Isuzu KB P190. Manual — part 807

Fuel System – V6

Page 6C – 26

Fuel vapour remains in the fuel tank even

when completely empty. Seal all openings in

the fuel tank using suitable material or a

plastic plug. Ensure no naked flames or other

ignition sources are nearby. Ensure all

cellular phones (and transmission devices

that may cause any metal objects to become

unintentional receiving antennas) are

switched off.

15

Place a suitable material over the opening in the fuel tank to prevent any foreign matter from entering the fuel

system.

Fuel Level Sender Assembly

Test

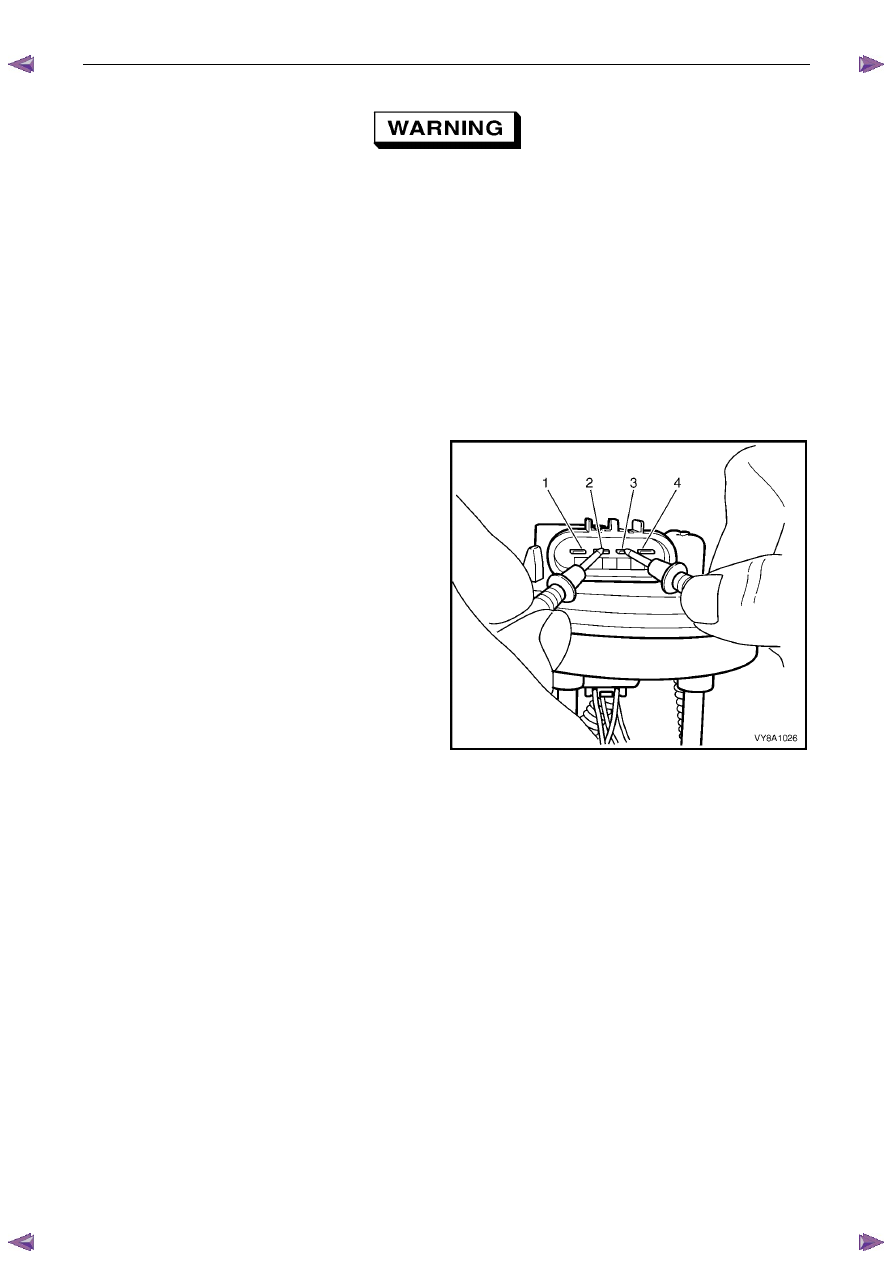

1

Measure the resistance across terminals 2 and 3 of

the fuel pump connector. Take the following

measurements:

a

With the float arm assembly in the empty

position, the resistance should be approximately

250

Ω.

b

With the float arm assembly rotated to the full

position, the resistance should be approximately

40

Ω.

2

If the resistance at either of these positions is not

within tolerance, replace the modular fuel pump and

sender assembly.

Figure 6C – 27

Reinstall

Reinstallation of the modular fuel pump and sender assembly is the reverse of the removal procedure, noting the

following:

1

Fit a new O-ring (3) to the modular fuel pump and sender assembly.

2

Install the modular fuel pump and sender assembly into the fuel tank, taking care not to damage the fuel sender

float or arm.

3

Ensure the locator in the pump cover engages in the slot in the fuel tank opening.

4

Using tool No. AU469 and a half-inch breaker bar, install the modular fuel pump and sender assembly cover

retainer lock ring by turning it clockwise.

5

Refit the three quick connect fittings.

Fuel System – V6

Page 6C – 27

4.6

Evaporative Emission Control Canister

Remove

1

Raise the vehicle on a hoist to give access to the evaporative emission control canister, located above the spare

wheel , refer to 0A General Information.

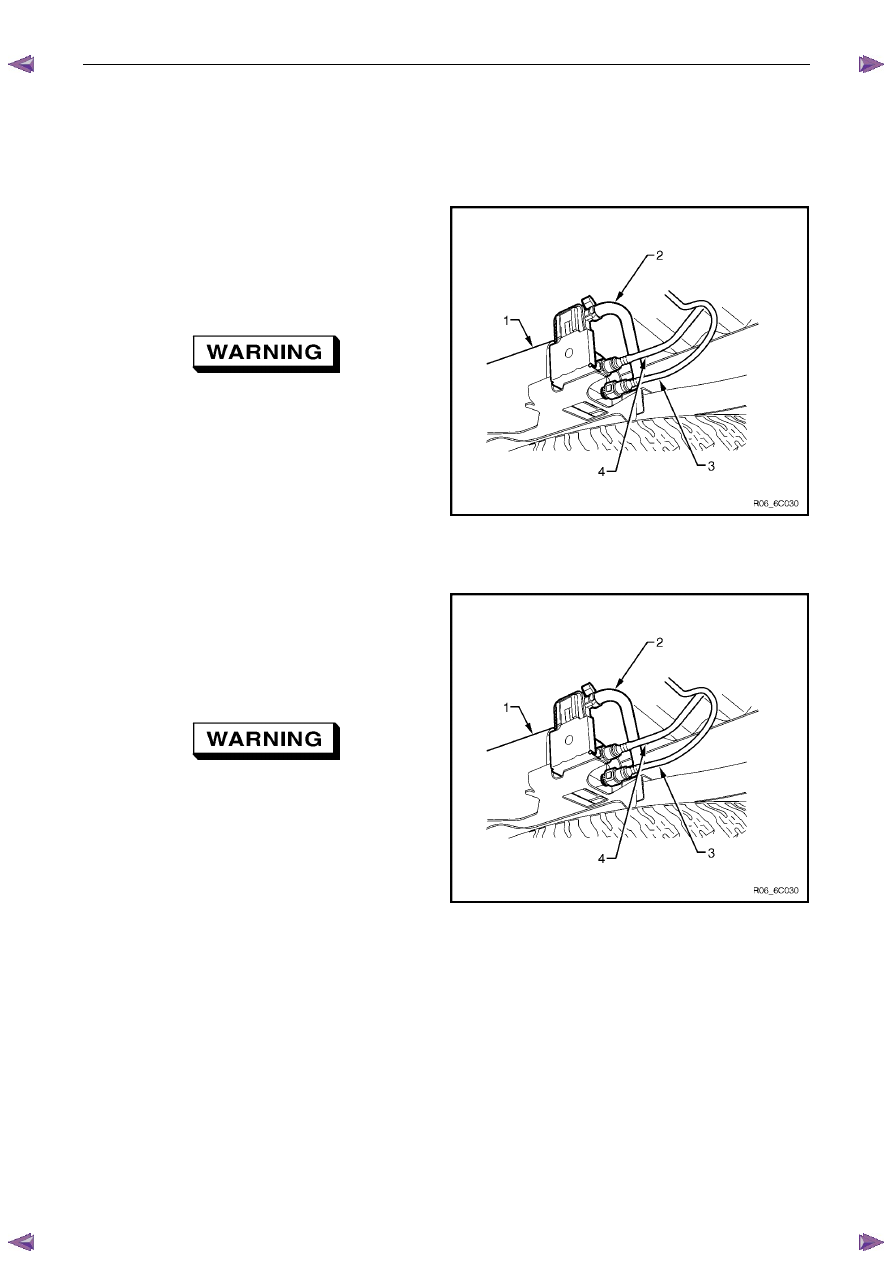

2

Disconnect the evaporative emission control canister

purge line (3) by using the following procedure:

a

Grasp both sides of the quick-connect fitting.

Twist the connector 1/4 turn in each direction in

order to loosen any dirt within the quick-connect

fitting.

Wear safety glasses when using compressed

air. Do not blow compressed air onto any

body part.

b

Using compressed air, blow any dirt out of the

quick-connect fitting.

c

Grasp the quick-connect fitting and push it

towards the canister.

d

Squeeze the quick-connect fitting to release the

retaining tabs, then pull back on the connector to

remove the canister purge line from the canister.

Figure 6C – 28

3

Disconnect the fuel tank vent line (4) by using the

following procedure:

a

Grasp both sides of the quick-connect fitting.

Twist the connector 1/4 turn in each direction in

order to loosen any dirt within the quick-connect

fitting.

Wear safety glasses when using compressed

air. Do not blow compressed air onto any

body part.

b

Using compressed air, blow any dirt out of the

quick connect fitting.

c

Grasp the quick-connect fitting and push it

towards the canister.

d

Squeeze the quick-connect fitting to release the

retaining tabs, then pull back on the connector to

remove the tank vent line from the canister.

Figure 6C – 29

Fuel System – V6

Page 6C – 28

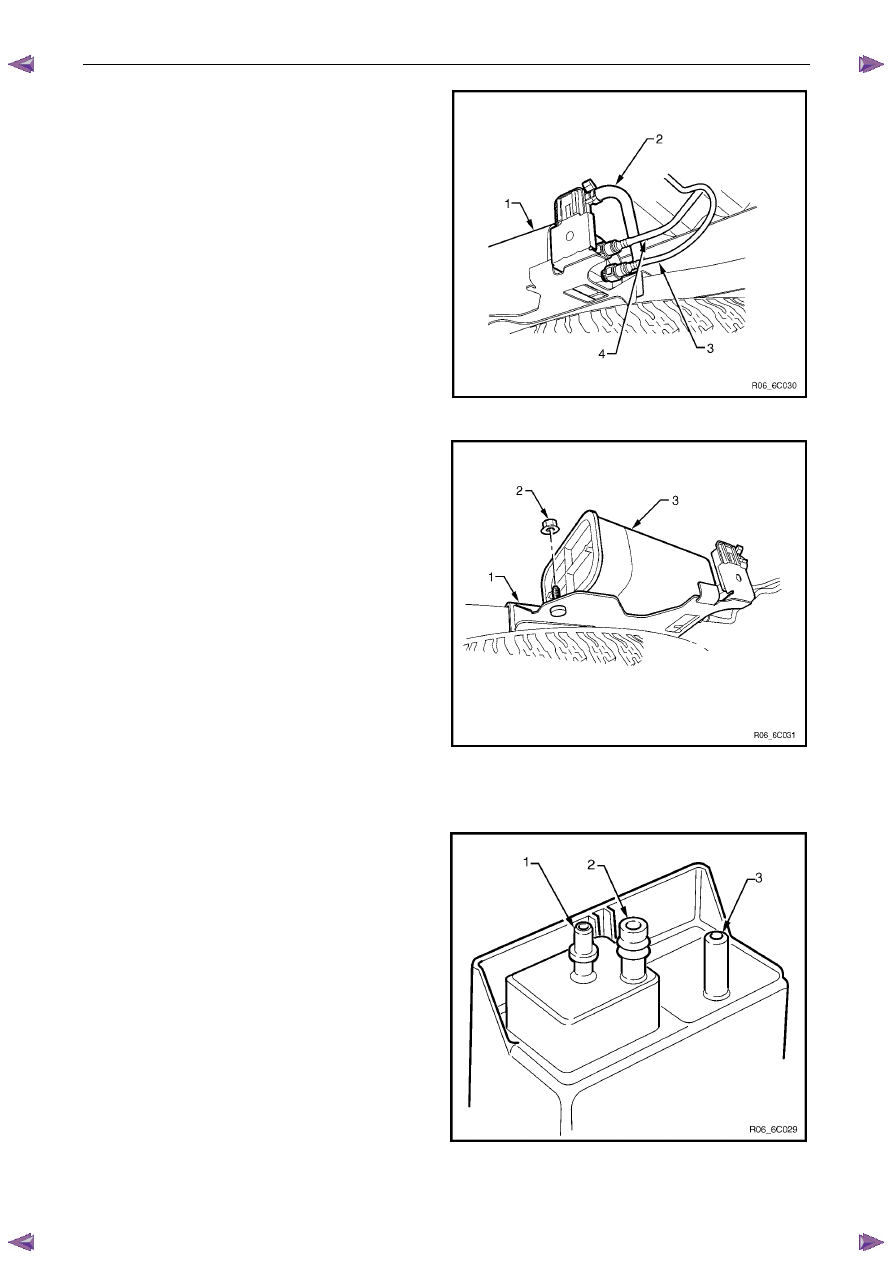

4

Remove the canister vent line (2) from the canister (1)

by twisting and pulling it off.

Refer to 4.1 Fuel Lines And Quick Connect Fittings for

further information.

Figure 6C – 30

5

Remove the canister retaining nut (2).

6

Remove the canister from the retaining stud and then

slide the canister (3) out of the retaining bracket (1).

Figure 6C – 31

Service Check

1

Remove the canister.

2

Shake the canister. There should be no audible sound

of carbon movement.

3

Using low pressure compressed air (20–35 kPa), blow

into the tank vent port (3). Check that air flows freely

from the canister vent port (1). Block the canister vent

port (1); air should flow from the canister purge

port (2).

4

If airflow through the canister vent port (1) is limited,

clean the atmospheric filter by blocking off the fuel

tank vent port (3) and blow compressed air at

approximately 300 kPa through the canister purge

port (2).

5

Check airflow through the filter as in step 3. If airflow

through the canister vent port (1) is still limited, replace

the canister.

Figure 6C – 32

Fuel System – V6

Page 6C – 29

6

Block the canister vent port (1) and the canister purge port (2). Apply low-pressure compressed air

(20–35 kPa) to the tank vent port (3). If any air leaks from the canister (that is, around the ports or seams), replace

the canister.

N O T E

In dusty areas, an alternative is to block the

canister purge port

(2). Blow air through the

canister vent

(1) port and check that air is

expelled through the tank vent port (3).

Reinstall

Reinstallation of the evaporative emission control canister is the reverse of the removal procedure.

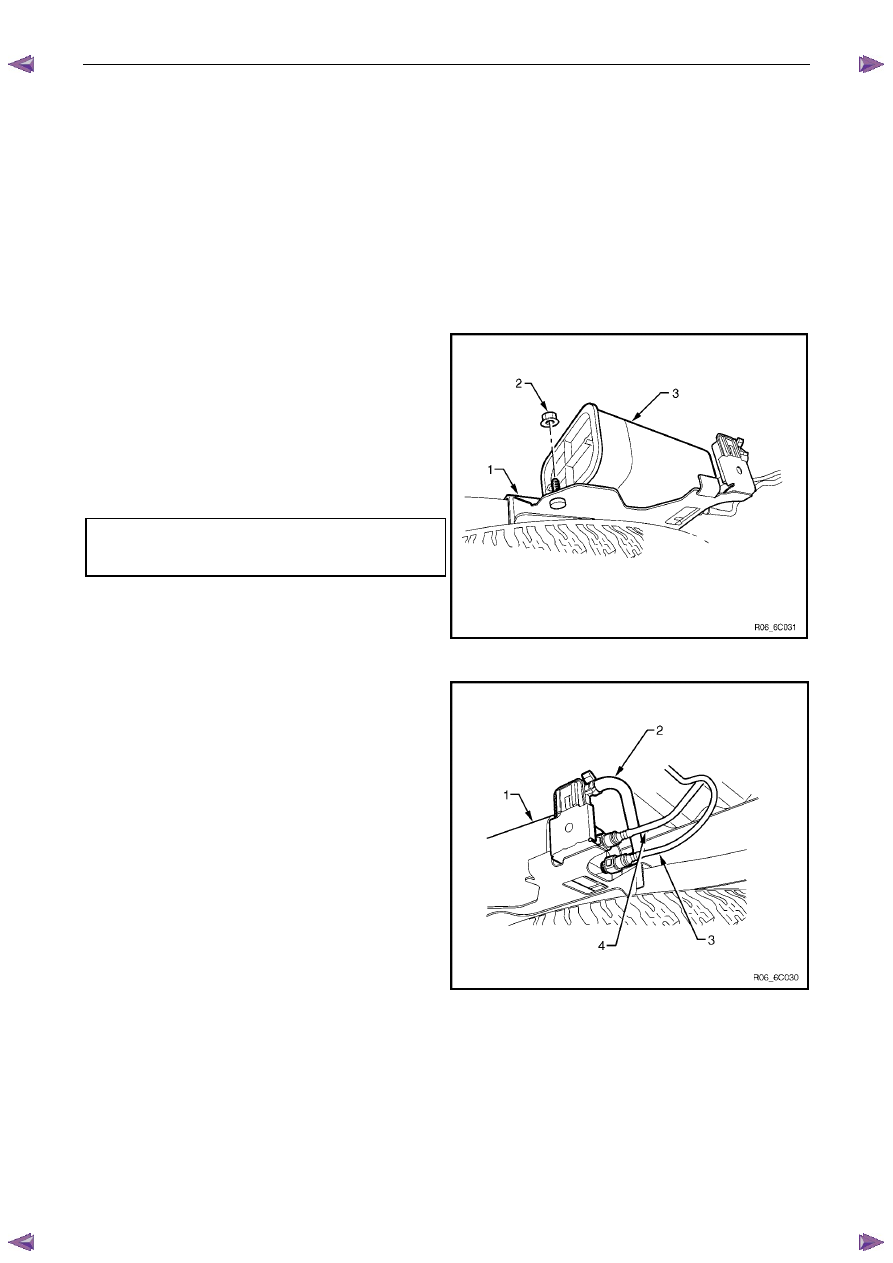

1

Reinstall the canister into the retainer (1) and over the

retaining stud.

2

Reinstall the canister retaining nut (2), then hand-

tighten.

3

Ensure the canister is located correctly and tighten the

canister retaining nut (2) to the specified torque.

Evaporative emission control canister

retaining nut

torque specification . . . . . . . . . .2.0 – 5.0 Nm

Figure 6C – 33

4

Reinstall the canister vent line (2).

5

Align the canister purge line quick-connect (3) with the

canister purge line port. Push the quick-connect firmly

onto the port.

6

Align the fuel tank vent line quick-connect (4) with the

fuel tank vent port. Push the quick-connect firmly onto

the port.

7

After installation, pull on each quick-connect to ensure

the connections are secure and locked in position.

Figure 6C – 34

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст