Isuzu KB P190. Manual — part 892

Engine Management – V6 – Service Operations

Page 6C1-3–44

3

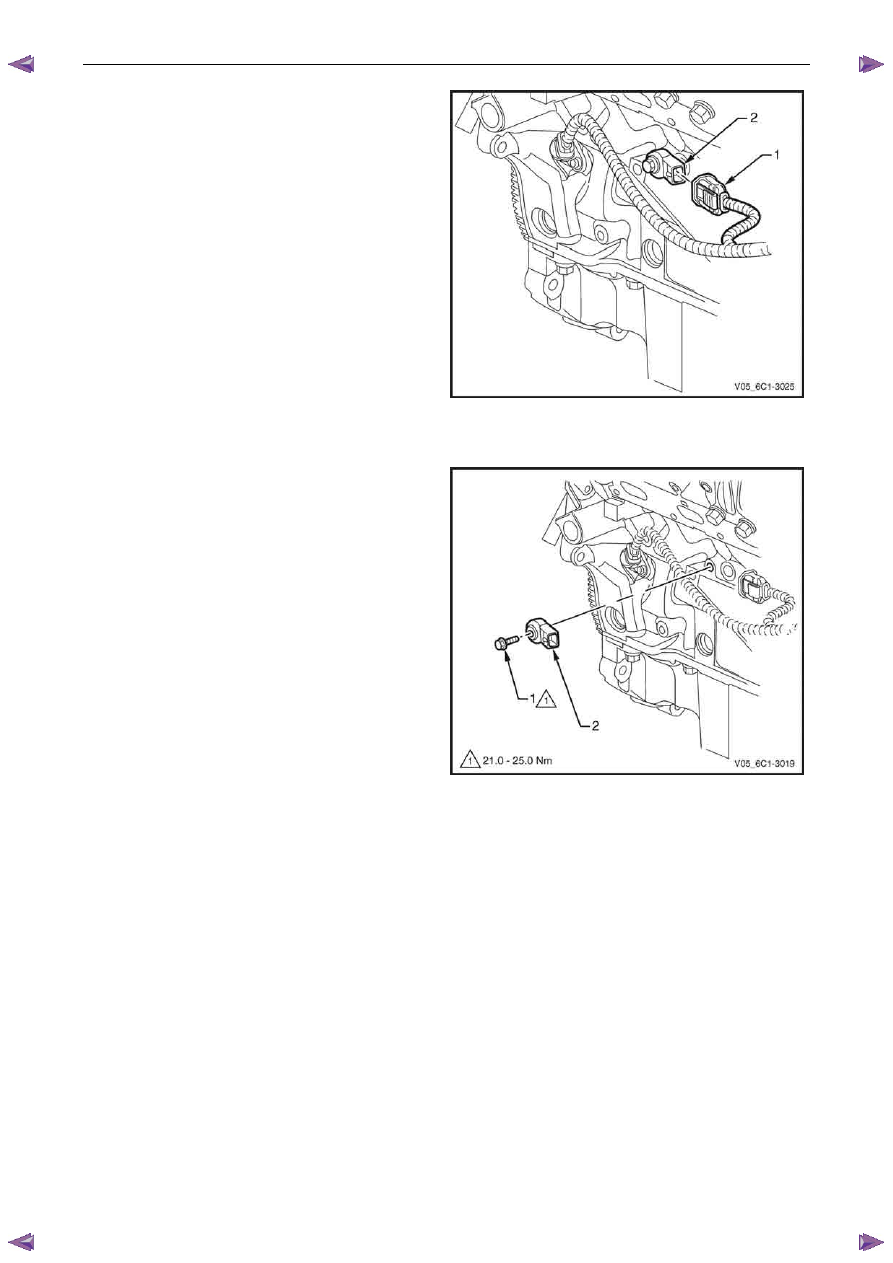

Disconnect the wiring harness connector (1) from the

knock sensor (2).

Figure 6C1-3 – 59

4

Remove the bolt (1) attaching the knock sensor (2) to

the engine block, and remove the knock sensor.

Figure 6C1-3 – 60

Reinstall

Reinstallation of the knock sensor is the reverse of the removal procedure, noting the following:

1

Ensure the knock sensor mounting surface is flat and free of any dirt, oxidisation, etc.

Engine Management – V6 – Service Operations

Page 6C1-3–45

Ensure the knock sensor is fully seated

before tightening the attaching bolt.

Do not over-tighten the attaching bolt as

incorrect operation of the knock sensor may

result.

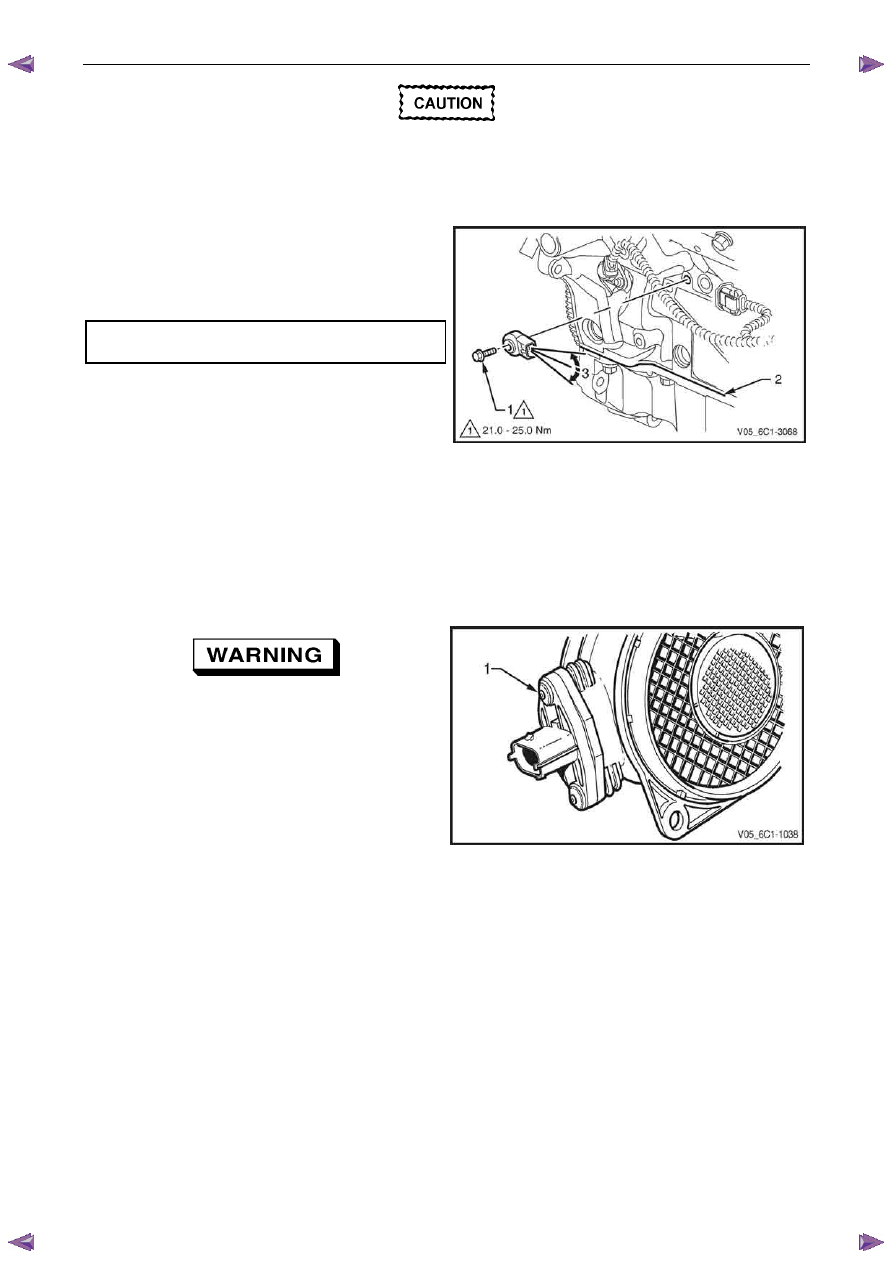

2

Reinstall the knock sensor and bolt (1). Align the

knock sensor so that it is parallel to the engine oil pan

mounting surface (2), ± 3° (3).

3

Tighten the knock sensor bolt to the correct torque

specification.

Knock sensor attaching bolt

torque specification . . . . . . . . .21.0 – 25.0 Nm

4

Road test the vehicle and check for correct operation.

Figure 6C1-3 – 61

2.20 Mass Air Flow Sensor

The intake air temperature (IAT) sensor is part of the mass air flow (MAF) Sensor. For the IAT sensor test procedure

refer to 2.17

Intake Air Temperature Sensor.

Handling Precautions

Under no circumstances should the MAF

sensor retaining screws (1) be loosened or

removed as the MAF will become

unserviceable and will require replacement.

Figure 6C1-3 – 62

Remove

1

Turn the ignition switch off.

Engine Management – V6 – Service Operations

Page 6C1-3–46

2

Disconnect the wiring harness connector (1) from the

MAF sensor.

3

Remove the air intake duct, refer to 2.16

Intake

Air Duct Assembly.

Figure 6C1-3 – 63

5

Remove the nut (1), two places, attaching the MAF

sensor (2) to the upper air cleaner housing (3).

6

Position the flexible air intake duct away from the MAF

sensor and remove the MAF sensor.

N O T E

The MAF sensor seal (4) is part of the air cleaner

upper housing and is not serviced as a separate

item.

Figure 6C1-3 – 64

Reinstall

Reinstallation of the mass air flow (MAF) sensor is the reverse of the removal procedure, noting the following:

Care must be taken not to over tighten the

MAF sensor attaching nuts. Over tightening

the nuts may cause damage to the MAF

sensor seal and allow unfiltered air to enter

the air intake system.

1

Tighten the MAF sensor nuts to the correct torque specification.

Mass air flow sensor attaching nut

torque specification . . . . . . . . . .1.8 – 2.2 Nm

2

Tighten the air intake duct retaining clamp screw to the correct torque specification.

Air intake duct retaining clamp

torque specification . . . . . . . . . .1.8 – 2.5 Nm

3

Start the engine and check for any air leaks between the air intake duct, the MAF and the upper air cleaner housing.

4

Road test the vehicle and check for correct operation, taking particular note that no air leaks are evident.

Engine Management – V6 – Service Operations

Page 6C1-3–47

2.21 Schrader Valve – Fuel Pressure Gauge

Connection Point

If the Schrader valve is to be removed but not

replaced immediately, it is advisable to

disconnect the battery to avoid possible fuel

discharge if an accidental attempt is made to

start the engine.

Disconnection of the battery affects vehicle

electronic systems. Refer to 6D1-3 Battery –

V6 before disconnecting the battery.

Remove

1

Depressurise the fuel system, refer to 6C Fuel System - V6.

2

Turn the ignition off.

A small amount of fuel may be released when

servicing the fuel pressure test point. To

reduce the chance of personal injury, cover

the fuel pressure test point with a shop towel

to absorb any fuel spillage when the Schrader

valve sealing cap and Schrader valve are

removed. After the procedure, place the towel

in an approved container for disposal.

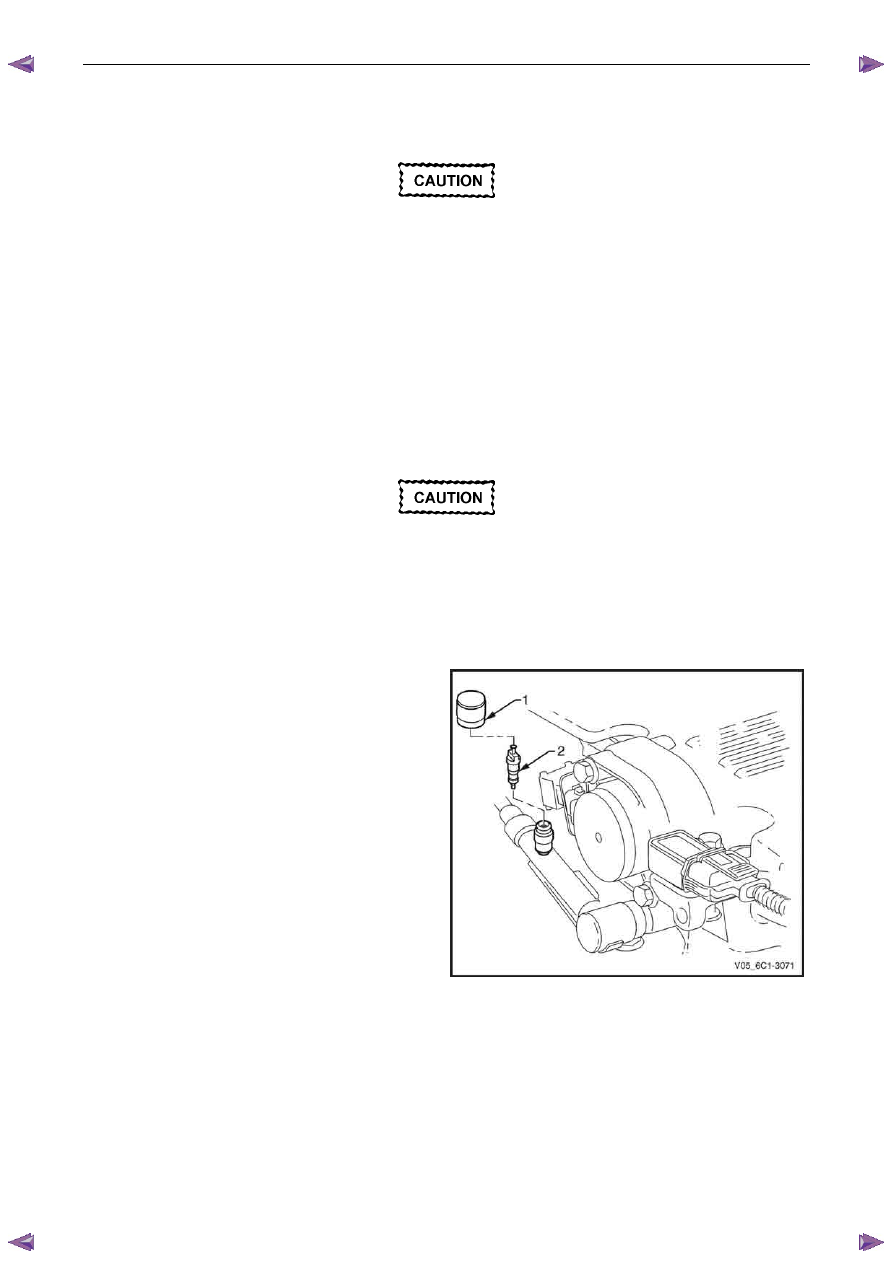

3

Remove the Schrader valve sealing cap (1).

4

Remove the Schrader valve (2) using a standard valve

core removal tool.

Figure 6C1-3 – 65

Reinstall

Reinstallation of the Schrader valve is the reverse of the removal procedure, noting the following:

1

Inspect the fuel rail and quick connect fitting for leaks, refer to 6C Fuel System - V6.

2

Road test the vehicle and check for correct operation.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст