Isuzu KB P190. Manual — part 665

Engine Mechanical – V6

Page 6A1–181

3.23 Engine Mounts and Brackets

Remove

1

Remove the exhaust manifold assembly from the side of the engine where the engine mount is to be removed,

refer to 3.11

Exhaust Manifold Assembly.

2

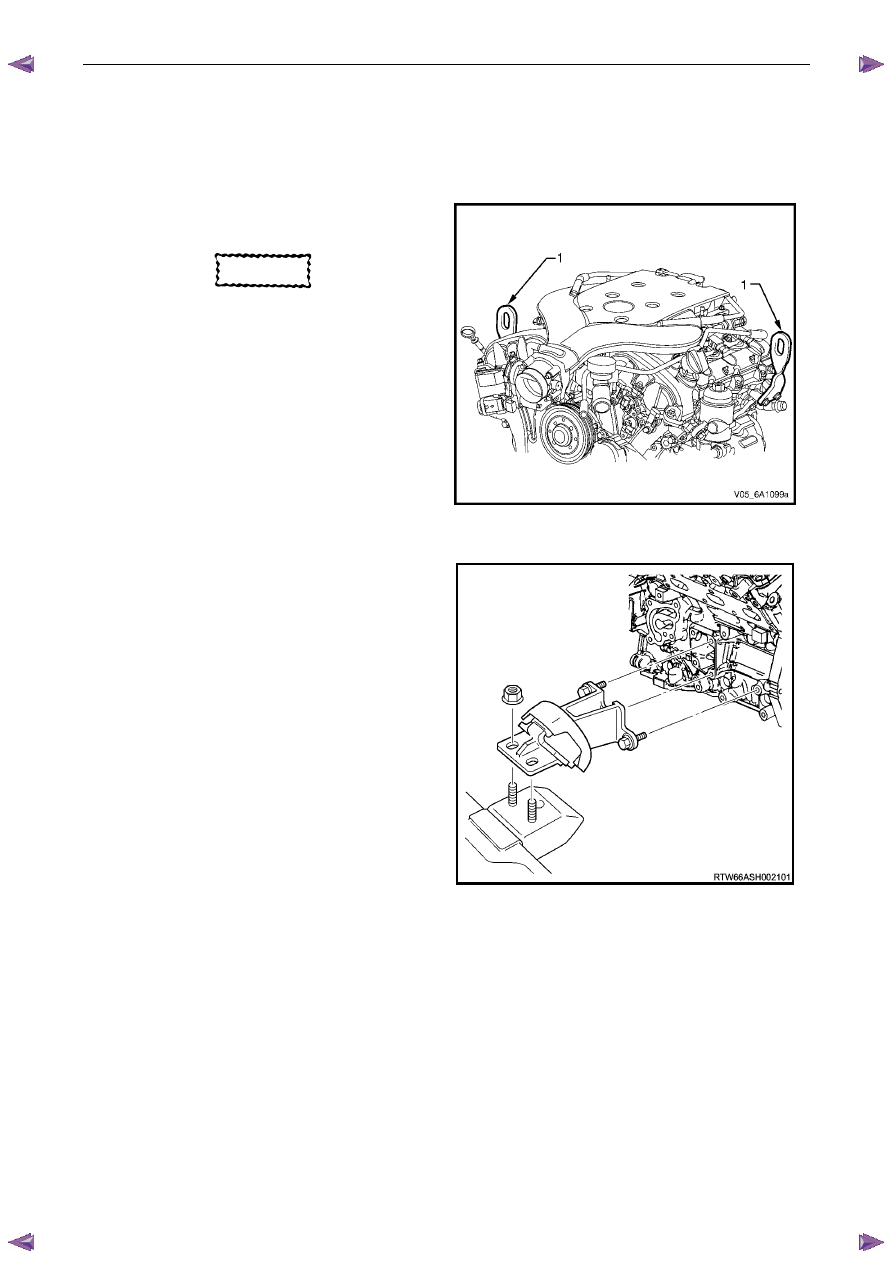

Fit the engine lift brackets, Tool No. EN-46114 (1) to

the cylinder heads.

CAUTION

Only lift the engine far enough to take the

weight off the engine mount, or damage to

the mount and lifting equipment failure may

occur.

3

Using an engine lifting crane, raise the side of the

engine where the mount is to be removed enough to

remove the weight from the engine mounts, and

create a slight tension in the lifting equipment.

Figure 6A1 – 314

4

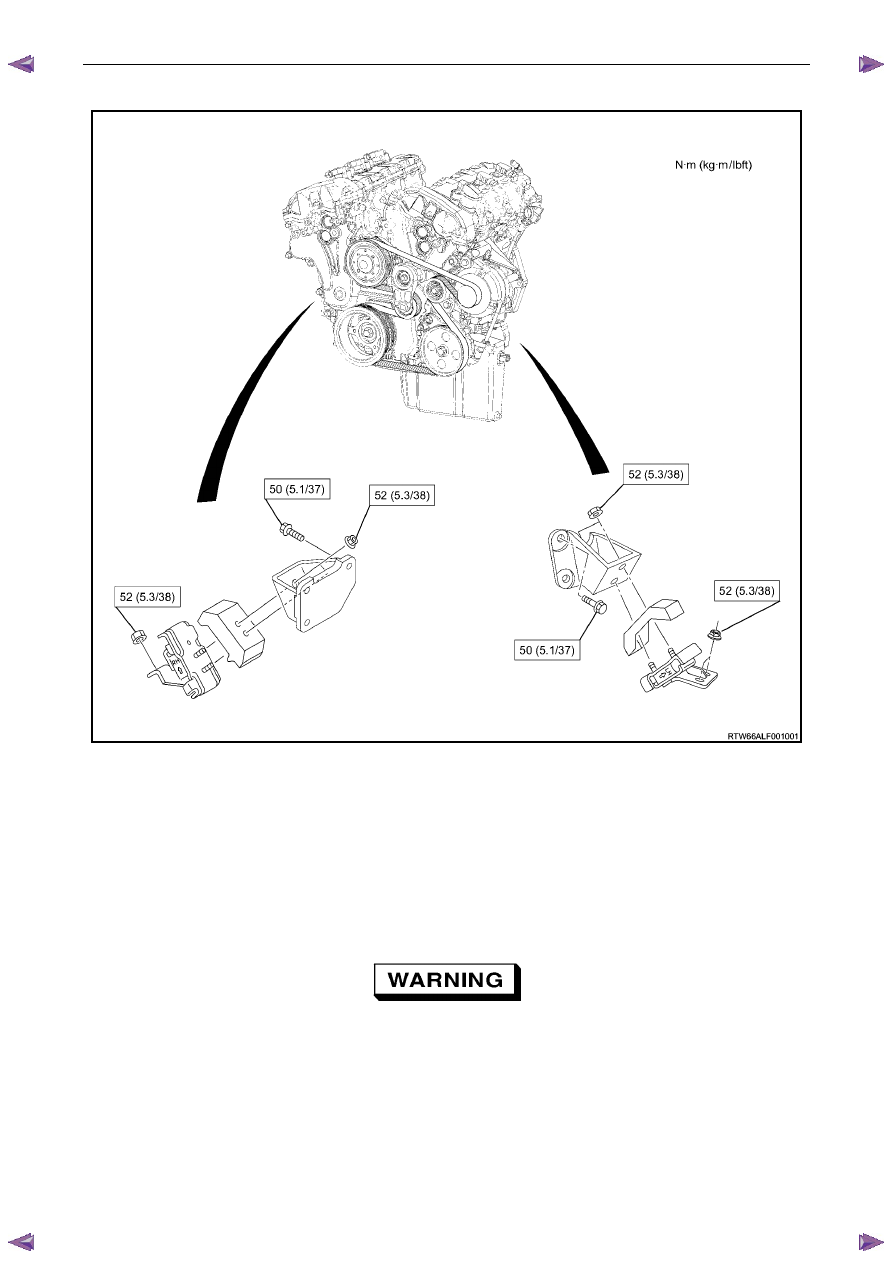

Remove the left-hand or right-hand side engine

mount and bracket as required.

Figure 6A1 – 315

Engine Mechanical – V6

Page 6A1–182

Engine Mount Location

Figure 6A1 – 316

Inspect

N O T E

Although the following procedure provides

information regarding on-vehicle engine mount

inspections, it is preferable to inspect the engine

mounts once removed from the vehicle.

1

Fit the engine lift brackets, Tool No. EN-4611 to the cylinder heads.

Only lift the engine enough to take the weight

off the engine mounts, or damage to the

mounts and lifting equipment failure may

occur.

2

Using a commercially available engine lifting crane, have an assistant raise the engine far enough to remove the

weight on the engine mounts and create a slight tension in the rubber.

3

Observe the engine mount while raising the engine.

4

Replace the engine mount if any of the following conditions are found:

Engine Mechanical – V6

Page 6A1–183

•

The hard rubber surface is covered with heat check cracks,

•

The rubber is split through the centre of the engine mount, or

•

The rubber is separated from the metal plate portion of the engine mount.

5

Remove the engine lift brackets, Tool No. EN-46114 from the engine.

Reinstall

The reinstallation procedure for the engine mounts is the reverse of the removal procedure, noting the following:

Ensure all fasteners are tightened to the correct torque specification.

Engine mount bracket to

cylinder block attaching bolt

torque specification

. . . . . . . . . . . . . . . . 43.0 – 57.0 Nm

Engine mount to bracket attaching nut

torque specification

. . . . . . . . . . . . . . . . 70.0 – 90.0 Nm

Engine mount to frame attaching nut

torque specification

. . . . . . . . . . . . . . . . 44.0 – 60.0 Nm

Engine Mechanical – V6

Page 6A1–184

4

Major Service Operations

A T T E N T I O N

The V6 engine is a combination of numerous components, containing machined, honed, polished and lapped

surfaces manufactured on the latest, high technology production equipment. Many of the components

contain tolerances measured in thousandths of a millimetre. Consequently, when any engine component is to

be serviced, care and cleanliness are extremely important.

Prior to re-assembly of the V6 engine, all components must be cleaned and inspected in accordance with the

relevant procedures throughout this section, and replaced or repaired where required.

In addition to cleaning and inspecting components, a liberal coating of engine oil should be applied to friction

surfaces during assembly to protect and lubricate the surfaces on initial operation.

When performing any service operation contained in this Section, it should be understood that correct

cleaning and protection of machined surfaces and friction areas is part of the repair procedure. This is

considered standard workshop practice, even if not specifically stated. Torque values must be used as

specified during reassembly to ensure correct retention of all components.

Through out this section, fastener torque wrench specifications may be accompanied with the following

identification marks:

■

Fasteners must be replaced after loosening.

Fasteners either have micro encapsulated sealant applied or incorporate a mechanical thread lock and

should only be re-used once. If in doubt, replacement is recommended.

If one of these identification marks is present alongside a fastener torque wrench specification, the

recommendation regarding that fastener must be adhered to.

4.1 Engine

Removal

CAUTION

• Allow the engine to cool to at least 50°°°° C,

before attempting fastener removal.

• As aluminium has a greater rate of thermal

expansion than that of cast iron,

aluminium bolt hole threads will change

dimension to a larger extent than cast iron

bolt threads.

• If a bolt or other threaded component is

removed before the engine is allowed to

cool to at least 50

°°°° C, threads could be

pulled from the cylinder block or cylinder

head.

• Do not use impact tools to remove bolts

during engine disassembly. While this may

be common practice with cast iron engine

components, use of these tools is likely to

pull the aluminium threads in the cylinder

block or head of this engine.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст