Isuzu KB P190. Manual — part 187

BRAKES 5C-49

Important Operations

Note:

• Wash the disassembled parts in clean brake fluid.

• Use compressed air to clean the ports.

• Protect the disassembled part surfaces from contamination

by dust and other foreign material.

• Before reassembly, check the part surfaces for

contamination with dust or other foreign material.

• Be sure to replace the designated parts with new ones.

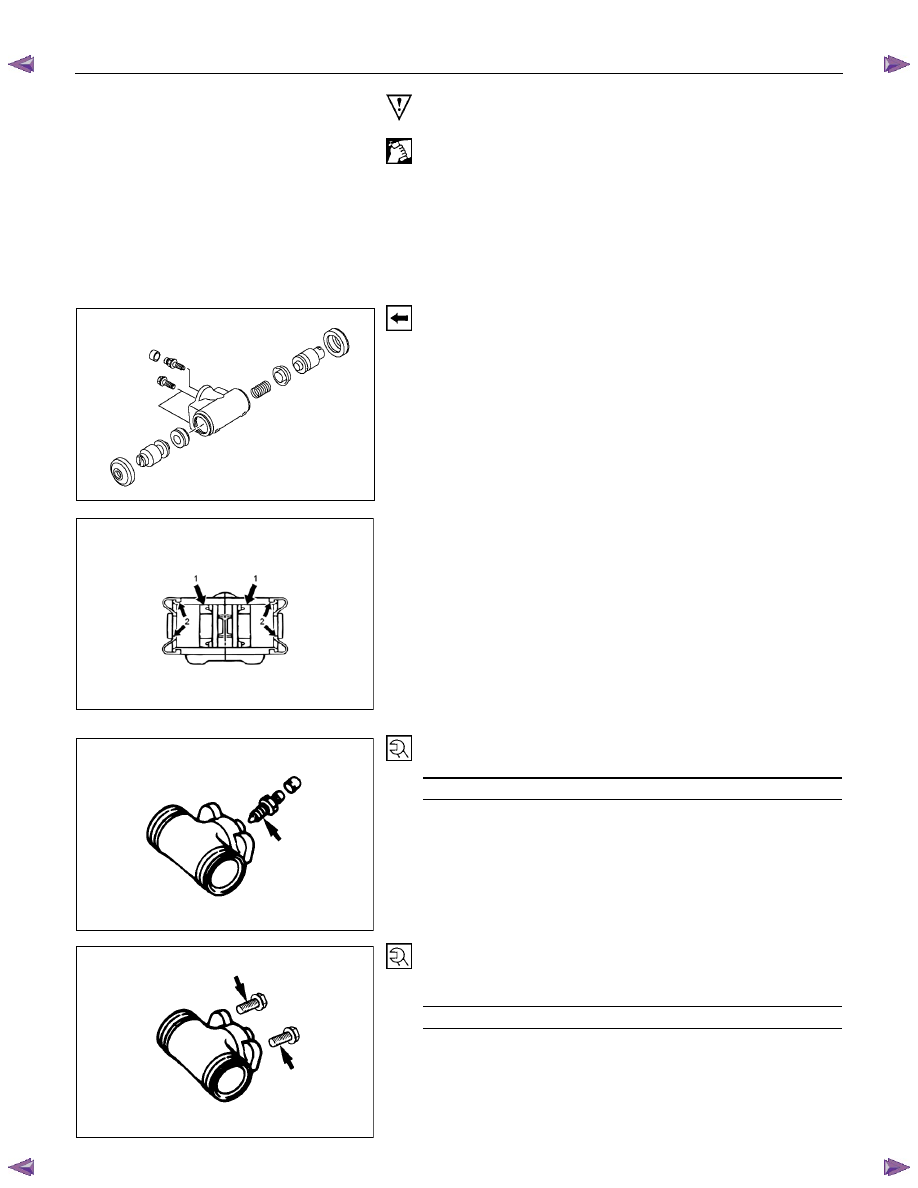

1. Piston Assembly

Install new piston cups on each piston so that the flared end of

the cups are turned to the inboard side of the pistons.

Attach the return spring and the boot to the piston.

Be sure to use new piston cup and boot.

RTW55CSH000201

• Apply brake fluid to the pistons and the inner face of the

boots.

• Note the direction of piston cup (1).

• Apply rubber grease to the boots (2) as shown in the

illustration.

5. Bleeder

Torque N

⋅m (kgf⋅m/Ib⋅in)

6 - 8 (0.6 – 0.8 / 52 - 69)

9. Wheel Cylinder Assembly

10. Bolt; Wheel cylinder

Torque N

⋅m (kgf⋅m/Ib⋅in)

14 - 18 (1.4 – 1.8 / 122 - 156)

5C-50 BRAKES

308R300008

11. Shoe; leading

• Be sure to use new spring; shoe hold.

12. Lever; parking

13. Washer; lever

14. Retainer

Install the lever, the washer and the retainer to the leading

brake shoe.

• Apply grease to the sliding surfaces of the lever and

brake shoe.

• Be sure to use new retainer and washer.

305R300009

16. Shoe; trailing

• Be sure to use new spring; shoe hold.

17. Spring; shoe to shoe, upper

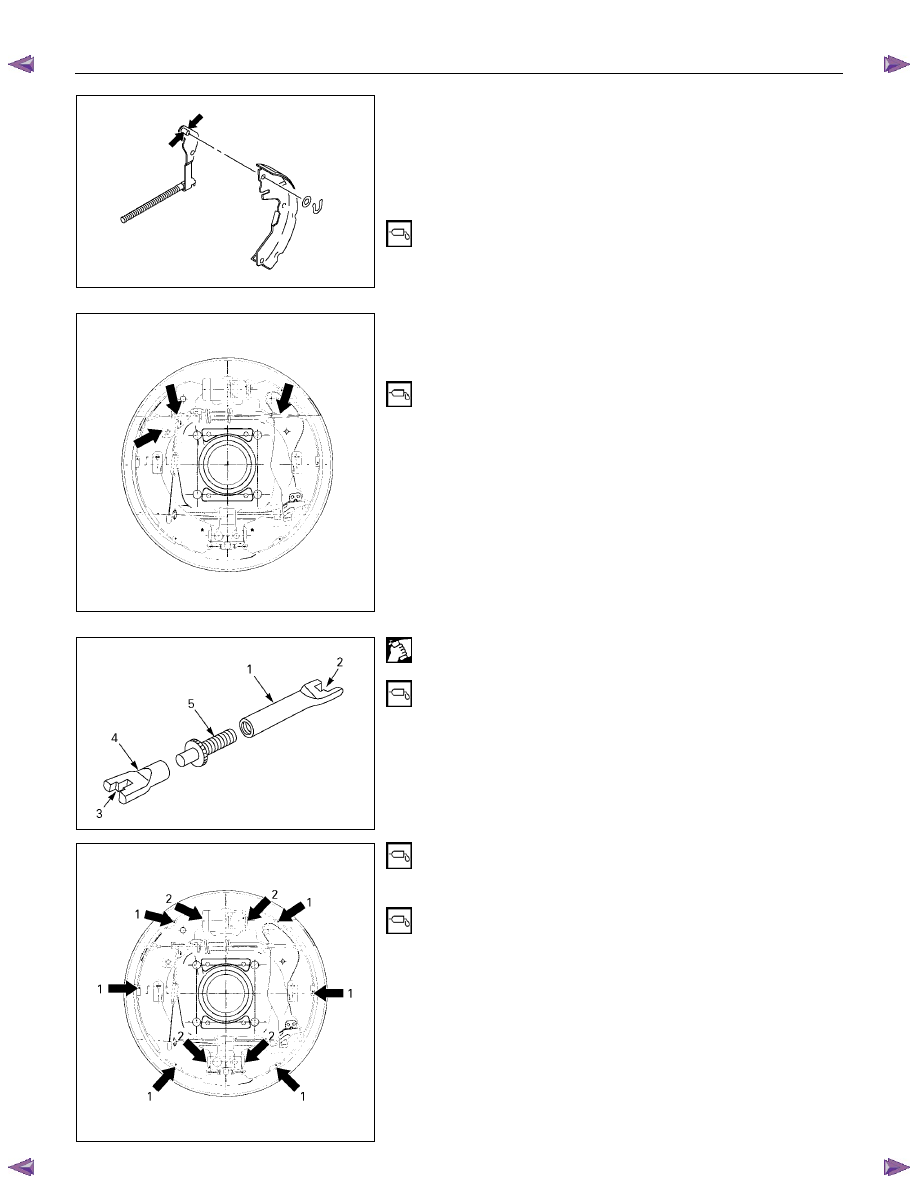

18. Adjuster assembly

1. Apply grease to each of the parts shown in the

illustration before installing the brake shoe.

• Lever; adjuster-shoe

• Adjuster-shoe

2. Clean the adjuster bolt (5) and the adjuster rods (1) (4).

Apply grease to the threaded portion of the adjuster bolt.

3. Install the adjuster rod to the adjuster bolt.

4. Apply grease to the adjuster arm ends (2) (3). Set the

spring upper to the adjuster arm, then install them to the

brake shoe.

305R300010

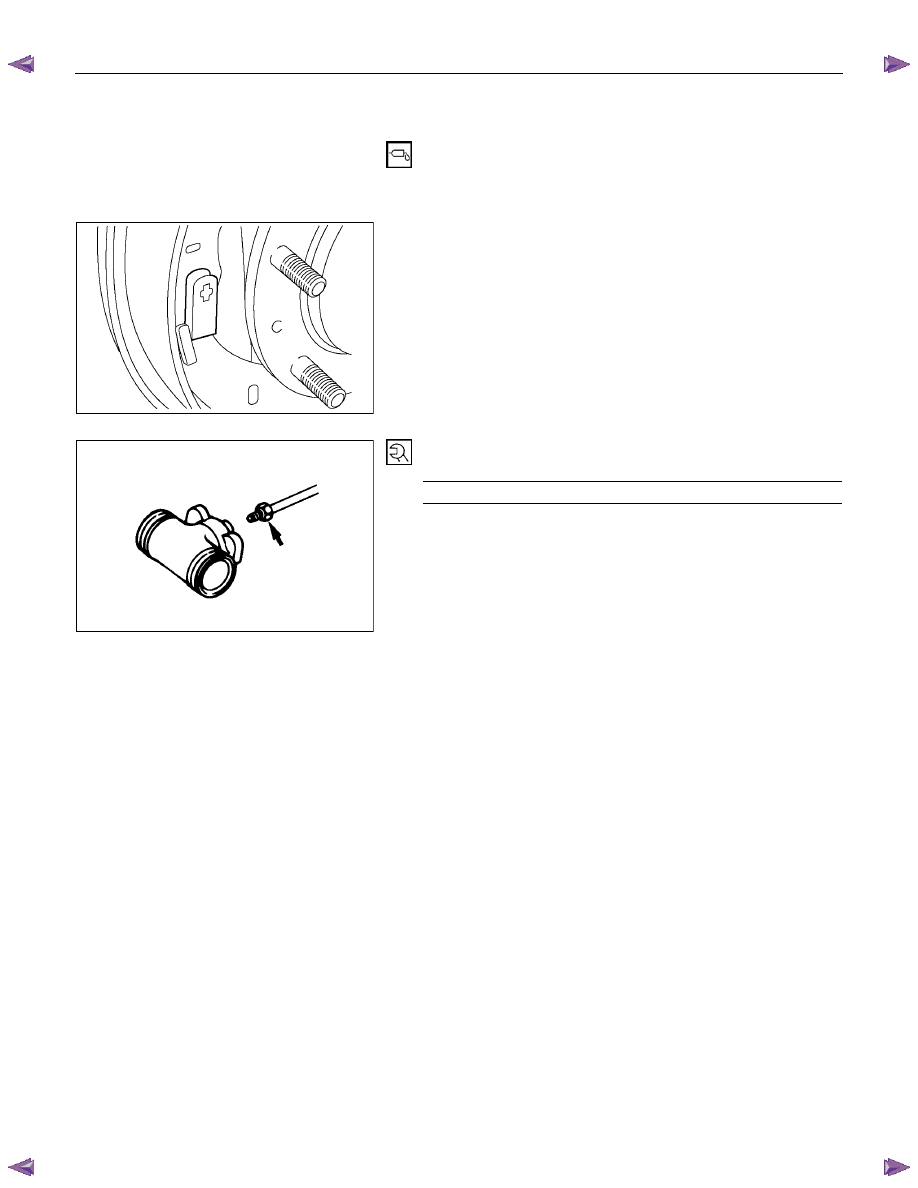

5. Before setting the brake shoes, apply grease to the back

plate portions (1) contacting the brake shoe edge as

shown in the illustration.

6. Apply grease to the wheel cylinder parts contacting the

brake shoe (2).

7. Install the brake shoe.

Note:

• Be careful not to damage the wheel cylinder dust cover.

• Do not allow the wheel cylinder piston to fly free.

BRAKES 5C-51

20. Lever; adjuster

21. Ring; Adjuster lever

• Apply grease to the lever adjuster sliding surface. Install

the lever adjuster and the ring to the shoe; trailing.

• Be sure to use a new ring.

RUW55CSH000501

22. Spring; shoe hold

23. Pin; shoe hold

• Install the brake drum.

• Install the rear wheel.

• If the wheel cylinder has been removed, the brake

system must be bled.

• Pump the brake pedal 10 times. Check that there is little

or no stroke length variation as the pedal is pumped.

• Adjust the lining clearance.

• Brake

Line

Torque N

⋅m (kgf⋅m/Ib⋅ft)

13 - 19 (1.3 - 1.9 / 9 - 14)

5C-52 BRAKES

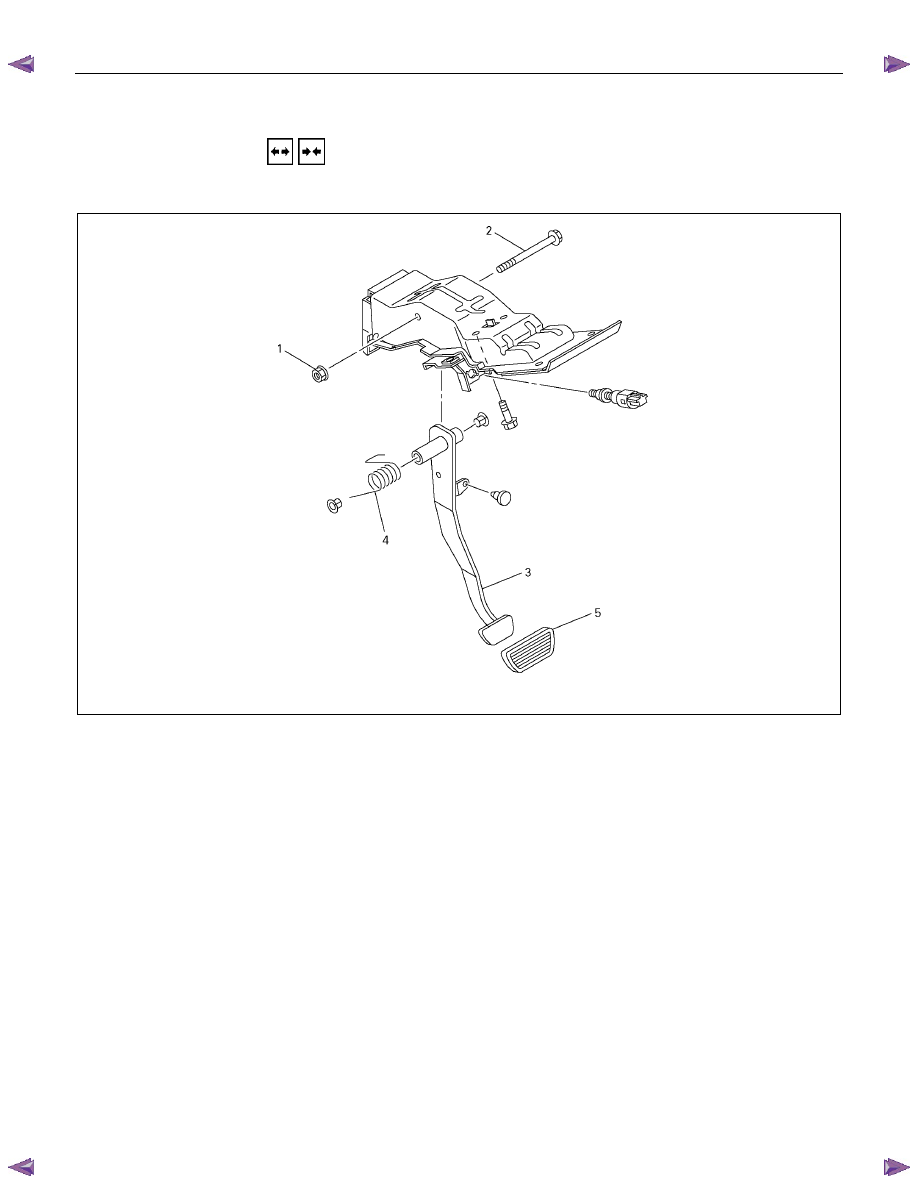

BRAKE CONTROL

REMOVAL AND INSTALLATION

BRAKE PEDAL ASSEMBLY

This illustration is based on the RHD model

310R300001

Removal Steps

1. Nut; Fulcrum pin

2. Pin; Fulcrum, pedal to bracket

3. Pedal arm

4. Return spring

5. Pedal pad

Installation steps

To install, follow the removal procedure in

reverse order.

Before installation, apply grease to the entire

circumference of the fulcrum pin (2).

Refer to “SERVICING” in this section for

adjustment procedure of brake pedal.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст