Isuzu KB P190. Manual — part 270

6E-46 Engine Control System (4JH1)

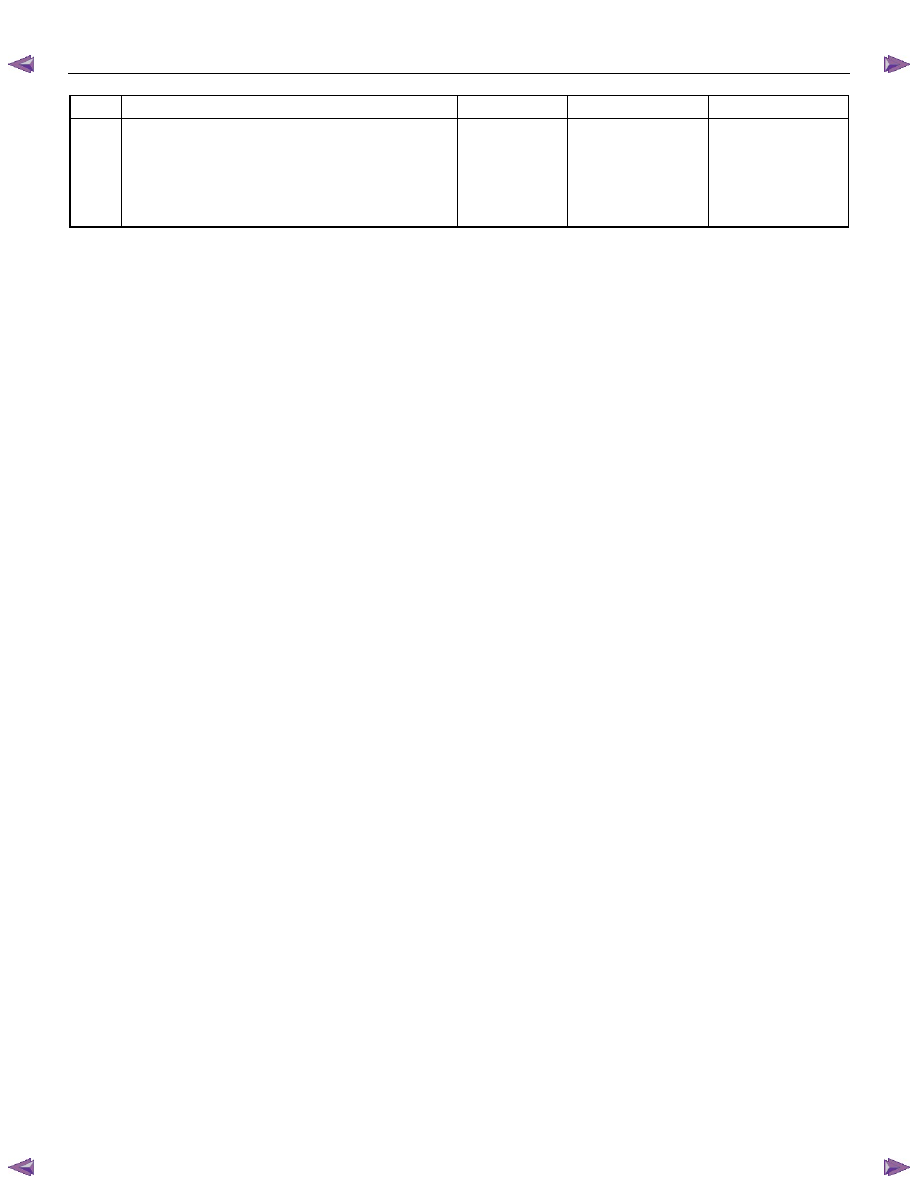

Step Action

Value(s)

Yes

No

17

1. Turn OFF the ignition.

2. Reconnect all disconnected connectors.

3. Turn the ignition ON with the engine OFF.

4. Attempt to establish scan tool communications

with the ECM.

Does the scan tool communicate with the ECM?

System OK

Go to Step 3

Engine Control System (4JH1) 6E-47

Engine Cranks but Does Not Run

Description

The Engine Cranks but Does Not Run diagnostic table

is an organized approach to identifying a condition that

causes an engine to not start. The diagnostic table

directs the service technician to the appropriate system

diagnosis. The diagnostic table assumes the following

conditions are met:

• The battery is completely charged and terminals

are cleaned and tight.

• The engine cranking speed is normal.

• There is adequate fuel in the fuel tank.

• There is no fuel leak in the fuel line.

• There is no air in the fuel line.

• Filters (Air, Fuel) are clean.

• Fuse and slow blow fuse are normal.

Diagnostic Aids

• If an intermittent condition is suspected, refer to

Intermittent Conditions in this section.

Step Action

Value(s)

Yes

No

1

Did you perform the Diagnostic System Check-

Engine Controls?

Go to Step 2

Go to Diagnostic

System Check-

Engine Controls

2

1. Install the scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Crank the engine for specified amount of time.

4. Monitor the Diagnostic Trouble Code (DTC)

Information with the scan tool.

Does the scan tool display any DTCs that failed this

ignition?

15 seconds

Go to Diagnostic

Trouble Code (DTC)

List

Go to Step 3

3

1. Check for normal readings at key up for the

following inputs and output: Refer to the scan

tool Data List or a known good vehicle to

determine normal values.

• System Voltage

• Engine Coolant Temperature (ECT)

• Intake Air Temperature (IAT)

• Mass Air Flow (MAF) Sensor

• Barometric Pressure

• Desired Injection Quantity

2. Repair or replace as necessary.

Did you find and correct the condition?

Go to Step 10

Go to Step 4

6E-48 Engine Control System (4JH1)

Step Action

Value(s)

Yes

No

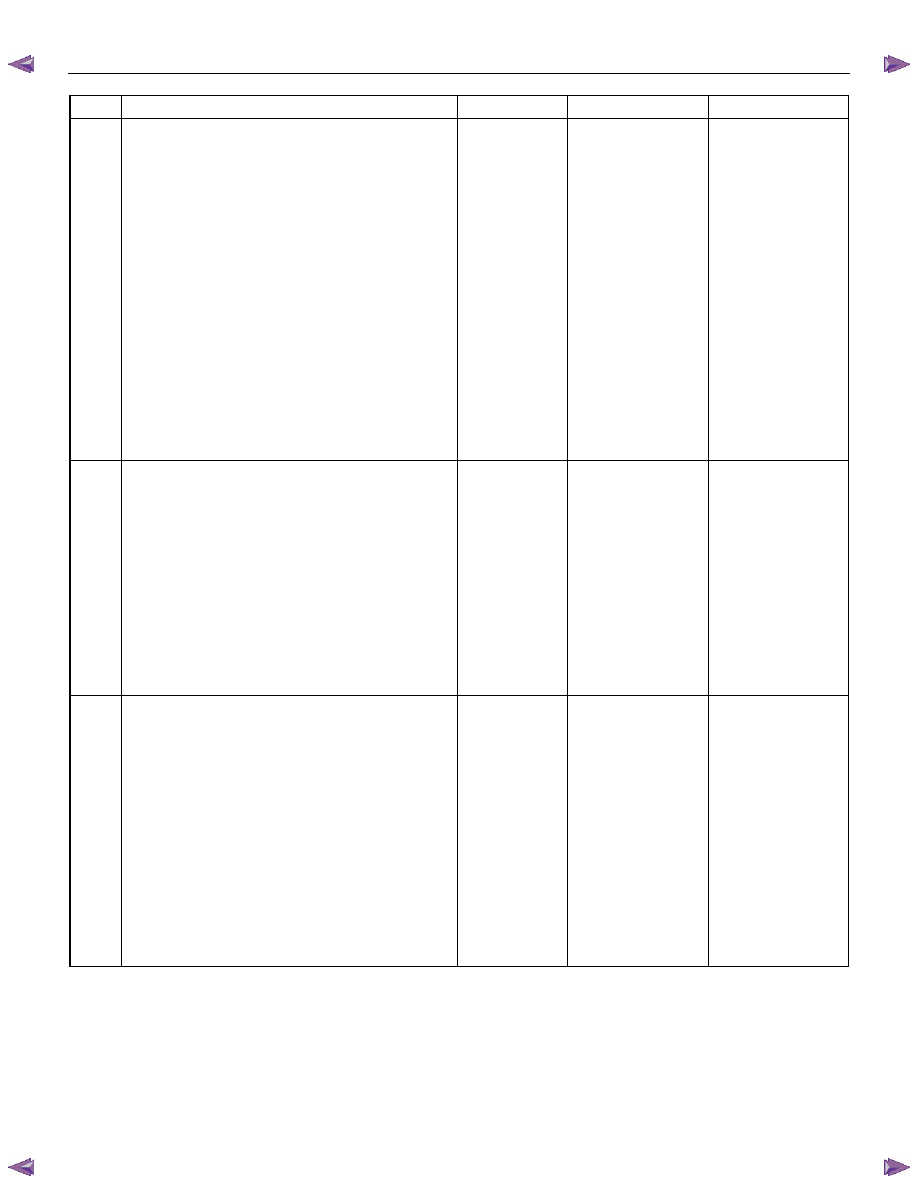

4

1. Inspect the high pressure side between the fuel

injection pump and the fuel injection nozzles for

fuel leakage. The following components may

contain an external leak.

• Fuel injection pump

• Fuel injection pump control unit (PCU)

• Fuel injection solenoid valve

• Timing control valve (TCV)

• Constant pressure valve (CPV)

• Fuel pipe between the fuel injection pump

and fuel injection nozzles

• Each fuel pipe sleeve nuts

• Each fuel pipe connectors

• Each

gaskets

Notice: Fuel may leak into the engine from the fuel

injection pump. In such case, the engine oil level will

rise. Inspect for fuel leakage into the engine oil.

2. Repair any fuel system leaks as necessary.

Did you find and correct the condition?

Go to Step 10

Go to Step 5

5

1. Turn OFF the ignition.

2. Check the fuel system line connections between

the fuel tank and the fuel injection pump for

tightness and all fuel hoses for cuts, cracks and

for the use of proper clamps.

3. Pump the priming pump on the fuel filter until it

becomes firm. If there is a leak on the suction

side of the fuel system between the priming

pump and the fuel injection pump, the priming

pump will not build up sufficient firmness and fuel

leakage may occur.

4. Repair or replace as necessary.

Did you find and correct the condition?

Go to Step 10

Go to Step 6

6

1. Remove the fuel hose that connects to the fuel

injection pump suction side.

2. Remove the fuel pipe connector that connects to

the fuel injection pump suction side.

3. Inspect the eye bolt for any type of restriction or

collapsed gauze filter.

Notice: If any type of restriction found, check for a

condition that causes contaminated fuel, such as the

customer is using an aftermarket fuel filter or

extended maintenance interval.Also inspect fuel

waxing or icing that is caused by an incorrect fuel

type used in winter season or water intrusion in the

fuel system.

4. Repair or replace as necessary.

Did you find and correct the condition?

Go to Step 10

Go to Step 7

Engine Control System (4JH1) 6E-49

Step Action

Value(s)

Yes

No

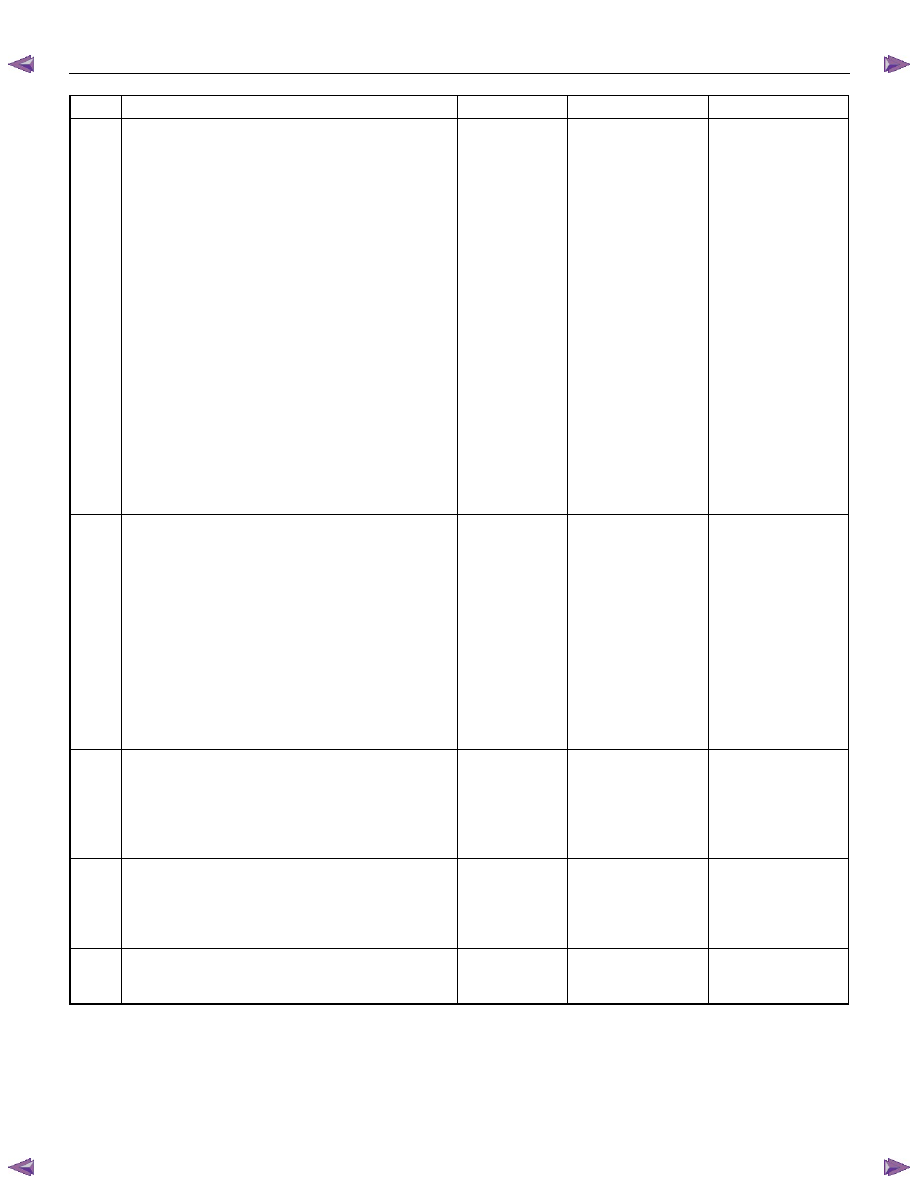

7

1. Disconnect the fuel hose that connects to the

fuel injection pump suction side. In order to

measure the discharged fuel amount, put the

hose into a bottle or a container.

2. Pump the priming pump on the fuel filter.

Notice: If there is a leak on the suction side of the

fuel system, the fuel from the disconnected hose will

not flow out sufficiently and fuel leakage may occur.

Also if there is a restriction on the suction side of the

fuel system, the fuel from the disconnected hose will

not flow out sufficiently that is most likely caused by

clogged fuel filter or kinked fuel hose or pipe.

3. Draw fuel from the fuel tank at the fuel line (as

close to the fuel tank as possible) going to the

fuel pickup tube to verify a clean stream of fuel

comes out (use the hand-held vacuum pump 5-

8840-0279-0/J-23738-A with a clear hose or

equivalent). This will ensure the fuel pickup tube

is not cracked drawing air into the fuel line.

4. Repair any fuel system leaks and restrictions as

necessary.

Did you find and correct the condition?

Go to Step 10

Go to Step 8

8

1. Other possible causes for the no-start condition:

• Fuel injection pump mechanical timing

incorrect

• Flywheel installed incorrectly causing the

crankshaft position (CKP) sensor to be

incorrectly timed to the engine. Disconnect

sensor and attempt to start engine to verify.

• Heavily restricted intake, exhaust or

catalytic converter plugged solid

• Poor engine compression

• Water or gasoline contamination in fuel

2. Repair or replace as necessary.

Did you find and correct the condition?

Go to Step 10

Go to Step 9

9

Important: The fuel injection pump must be timed to

the engine.

Replace the fuel injection pump. Refer to Fuel

Injection Pump Replacement in engine mechanical

section.

Did you complete the replacement?

Go to Step 10

10

1. Reconnect all previously disconnected harness

connector(s).

2. Turn OFF the ignition for 30 seconds.

3. Attempt to start the engine.

Does the engine start and continue to run?

Go to Step 11

Go to Step 2

11

Observe the DTC Information with the scan tool.

Are there any DTCs that you have not diagnosed?

Go to Diagnostic

Trouble Code (DTC)

List System

OK

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст