Isuzu KB P190. Manual — part 197

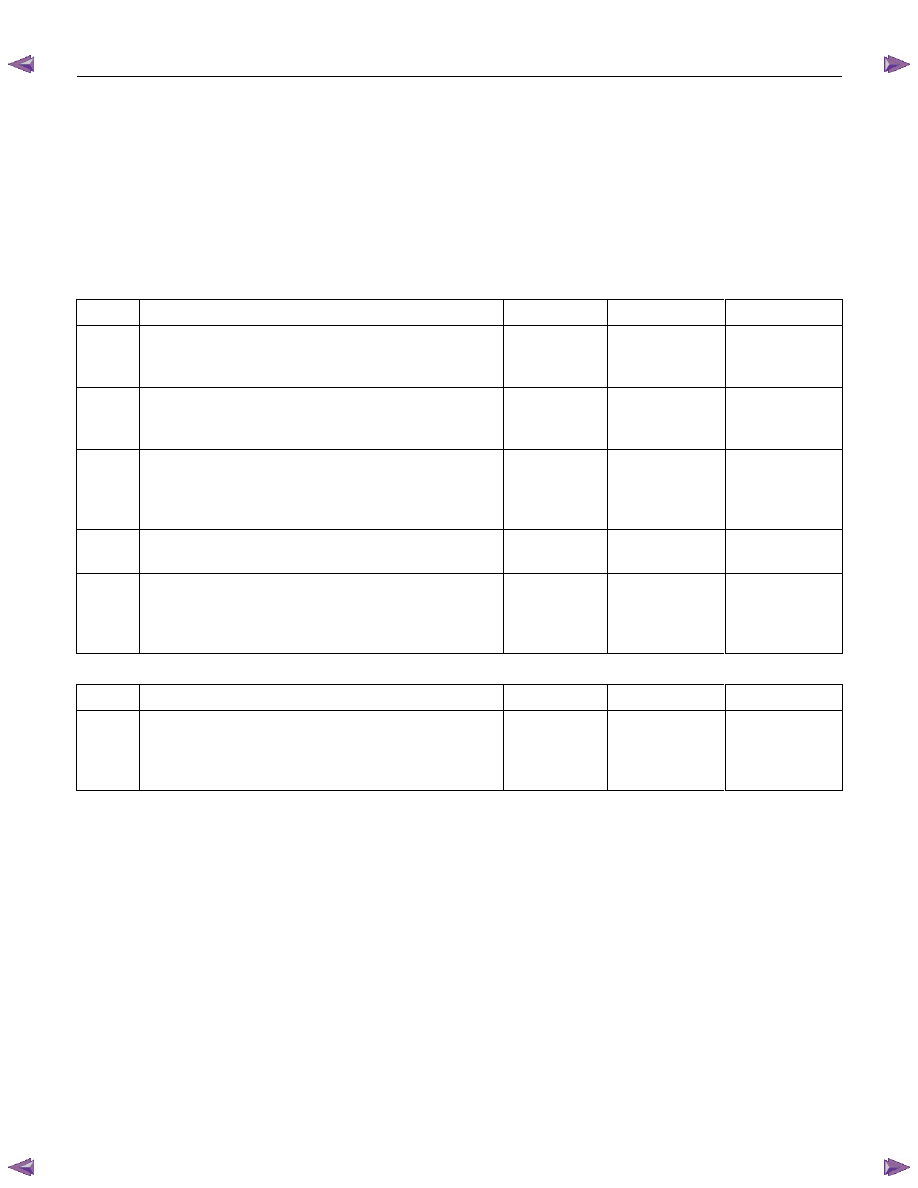

TROUBLESHOOTING 6 – 3

1. Hard Starting

Inspect the following items before diagnosis.

1. The battery conditions.

The terminal connection condition.

The battery charge condition or battery power weakness.

2. The fan belt loosen or broken.

3. The main fuse condition (open or not).

4. Fuel quantity level.

1

–

1 Starter motor inoperative

Step Action Value(s)

Yes

No

1

Check the starter switch.

Does the starter switch work?

—

Go to Step 2

Repair or

replace the

starter switch

2

Check the starter relay.

Does the starter relay work?

—

Go to Step 3

Repair or

replace the

starter relay

3

Check the magnetic switch.

Does the magnetic switch work?

—

Go to Step 4

Repair or

replace the

magnetic

switch

4

Check the pinion gear condition on the starter motor.

Was the condition normal?

—

Go to Step 5

Replace the

pinion gear

5

Check the brush wear or brush spring weakness.

Was the condition normal?

—

Replace the

starter motor

assembly

Repair or

replace the

brush or brush

spring

1-2 Starter motor operates but engine does not turn over

Step Action Value(s)

Yes

No

1

Check the engine internal seizure.

Was the engine seized?

—

Repair or

replace seized

parts

Check other

DTC by Tech

2 and go to

indicated DTC

6 – 4 TROUBLESHOOTING

1-3 Engine turn over but does not start engine

Incase of the fuel not being delivered to the injection pump

Step Action Value(s)

Yes

No

1

Check clogged, damaged the fuel piping or the

connector loosen.

Was any problem found?

—

Repair replace

problem parts.

Go to Step 2

2

Was the over flow valve on the fuel filter closed?

—

Repair

replace

the over flow

valve Go

to

Step 3

3

Was the fuel filter element clogged?

—

Replace

the

fuel filter

element Go

to

Step 4

4

Was the fuel line air bled?

—

Go

to

Step 5

Bleed the air

5

Are any DTC stored?

—

Go

to

indicated

DTC Solved

Incase of the fuel is being delivered to the injection pump

Step Action Value(s)

Yes

No

1

Was the water contain in the fuel?

—

Replace

the

fuel Go

to

Step 2

2

Was the fuel line air bled?

—

Go

to

Step 5

Bleed the air

3

Was the injection spray condition complete?

—

Go to Step 4

Replace the

injection nozzle

4

Was the injection nozzle injection starting pressure

OK?

(See below)

Go to Step 5

Replace the

injection nozzle

5

Was the injection nozzle sticking?

—

Replace

the

injection nozzle

Go to Step 6

6

Are any DTC stored?

—

Go

to

indicated

DTC Solved

Injection nozzle opening pressure

1st = 19.5 MPa (199 kg/cm

2

, 2828 psi)

TROUBLESHOOTING 6 – 5

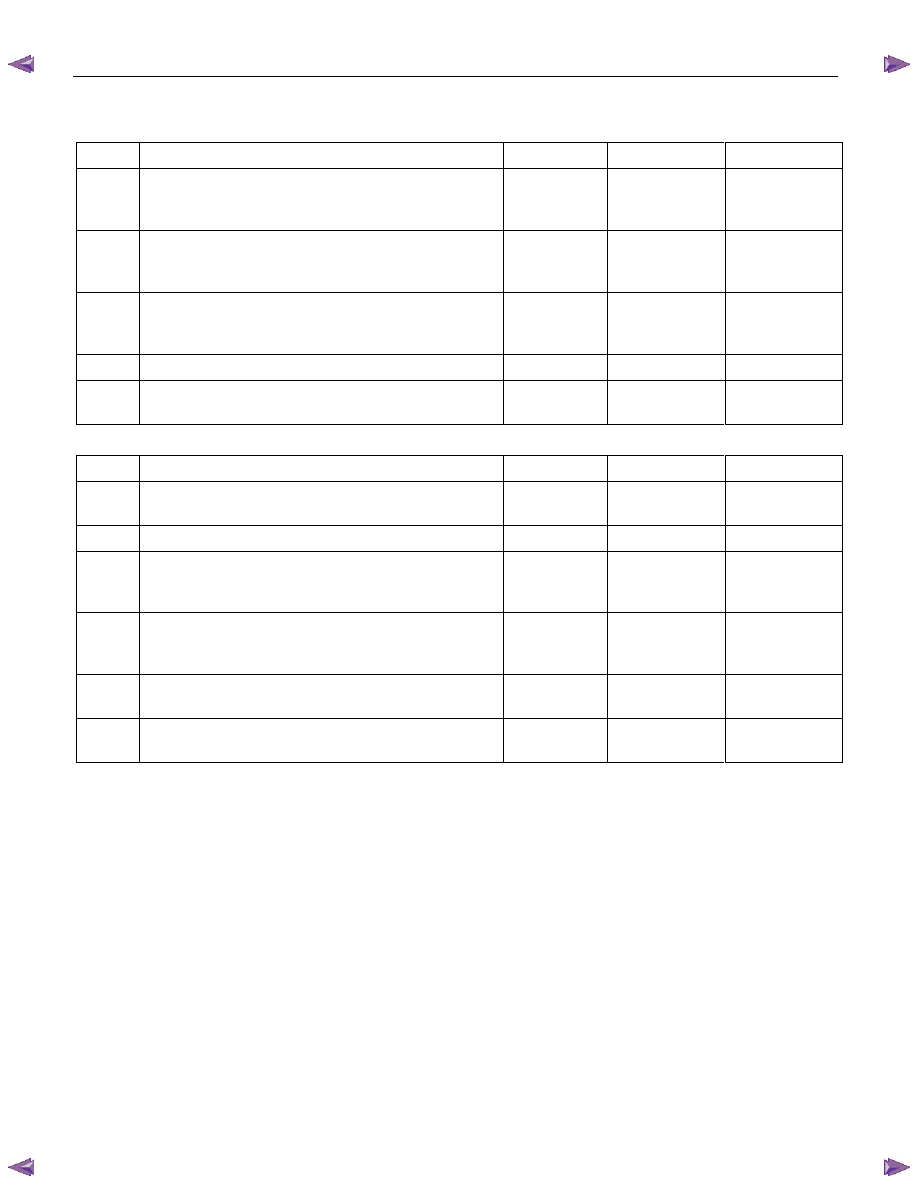

2. Unstable Idling

Step Action Value(s)

Yes

No

1

Was the fuel line air bled completely?

—

Go

to

Step 3

Bleed the air

2

Was the fuel line leakage or blockage found?

—

Repair

or

replace relation

parts. Go

to

Step 4

3

Was the water contained in the fuel?

—

Replace

the

fuel Go

to

Step 5

4

Was the fuel filter element clogged?

—

Replace

the

fuel filter

element Go

to

Step 6

5

Was the injection starting pressure or the injection

spray condition OK?

(See below)

Go to Step 7

Replace the

injection nozzle

6

Was the injection nozzle sticking?

See Step 6 Replace

the

injection nozzle

Go to Step 8

7

Check the throttle valve condition.

Was the idling port clogged in the throttle valve?

—

Repair

or

replace the

throttle valve

Go to Step 9

8

Was the valve clearance improper adjusted?

0.4 mm

(0.016 in)

both intake

and exhaust

valves

Adjust the

valve clearance

Go to Step 10

9

Was the compression pressure OK?

3,040 kPa

(31 kg/cm

2

,

441 psi) at

200rpm

Go to Step 11

Readjust the

valve clearance

or replace the

cylinder head

gasket or

cylinder liner or

piston or piston

ring or valve

and valve seat

10

Are any DTC stored?

—

Go

to

indicated

DTC Solved

Injection nozzle opening pressure

1st = 19.5 MPa (199 kg/cm

2

, 2828 psi)

6 – 6 TROUBLESHOOTING

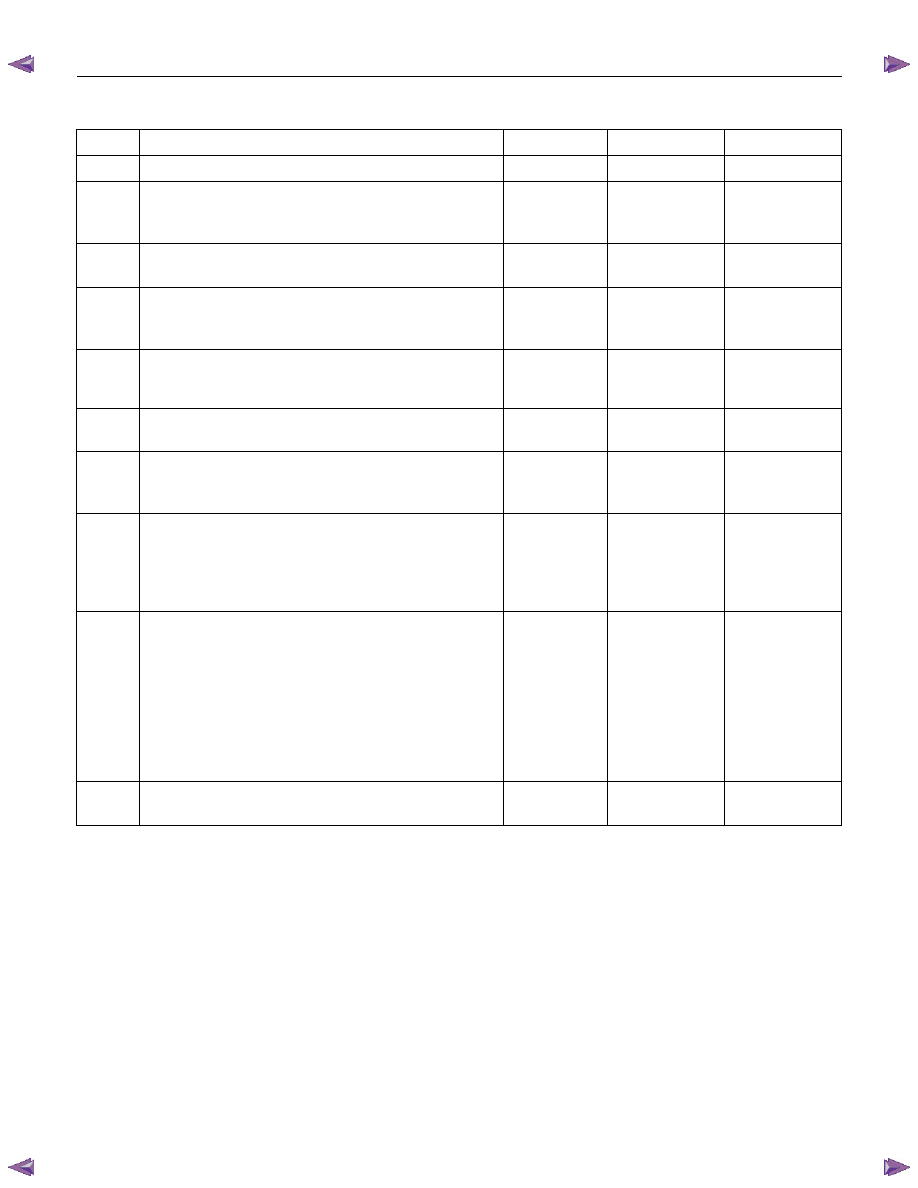

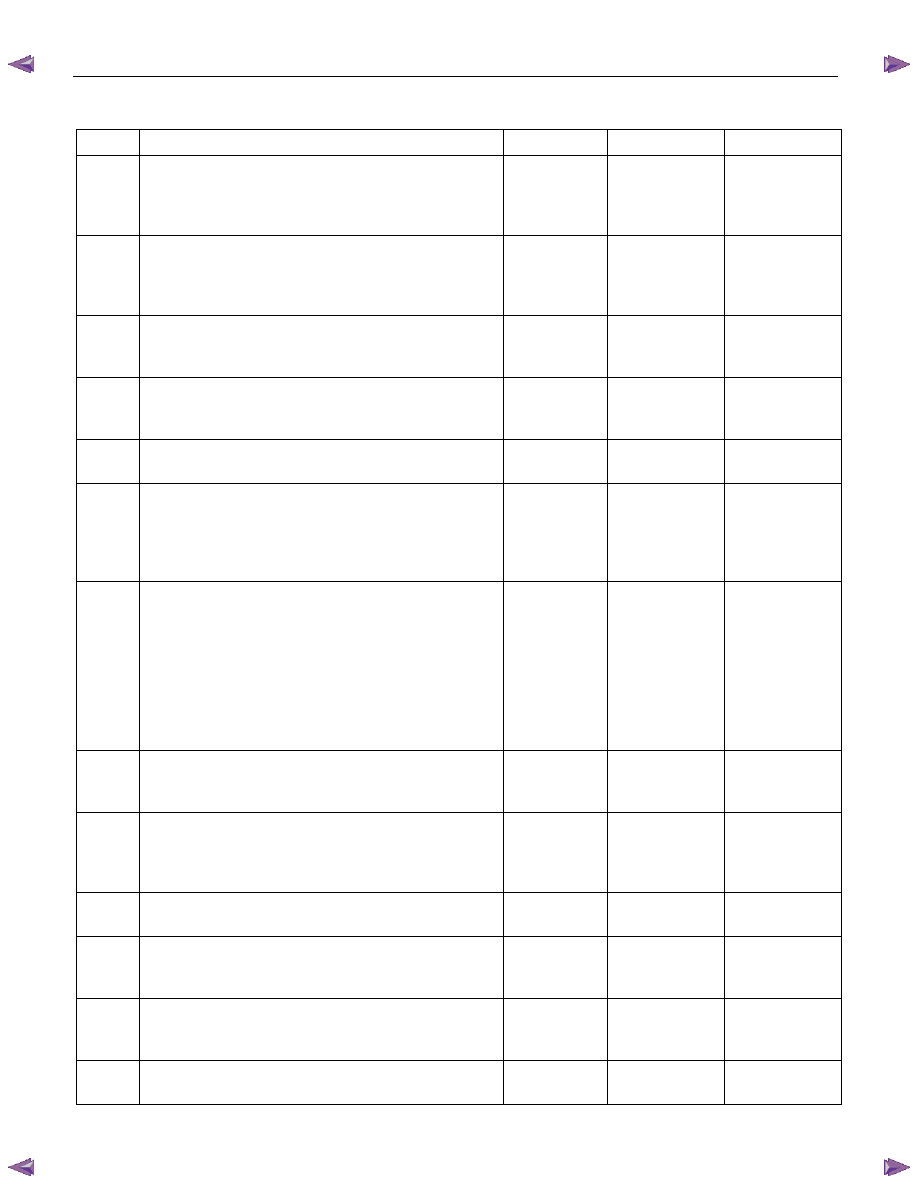

3. Insufficient Power

Step Action Value(s)

Yes

No

1

Was the air cleaner element condition OK? (Clogged

or not)

—

Go to Step 2

Clean or

replace the air

cleaner

element.

2

Was the intake air leakage found from intake

system?

—

Repair

or

replace the

intake air

system. Go

to

Step 3

3

Was the fuel filter element condition OK? (Clogged

or not)

—

Go to Step 4

Clean or

replace the fuel

filter element.

4

Check the fuel injection pipes.

Does the injection pipes have obstruction or any

damage?

—

Repair

or

replace the fuel

injection pipes.

Go to Step 5

5

Was the water contained in the fuel?

—

Replace

the

fuel Go

to

Step 6

6

Was the injection nozzle pressure or spray pattern

normal?

—

Go to Step 7

Readjust the

injection nozzle

pressure or

replace the

nozzle.

7

Was the compression pressure OK?

3.0 MPa

(31.0 kg/cm

2

,

441 psi) at

200 rpm

Go to Step 8

Readjust the

valve clearance

or replace the

cylinder head

gasket or

cylinder liner or

piston or piston

ring or valve

and valve seat

8

Was the exhaust pipe clogged?

—

Repair

or

replace the

exhaust pipe.

Go to Step 9

9

Was the exhaust gas leakage found from exhaust

system?

—

Repair

or

replace the

exhaust

system. Go

to

Step 10

10

Was the waste gate control actuator hose broken or

cracked?

—

Replace

the

hose. Go

to

Step 11

11

Was the waste gate working completely?

—

Go to Step 12

Replace the

turbocharger

assembly.

12

Was turbocharger working completely?

—

Go to Step 13

Replace the

turbocharger

assembly.

13

Are any DTC stored?

—

Go

to

indicated

DTC Solved

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст