Isuzu KB P190. Manual — part 898

Charging System – V6

Page 6D1-1-5

•

Death or injury to other people in or near the workplace area, and / or

•

Death or injury to the driver / or passenger(s) of the vehicle or other people, if the vehicle has been improperly

repaired.

CAUTION defined

A CAUTION statement immediately precedes an operating procedure or maintenance practice which, if not correctly

followed, could result in damage to or destruction of equipment, or corruption of data. If a CAUTION statement is

ignored, the following consequences may occur:

•

Damage to the vehicle,

•

Unnecessary vehicle repairs or component replacement,

•

Faulty operation or performance of any system or component being repaired,

•

Damage to any system or components which depend on the proper operation of the system or component being

repaired,

•

Faulty operation or performance of any systems or components which depend on the proper operation or

performance of the system or component under repair,

•

Damage to fasteners, basic tools or special tools and / or

•

Leakage of coolant, lubricant or other vital fluids.

NOTE defined

A NOTE statement immediately precedes or follows an operating procedure, maintenance practice or condition that

requires highlighting. A NOTE statement also emphasises necessary characteristics of a diagnostic or repair procedure.

A NOTE statement is designed to:

•

Clarify a procedure,

•

Present additional information for accomplishing a procedure,

•

Give insight into the reasons for performing a procedure in the recommended manner, and / or

•

Present information that gives the technician the benefit of past experience in accomplishing a procedure with

greater ease.

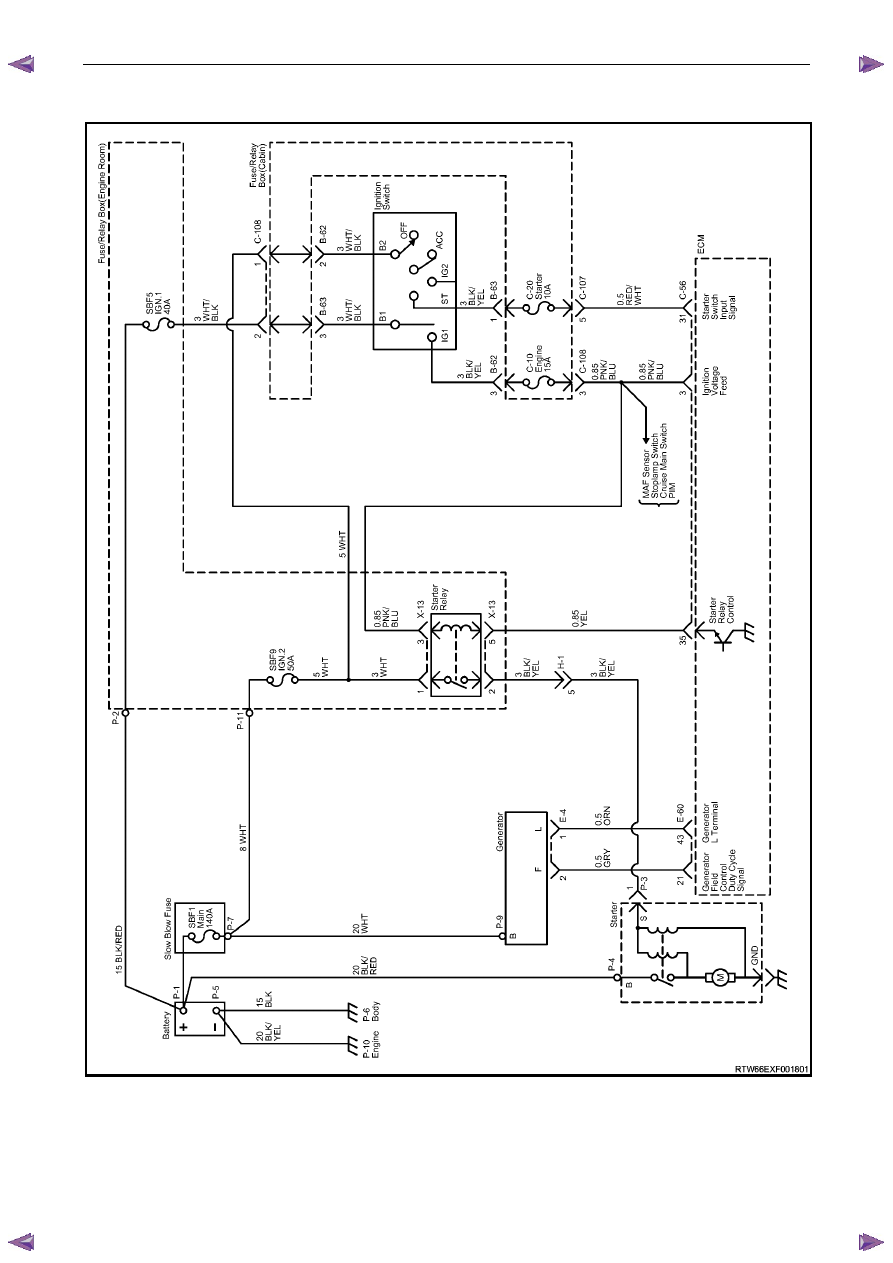

1.3 System

Operation

Operation

With the ignition switch in the ON position and the engine at rest, current is supplied via the regulator to generator

connector E-4 pin 1 and to the engine control module ECM connector E-60 pin 43. This initiates current flow (within the

regulator) from the generator connection P-9, to the brushes and rotor winding, to ‘excite’ the circuit.

The current in the rotor winding creates magnetic fields between adjacent rotor poles.

With the engine running, the rotor spins, the stator windings cut through this field and induce voltage. As the engine

speed is increased, this induced voltage increases. Current then flows through the three-phase diode bridge in the

rectifier to convert the AC voltage to DC. This is supplied to the generator connector P-9 output and then to the battery

terminal via fuse SBF1.

The regulator monitors the voltage to the battery. When this voltage reaches approximately 14.5 V, the regulator opens

the circuit through the rotor winding, causing the generator output voltage to drop. When the regulator senses a voltage

below a preset voltage, the regulator closes the circuit through the rotor winding and voltage to the battery again

increases. This cycle repeats very rapidly.

Charging System – V6

Page 6D1-1-6

Alternator Warning

N O T E

All generator faults are displayed as

Check Alternator Warning on the instrument

cluster MFD, refer to 8A Electrical Body and

Chassis.

The ECM monitors the voltage on connector E-60 pin 21 and pin 43.

The voltage at the generator connector E-4 pin 2 will remain low when a fault condition is detected in the generator or

associated external circuits. The voltage remains low (while the ignition switch is on) until the fault is repaired.

N O T E

For more information on the alternator warning

refer to 8A Electrical Body and Chassis.

Fault conditions include the following:

•

open circuit or excessive voltage drop in circuit 1,

•

open circuit in the generator phase connection,

•

overcharging conditions,

•

short circuit in the regulator output stage,

•

open circuit in the rotor winding,

•

poor contact between the rectifier and the regulator, and / or

•

high resistance in the fusible link assembly.

Charging System – V6

Page 6D1-1-7

2 Diagnosis

2.1

Diagnostic General Information

Basic Diagnostic Tools Required

Use of incorrect electrical circuit diagnostic

tools when performing the generator

diagnostic procedures could result in

incorrect diagnostic results or damage to

components.

The following electrical circuit testing tools are required to perform the diagnostic procedures detailed in this Section:

•

digital multimeter with 10 mega ohms impedance, and

•

connector test adapter kit Tool No. KM609.

For further information on the use of these tools, refer to 8A Electrical Body and Chassis.

2.2

Tech 2 Data List

The Tech 2 displays the status of certain charging system parameters.

To view the data list:

1

Connect Tech 2 to the DLC.

2

On Tech 2 select:

Engine / V6 Engine / Data Display / Data List / Electrical/Theft Data.

Tech 2 Parameter

Units Displayed

Typical Display Values

Alternator L Terminal D

Percentage

Various

2.3

Diagnostic Systems Check

Step Action

Yes

No

1

1

Connect Tech 2 to the DLC.

2

Ignition ON, engine OFF.

3

On Tech 2 select:

Engine / V6 Engine / Diagnostic Trouble codes / Read

DTC’s.

Are there any set DTC’s?

Go to the

appropriate DTC

table in 6C1-2

Engine

Management – V6 –

Diagnostics.

Refer to 2.5

Charging

System Inoperative

/ Malfunctioning

Reference to following information will assist when diagnosing charging circuit faults:

•

for battery testing, refer to 6D1-3 Battery – V6,

•

for wiring diagram details, refer to Figure 6D1-1 2, and

•

for electrical component locations, refer to 8A Electrical Body and Chassis.

Charging System – V6

Page 6D1-1-8

2.4 Wiring

Diagram

Figure 6D1-1 2

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст