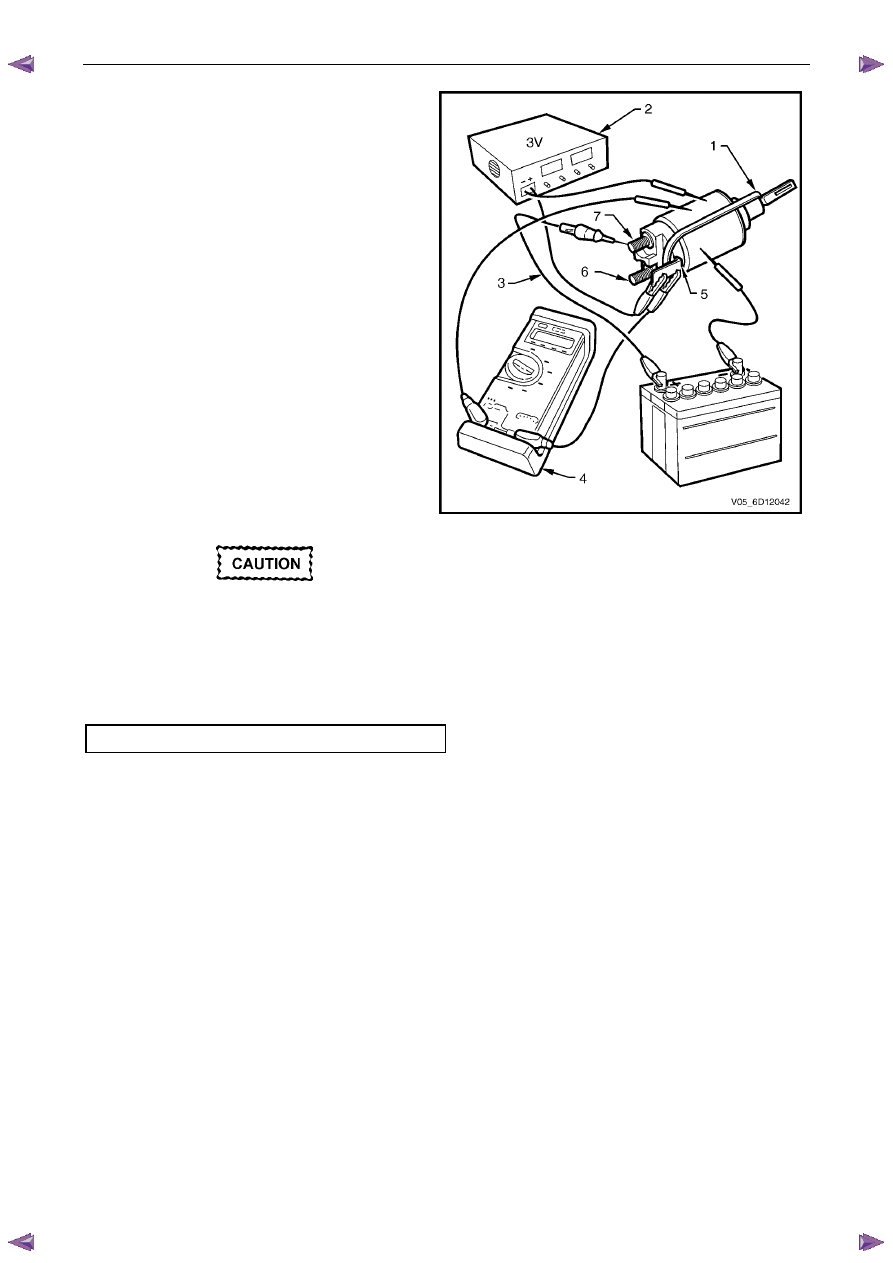

10

Fit a rubber band (1) around the plunger and

switch housing to avoid ejecting the plunger.

11

Hold the solenoid switch vertically with the

plunger pointing upwards.

12

Use a power supply (2) capable of supplying 30 A

or use a battery and a variable resistor.

13

Set the power supply to 3.0 V.

14

Connect the power supply negative lead to the

solenoid switch body.

15

Connect the power supply positive lead to the

solenoid switch terminal P – 3 (5).

16

Connect a test lamp (3) between the solenoid

switch terminal P – 4 (7) and the battery.

17

Connect a multimeter set to measure voltage (4)

between the solenoid switch terminal P – 3 (5)

and the solenoid switch housing.

18

Press the solenoid plunger in until the test lamp

illuminates.

19

Allow the plunger to move out by 8 – 10 mm.

20

Hold the plunger in this position.

The test duration for the following step

should be no more than 2 seconds.

Figure 6D1-2 – 25

21

Slowly increase the power supply voltage on the solenoid switch terminal P – 3 until the plunger pulls in.

22

Record the multimeter reading and reduce the voltage applied to the solenoid switch terminal P – 3.

23

Replace the solenoid switch if the voltage reading is significantly higher than the specification.

Pull-in voltage @ 20

°C. . . . . . . . . . . 8.0 V

24

Check the continuity across the main contacts in the switch.

25

Increase the voltage on the solenoid switch terminal P – 3 (5) until the plunger pulls in.

26

Ensure the test lamp illuminates fully.

Starting System – V6

Page 6D1-2–29

27

Replace the solenoid switch if the test lamp

illuminates poorly.

28

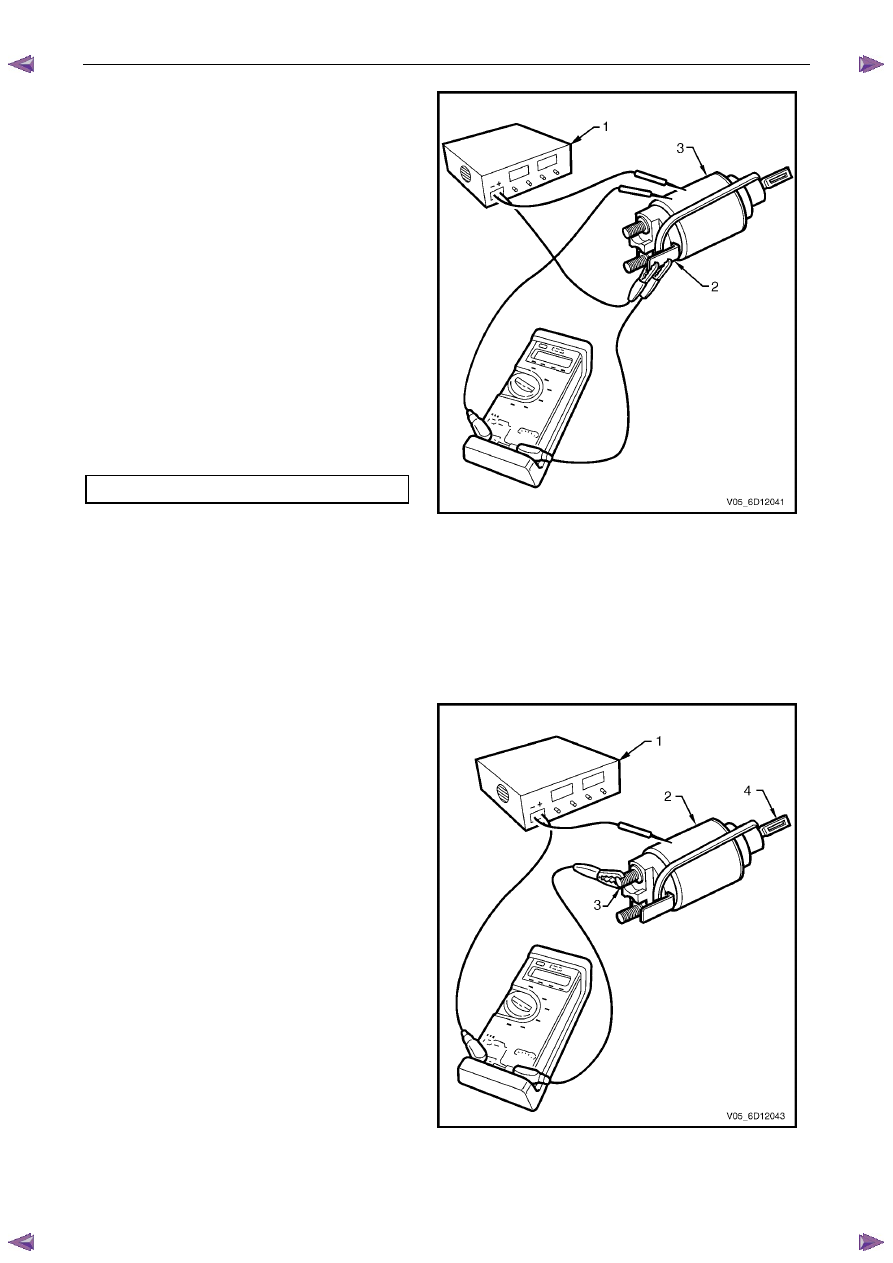

Set the power supply to 12 V (1).

29

Connect the power supply positive lead to the

solenoid switch terminal P – 3 (2).

30

Connect the power supply negative lead to the

solenoid switch housing (3).

31

Press the plunger in fully.

32

Release the plunger. The hold-in winding should

hold the plunger in.

33

Replace the solenoid switch if the winding does

not hold the plunger in.

34

Decrease the voltage until the plunger releases.

35

Record the multimeter reading.

36

Replace the solenoid switch if the voltage

reading is significantly higher than the

specification.

Hold-in voltage @ 20

°C. . . . . . ..1.7 – 3.0 V

37

Connect a test lamp between the solenoid

switch terminal P – 4 and the 12 volt power

supply.

38

Press the plunger in until the test lamp

illuminates.

39

Attempt to press the plunger into the solenoid

switch housing a further 1 mm.

40

Replace the solenoid switch if the plunger

cannot move at least a further 1 mm.

Figure 6D1-2 – 26

41

Connect the positive lead of a 24 volt power

supply (1) to the positive lead of a multimeter set

to measure voltage.

42

Connect the negative lead of a 24 volt power

supply to the solenoid switch housing (2).

43

Connect the multimeter negative lead to the

solenoid switch terminal P – 4 (3).

44

Press the plunger (4) in fully.

45

Release the plunger. The plunger should return

to its rest position.

46

Replace the solenoid switch if the plunger does

not return.

N O T E

This indicates the windings have an

internal winding short circuit. When the

solenoid switch is connected in this way,

the winding fields are in opposition to each

other.

Figure 6D1-2 – 27

Starting System – V6

Page 6D1-2–30

5 Specifications

Type. . . . . . . . . . . ... Six Pole Permanent Magnet, Four Brush, Planetary Drive

Rotation (Drive-End View) . . . . . . . . . . . . . . . . . . . . . ... Clockwise

Number of Pinion Teeth. . . . . . . . . . . . . . . . . . . . . . . . . . 10

N o l o a d :

Minimum RPM . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..2370

Maximum Current Draw. . . . . . . . . . . . . . . . . . . 65 A at 12.0

± 0.1 V

M Terminal Voltage. . . . . . . . . . . . . . . . . . . . . . . . . . 12

± 1 V

L o c k e d :

Maximum Current (Including Solenoid Switch) . . . . . . . . . . . . . . . ... 780 A

M Terminal Voltage. . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 V

Minimum Torque. . . . . . . . . . . . . . . . . . . . . . . . . . . 20 Nm

S o l e n o i d d e t a c h e d :

Pull-in Winding Resistance @ 20°C . . . . . . . . . . . . . . . . ... 0.33 – 0.37

Ω

Hold-in Winding Resistance @ 20°C . . . . . . . . . . . . . . . . .. 0.75 – 0.87

Ω

Pull-in Voltage @ 20°C . . . . . . . . . . . . . . . . . . . . . . ..8 V @ 20

°C

Hold-in Voltage @ 20°C. . . . . . . . . . . . . . . . . . . . . . .. 1.7 – 3.0 V

Starting System – V6

Page 6D1-2–31

6

Torque Wrench Specifications

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Nm

Solenoid Switch Mounting Screw . . . . . . . . . . . . . . 4.1 – 7.6

Solenoid Switch Terminal M Nut . . . . . . . . . . . . . . . . 10.0

Solenoid Switch Terminal P – 3 Nut . . . . . . . . . . . . . . ... 10.0

Starter Motor Mounting Bolt. . . . . . . . . . . . . . . . . . 45.0

Knock Sensor Bolt . . . . . . . . . . . . . . . . . . . . 23.0 Nm

Starter Motor Heat Shield Lower Bolt . . . . . . . . . . . . ... 23.0 Nm

Starter Motor Heat Shield Upper Screw . . . . . . . . . . 3.0 – 5.0 Nm

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст