Isuzu KB P190. Manual — part 664

Engine Mechanical – V6

Page 6A1–177

11

Place the collets into position by pushing the tool (1)

downward and releasing tension on the valve spring

compressor (2).

12

Verify the valve collets are installed by placing a rag

over the valve tip and tapping with a dead-blow

hammer. The valve collets and the spring should

remain in place.

Figure 6A1 – 305

Reinstall

Right-hand Side (Bank 1) Cylinder Head

The reinstallation procedure for the right-hand side cylinder head assembly is the reverse of the removal procedure,

noting the following:

1

Ensure all fasteners are tightened to the correct torque specification.

2

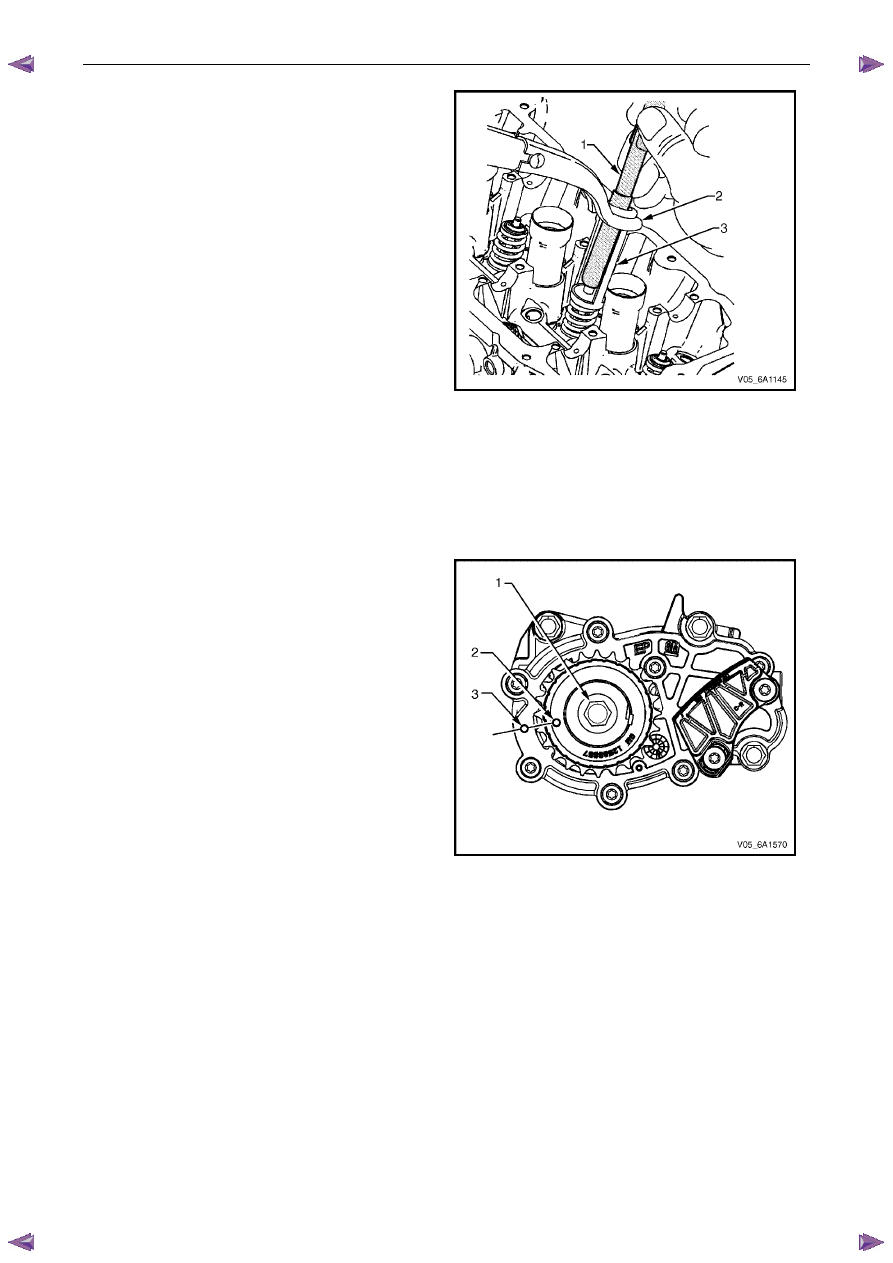

Using crankshaft rotation Tool No. EN-46111 (1),

align the crankshaft sprocket timing mark (2) with the

indexing mark (3) on the oil pump housing.

Figure 6A1 – 306

Engine Mechanical – V6

Page 6A1–178

3

Ensure the deck face is clean and the cylinder head

locating pins are securely mounted in the cylinder

block deck face.

4

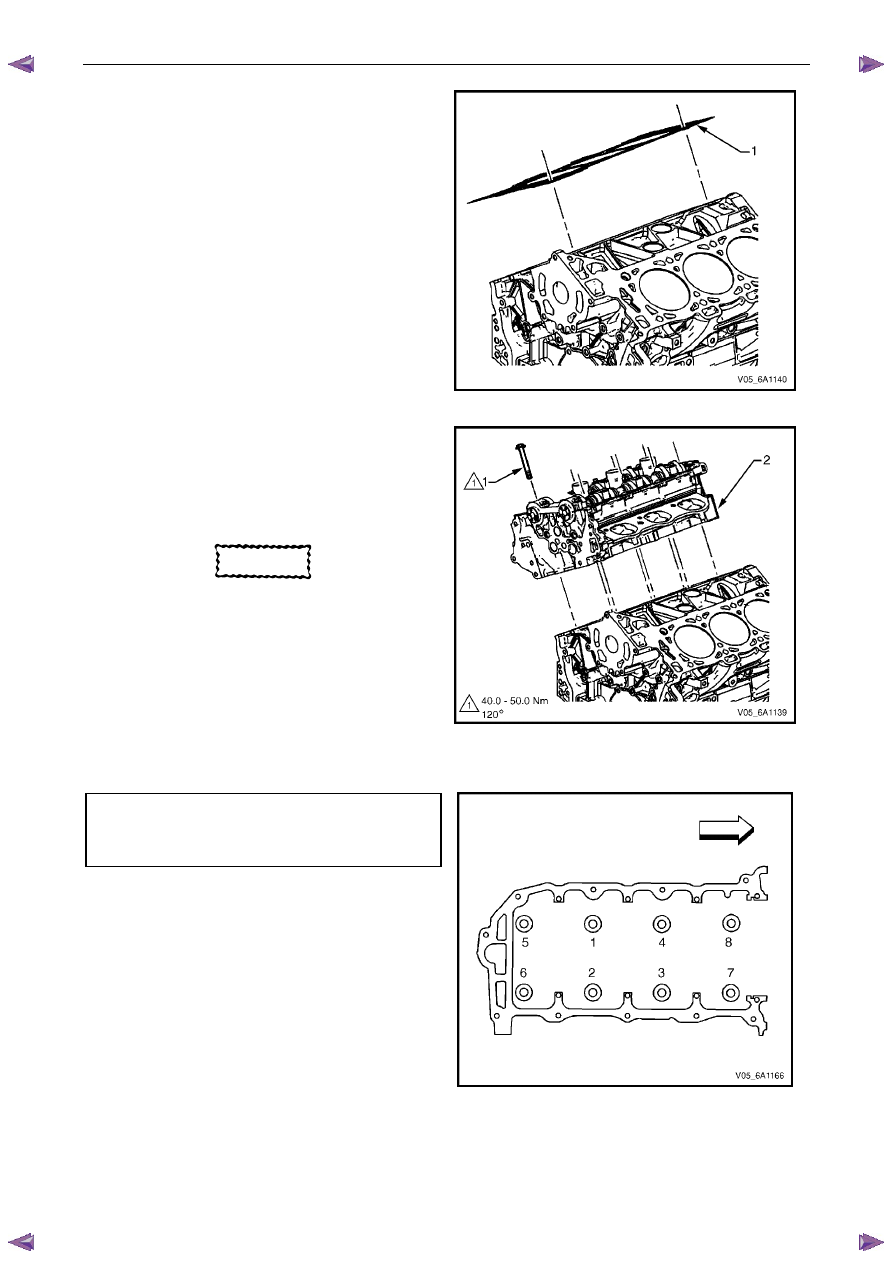

Install a new right-hand cylinder head gasket (1)

using the deck face locating pins for retention.

Figure 6A1 – 307

5

Align the cylinder head with the locating pins.

6

Place the cylinder head in position on the deck face.

N O T E

Do not allow oil on the cylinder head bolt

bosses.

CAUTION

Do not reuse the old M11 cylinder head bolts

(1 to 8 inclusive).

7

Install new M11 cylinder head bolts (1) eight places

and tighten in the sequence shown and to the correct

torque specification.

Figure 6A1 – 308

Cylinder head M11 attaching bolt

torque specification:

Stage 1: . . . .40.0 – 50.0 Nm

Stage

2: . . . . . . . ..120°

Figure 6A1 – 309

Left-hand Side (Bank 2) Cylinder Head

The reinstallation procedure for the left-hand side cylinder head assembly is the reverse of the removal procedure, noting

the following:

Engine Mechanical – V6

Page 6A1–179

1

Ensure all fasteners are tightened to the correct torque specification.

2

Using crankshaft rotation Tool No. EN-46111 (1),

align the crankshaft sprocket timing mark (2) with the

indexing mark (3) on the oil pump housing.

Figure 6A1 – 310

3

Ensure the deck face is clean and the cylinder head

locating pins are securely mounted in the cylinder

block deck face.

4

Install a new cylinder head gasket (1) using the deck

face locating pins for retention.

Figure 6A1 – 311

5

Align the cylinder head with the locating pins.

6

Place the cylinder head in position on the deck face.

N O T E

Do not allow oil on the cylinder head bolt

bosses.

CAUTION

Do not reuse the old M11 cylinder head bolts

(1 to 8 inclusive).

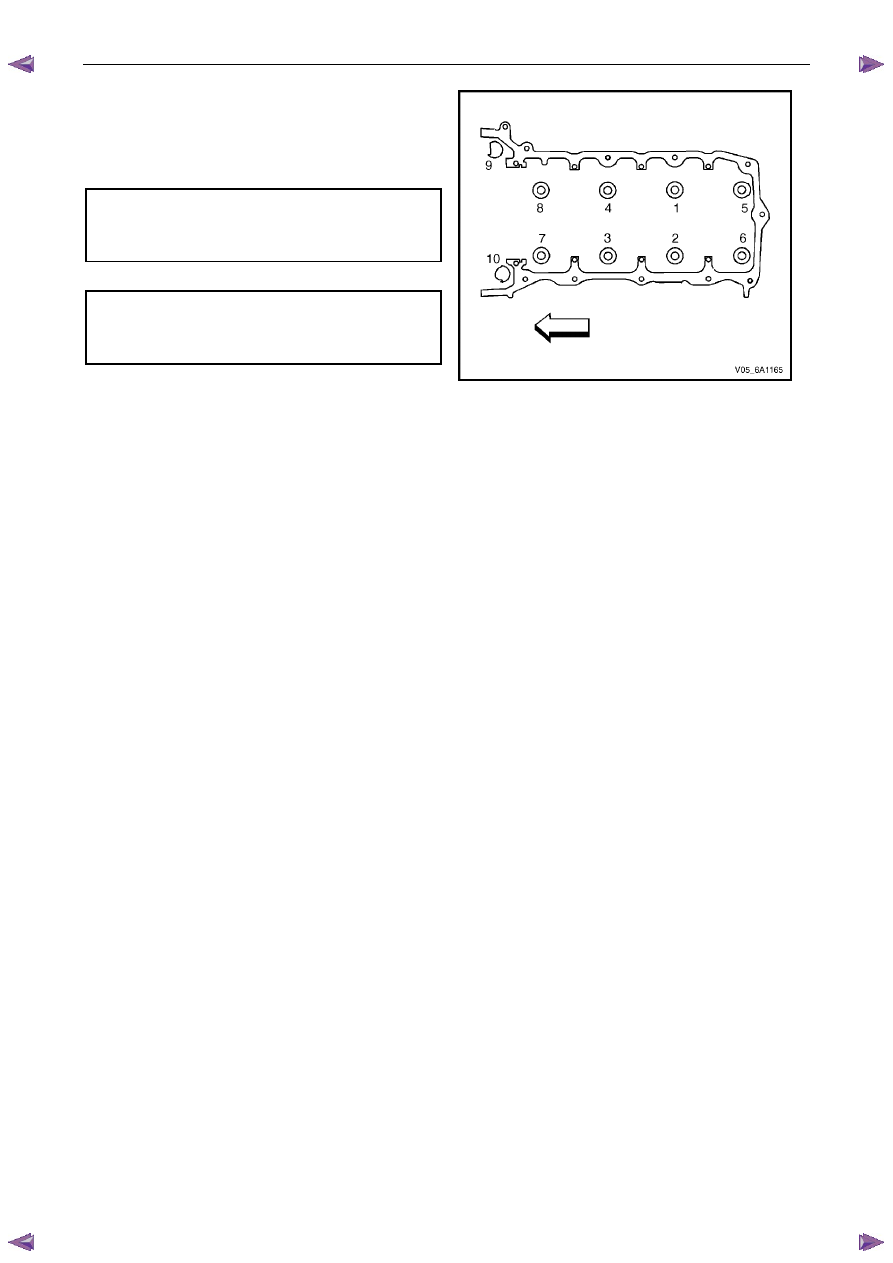

7

Install new M11 cylinder head bolt (1), eight places,

and tighten in the sequence shown and to the correct

torque specification.

Figure 6A1 – 312

Engine Mechanical – V6

Page 6A1–180

8

Install the front M8 cylinder head bolt (2), two places,

and tighten in the sequence (9 and 10) and to the

correct torque.

Cylinder head M11 attaching bolt

torque specification:

Stage 1: . . . .40.0 – 50.0 Nm

Stage

2: . . . . . . . ..120°

M8 cylinder head bolt

torque specification

Stage 1: . . . .12.0 – 18.0 Nm

Stage

2: . . . . . . . . 60°

Figure 6A1 – 313

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст