Isuzu KB P190. Manual — part 365

6A-100 ENGINE MECHANICAL (4JK1/4JJ1)

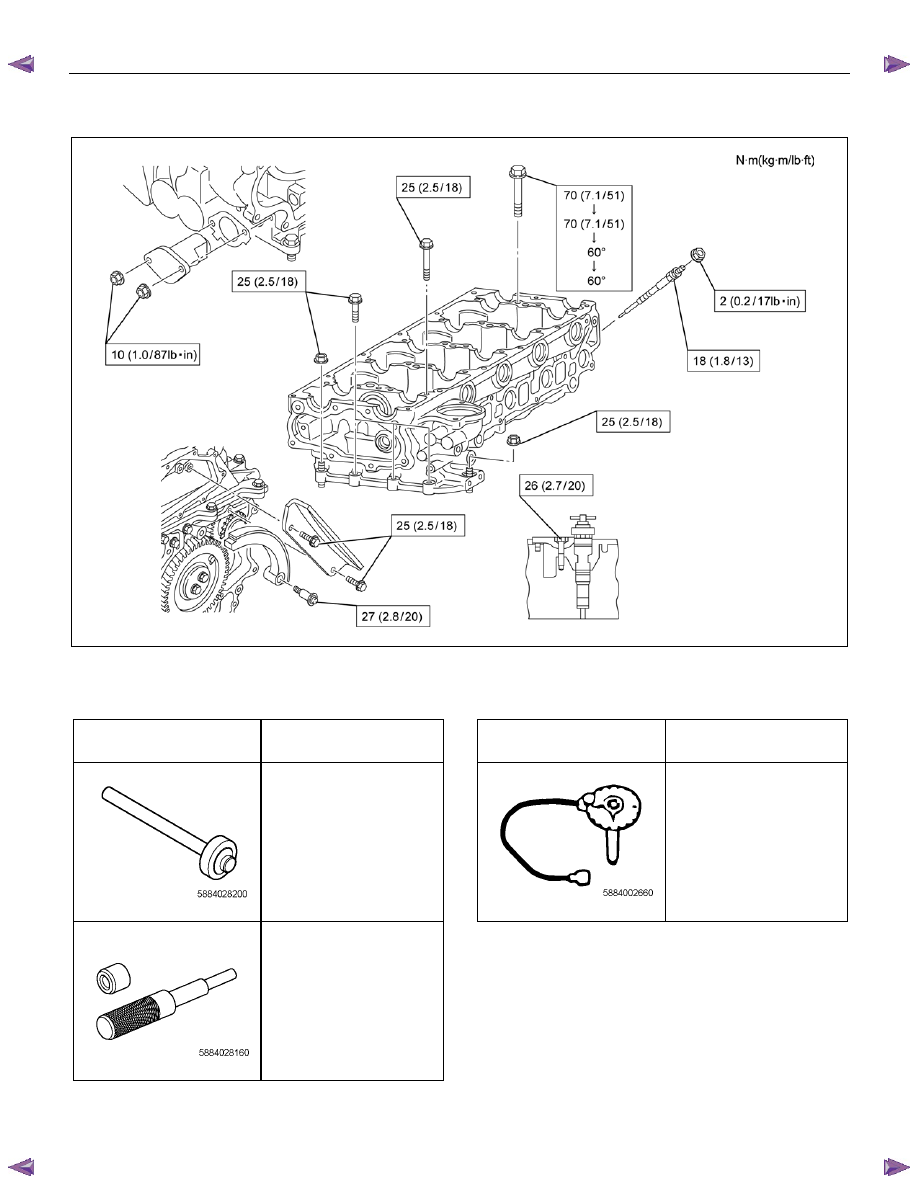

Torque Specifications

RTW76AMF000201

Special Tools

ILLUSTRATION

PART NO.

PART NAME

ILLUSTRATION

PART NO.

PART NAME

5-8840-2820-0

Injection pipe oil seal

installer

5-8840-0266-0

Angle gauge

5-8840-2816-0

Valve guide remover and

installer

ENGINE MECHANICAL (4JK1/4JJ1) 6A-101

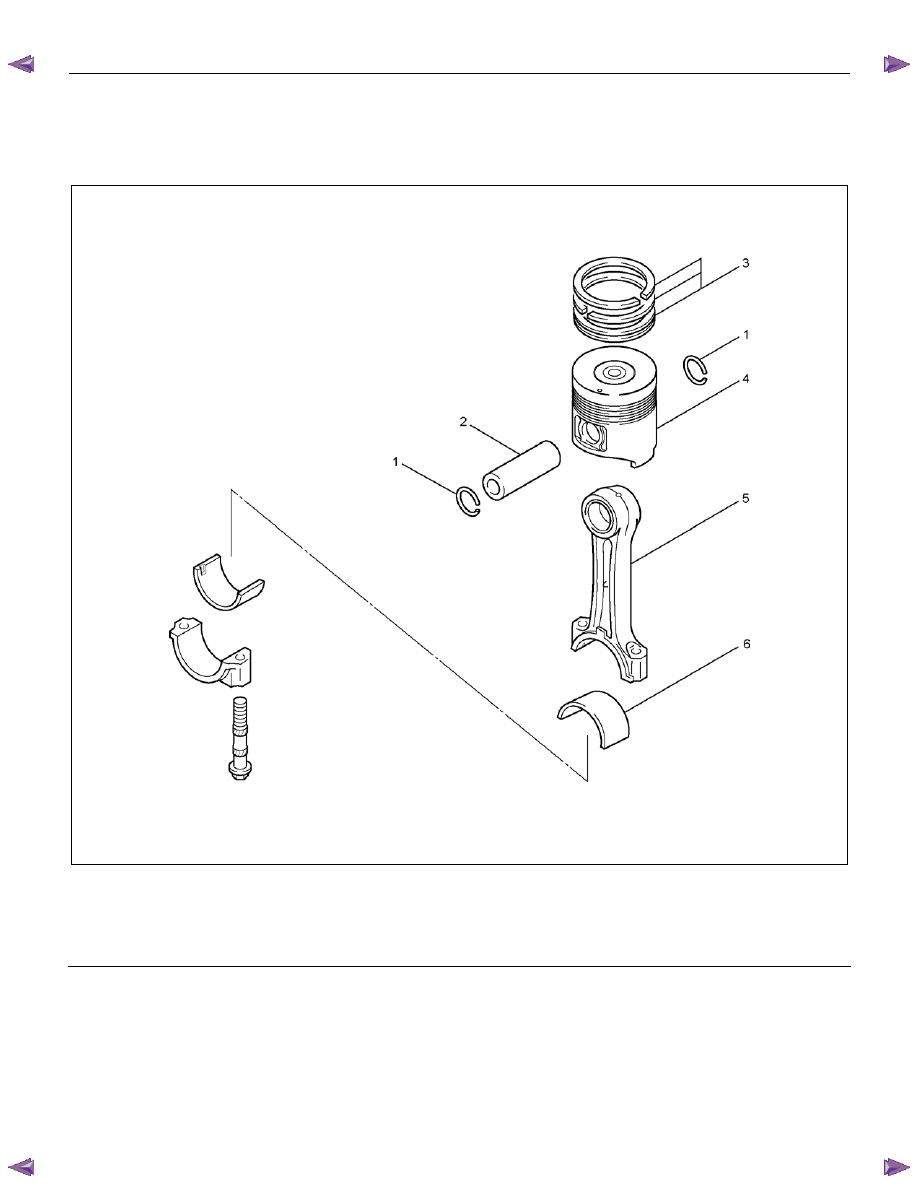

Piston and Connecting Rod

Components

RTWA56ALF001601

Legend

1. Piston Pin Snap Ring

2. Piston

Pin

3. Piston

Ring

4.

Piston

5. Connecting

Rod

6. Bearing

Removal

1. Demount the engine assembly.

Refer to “Engine Assembly”.

2. Remove the cylinder head cover.

Refer to “Cylinder Head Cover”.

3. Remove the camshaft assembly.

Refer to “Camshaft Assembly”.

4. Remove the cylinder head.

Refer to “Cylinder Head”.

5. Remove the gear case assembly.

Refer to “Gear Case Assembly”.

6. Remove the oil pan.

Refer to “Oil Pan” .

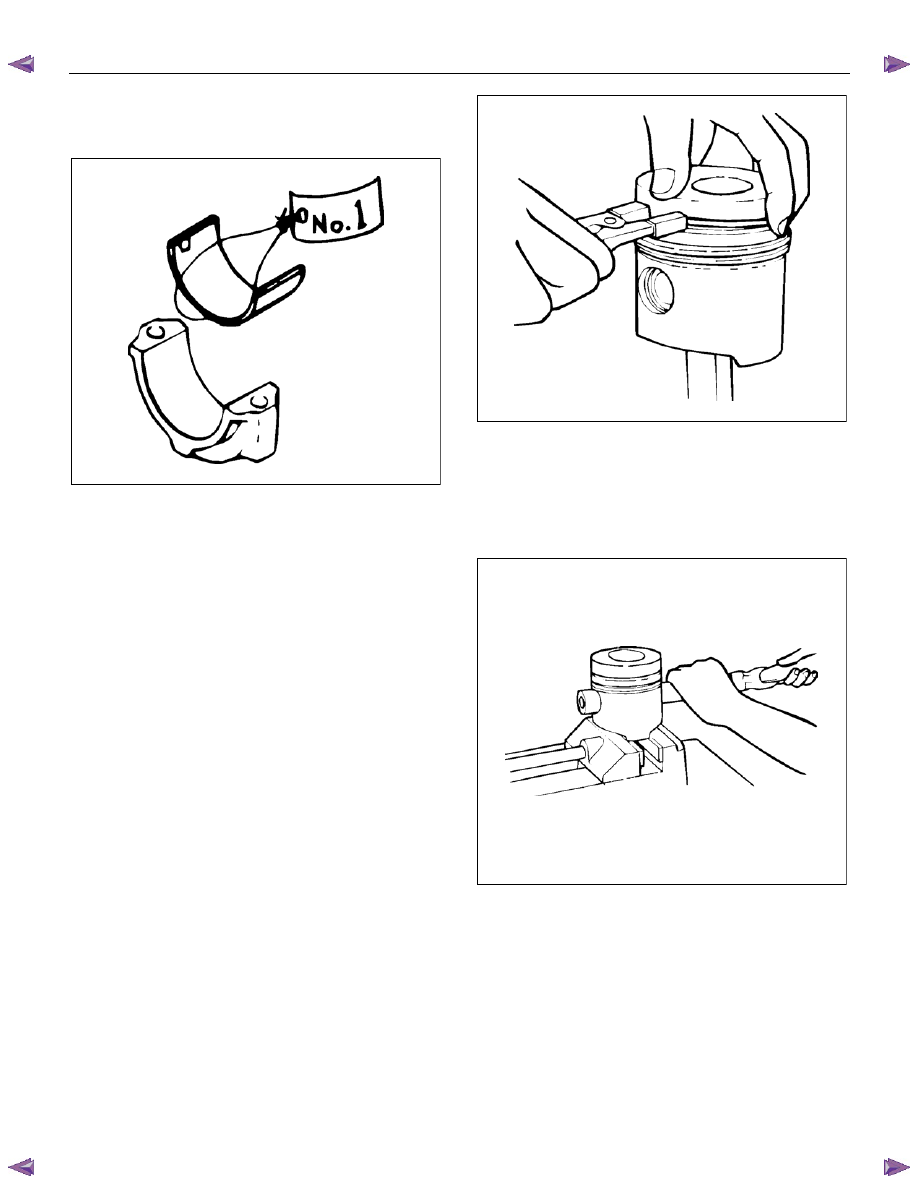

7. Remove the connecting rod cap.

6A-102 ENGINE MECHANICAL (4JK1/4JJ1)

Note:

Sort the removed bearings according to cylinders by

using tags.

LNW21BSH004901

8. Remove the piston and connecting rod.

• Remove carbon on the upper side of the

cylinder block with a scraper.

• Pull out the piston and connecting rod towards

the cylinder head.

Note:

Be sure not to damage the oil jet and cylinder block

when pushing out the connecting rod.

9. Remove the connecting rod bearing.

Note:

Sort the bearings in the order of cylinders when reusing

them so that they are not confused with the bearings of

other cylinders.

Disassembly

1. Remove the piston ring.

• Use ring pliers to remove the piston ring.

Note:

Sort the piston rings in the same order as the cylinders

when reusing them so that they are not confused with

the pistons and piston rings of other cylinders.

LNW21BSH005101

2. Remove the snap ring.

3. Remove the piston pin.

Note:

Sort the disassembled piston pins,

pistons and

connecting rods together in the same order as the

cylinders.

LNW21BSH005201

4. Remove the connecting rods from the piston.

5. Clean the piston.

• Carefully clean carbon that is adhered to the

head of the piston and the groove of the piston

ring.

Note:

Do not use a wire brush to clean the piston because it

scratches the piston.

Visually inspect the piston for cracks, burns and other

excessive wear, and replace it if there is any

abnormality.

ENGINE MECHANICAL (4JK1/4JJ1) 6A-103

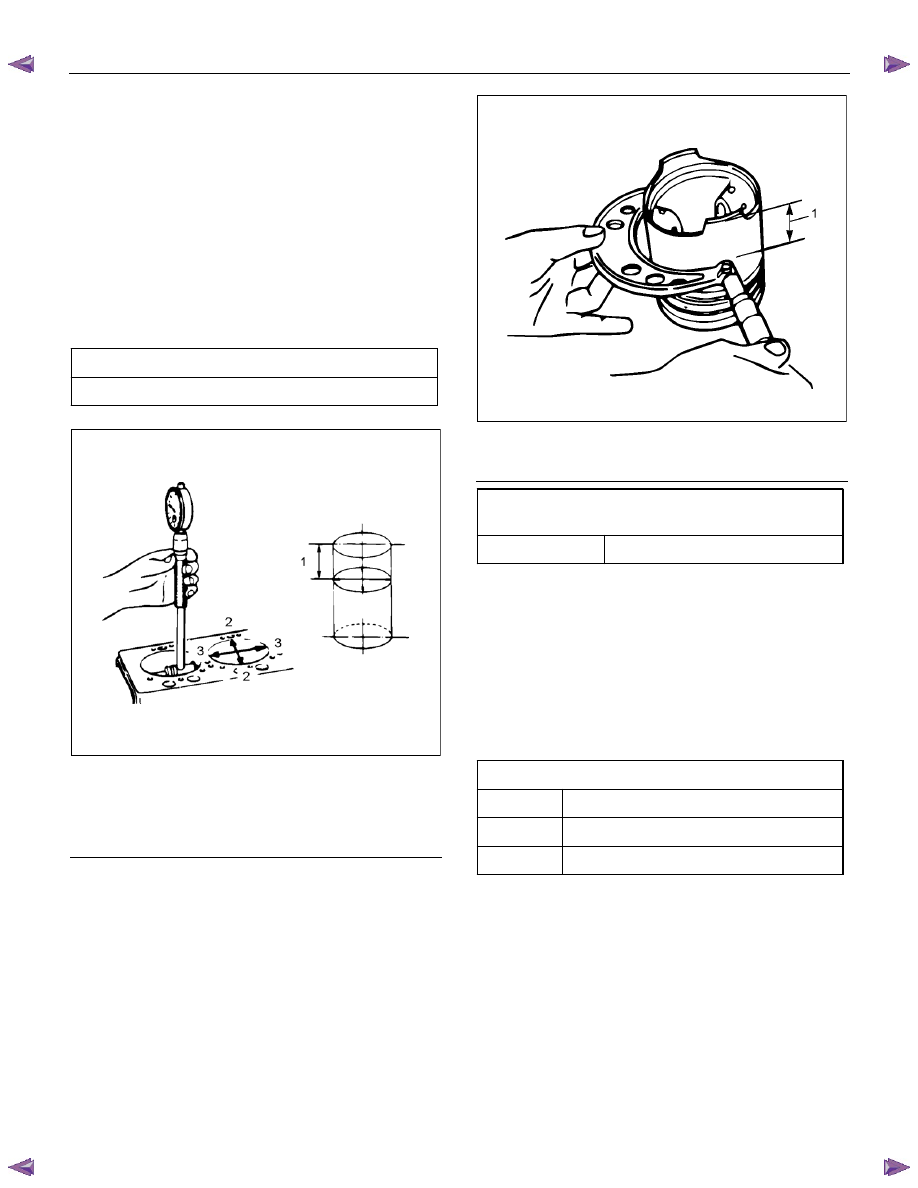

6. Measure the gap between the piston and the inner

diameter of the cylinder block.

Inner diameter of the cylinder block.

• Use a cylinder bore dial indicator to measure

the cylinder block inner diameter both in the

thrust and radial directions in the designated

position.

• Measurement position (from the upper surface

of the cylinder block) 20 mm (0.79 in)

• Measure the cylinder block inner diameter

based on the average value of the actual

measurement values on 6 positions.

Cylinder block inner diameter

mm (in)

95.421 – 95.450 (3.75673 – 3.75787)

LNW61ASH006401

Legend

1. 20 mm (0.79 in)

2. Radial

3. Thrust

Piston outside diameter

• Use a micrometer to measure the outside

diameter of the piston in the right angle to the

piston pin in the designated position.

• Measurement position (from the bottom surface

of the piston) 11.00 mm (0.43 in).

RTW56ASH023101

Legend

1. 11 mm (0.43 in)

Gap between the piston and the inner

diameter of the cylinder block

mm (in)

Standard

0.082 – 0.100 (0.0032 – 0.0039)

NOTE:

If the gap exceeds the standard value, replace the

piston or rebore the cylinder block.

7. Piston replacement

• The head of piston has a marking of grade A, B

or C.

• Refer to “Cylinder Block” if over size piston is

installed.

Piston Grade (Service Part)

mm (in)

A

95.330 – 95.339 (3.75314 – 3.75350)

B

95.340 – 95.349 (3.75354 – 3.75389)

C

95.350 – 95.359 (3.75393 – 3.75428)

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст