Isuzu KB P190. Manual — part 216

ENGINE MECHANICAL 6A – 59

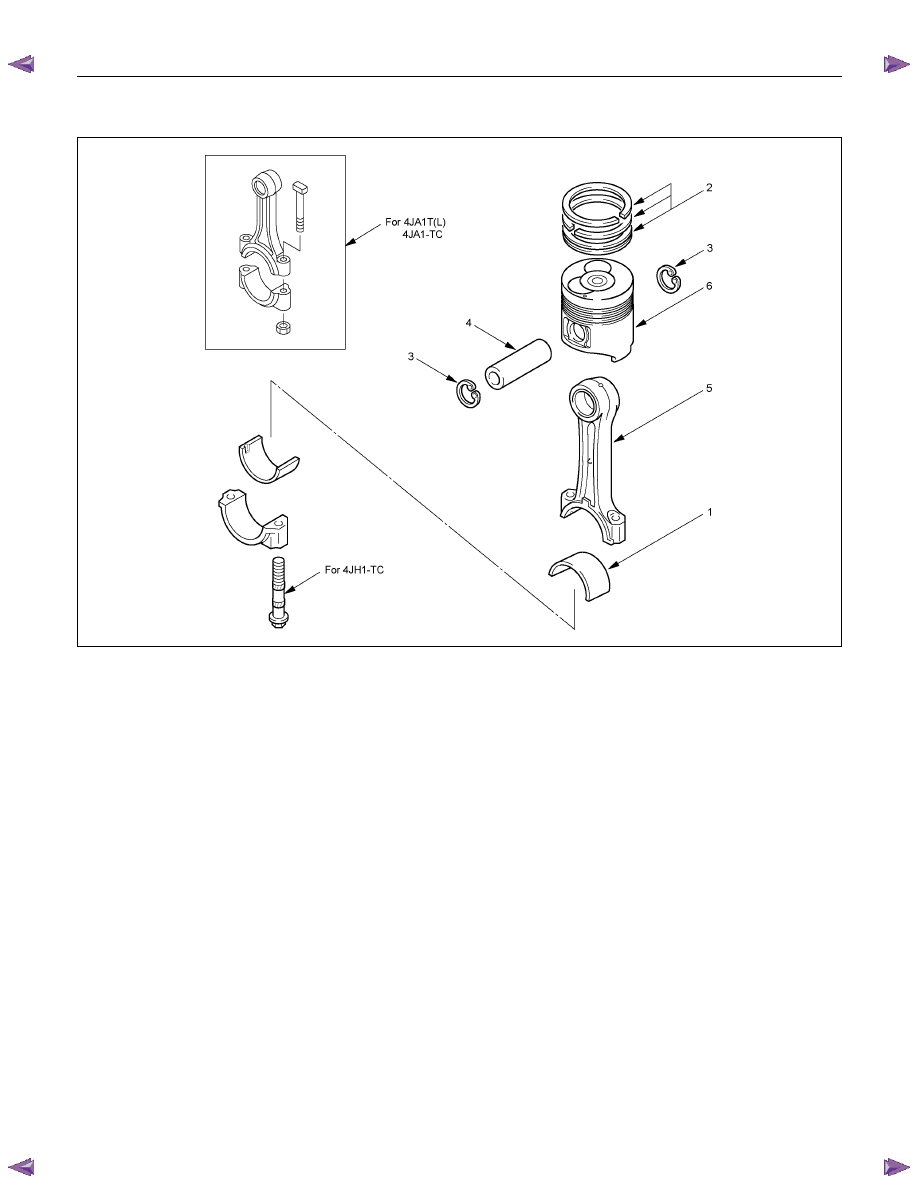

PISTON AND CONNECTING ROD

RTW46ALF000301

Disassembly Steps

1.

Connecting rod bearing

4.

Piston pin

2.

Piston ring

5.

Connecting rod

3.

Piston pin snap ring

6.

Piston

6A – 60 ENGINE MECHANICAL

RTW36ASH001501

Disassembly

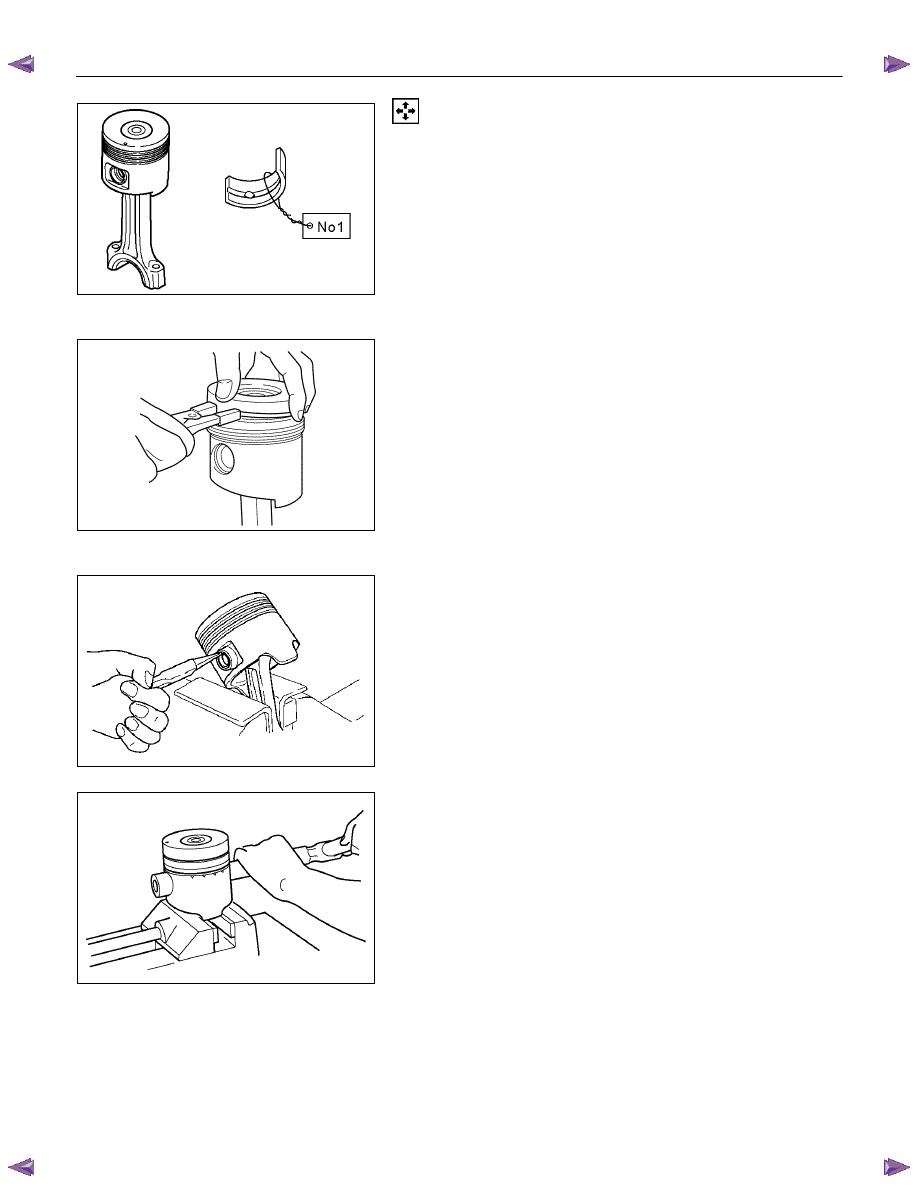

1. Connecting Rod Bearing

If the connecting rod bearings are to be reinstalled, mark

their fitting positions by tagging each bearing with the

cylinder number from which it was removed.

015RW041

2. Piston

Ring

1. Clamp the connecting rod in a vise.

Take care not to damage the connecting rod.

2. Use a piston ring replacer to remove the piston rings.

Piston Ring Replacer

Do not attempt to use some other tool to remove the

piston rings. Piston ring stretching will result in

reduced piston ring tension.

3. Piston Pin Snap Ring

Use a pair of pliers to remove the piston pin snap rings.

RTW36ASH001601

4. Piston

Pin

5. Connecting

Rod

6. Piston

Tap the piston pin out with a hammer and a brass bar.

If the pistons and piston pins are to be reinstalled, mark

their installation positions by tagging each piston and piston

pin with the cylinder number from which it was removed.

F06MV015

ENGINE MECHANICAL 6A – 61

INSPECTION AND REPAIR

Make the necessary adjustments, repairs, and part replacements if excessive wear or damage is discovered during

inspection.

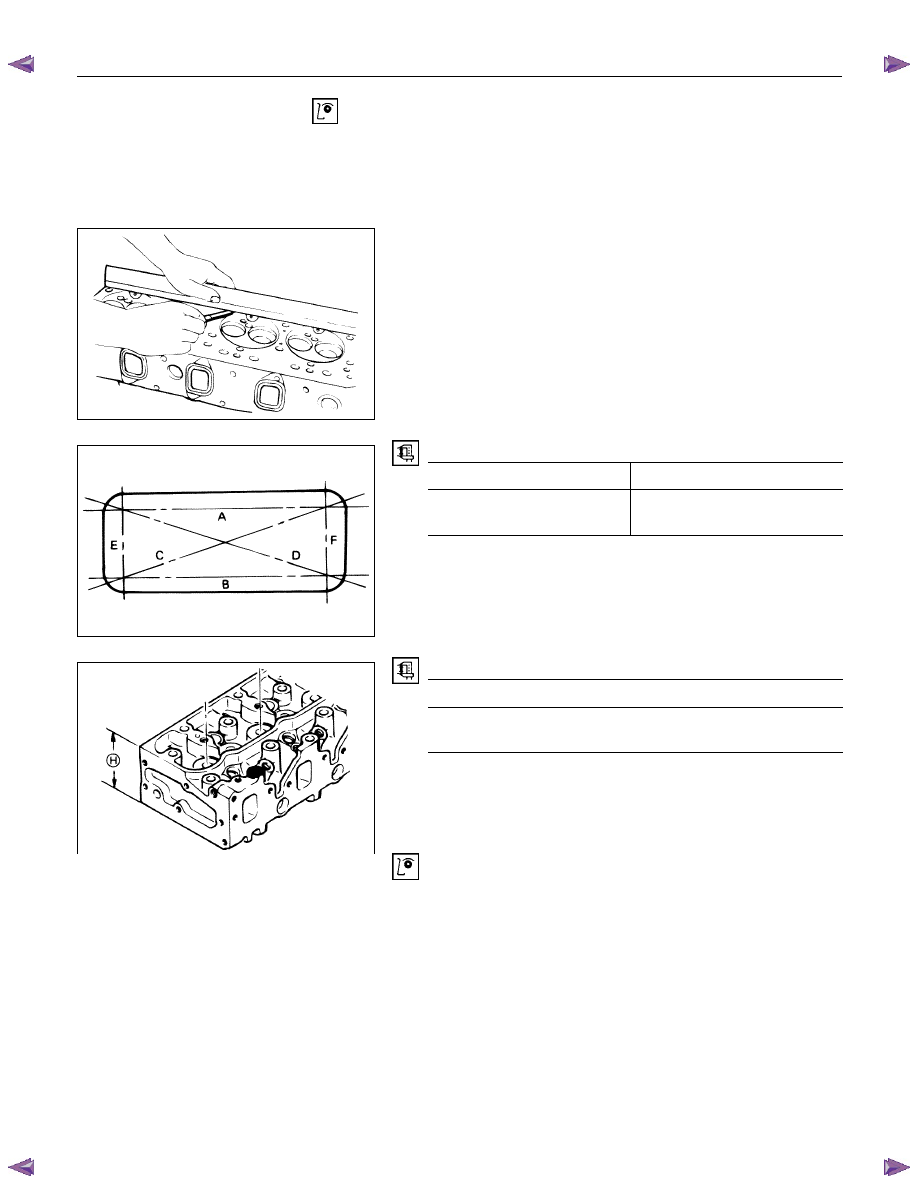

CYLINDER HEAD

Cylinder Head Lower Face Warpage

1. Use a straight edge and a feeler gauge to measure the

four sides and the two diagonals of the cylinder head lower

face.

2. The cylinder head lower surface warpage is more than the

limit, it should be replaced.

Cylinder Head Lower Face Warpage

mm (in)

Standard Limit

0.05

(0.002) or less

0.20

(0.0079)

NOTE:

The cylinder head lower face cannot be reground.

Cylinder Head Height (

H)

(Reference)

mm (in)

Standard

91.95 – 92.05

(3.620 – 3.624)

Positive Crankcase Ventilation (PCV) Valve

1. Remove PCV valve assembly from cylinder head cover.

2. Inspect the diaphragm for broken.

3. Inspect the spring for broken or weaken.

4. If find any abnormal condition, replace the PCV valve

assembly.

011RY00012

011RY00013

011RY00014

6A – 62 ENGINE MECHANICAL

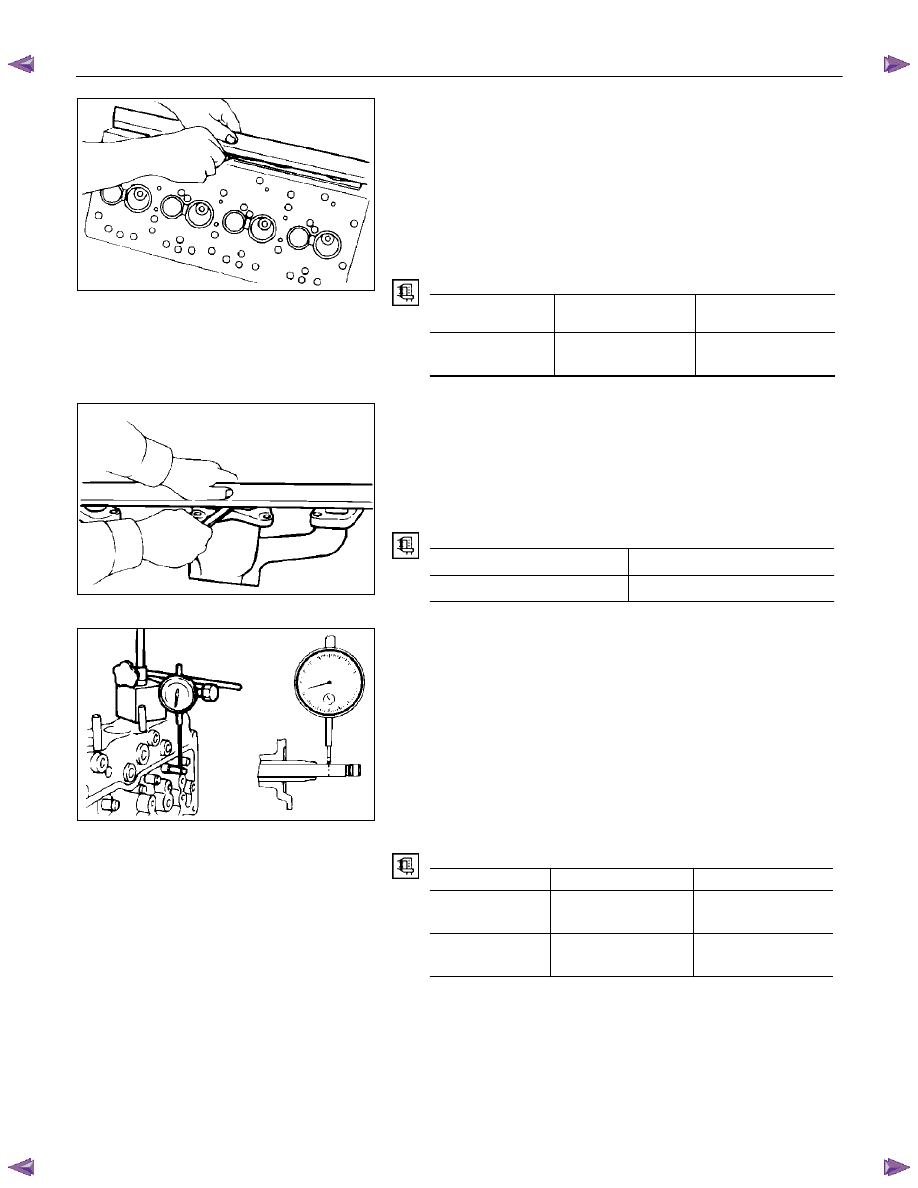

Manifold Fitting Face Warpage

Use a straight edge and a feeler gauge to measure the

manifold cylinder head fitting face warpage.

Regrind the manifold cylinder head fitting surfaces if the

measured values are greater than the specified limit but less

than the maximum grinding allowance.

If the measured values exceed the maximum grinding

allowance, the cylinder head must be replaced.

Manifold Fitting Face Warpage

mm (in)

Standard Limit

Maximum Grinding

Allowance

0.05

(0.002) or less

0.20

(0.008)

0.40

(0.016)

Exhaust Manifold Warpage

Use a straight edge and a feeler gauge to measure the

manifold cylinder head fitting face warpage.

If the measured values exceed the specified limit, the manifold

must be replaced.

Exhaust Manifold Warpage

mm (in)

Standard Limit

0.05 (0.002) or less

0.20 (0.008)

Valve Stem and Valve Guide Clearance

Measuring Method-I

1. With the valve stem inserted in the valve guide, set the dial

indicator needle to "0".

2. Move the valve head from side to side.

Read the dial indicator.

Note the highest dial indication.

If the measured values exceed the specified limit, the valve

and the valve guide must be replaced as a set.

Valve Stem Clearance

mm (in)

Standard

Limit

Intake Valve

0.039 - 0.071

(0.0015 - 0.0028)

0.200

(0.008)

Exhaust Valve

0.064 - 0.096

(0.0025 - 0.0038)

0.250

(0.0098)

027RY00001

027RY00002

011RY00022

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст