Isuzu KB P190. Manual — part 188

BRAKES 5C-53

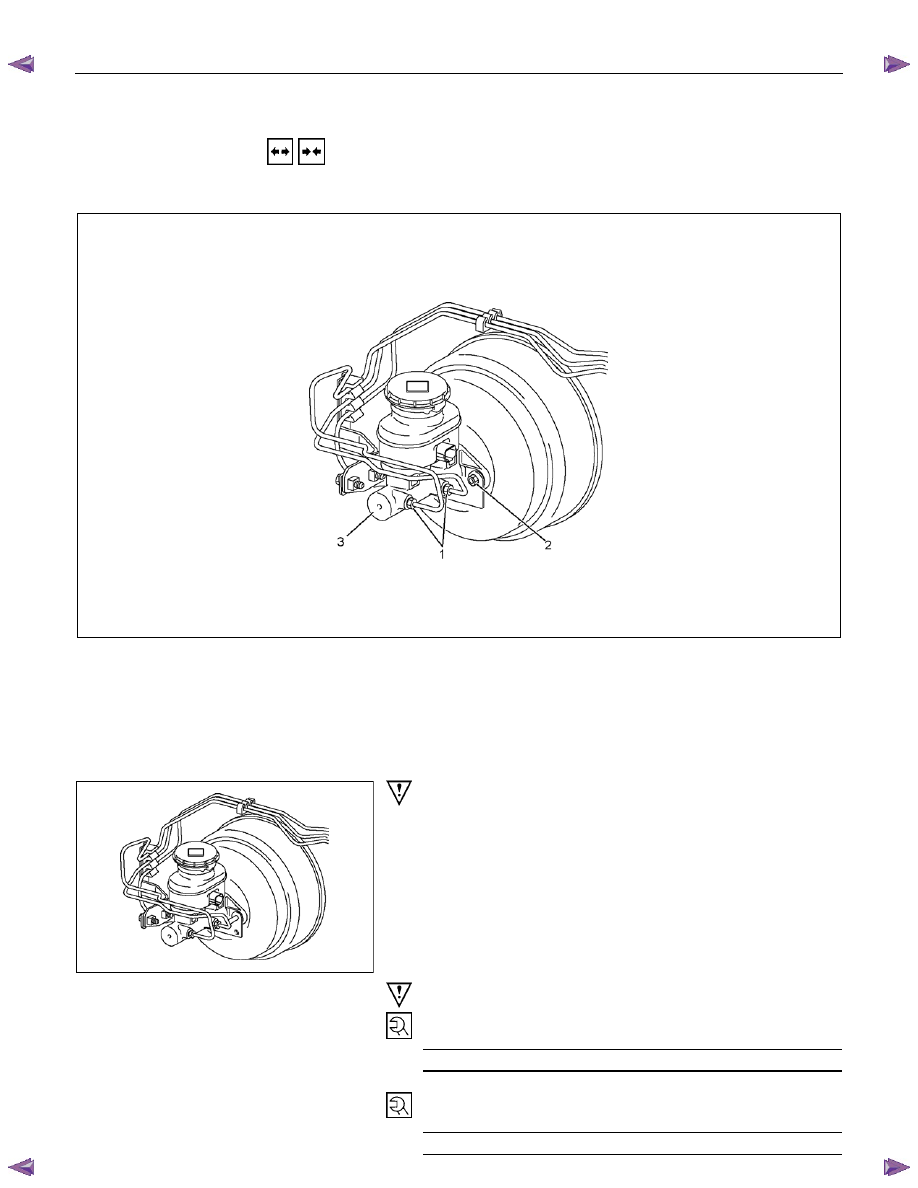

MASTER CYLINDER

REMOVAL AND INSTALLATION

MASTER CYLINDER ASSEMBLY

This illustration is based on the RHD model

RTW75CMF000901

Removal Steps

▲ 1. Brake line

2. Nut; Master cylinder to vacuum booster

3. Master cylinder assembly

Installation Steps

3. Master cylinder assembly

▲ 2. Nut; Master cylinder to vacuum booster

▲ 1. Brake line

RTW75CSH002701

Important Operation - Removal

1. Brake Line

Be very careful not to spill brake fluid on the painted surface.

Damage to the painted surface will result.

Important Operation - Installation

2. Nut; Master Cylinder to Vacuum Booster

Torque N

⋅m (kgf⋅m/lb⋅ft)

10 – 16 (1.0 – 1.6 / 7 – 12)

1. Brake Line

Torque N

⋅m (kgf⋅m/lb⋅ft)

13 – 19 (1.3 – 1.9 / 9 – 14)

5C-54 BRAKES

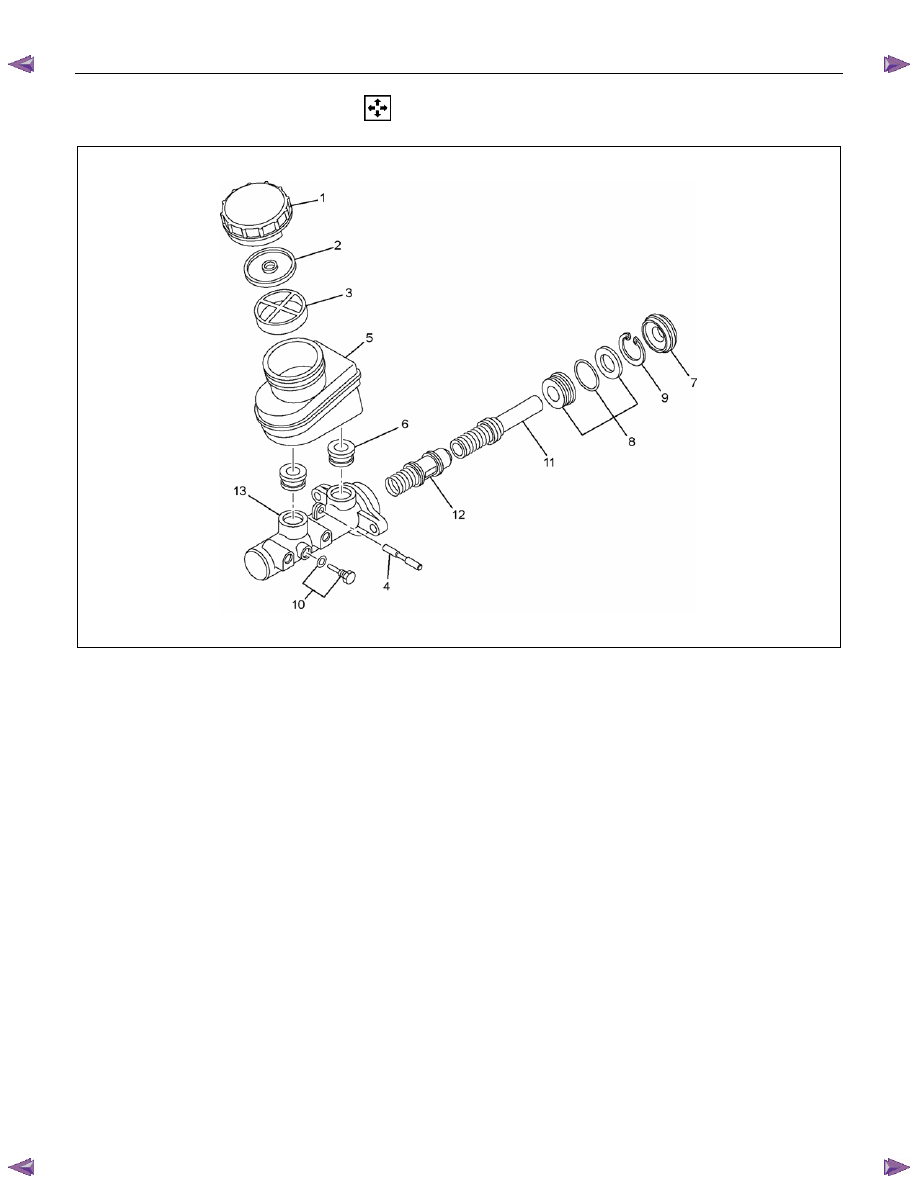

DISASSEMBLY

RTW75CMF000701

Disassembly Steps

1.

Cap

2.

Diaphragm

3.

Filter

4.

Pin

5. Reservoir tank

6.

Grommet

▲ 7. Front seal

8. Guide assembly

▲ 9. Snap ring

▲10. Stopper bolt and gasket

▲11. Primary piston

▲12. Secondary piston

13. Cylinder body

Note:

• Be sure to replace the designated with new ones.

• Wash the disassembled parts in clean brake fluid.

• Use compressed air to clean the ports.

• Do not allow dirt and dust to contaminate the disassembled

parts.

BRAKES 5C-55

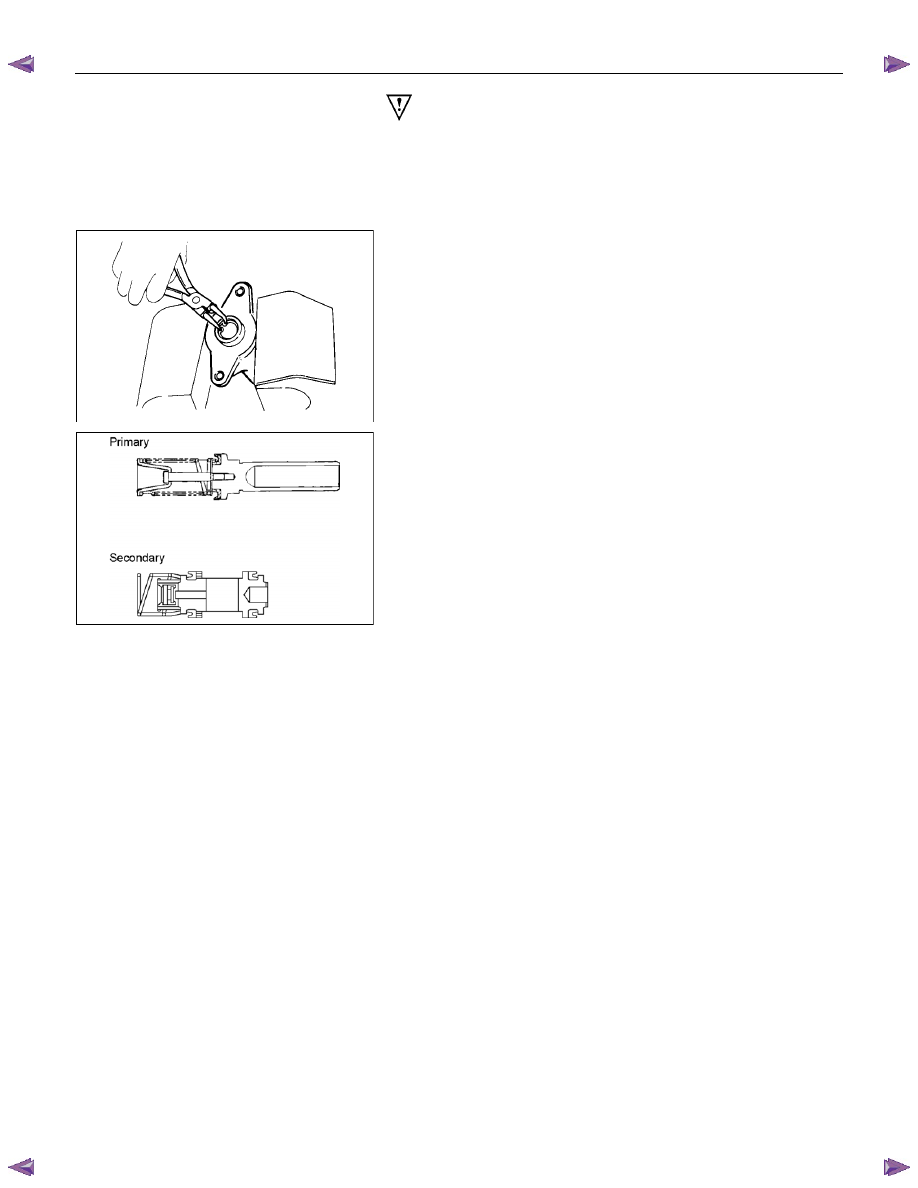

Important Operations

When disassembling, inspecting or reassembling the master

cylinder assembly, take care not to bring the parts into contact

with mineral oil or dust. Wash the piston cups only with brake

fluid. Do not use gasoline or other mineral-base cleaning

solvents.

7. Front Seal

Front seal remain in the vacuum booster side, when removing

master cylinder.

9. Snap Ring

Remove the snap ring from the cylinder body with pushing in

the primary and secondary pistons.

10. Stopper Bolt and Gasket

Remove the stopper bolt from the cylinder body with pushing in

the primary and secondary pistons.

RTW75CSH002201

11. Primary Piston

12. Secondary Piston

Don’t remove the spring from the piston.

5C-56 BRAKES

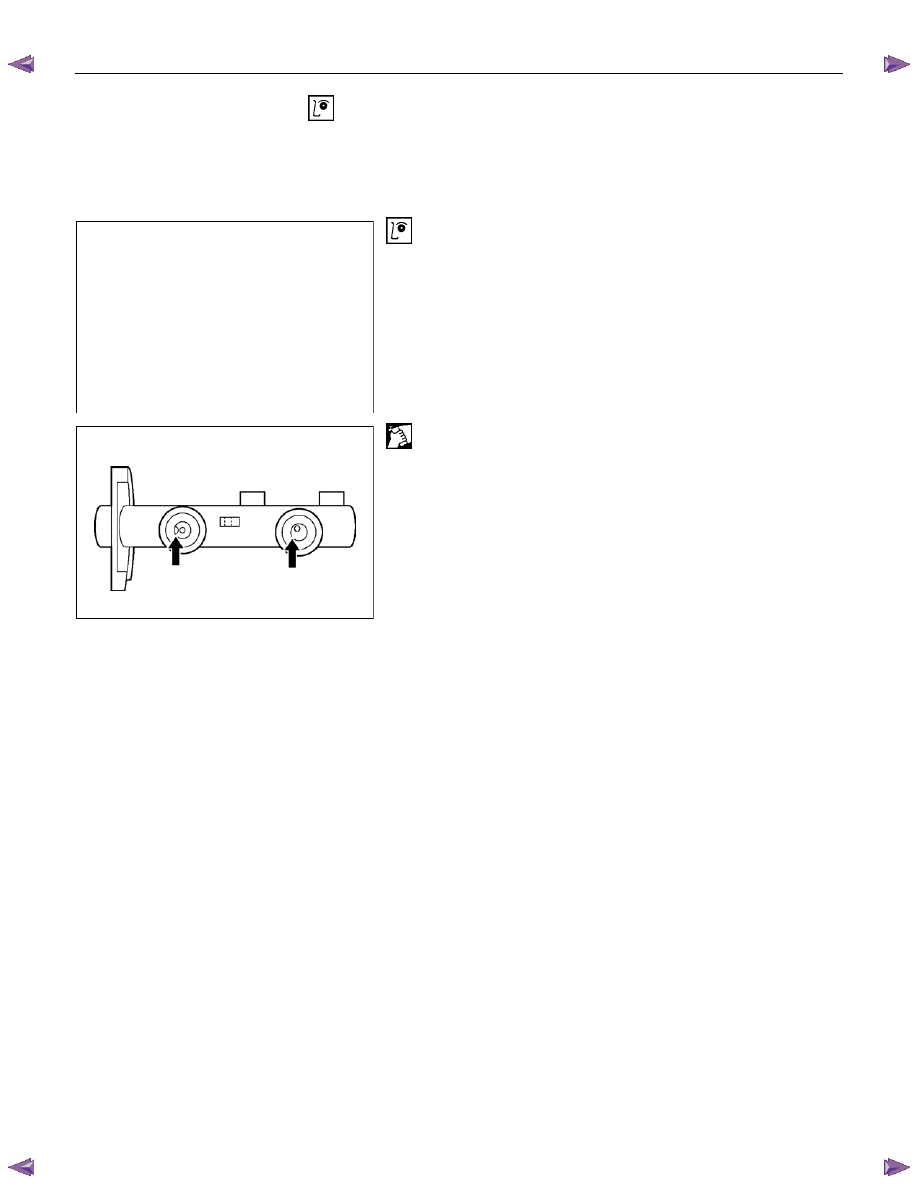

INSPECTION AND REPAIR

Make necessary correction or parts replacement if wear damage or any other abnormal conditions are found

through inspection.

• Cylinder body inside face

• Piston

• Piston cup

• Return port, Supply port

• Return spring

• Guide assembly (O-ring, Cup)

• Front seal

Visual Check

Inspect the following parts for wear, distortion, cuts, nicks,

corrosion, or other abnormal conditions.

RTW75CSH002401

Return Port

Check the return port for obstructions and if necessary, clean

with a tag wire.

Blow away foreign matter with compressed air.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст