Isuzu KB P190. Manual — part 660

Engine Mechanical – V6

Page 6A1–161

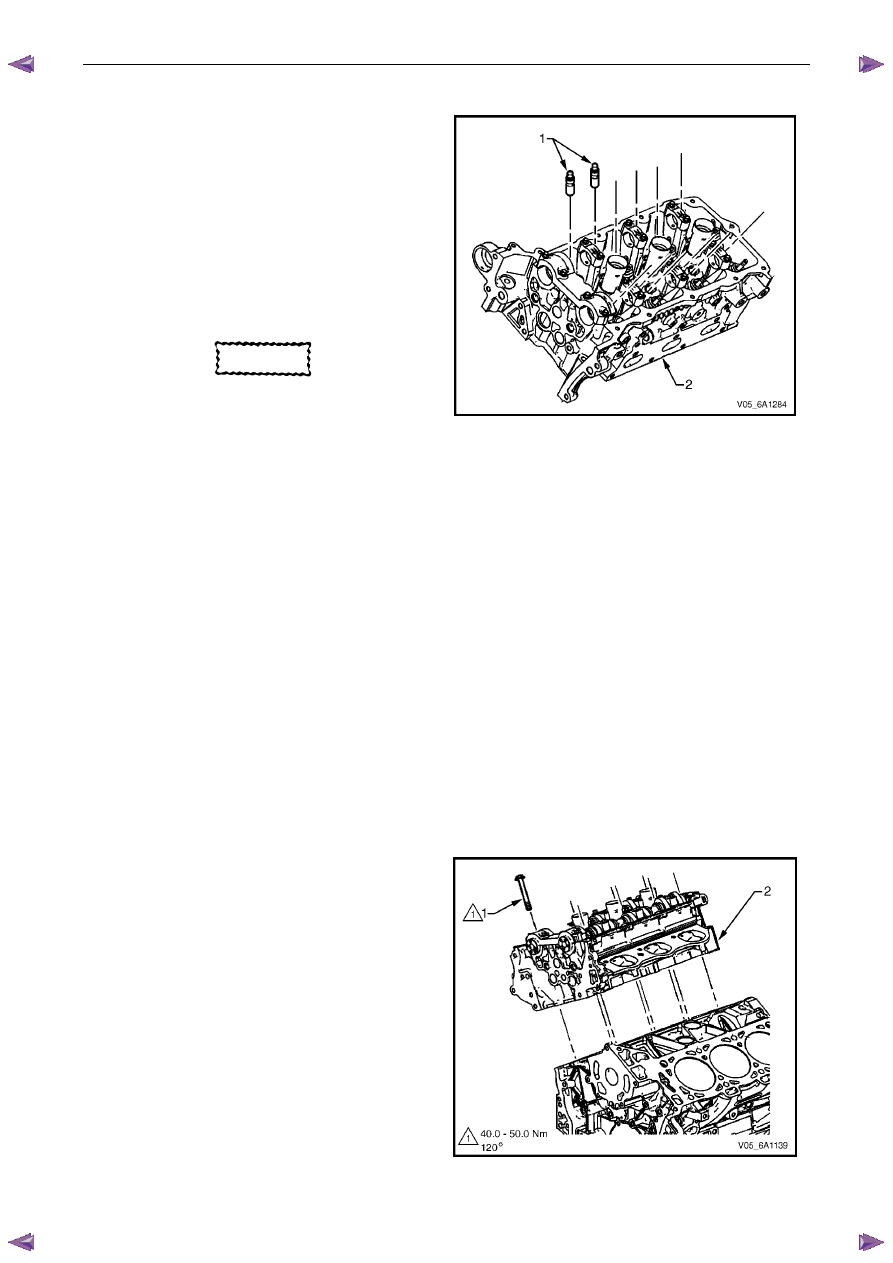

Reinstall

1

Fill the stationary hydraulic lash adjuster (SHLA) with

clean engine oil. Take precautions to prevent

scratching the pivot sphere area of the SHLA.

2

Lubricate the SHLA bores in the cylinder head with

clean engine oil.

3

Install the SHLA in the cylinder head (2).

4

Apply a liberal amount of commercially available

camshaft/lifter prelube to the SHLA pivot spheres.

5

Install the rocker arms, refer to 3.20

Rocker Arm.

CAUTION

Ensure each lash adjuster (1) is filled with

clean engine oil and the adjuster does not

tip over, plunger down, before the

installation. The loss of oil in the adjuster

lower pressure chamber, or the dry

stroking/cycling of the adjuster plunger, will

allow air to enter the high pressure chamber

of the valve lifter. Air in the high pressure

chamber of the adjuster may not be purged

causing cavitation and extensive engine

component damage.

Figure 6A1 – 274

3.22 Cylinder Head Assembly

Remove

Right-hand Side (Bank 1) Cylinder Head

1

Remove the heater hoses and heater pipe assembly, refer to 6B1 Engine Cooling – V6.

2

Remove the intake manifold assembly, refer to 3.10

Intake Manifold Assembly – Complete.

3

Remove the exhaust manifold, refer to 3.11

Exhaust Manifold Assembly.

4

Remove engine harness ground terminal attaching bolts from the cylinder head, refer to 8A Electrical Body and

Chassis.

5

Remove the right-hand side secondary timing chain, refer to 3.16 Timing Chains, Tensioners, Shoes and Guides.

6

Remove the camshaft sprockets, refer to 3.18 Camshaft Sprocket.

7

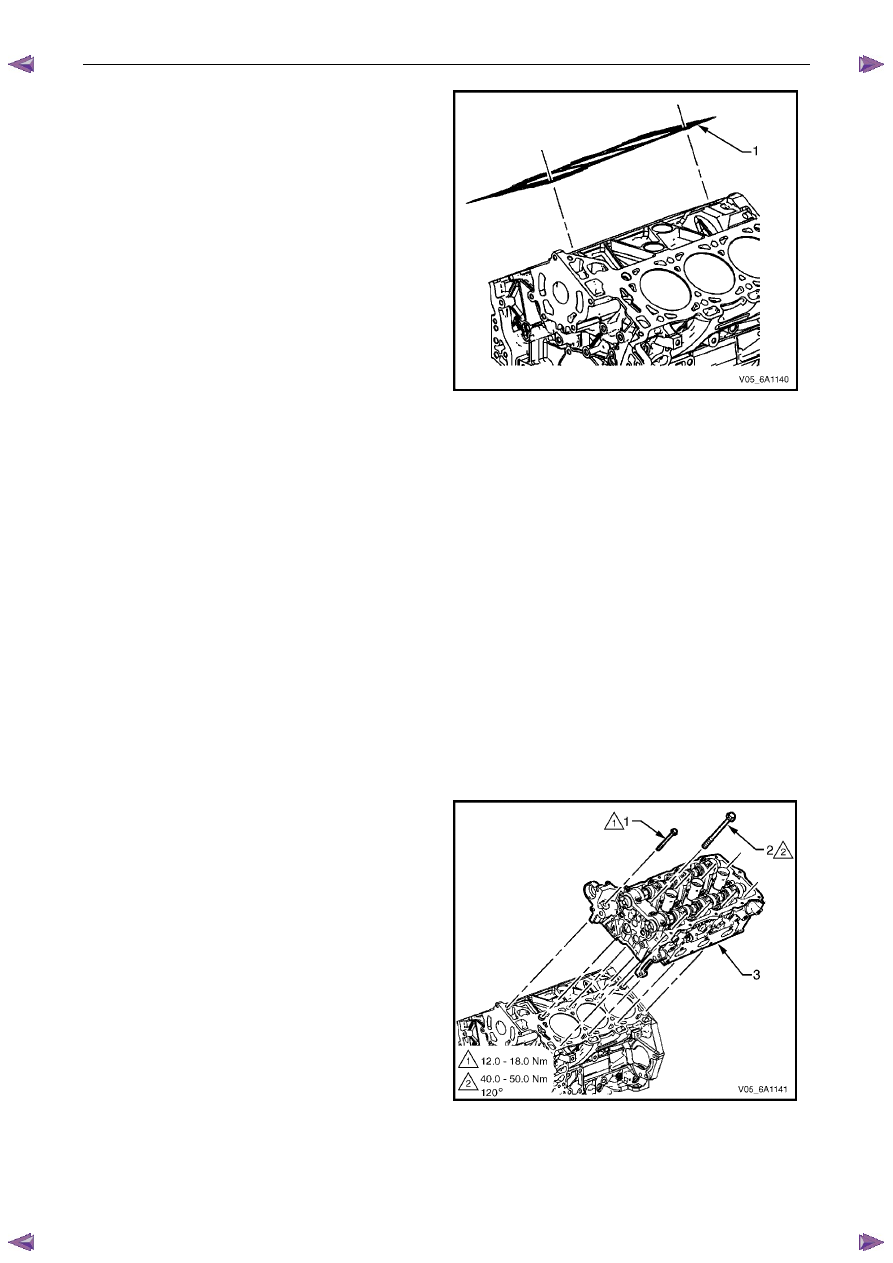

Remove the cylinder head attaching bolt (1), eight

places.

8

Remove the cylinder head.

N O T E

There is no bolt fitted to the hole in the rear of

the right-hand-hand cylinder head.

Figure 6A1 – 275

Engine Mechanical – V6

Page 6A1–162

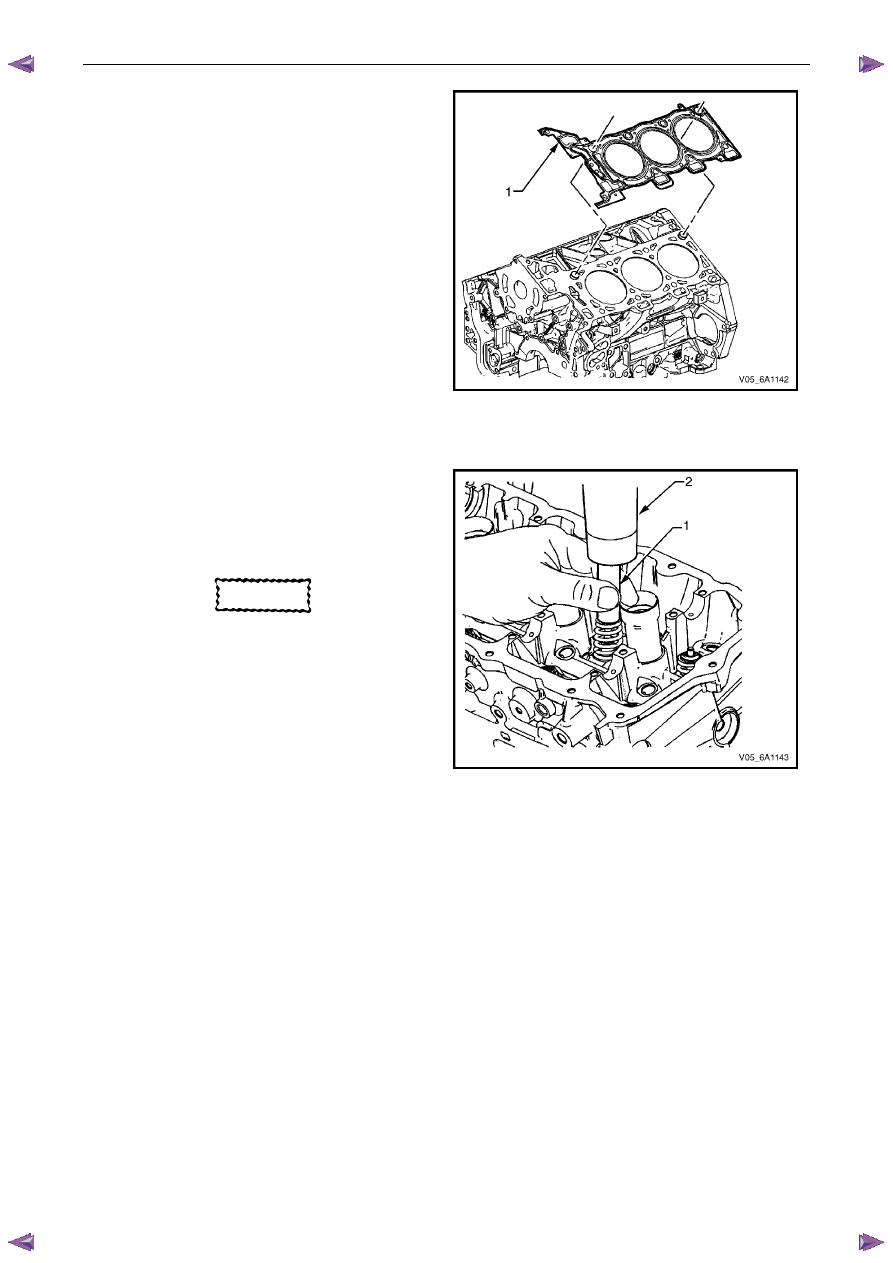

9

Remove and discard the cylinder head gasket (1).

Figure 6A1 – 276

Left-hand Side (Bank 2) Cylinder Head

1

Remove the intake manifold assembly, refer to 3.10

Intake Manifold Assembly – Complete.

2

Remove the exhaust manifold, refer to 3.11

Exhaust Manifold Assembly.

3

Remove the power steering reservoir and pump mounting brackets, refer to 3.8

Power Steering Pump Bracket.

N O T E

Do not disconnect the power steering pipes

and/or hoses.

4

Remove the oil filter adapter upper bolt.

N O T E

Do not remove the oil filter adapter.

5

Remove the engine coolant temperature (ECT) sensor, refer to 6C1-3 Engine Management – V6 – Service

Operations.

6

Remove engine harness ground terminal attaching bolt from cylinder head, refer to 8A Electrical Body & Chassis.

7

Remove the left-hand bank secondary timing chain, refer to 3.16 Timing Chains, Tensioners, Shoes and Guides.

8

Remove the camshaft position actuators, refer to 3.18

Camshaft Sprocket.

9

Remove the front M8 (1) cylinder head attaching bolt,

two places.

10

Remove the cylinder head attaching bolt (2), eight

places.

11

Remove the cylinder head (3).

Figure 6A1 – 277

Engine Mechanical – V6

Page 6A1–163

12

Remove and discard the cylinder head gasket (1).

Figure 6A1 – 278

Disassemble

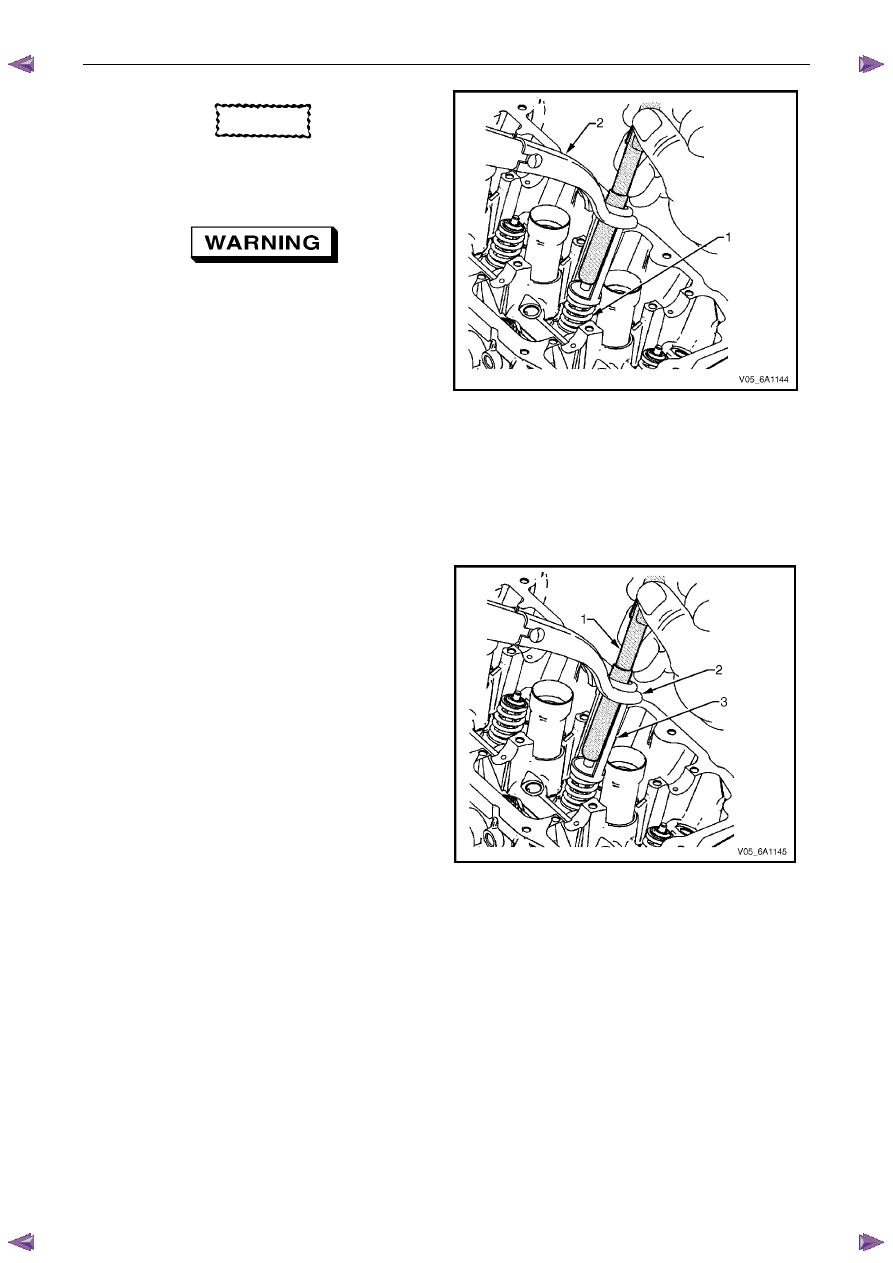

1

Using an appropriately sized deep socket (1) and a

plastic hammer (2), lightly tap on the valve spring

retainer to loosen the valve collets.

CAUTION

Ensure valve heads will not contact anything

during this step in order to avoid bending or

damage.

Figure 6A1 – 279

Engine Mechanical – V6

Page 6A1–164

CAUTION

Do not compress the valve springs less than

24.0 mm. Contact between the valve spring

retainer and the valve stem oil seal can

cause potential valve stem oil seal damage.

Compressed valve springs (1) have high

tension against the valve spring

compressor (2). Valve springs that are not

correctly compressed by, or are released

from the valve spring compressor can be

ejected from the valve spring compressor

with intense force. Use care when

compressing or releasing the valve spring

with the valve spring compressor and when

removing or installing the valve stem keys.

Failing to use care may cause personal

injury.

2

Compress the valve spring (1) using valve spring

compressor Tool No. J-8062 (2) and adaptor Tool No.

EN-46119.

Figure 6A1 – 280

3

Remove the valve collets using Tool EN-46117 (1).

4

Remove the valve spring compressor (2) and the

adapter (3).

Figure 6A1 – 281

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст