Isuzu KB P190. Manual — part 659

Engine Mechanical – V6

Page 6A1–157

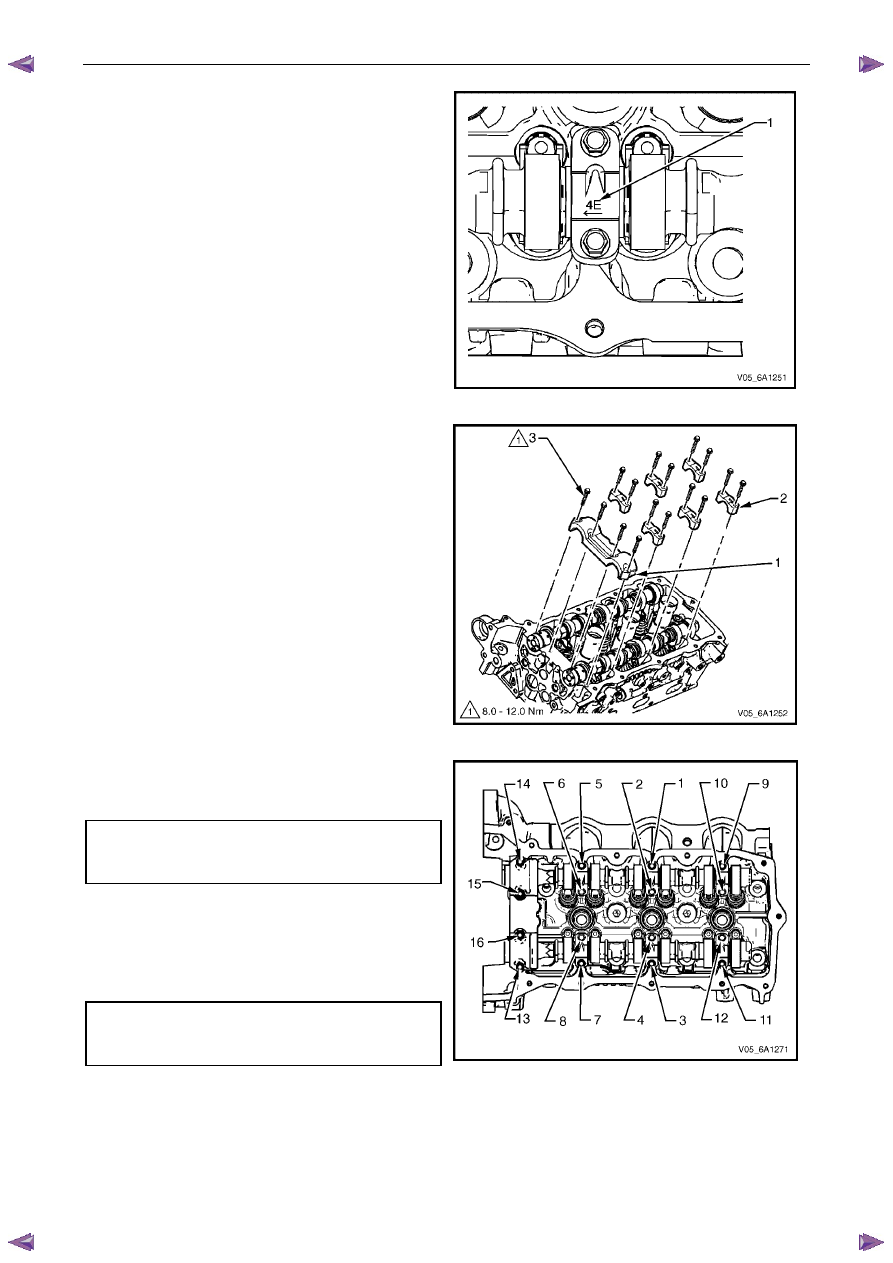

7

Observe the markings on the left-hand cylinder head

camshaft bearing caps. Each bearing cap is

marked (1) to identify its location. The markings have

the following meanings:

•

The raised feature must always be oriented

toward the centre of the cylinder head.

•

The I indicates the intake camshaft.

•

The E indicates the exhaust camshaft.

•

The number 2, 4, 6 indicates the cylinder

position from the front of the engine.

8

Apply a liberal amount of engine oil to the camshaft

bearing caps.

Figure 6A1 – 265

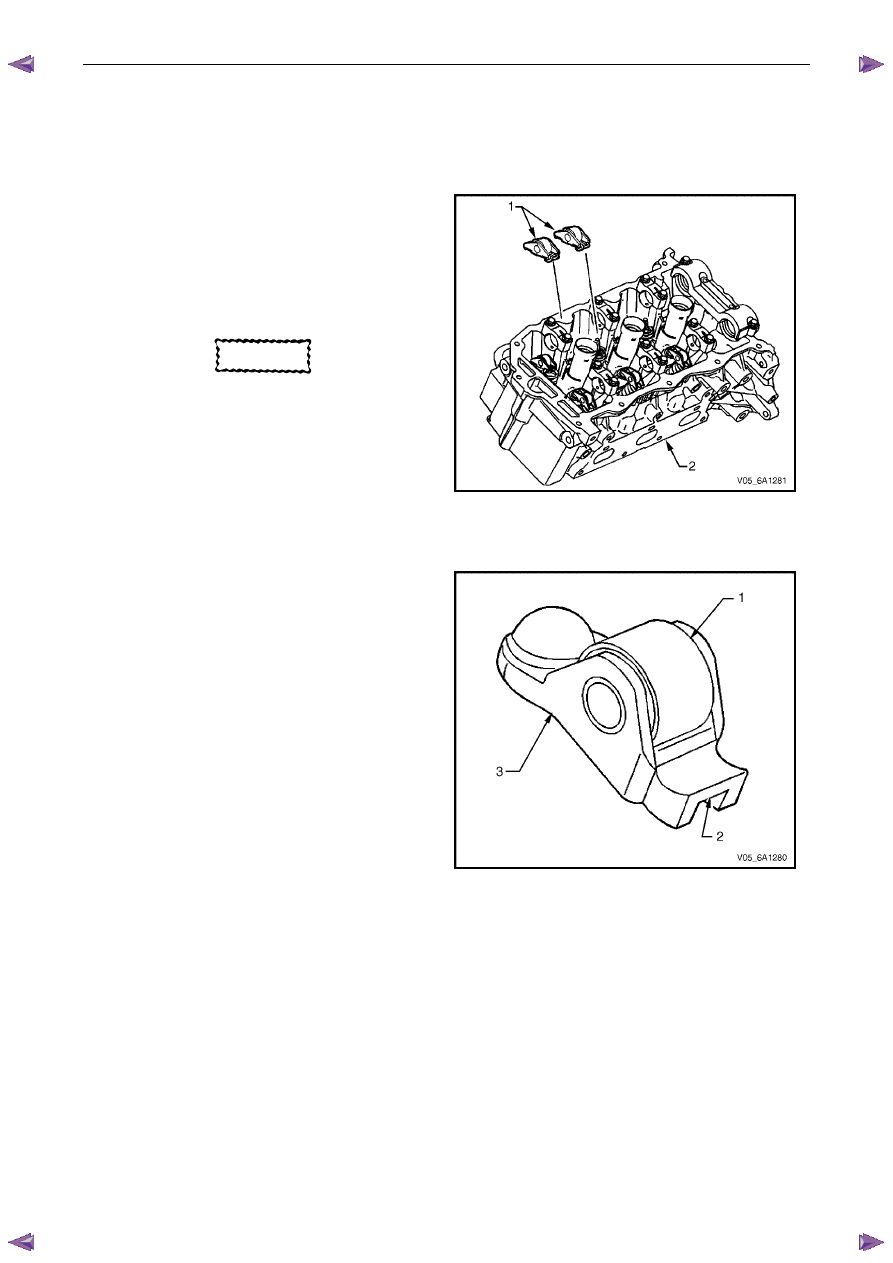

9

Install the camshaft bearing thrust cap (1) in the first

journal of the left-hand cylinder head.

10

Install the remaining bearing caps (2) with their

orientation mark toward the centre of the cylinder

head.

11

Hand start all the camshaft bearing cap bolts (3).

Figure 6A1 – 266

12

Tighten the camshaft bearing cap bolts to the correct

torque specification and in the sequence shown.

Camshaft bearing cap

bolt torque specification:

Stage 1:. . . . . . . . . . . . . .8.0 – 12.0 Nm

13

Loosen the centre intake camshaft bearing cap bolts

1, and 2, and the centre exhaust camshaft bearing

cap bolts 3 and 4.

14

Retighten the centre camshaft bearing cap bolts 1, 2,

3 and 4 to the correct torque specification.

Camshaft bearing cap

bolt torque specification:

Stage 2:. . . . . . . . . . . . . .8.0 – 12.0 Nm

Figure 6A1 – 267

Engine Mechanical – V6

Page 6A1–158

3.20 Rocker

Arm

Remove

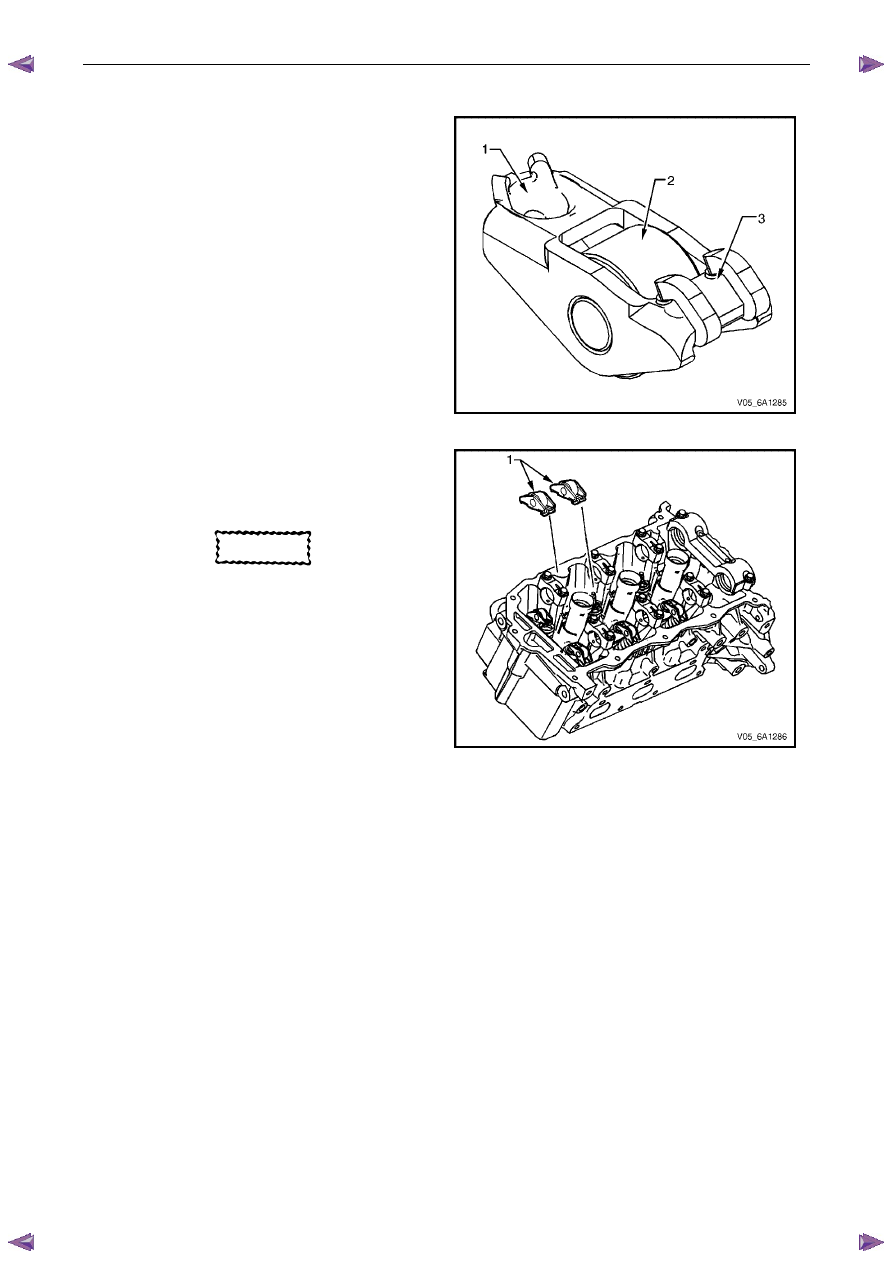

1

Remove the camshafts from the appropriate cylinder head, refer to 3.19

Camshaft.

2

Remove the rocker arm (1) from the cylinder head (2).

N O T E

Record the rocker arm positions during removal.

CAUTION

If the rocker arms are being reused, they

must be reinstalled in their original location.

Figure 6A1 – 268

Clean and Inspect

1

Inspect the rocker arm roller (1) for the following:

•

flat spots,

•

excessive scoring and pitting, and

•

ensure the roller spins freely

2

Inspect the rocker arm valve tip area (2).

3

Inspect the rocker arm stationary hydraulic lash

adjuster (SHLA) pivot area (3).

4

Replace the rocker arm as required.

Figure 6A1 – 269

Engine Mechanical – V6

Page 6A1–159

Reinstall

1

Apply a liberal amount of commercially available

camshaft / lifter prelube or equivalent to the pivot

pocket (1), roller (2) and valve slot (3) areas of the

camshaft followers.

Figure 6A1 – 270

2

Place the rocker arm in position on the valve tip and

stationary hydraulic lash adjuster (SHLA). The

rounded head end of the arm seats on the SHLA

while the flat end seats on the valve tip.

CAUTION

• The rocker arm (1) must be positioned

squarely on the valve tip so the full width

of the roller will completely contact the

camshaft lobe.

• If the rocker arms are being reused, they

must be reinstalled in their original

location.

3

Clean the camshaft journals and carriers with a clean,

lint-free cloth.

4

Reinstall the camshafts, refer to 3.19 Camshaft.

Figure 6A1 – 271

Engine Mechanical – V6

Page 6A1–160

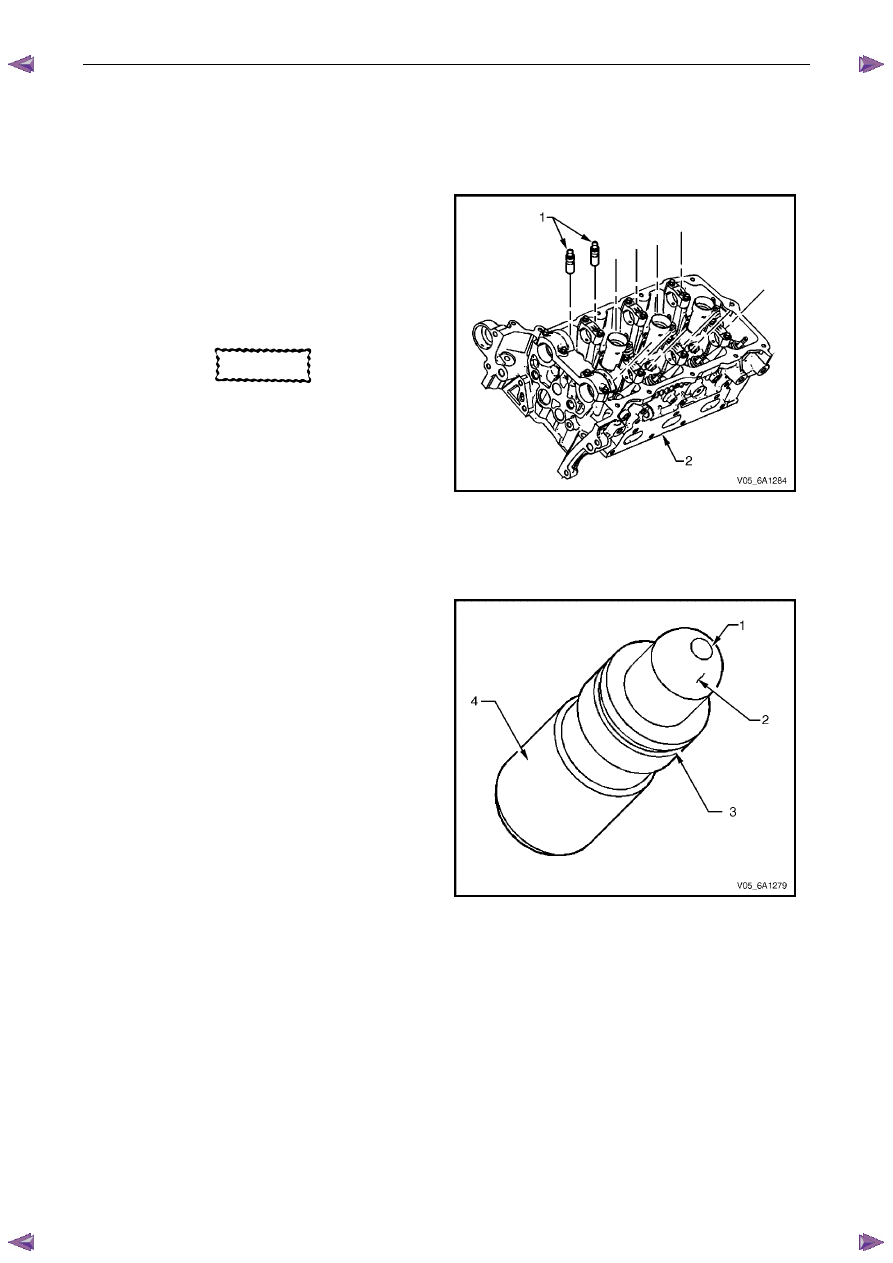

3.21 Stationary Hydraulic Lash Adjuster

Remove

1

Remove the rocker arms from the appropriate

cylinder head, refer to 3.20

Rocker Arm.

2

Remove the stationary hydraulic lash adjuster (SHLA)

from the cylinder head (2).

CAUTION

• Do not stroke/cycle the stationary

hydraulic lash adjuster (1) plunger

without oil in the lower pressure

chamber.

• Do not allow the stationary hydraulic lash

adjuster to tip over, plunger down, after

the oil fill.

Figure 6A1 – 272

Clean and Inspect

1

Inspect the stationary hydraulic lash adjuster (SHLA)

in the following areas:

•

a plugged oil passage (1),

•

a scored or worn camshaft follower pivot

area (2),

•

a damaged or broken retainer (3), and

•

a severely scuffed or worn SHLA body (4).

2

Replace the SHLA as required.

Figure 6A1 – 273

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст