Isuzu KB P190. Manual — part 217

ENGINE MECHANICAL 6A – 63

Measuring Method-II

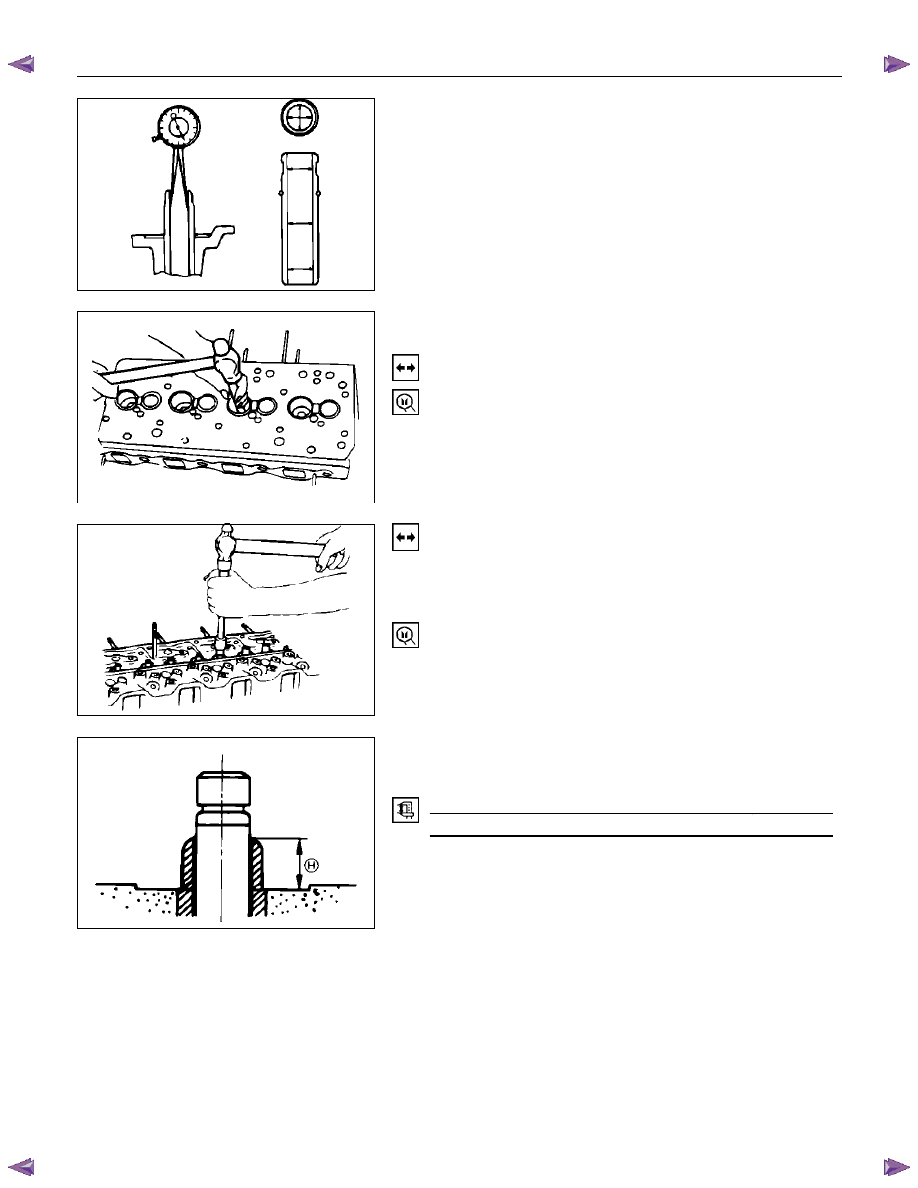

1. Measure the valve stem outside diameter.

Refer to the Item "Valve Stem Outside Diameter".

2. Use a caliper calibrator or a telescoping gauge to measure

the valve guide inside diameter.

Valve Guide Replacement

Valve Guide Removal

Use a hammer and the valve guide replacer to drive out the

valve guide from the cylinder head lower face.

Valve Guide Replacer: 9-8523-1212-0

Valve Guide Installation

1. Apply engine oil to the valve guide outer circumference.

2. Attach the valve guide installer to the valve guide.

3. Use a hammer to drive the valve guide into position from

the cylinder head upper face.

Valve Guide Replacer: 9-8523-1212-0

4. Measure the height of the valve guide upper end from the

upper face of the cylinder head.

Valve Guide Upper End Height (H) (Reference)

mm (in)

12.8-13.2 (0.50-0.52)

NOTE:

If the valve guide has been removed, both the valve

and the valve guide must be replaced as a set.

011LX029

011RY00024

011RY000025

011RY00023

6A – 64 ENGINE MECHANICAL

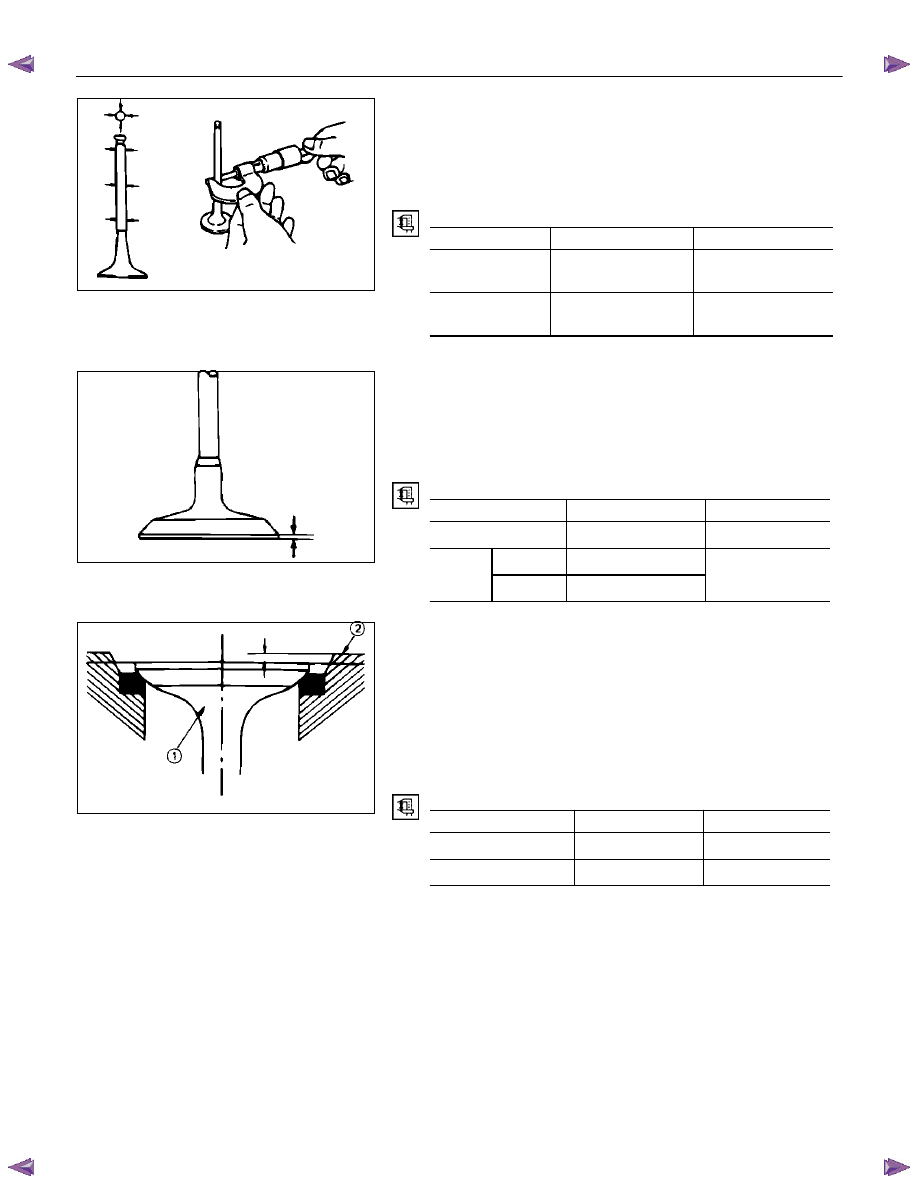

Valve Stem Outside Diameter

Measure the valve stem diameter at three points.

If the measured value is less than the specified limit, the valve

and the valve guide must be replaced as a set.

Valve Stem Outside Diameter

mm (in)

Standard

Limit

Intake Valve

7.946 - 7.961

(0.3128 - 0.3134)

7.880

(0.3102)

Exhaust Valve

7.921 - 7.936

(0.3119 - 0.3124)

7.850

(0.3090)

Valve Thickness

Measure the valve thickness.

If the measured value is less than the specified limit, the valve

and the valve guide must be replaced as a set.

Intake and Exhaust Valve Thickness

mm (in)

Standard

Limit

4JA1T (L)

1.8 (0.07)

1.5 (0.06)

Inlet 1.34

(0.054)

4JA1TC,

4JH1TC

Exhaust 1.36

(0.055)

1.1 (0.045)

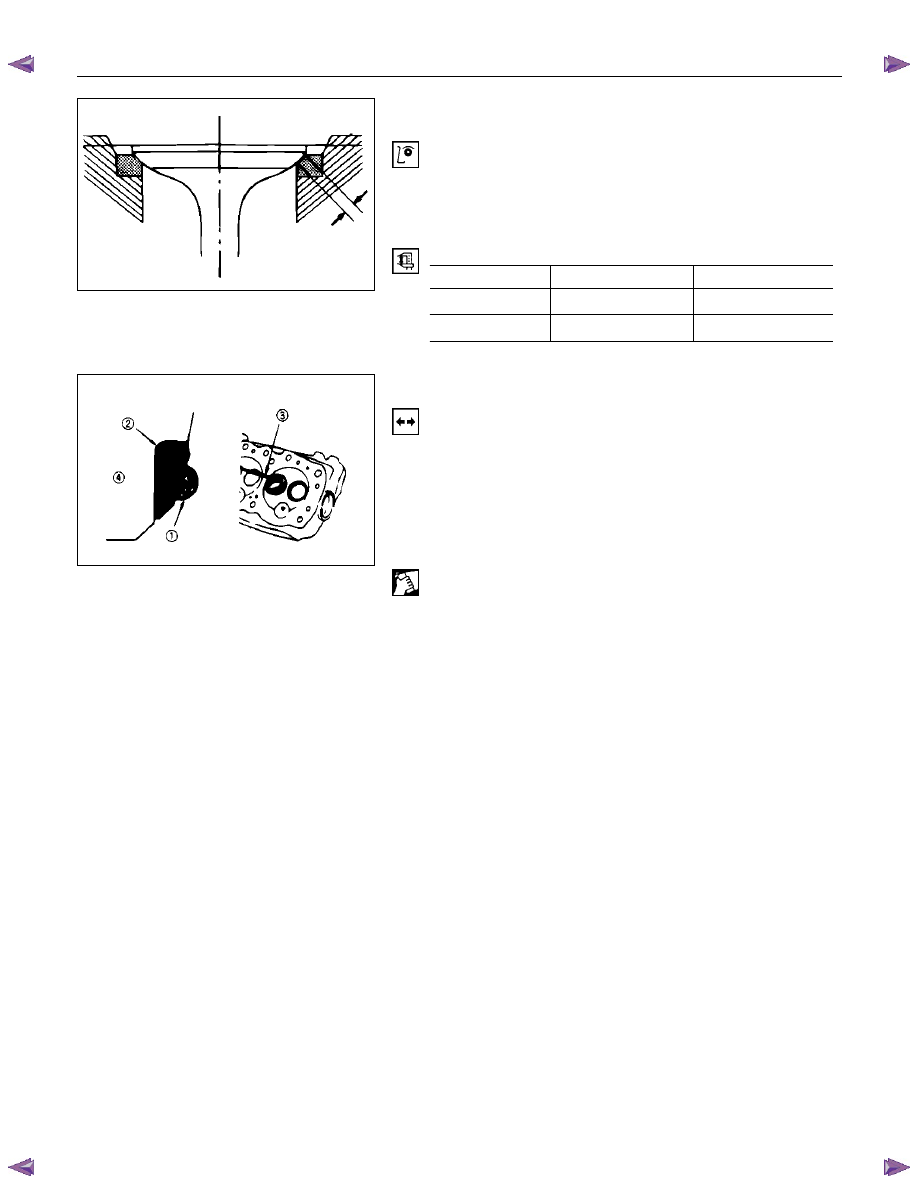

Valve Depression

1. Install the valve (1) to the cylinder head (2).

2. Use a depth gauge or a straight edge with steel rule to

measure the valve depression from the cylinder head lower

surface.

If the measured value exceeds the specified limit, the valve

seat insert must be replaced.

Valve Depression

mm (in)

Standard

Limit

4JA1T(L)

0.72 (0.029)

1.28 (0.050)

4JA1TC, 4JH1TC

1.17 (0.048)

1.67 (0.068)

011LX027

014RY00020

014RY00021

ENGINE MECHANICAL 6A – 65

Valve Contact Width

1. Check the valve contact faces for roughness and

unevenness. Make smooth the valve contact surfaces.

2. Measure the valve contact width.

If the measured value exceeds the specified limit, the valve

seat insert must be replaced.

Valve Contact Width

mm (in)

Standard

Limit

Intake

1.7 (0.067)

2.2 (0.087)

Exhaust

2.0 (0.079)

2.5 (0.078)

Valve Seat Insert Replacement

Valve Seat Insert Removal

1. Arc weld the entire inside circumference (1) of the valve

seat insert (2).

2. Allow the valve seat insert to cool for a few minutes.

This will invite contraction and make removal of the valve

seat insert easier.

3. Use a screwdriver (3) to pry the valve seat insert free.

Take care not to damage the cylinder head (4).

4. Carefully remove carbon and other foreign material from

the cylinder head insert bore.

014RY00027

011LX039

6A – 66 ENGINE MECHANICAL

Valve Seat Insert Installation

1. Carefully place the attachment (1) (having a smaller

outside diameter than the valve seat insert) on the valve

seat insert (2).

NOTE:

The smooth side of the attachment must contact the

valve seat insert.

2. Use a bench press (3) to gradually apply pressure to the

attachment and press the valve seat insert into place.

NOTE:

Do not apply an excessive amount of pressure with

the bench press. Damage to the valve seat insert will

result.

Valve Seat Insert Correction

1. Remove the carbon from the valve seat insert surface.

2. Use a valve cutter (15

°

, 45

°

, and 75

°

blades) to minimize

scratches and other rough areas. This will bring the

contact width back to the standard value.

Remove only the scratches and rough areas. Do not cut

away too much. Take care not to cut away unblemished

areas of the valve seat surface.

Valve Seat Angle

Degree

45

NOTE:

Use an adjustable valve cutter pilot.

Do not allow the valve cutter pilot to wobble inside the

valve guide.

3. Apply abrasive compound to the valve seat insert surface.

4. Insert the valve into the valve guide.

5. Turn the valve while tapping it to fit the valve seat insert.

6. Check that the valve contact width is correct.

7. Check that the valve seat insert surface is in contact with

the entire circumference of the valve.

011LX063

014RY00026

011LX037

011LX038

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст