Isuzu KB P190. Manual — part 808

Fuel System – V6

Page 6C – 30

4.7

Fuel Tank Siphon Procedure

• Fuel vapour remains in the modular fuel

pump and sender assembly and fuel lines

that can be spilled during service

operations. Ensure no naked flames or

other ignition sources are nearby. Ensure

all cellular phones (and transmission

devices that may cause any metal objects

to become unintentional receiving

antennas) are switched off.

• Place a dry chemical (Class

B) fire

extinguisher nearby before performing any

on-vehicle service procedures. Failure to

follow these precautions may result in

personal injury.

For an exploded view of fuel tank components, refer Figure 6C – 17.

1

Depressurise the fuel system, refer to 3.4

Fuel System Depressurisation.

2

Reinstall the fuel pump relay, refer to 8A Electrical Body and Chassis.

Disconnecting the battery affects certain

vehicle electronic systems. 1.1

WARNING,

CAUTION and NOTES.

3

Disconnect the negative battery terminal.

4

Remove the fuel filler cap.

N O T E

Lubricate the fuel siphon hose with J36850

TransJel Transmission Assembly Lubricant or

equivalent to aid hose insertion. Use only an

approved lubricant.

5

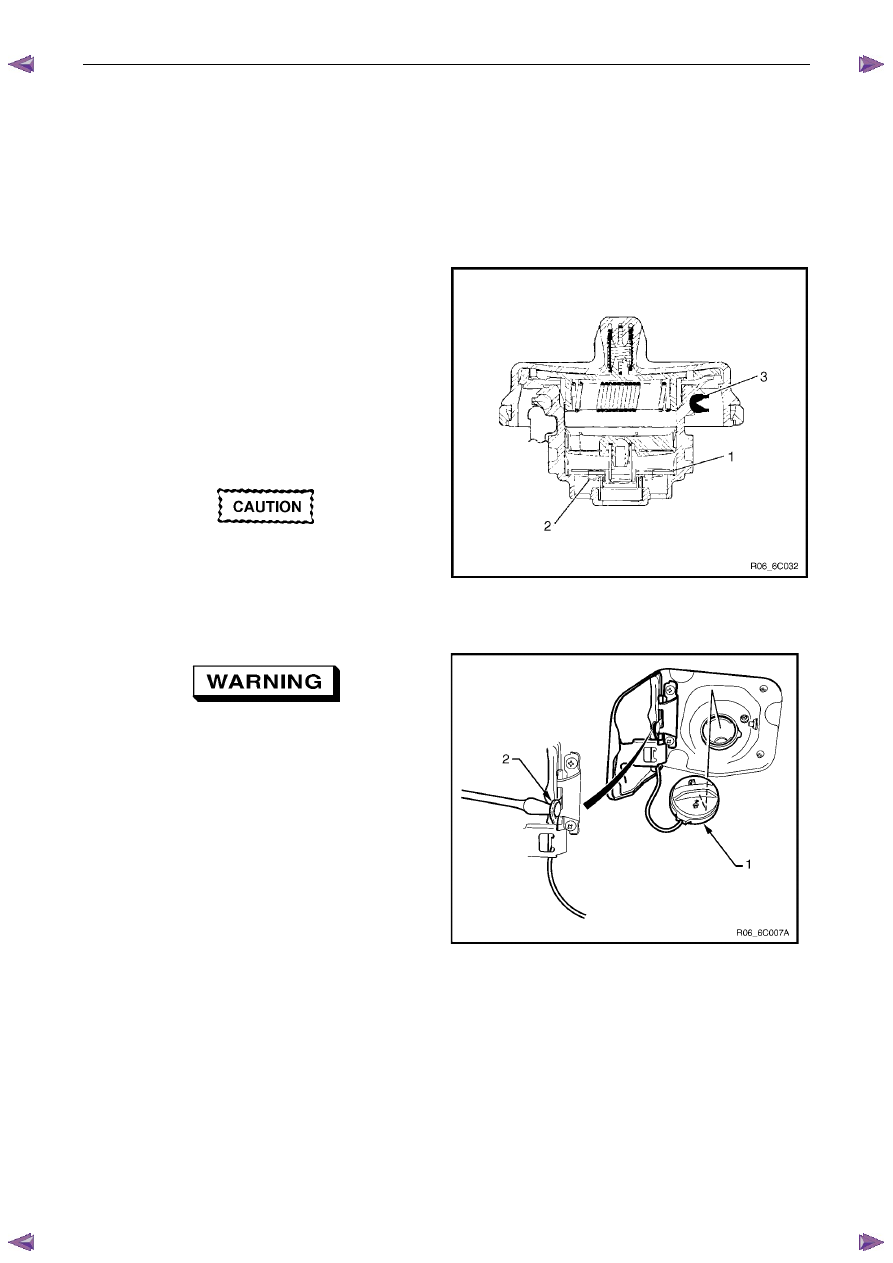

Install J44284–2 flapper door holder (2) into the fuel

filler neck to hold the door open.

Do not siphon, drain or store fuel into an

open container, due to the possibility of fire

or explosion, or contamination. Always use

and approved fuel storage container.

6

Insert the J45004–1 fuel tank siphon hose (1) into the

fuel tank filler neck and gradually twist it until the tip of

the hose meets the fuel tank check valve (3) and

continues to the bottom of the fuel tank.

7

Use a hand-operated or air-operated pump device to

siphon as much fuel through the fuel fill pipe as

possible.

Figure 6C – 35

Fuel System – V6

Page 6C – 31

Fuel vapour remains in the fuel tank even

when completely empty. Seal all openings in

the fuel tank using suitable material or a

plastic plug. Ensure no naked flames or other

ignition sources are nearby. Ensure all

cellular phones (and transmission devices

that may cause any metal objects to become

unintentional receiving antennas) are

switched off.

Do not use excessive force when removing

the fuel siphon hose from the fuel filler neck.

If the fuel siphon hose gets stuck upon

removal, gently twist and tug the fuel siphon

hose back and forth until it releases.

N O T E

• If fuel does not siphon from the fuel tank, the

fuel siphon hose may have entered the fuel

tank through a roof-facing check valve

opening. If required, insert the J45004–1 fuel

siphon hose (1) into the fuel tank filler neck,

refer to Figure 6C – 35, but twist the fuel

siphon hose 90° as it slides down the filler

neck. This enables the fuel siphon hose to

enter the fuel tank through a floor-facing

check valve opening.

• The siphon procedure will not remove all fuel

from the fuel tank. If required, fuel remaining

in the fuel tank may be siphoned out through

the top of the fuel tank, once the modular fuel

pump and sender assembly is removed from

the tank, refer to 4.4

Fuel Tank.

8

Remove the siphon equipment.

Fuel System – V6

Page 6C – 32

4.8

Fuel Filler Cap

The fuel filler cap is a 'screw on' type, with an integrated tightening torque limiting mechanism. When installing the fuel

filler cap, tighten it until a ratcheting (clicking) sound is audible, indicating the fuel filler cap is properly tightened. The fuel

filler cap is tethered to the fuel filler pocket.

Remove

The fuel filler cap requires a quarter of a turn anticlockwise to be removed.

Vacuum and pressure valves are built into the fuel filler cap

which regulate the pressure in the fuel tank and prevent fuel

tank and system damage.

Inspection

Inspect the fuel filler cap and seal for any signs of damage.

Replace the fuel filler cap if found to be defective.

1 Pressure

Valve

2 Vacuum

Valve

3 Seal

Ring

A replacement fuel filler cap must be the

same type as the original. The fuel filler cap

pressure and vacuum valves are specific to a

particular application and must be replaced

with the same type or fuel system damage

may occur.

Figure 6C – 36

If the fuel filler cap needs replacing, use only

a 'screw on' fuel tank filler cap with an

integrated tightening torque limiting

mechanism. Failure to use the correct fuel

tank filler cap can result in a serious

malfunction of the emission control or fuel

system.

1

Untwist and remove the fuel filler cap (2) from the fuel

filler neck opening.

2

Cover the fuel filler opening with a suitable material to

prevent foreign objects from entering the fuel tank.

3

To remove the fuel filler cap tether line use a flat-

bladed screwdriver to prise the tether line fastener (2)

from it’s mounting hole.

N O T E

Check the fuel filler cap for serviceability and

replace if required.

Figure 6C – 37

Reinstall

Reinstallation of the fuel filler cap is the reverse of the removal procedure.

Fuel System – V6

Page 6C – 33

4.9 Fuel

Lines

Remove

• A depressurised fuel system contains fuel

in the fuel filter and fuel lines that can be

spilled during service operations.

• Fuel vapour remains in the fuel tank even

when completely empty. Seal all openings

in the fuel tank using suitable material or a

plastic plug. Ensure no naked flames or

other ignition sources are nearby. Ensure

all cellular phones (and transmission

devices that may cause any metal objects

to become unintentional receiving

antennas) are switched off.

• Place a dry chemical (Class

B) fire

extinguisher nearby before performing any

on-vehicle service procedures. Failure to

follow these precautions may result in

personal injury.

• Wear safety glasses when using

compressed air. Do not blow compressed

air onto any body part.

1

Remove the fuel pump relay, refer to 8A Electrical Body and Chassis.

2

Depressurise the fuel system, refer to 3.4

Fuel System Depressurisation.

Never drain or store fuel into an open

container, due to the possibility of fire or

explosion.

3

Raise the vehicle, preferably on a hoist, refer to 0A General Information.

Before proceeding, clean all traces of dirt and

other foreign material from the fuel lines.

4

Use compressed air to ensure that all dirt and foreign materials are removed from all fuel connections before the

parts are disconnected.

5

If required, remove the stone guard, refer to Figure 6C – 17 and fuel lines. Use the following illustrations showing

the fuel line layout and location of other items relating to the fuel system as a guide, also refer to 4.1 Fuel Lines

And Quick Connect Fittings and 4.6

Evaporative Emission Control Canister.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст