Isuzu KB P190. Manual — part 791

Engine Cooling – V6 Engine

Page 6B1–29

Inspect

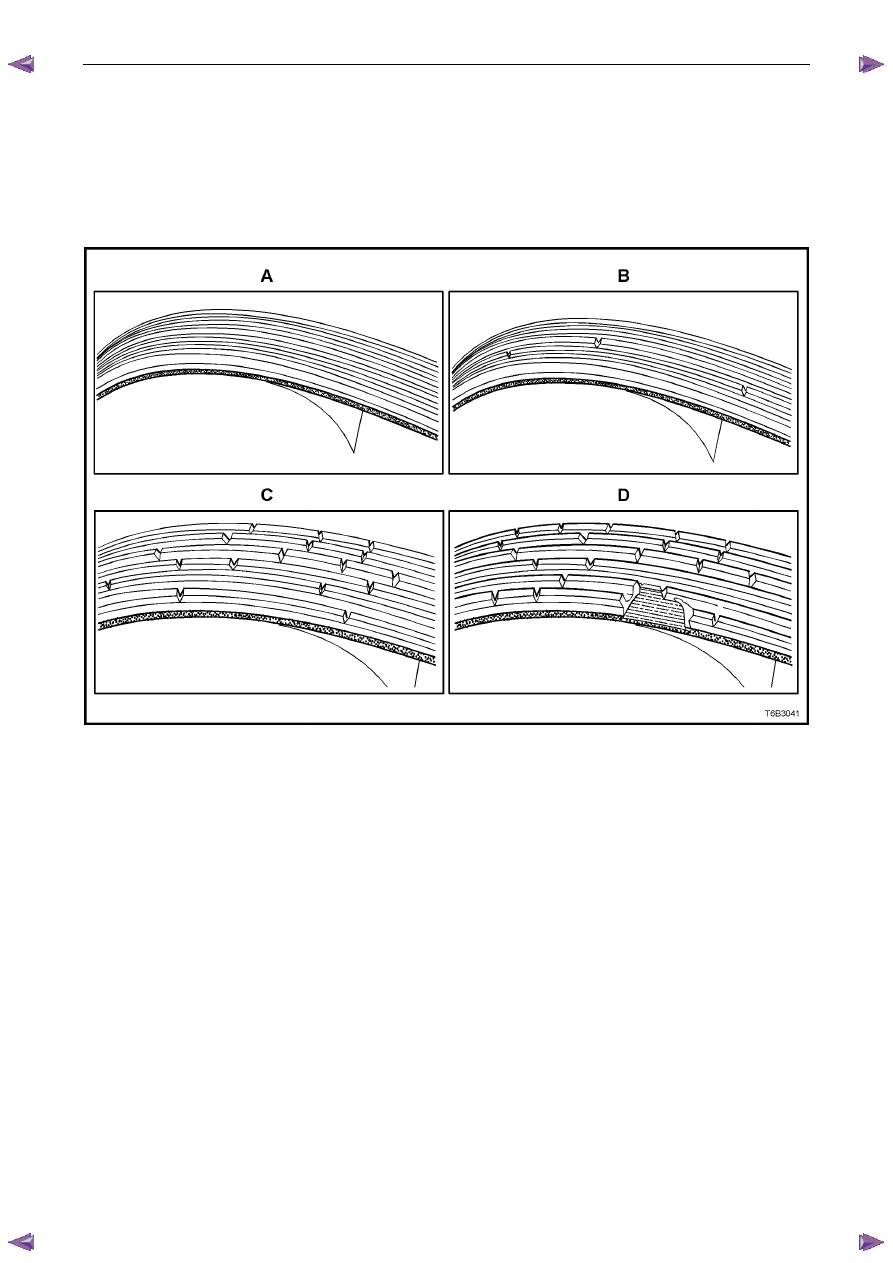

The four views in Figure 6B1 – 26 show the various stages of drive belt wear, to assist in belt replacement decisions.

N O T E

Condition of the belt ribs can be better assessed

if the belt is wrapped over the coolant pump drive

pulley.

Figure 6B1 – 26

Legend

A

New Belt: No cracks or chunks.

B

Moderately Used Belt: Few cracks, with some wear on the ribs and in the grooves. Belt replacement not required.

C

Severely Used Belt: Several cracks per 30 mm. Should be replaced before chunking occurs

D

Failed Belt: Separation of rib material from backing (chunking). Belt must be replaced immediately.

Engine Cooling – V6 Engine

Page 6B1–30

3.6 Coolant

Hoses

Always wear protective safety glasses when

working with spring type hose clamps. Failure

to do so could result in eye injury.

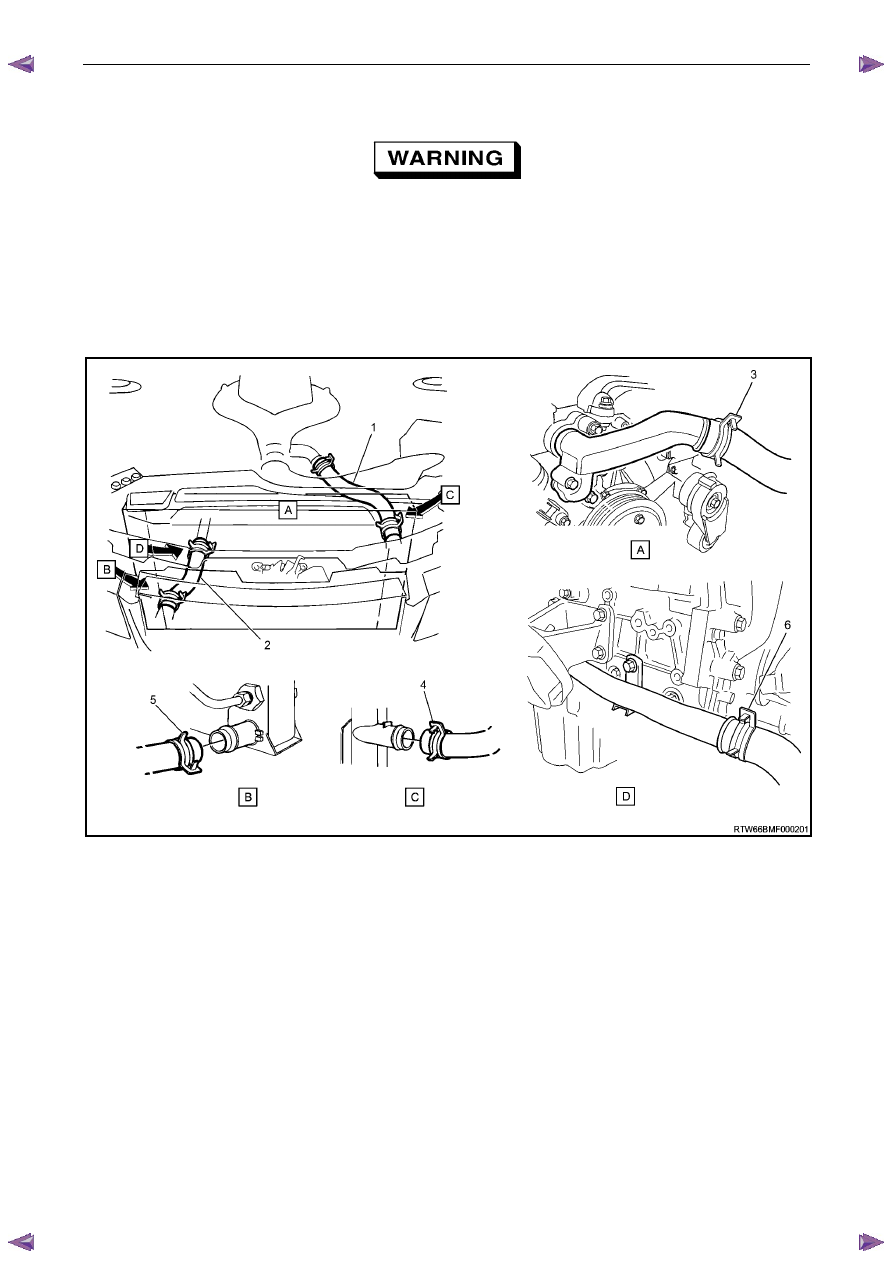

Coolant hoses are installed as shown in the following illustrations, taking note that there are a number of variants,

depending on a specific vehicle specification.

Hose connections should be thoroughly cleaned before installing any new hose.

After all hoses are installed, always refill the cooling system with correct concentration of coolant, refer to 3.3

Draining

and Filling Cooling System and pressure test cooling system, refer to 3.7

Pressure Testing in this Section.

Figure 6B1 – 27

Legend

1

Radiator Hose – Upper

2

Radiator Hose – Lower

3

Hose Clamp – Upper Hose to Engine Outlet Housing

4

Hose Clamp – Upper Hose to Radiator Inlet

5

Hose Clamp – Lower Hose to Radiator Outlet

6

Hose Clamp – Lower Hose to Engine Coolant Inlet Pipe

Engine Cooling – V6 Engine

Page 6B1–31

3.7 Pressure

Testing

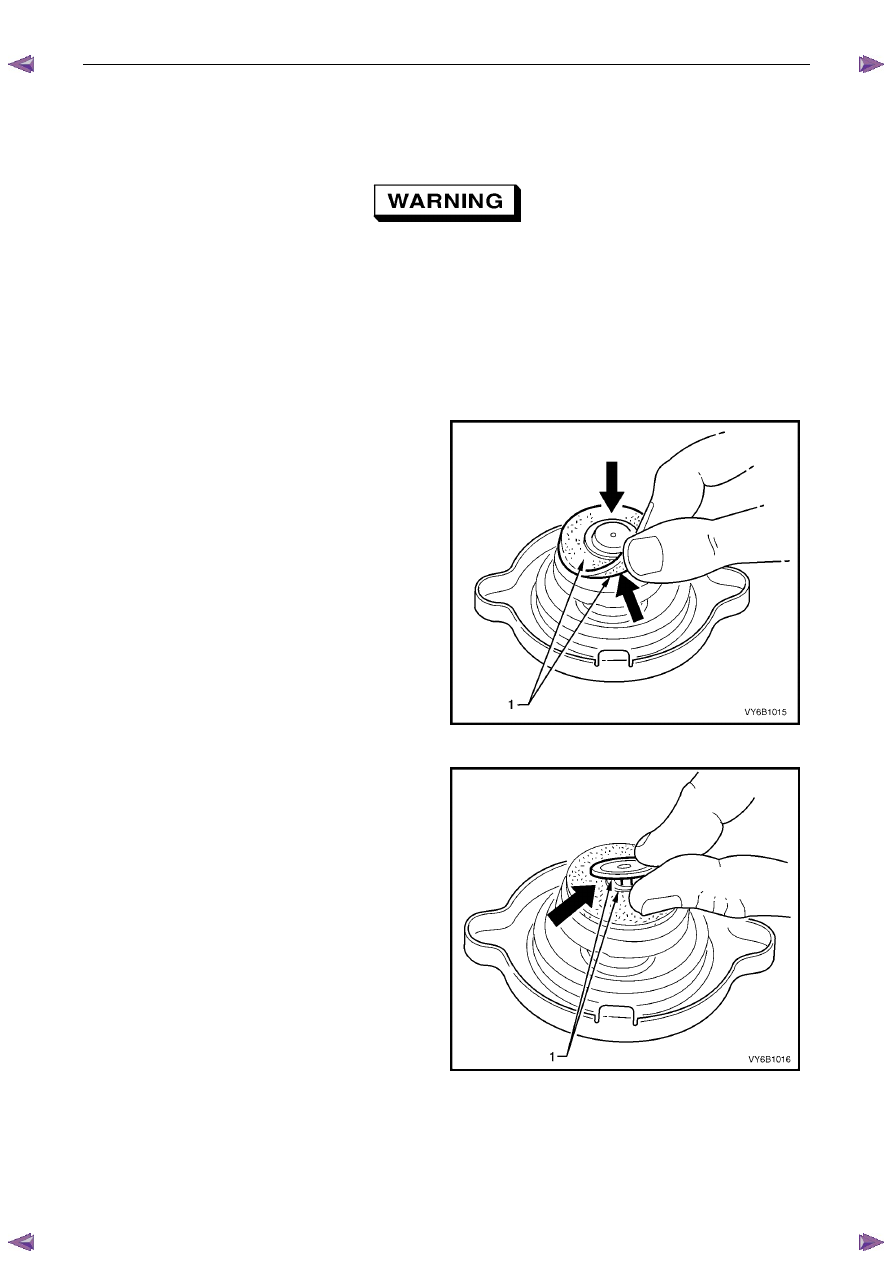

Coolant Filler Cap Pressure Testing

Refer to 3.1 Service Notes in this Section, for

important safety items.

1

Allow engine to cool to ambient temperature (less than 50

° C), then remove coolant filler cap.

2

Inspect and clean both sides (1) of coolant filler cap

gasket with a wet cloth.

N O T E

Use only water to wet the cleaning cloth.

Figure 6B1 – 28

3

Lift centre vacuum valve. Clean and inspect the

gasket and sealing surface under the valve (1).

Figure 6B1 – 29

Engine Cooling – V6 Engine

Page 6B1–32

4

Attach coolant filler cap (2) to a commercially

available cooling system pressure tester (1), using

the pressure cap adaptor.

5

Slowly pressurise cap to 120 – 130 kPa. The cap is

serviceable if it unloads slightly above this pressure

range and holds pressure at 120 kPa.

N O T E

Should the cap fail to reach or hold the

specified pressure, replace the cap.

Figure 6B1 – 30

6

Prior to installing coolant filler cap ensure that the

coolant filler neck cap seating surface is clean and

free from obstruction.

Figure 6B1 – 31

Cooling System Pressure Testing

Refer to 3.1 Service Notes in this Section, for

important safety items.

1

Allow the engine to cool to ambient temperature (less than 50

° C), then remove coolant filler cap.

2

Ensure that the coolant level is correct.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст