Isuzu KB P190. Manual — part 680

Engine Mechanical – V6

Page 6A1–241

2

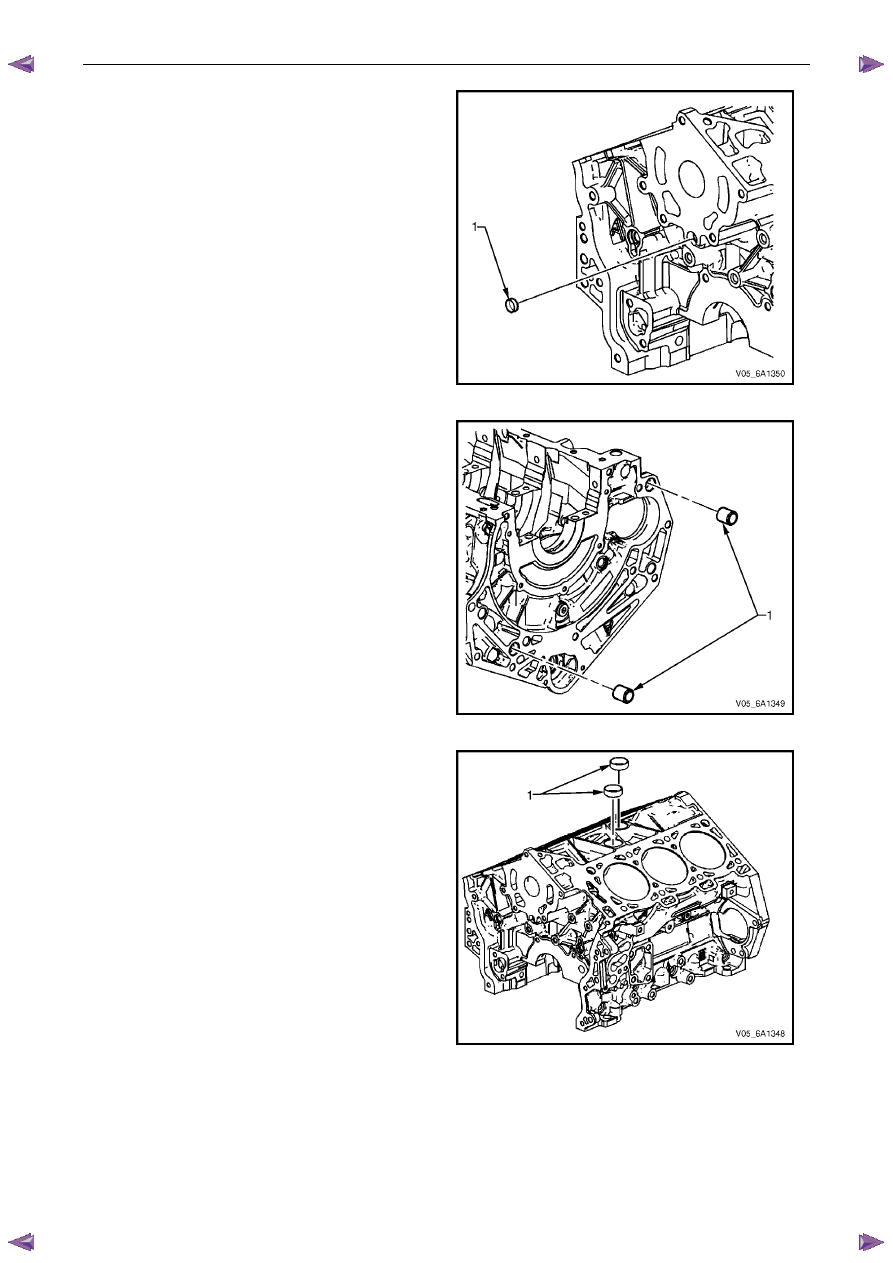

Install a new front oil gallery expansion plug (1).

Figure 6A1 – 451

3

Install the cylinder block-to-transmission alignment

dowels (1).

Figure 6A1 – 452

4

Place RTV sealant on new coolant expansion plugs

(1) and install the new coolant expansion plugs.

Figure 6A1 – 453

Engine Mechanical – V6

Page 6A1–242

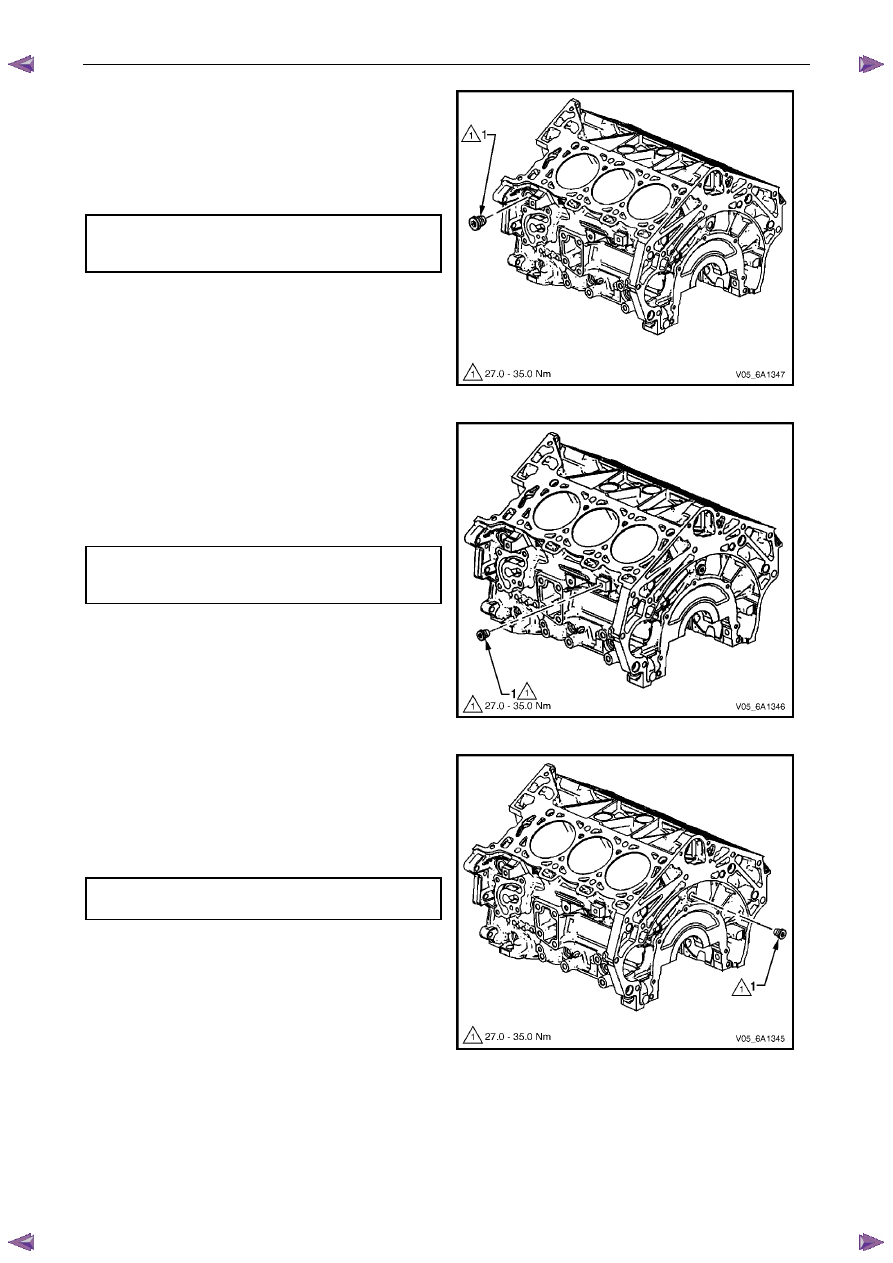

5

Install the left-hand side M20 oil gallery threaded plug

(1) and tighten to the correct torque specification.

Left-hand side M20 cylinder block

oil gallery threaded plug

torque specification . . . . . . . . .27.0 – 35.0 Nm

Figure 6A1 – 454

6

Install the left-hand side M14 coolant drain threaded

plug (1) and tighten to the correct torque specification.

Left-hand side M14 cylinder block

coolant drain threaded plug

torque specification . . . . . . . . .27.0 – 35.0 Nm

Figure 6A1 – 455

7

Install the M14 rear oil gallery threaded plug (1) and

tighten to the correct torque specification.

M14 cylinder block rear oil gallery

threaded plug torque specification . . ..27.0 – 35.0 Nm

Figure 6A1 – 456

Engine Mechanical – V6

Page 6A1–243

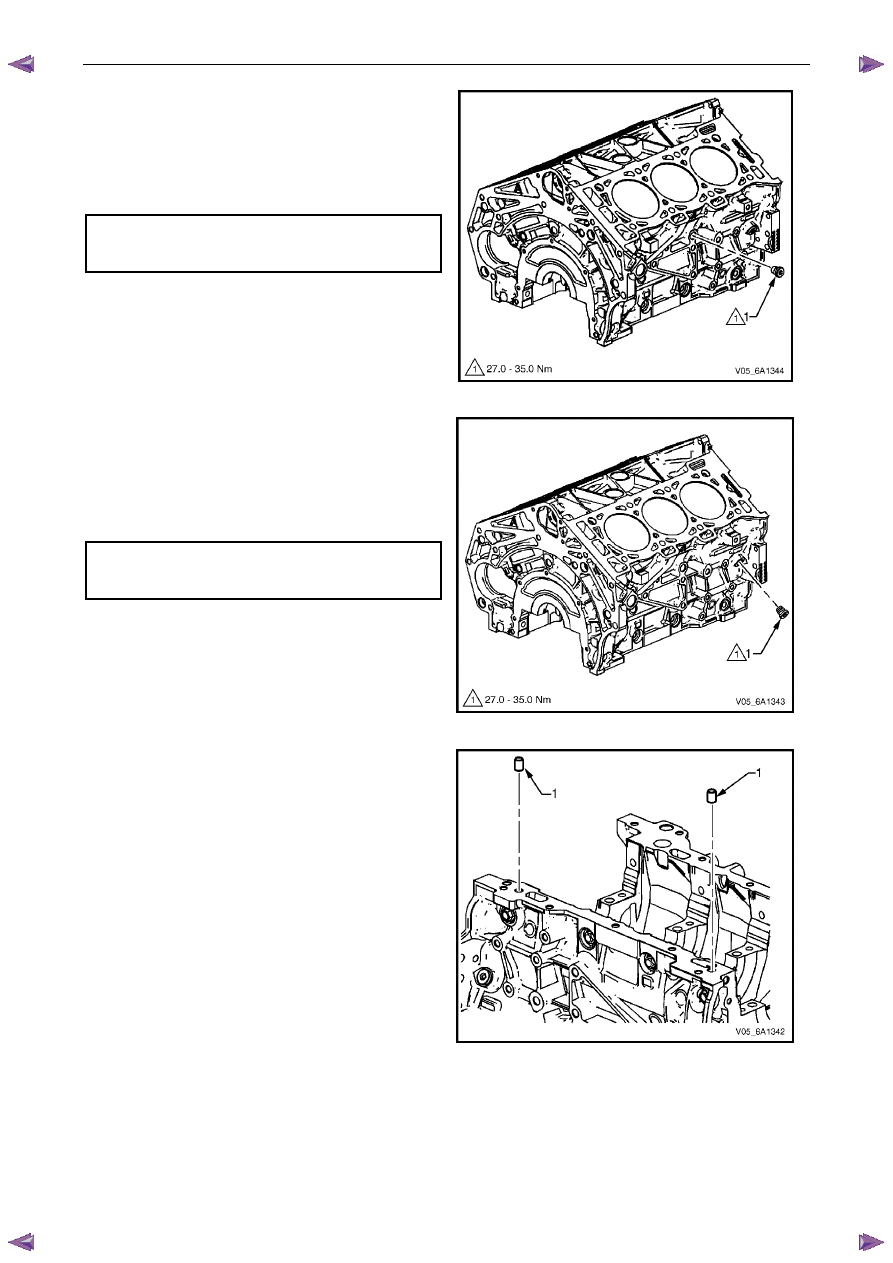

8

Install the right-hand side M14 coolant drain threaded

plug (1) and tighten to the correct torque specification.

Right-hand side M14 cylinder block

coolant drain threaded plug

torque specification . . . . . . . . .27.0 – 35.0 Nm

Figure 6A1 – 457

9

Install the right-hand side M14 oil gallery threaded

plug (1) and tighten to the correct torque specification.

Right-hand side M14 cylinder block

oil gallery threaded plug

torque specification . . . . . . . . .27.0 – 35.0 Nm

Figure 6A1 – 458

10

Install the cylinder block-to-oil pan alignment

dowels (1).

Figure 6A1 – 459

Engine Mechanical – V6

Page 6A1–244

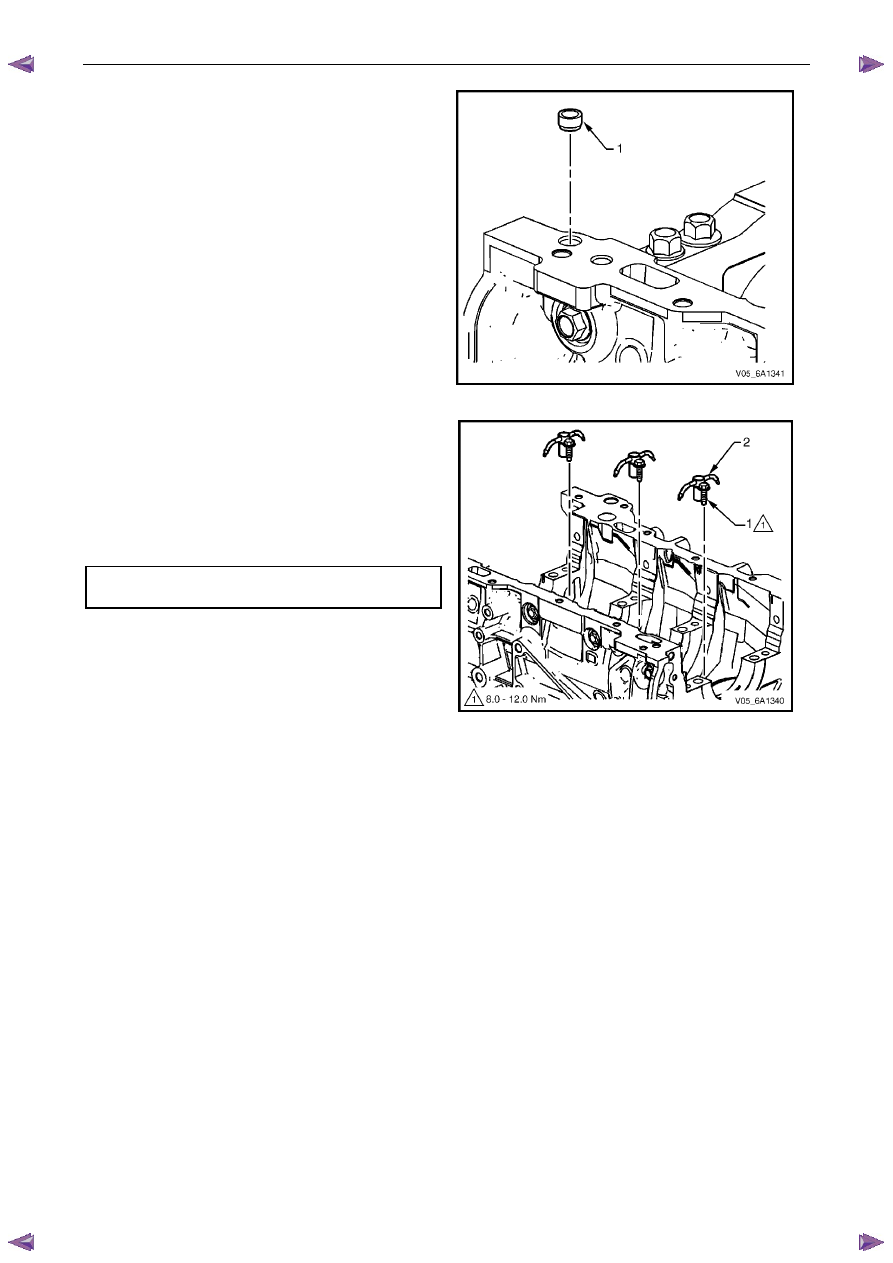

11

Install the new right-hand front oil pan rail oil gallery

expansion plug (1).

Figure 6A1 – 460

12

Install the oil jet (2), three places.

13

Install the oil jet attaching bolt (1), three places and

tighten to the correct torque specification.

Oil jet attaching bolt

torque specification . . . . . . . . ...8.0 – 12.0 Nm

Figure 6A1 – 461

4.8 Thread

Repairs

General Information

The thread repair process involves a solid, thin walled, self-locking, carbon steel, bushing type insert. During the insert

installation process, the installation driver tool cold-rolls the bottom internal threads and expands the bottom external

threads of the insert into the base material. This action mechanically locks the insert into place.

This Section describes the recommended method of repairing threads in three specific areas of the engine.

•

general thread repair,

•

cylinder block main bearing cap bolt hole thread repair, and

•

cylinder head bolt hole thread repair.

For detailed descriptions of all thread specifications used refer to 4.9

Thread Repair Specifications.

The drill-bit and counter-bore tool from the thread repair kit, Tool No. J-42385-700 and J-42385-2000 are designed for

use with either a suitable tap wrench or drill motor. Limited access and larger hole repair may process better using a tap

wrench. An extension from Tool J 43965 may also be required to drive the thread repair tooling dependent on access to

the hole being repaired. Use only a tap wrench when tapping the hole and during installation of the insert.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст