Isuzu KB P190. Manual — part 890

Engine Management – V6 – Service Operations

Page 6C1-3–36

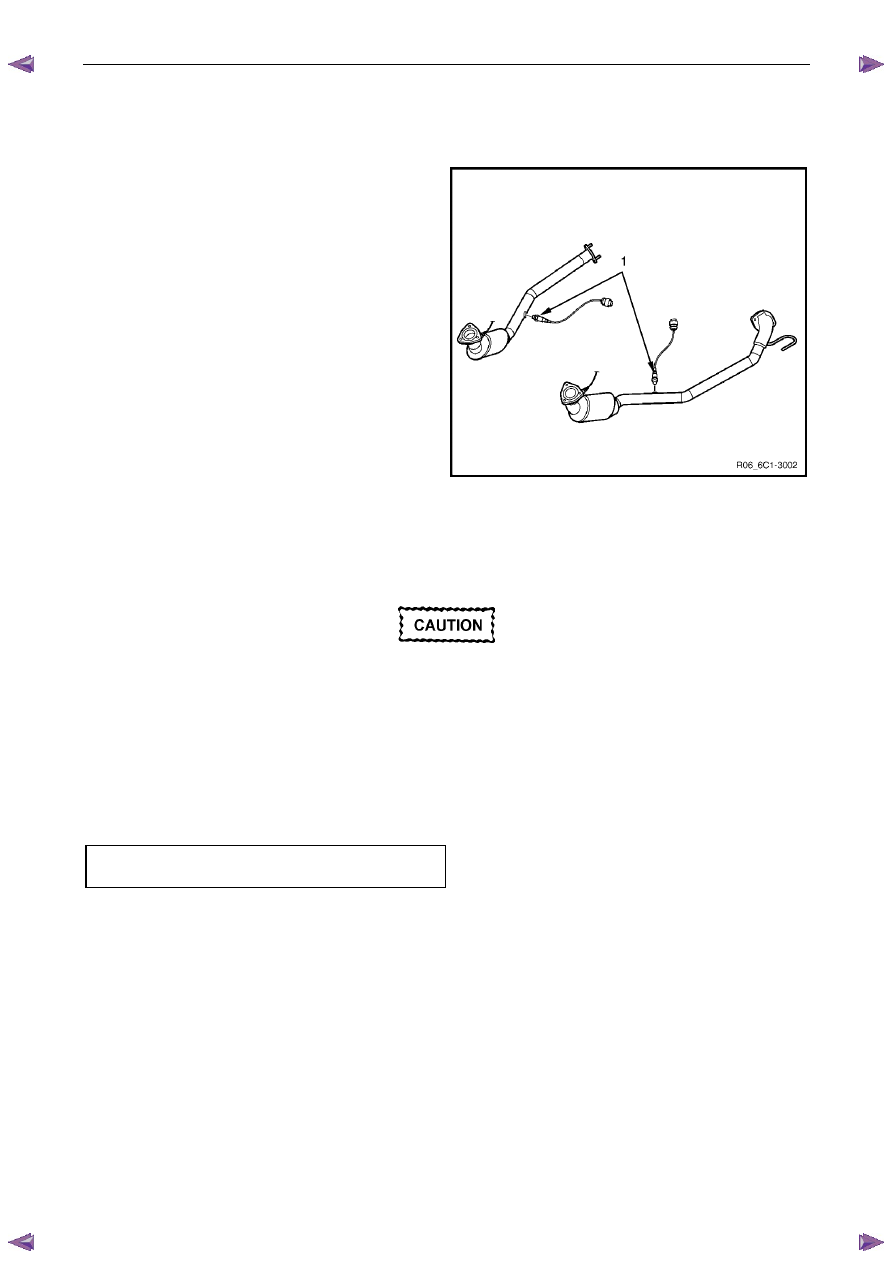

Remove

1

Turn the ignition switch off.

2

Raise the vehicle and support on safety stands, refer to 0A General Information for location of the jacking points.

3

Unclip the HO2S wiring harness (1) from the

transmission.

4

Depress the harness connector retaining clip (2) and

separate the harness connectors.

5

Unscrew the HO2S (3) from the exhaust pipe and

remove.

6

If required, test the HO2S, refer to the Test in this

Section.

Figure 6C1-3 – 46

Reinstall

Reinstallation of the heated oxygen sensor (HO2S) is the reverse of the removal procedure, noting the following:

A special anti-seize compound is used on the

HO2S threads. A new HO2S will already have

the anti-seize compound applied to the

threads.

If a HO2S has been removed, but not replaced,

then anti-seize compound must be applied to

the threads prior to installation.

1

Coat the cleaned threads of the sensor with anti-seize compound.

2

Tighten the HO2S to the correct torque specification.

Heated oxygen sensor

torque specification . . . . . . . . .40.0 – 50.0 Nm

3

Road test the vehicle and check for correct operation, taking particular note that no exhaust leakage is evident.

Engine Management – V6 – Service Operations

Page 6C1-3–37

Test

Under no circumstances should battery

voltage be applied to the heated oxygen

sensor (HO2S) heater.

To prevent component damage use connector

test adaptor kit J 35616-A.

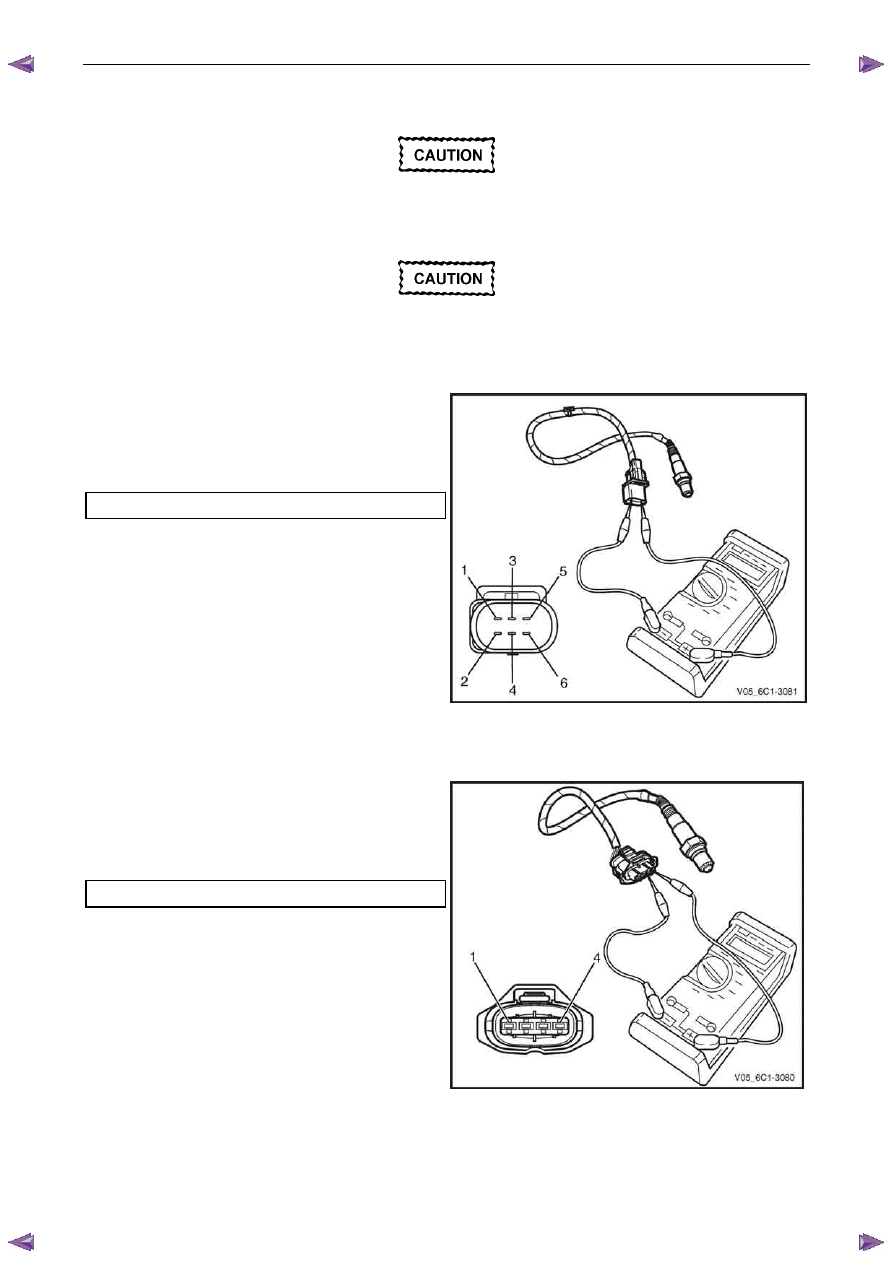

Heater Resistance Check – Six Wire HO2S

1

Connect a digital ohmmeter using connector test

adaptor kit J 35616-A to the HO2S.

2

Measure the resistance across terminals 3 and 4.

3

Compare the reading against the specification.

HO2S heater resistance @ 20°C . . . . 8.0 – 10.0

Ω

4

If the resistance is not within specification, replace the

HO2S.

Figure 6C1-3 – 47

Heater Resistance Check – Four Wire HO2S

1

Connect a digital ohmmeter using connector test

adaptor kit J 35616-A to the HO2S.

2

Measure the resistance across terminals 1 and 2.

3

Compare the reading against the specification.

HO2S heater resistance @ 20°C . . . . 8.0 – 10.0

Ω

4

If the resistance is not within specification, replace the

HO2S.

Figure 6C1-3 – 48

Engine Management – V6 – Service Operations

Page 6C1-3–38

2.15 Ignition

Coil

Ignition Coils

The replacement procedure for all ignition coils is the same except for the removal of the ignition coil on cylinder No's 1,

3 and 4, it is necessary to remove the upper intake manifold assembly.

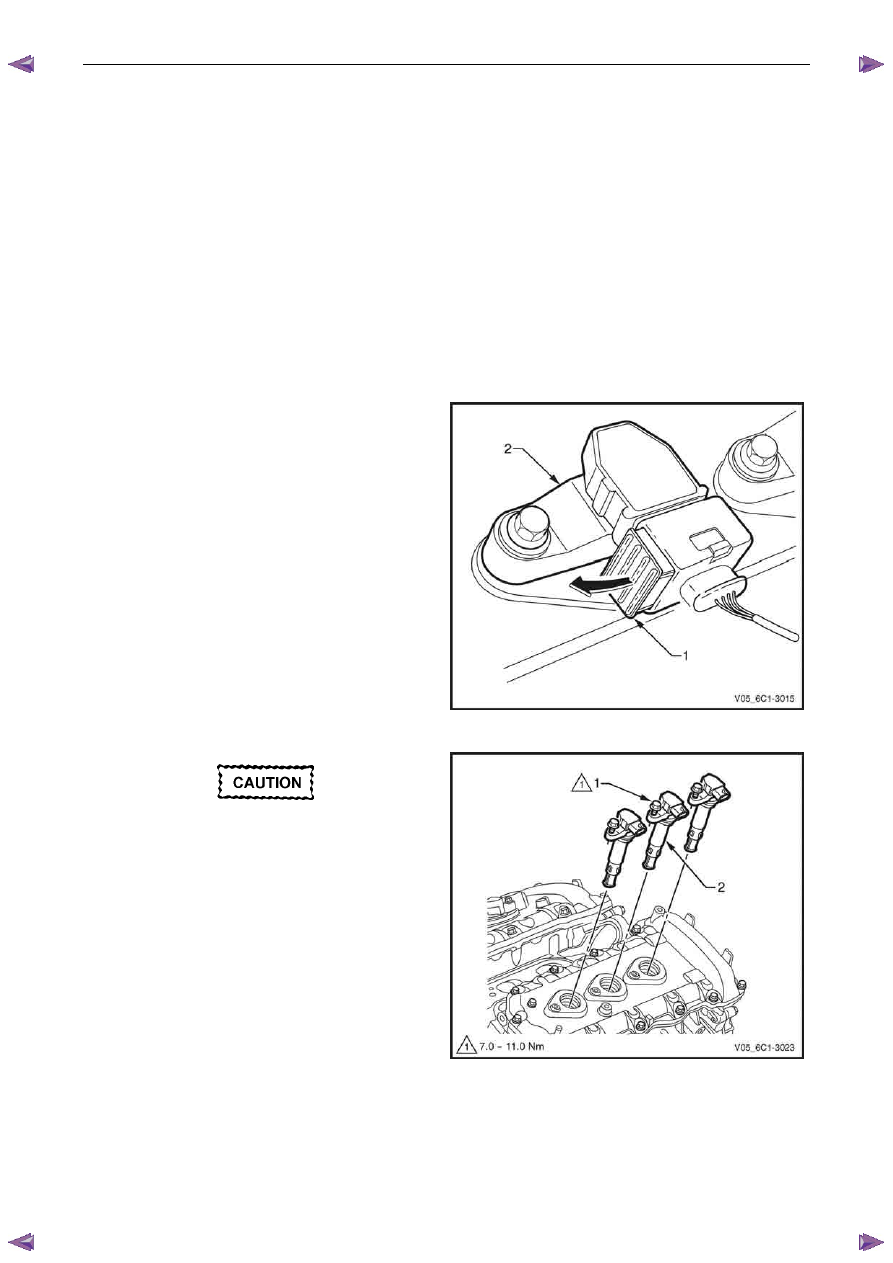

Remove

1

Turn the ignition switch off.

N O T E

If the upper intake manifold has been removed,

plug the lower manifold openings to prevent dirt

and other contaminants from entering.

2

If required, remove the upper intake manifold assembly, refer to 6A1 Engine Mechanical – V6.

3

Using a flat-blade screwdriver, slide the connector

retaining latch (1) in the direction of the arrow.

4

Remove the wiring harness connector from the ignition

coil (2).

Figure 6C1-3 – 49

Clean the area around the ignition coil before

removal to avoid debris from entering the

engine.

5

Fully loosen the bolt (1) attaching the ignition coil (2) to

the camshaft cover.

N O T E

The ignition coil bolts are captive. Do not attempt

to remove the bolts from the ignition coil.

6

Remove the ignition coil by first, twisting the coil to

release it, and then pulling the ignition coil upwards to

remove it.

Figure 6C1-3 – 50

Engine Management – V6 – Service Operations

Page 6C1-3–39

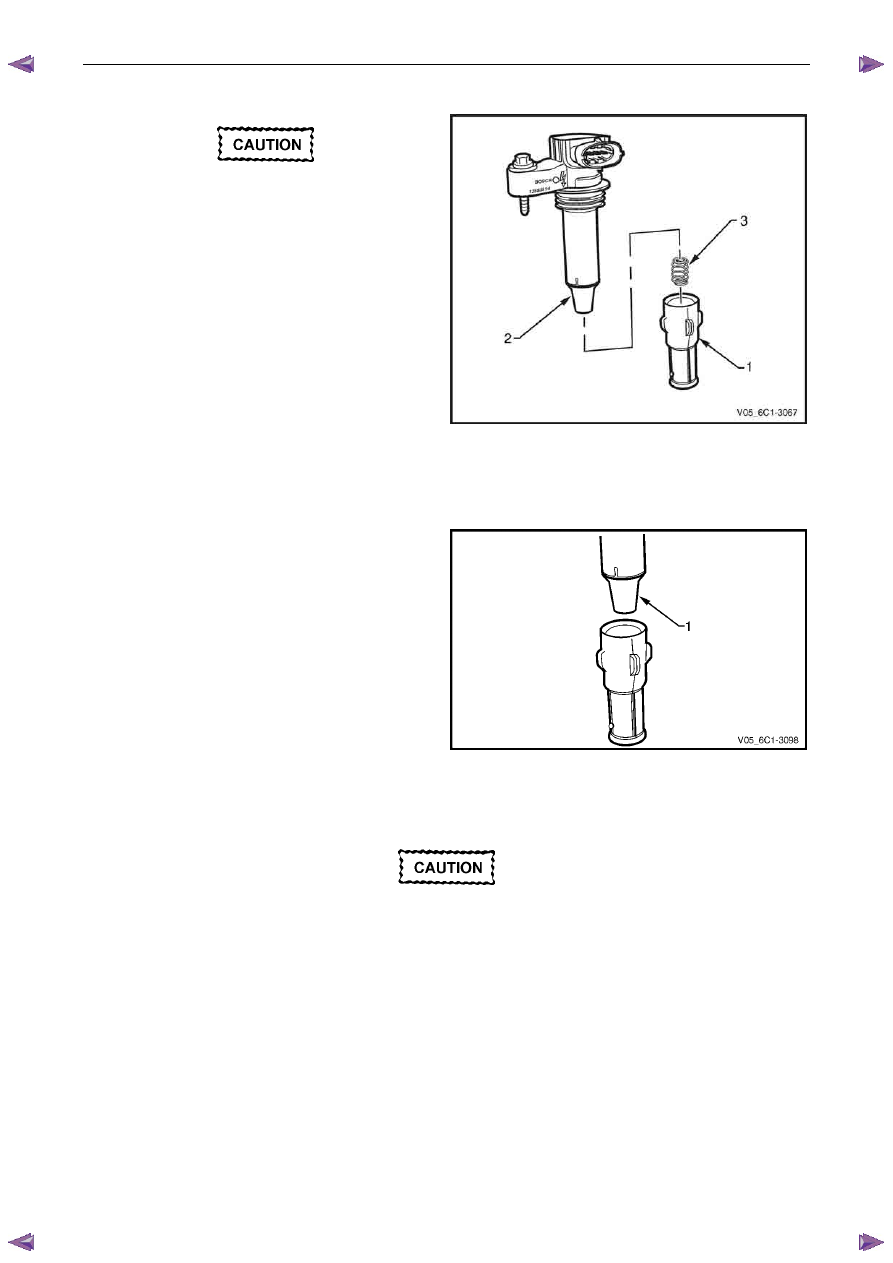

Disassemble

Do not use a sharp implement such as a knife

to cut the ignition coil boot (1) from the

ignition coil. Using a sharp implement may

damage the ignition coil insulator (2).

1

Using your thumb, work the ignition coil boot off the

ignition coil insulator.

N O T E

Take care the spring (3) does not become

dislodged as the boot is removed.

To aid removal of the boot, use a blunt

instrument to lift the boot edge away from the

coil insulator and spray a release agent between

the boot and the coil insulator.

2

Remove the spring from the ignition coil insulator.

Figure 6C1-3 – 51

Reassemble

1

Position the spring (3) in the insulator recess, refer to Figure 6C1-3 – 51.

2

Lubricate the ignition coil insulator (1) with talcum

powder.

3

Fit the ignition coil boot, ensuring it is fully seated at

the top of the insulator.

Figure 6C1-3 – 52

Test

Never probe the ignition coil with a 12 V tester

as the ignition coil will be damaged.

Due to the internal components of the ignition coil assembly, it is not possible to perform any primary and / or secondary

resistance checks. For further information on the ignition coil operation, refer to 6C1-1 Engine Management – V6 –

General Information.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст