Isuzu KB P190. Manual — part 891

Engine Management – V6 – Service Operations

Page 6C1-3–40

Reinstall

Reinstallation of the ignition coil is the reverse of the removal procedure, noting the following:

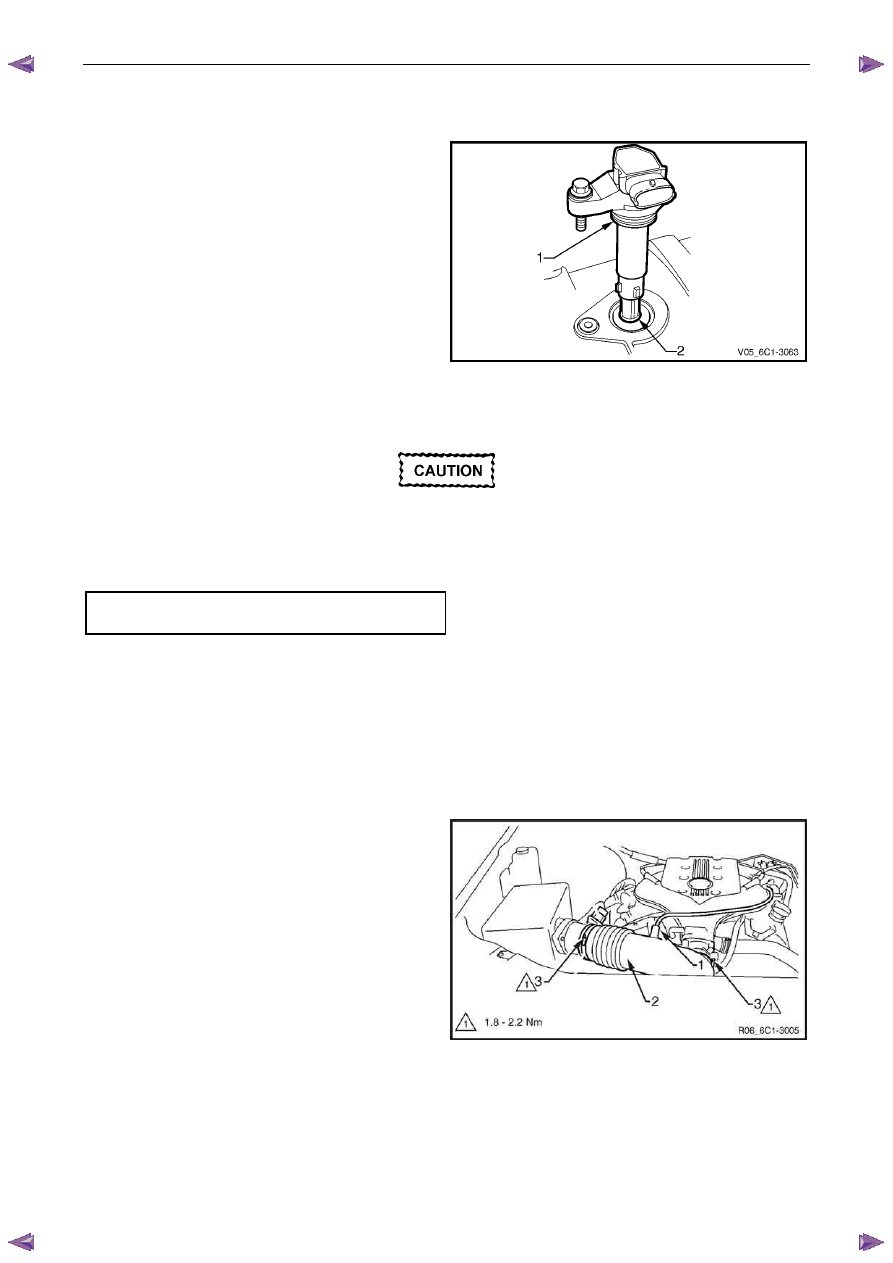

1

Lubricate the ignition coil sealing rubber (1) with clean

engine oil, and the inside of the ignition coil boot (2)

with talcum powder.

Figure 6C1-3 – 53

2

Reinstall the ignition coil by pushing down on the ignition coil to engage the sealing rubber in the camshaft cover.

Ensure the ignition coil is fully seated before

tightening the attaching bolt to the specified

torque.

3

Reinstall the ignition coil bolt and tighten to the correct torque specification.

Ignition coil attaching bolt

torque specification . . . . . . . . ...7.0 – 11.0 Nm

4

Road test the vehicle and check for correct operation.

2.16 Intake Air Duct Assembly

Remove

1

Turn the ignition switch off.

2

Disconnect the crankcase ventilation hose (1) from the air intake duct (2).

3

Loosen the two air intake duct retaining clamps (3),

4

Pull the air intake duct away from the throttle body.

5

Pull the air intake duct away from the mass air flow

sensor.

Figure 6C1-3 – 54

Reinstall

Reinstallation of the air intake duct is the reverse of the removal procedure, noting the following:

Engine Management – V6 – Service Operations

Page 6C1-3–41

Ensure the air intake duct sealing rubber is

correctly positioned on the throttle body.

Failure to do this may result in engine

damage due to unfiltered air entering the

engine intake system.

1

Reinstall the air intake duct and tighten the retaining clamps to the correct torque specification.

Air intake duct retaining clamp

torque specification . . . . . . . . . .1.8 – 2.2 Nm

2

Road test the vehicle and check for correct operation, taking particular note that no air leaks are evident.

2.17 Intake Air Temperature Sensor

The intake air temperature (IAT) sensor is part of the mass air flow (MAF) sensor assembly, refer to 2.20

Mass Air

Flow Sensor for the replacement procedure.

Test

To prevent component damage use connector

test adaptor kit J 35616-A.

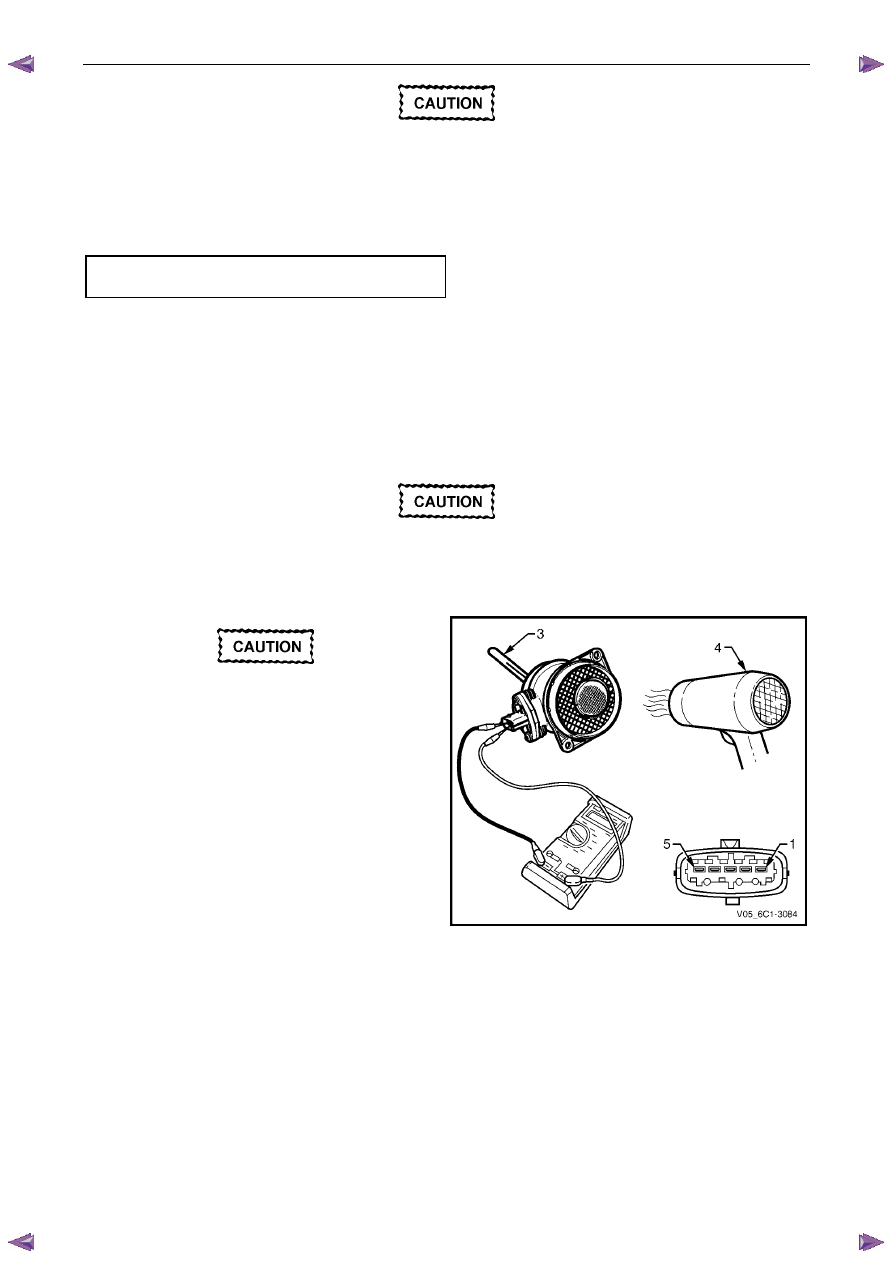

Resistance Check

Do not use a high temperature heat gun as

damage to the MAF sensor will result.

1

Connect a digital ohmmeter using connector test

adaptor kit J 35616-A to the MAF sensor.

2

Whilst holding a thermometer (3), use a commercially

available hair dryer (4) to blow warm air through the

MAF sensor.

3

Measure the resistance across terminals 1 and 2.

Figure 6C1-3 – 55

Engine Management – V6 – Service Operations

Page 6C1-3–42

4

Observe the resistance values as the temperature

increases and compare the temperature / resistance

change to the specifications.

5

If the resistance is not within specifications, replace

the MAF sensor.

Intake Air Temperature Vs Resistance

Temperature °C

Resistance – Ohms (

Ω)

-40

35140 – 43760

-20

12660 – 15120

-10

7943 – 9307

0

5119 – 5892

20

2290 – 2551

25

1900 – 2100

40

1096 – 1238

60

565 – 654

80

312 – 370

100

184 – 222

120

114 – 141

140

74 – 93

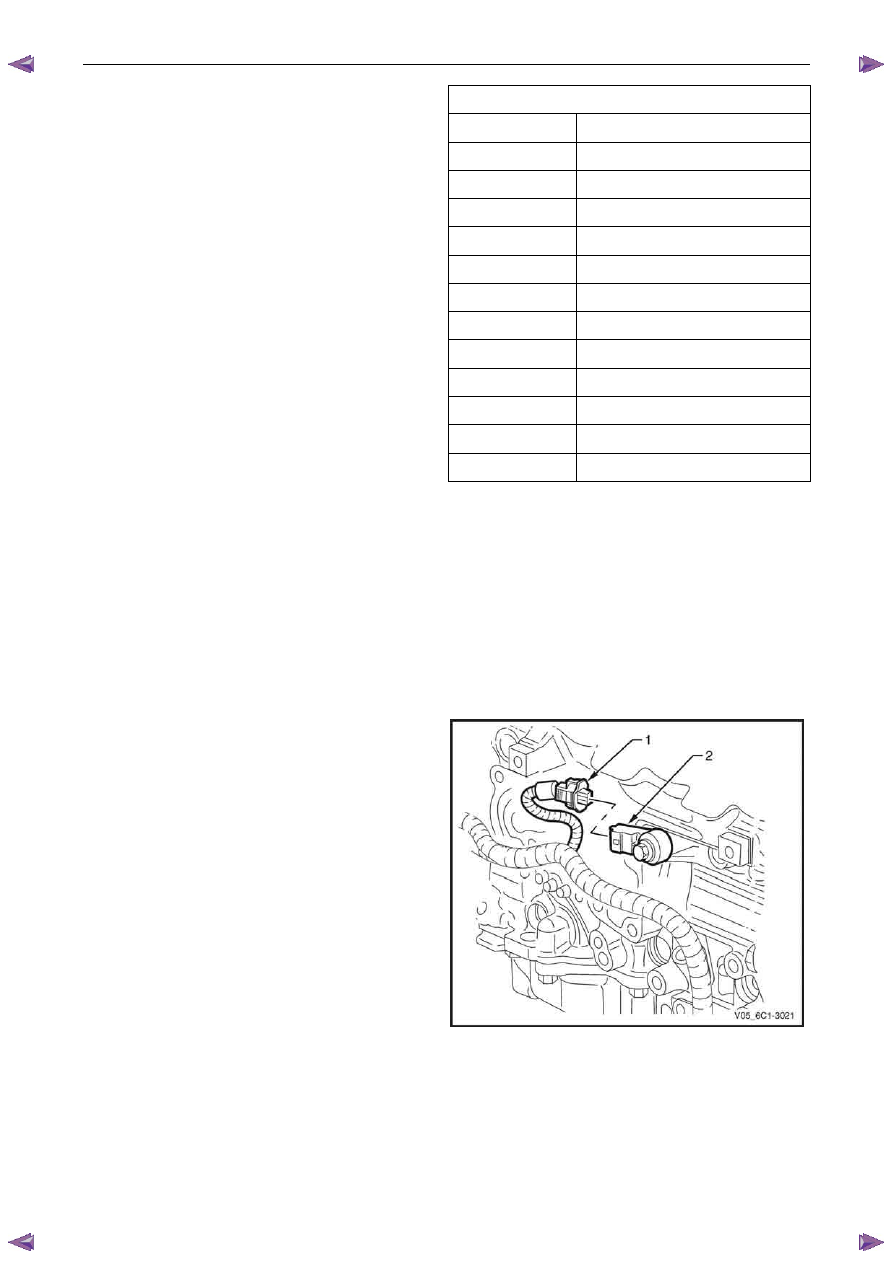

2.18 Knock Sensor, Bank 2 (LHS)

Remove

1

Turn the ignition switch off.

2

Disconnect Bank 2 pre-catalytic converter HO2S wiring harness connector, refer to 2.14

Heated Oxygen

Sensor.

3

Raise the front of the vehicle and support on safety stands. Refer to 0A General Information for location of the

jacking points.

4

Remove the starter motor heat shield, refer to 6D1-2 Starting System – V6.

5

Disconnect the wiring harness connector (1) from the

knock sensor (2).

Figure 6C1-3 – 56

Engine Management – V6 – Service Operations

Page 6C1-3–43

6

Remove the bolt (1) attaching the knock sensor (2) to

the engine block and remove the knock sensor.

Figure 6C1-3 – 57

Reinstall

Reinstallation of the knock sensor is the reverse of the removal procedure, noting the following:

1

Ensure the knock sensor mounting surface is flat and free of any dirt, oxidisation, etc.

Ensure the knock sensor is fully seated and

correctly aligned before tightening the

attaching bolt.

Do not over-tighten the attaching bolt as

incorrect operation of the knock sensor may

result.

2

Reinstall the knock sensor and bolt (1). Align the

knock sensor so that it is parallel to the engine oil pan

mounting surface (2), ± 3° (3).

3

Tighten the knock sensor bolt to the correct torque

specification.

Knock sensor attaching bolt

torque specification . . . . . . . . .21.0 – 25.0 Nm

4

Road test the vehicle and check for correct operation,

taking particular note that no exhaust leaks are

evident.

Figure 6C1-3 – 58

2.19 Knock Sensor, Bank 1 (RHS)

Remove

1

Turn the ignition switch off.

2

Raise the front of the vehicle and support on safety stands, refer to 0A General Information for location of the

jacking points.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст