Isuzu KB P190. Manual — part 937

Powertrain Interface Module – V6

Page 6E1–87

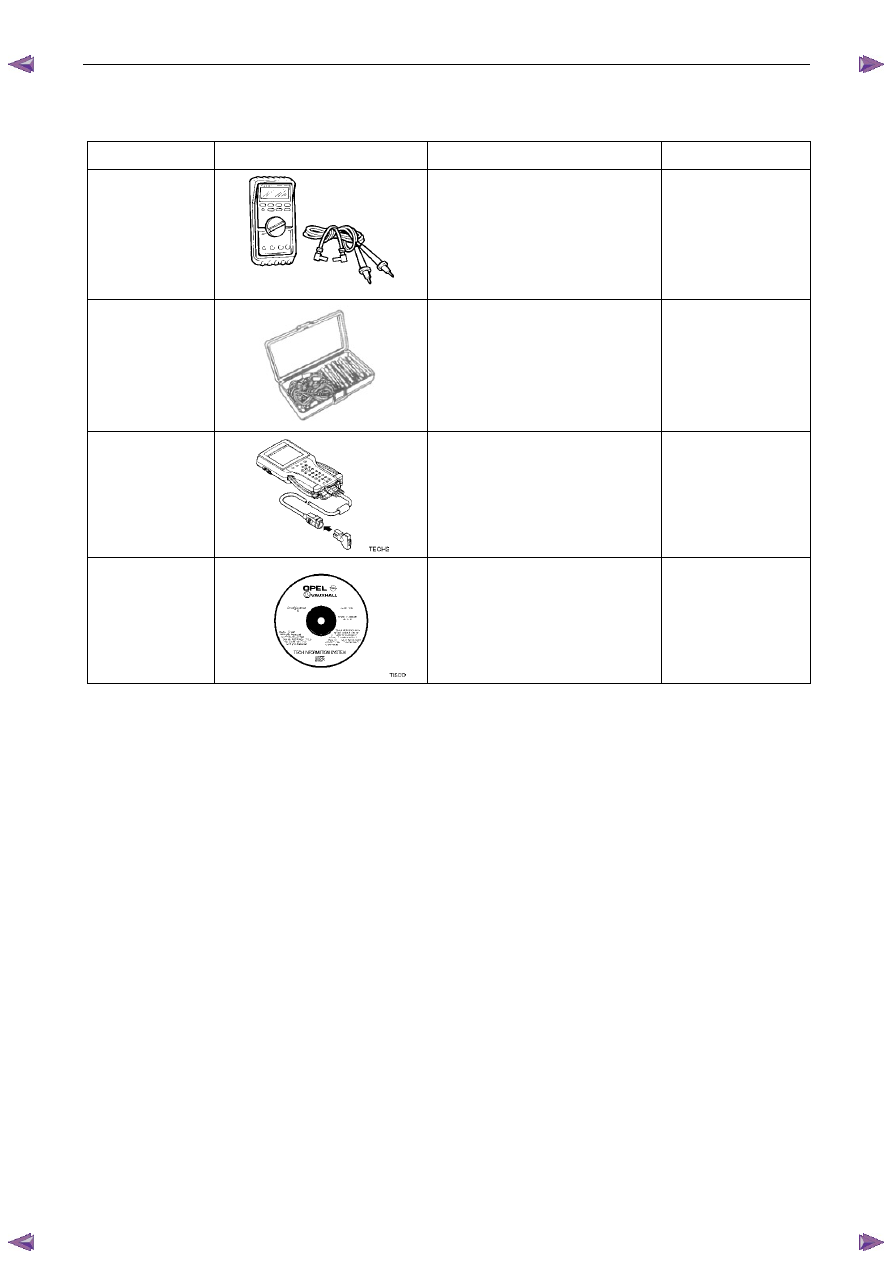

16 Special

Tools

Tool

Number Illustration

Description Tool

Classification

3588

Digital Multimeter

Previously released as J39200 or

equivalent.

NOTE: The instrument must have 10

mega ohms impedance and be

capable of reading frequencies.

Mandatory

J35616

Connector Test Adaptor Kit

Used when carrying out electrical

diagnostic circuit checks.

Desirable

70000861

Tech 2 Diagnostic Scan Tool

Previously released.

Mandatory

N/A

Technical Information System (TIS)

CD ROM

Available to Authorised Dealers.

Mandatory

Exhaust System – V6

Page 6F – 1

6F

Exhaust System – V6

A T T E N T I O N

Before performing any service operations or other procedure described in this Section, refer to

1.3

WARNING, CAUTION and NOTES for correct workshop practices with regard to safety and / or

property damage.

1

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2

1.1

Emission Reductions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Euro 3 Emissions Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2

General Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ... 4

Service Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.3

WARNING, CAUTION and NOTES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1 Definition of WARNING, CAUTION and NOTE Statements. . . . . . . . . . . . . . . . . . ... 5

WARNING defined . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

CAUTION defined . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 5

NOTE defined . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2

Front and Centre Exhaust Pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 7

Reinstallation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3

Silencer and Rear Exhaust Pipe. . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 9

Reinstallation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4

Torque Wrench Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Exhaust System – V6

Page 6F – 2

1 General

Information

Information contained within this section describes the general exhaust system.

1.1 Emission

Reductions

Through developments in various vehicle emissions reduction systems, significant reductions in emissions have been

achieved. The developments have been primarily concerned with refinements in engine calibration and the optimisation

of exhaust system catalytic converter configurations.

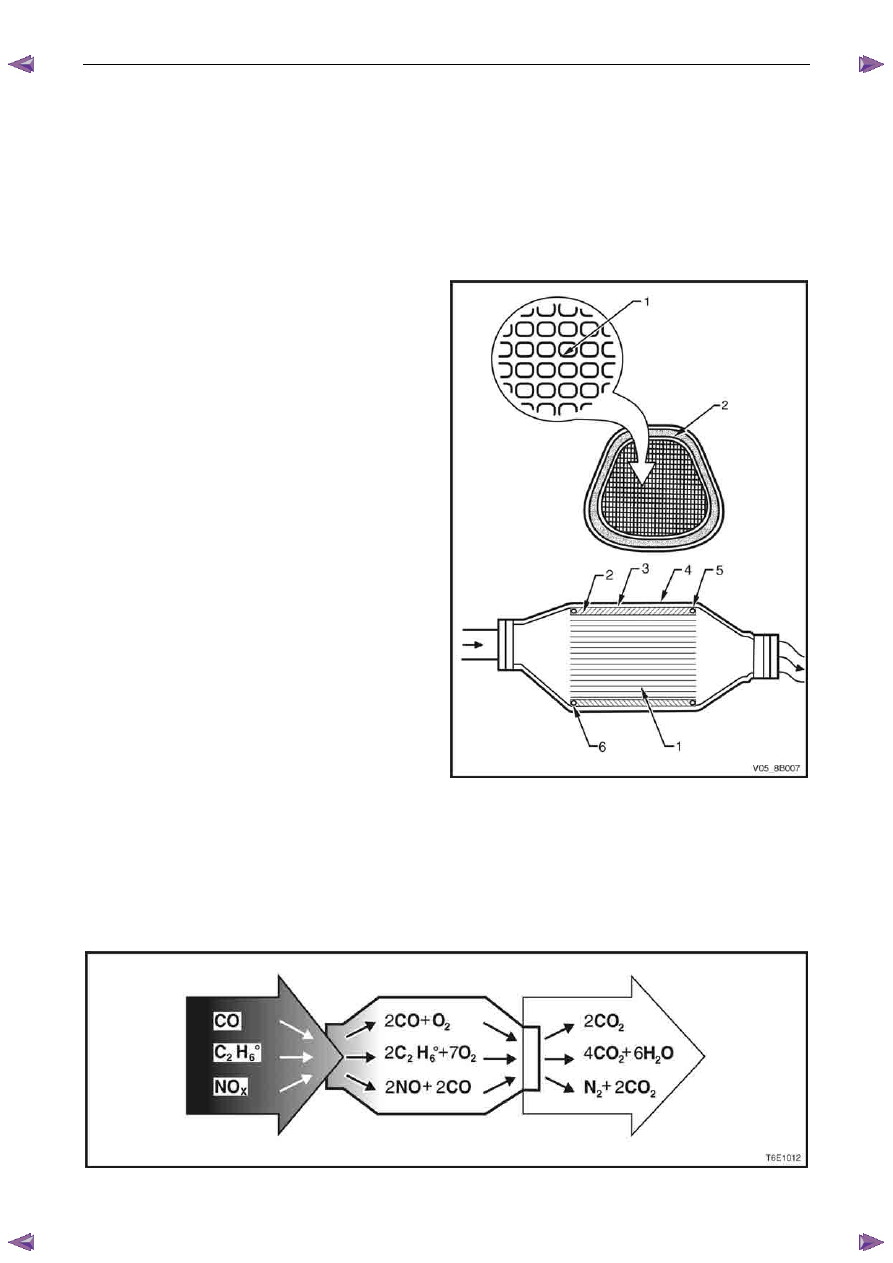

The catalytic converter is similar to a muffler in appearance

however, within the outer stainless steel shell (4), there is a

ceramic monolith (1) which is honeycombed in the direction

of exhaust flow, as shown. The ceramic monolith is

surrounded by a mat (2), which has the primary function of

holding the monolith firmly in place to prevent any contact

with the inner shell (3). A mesh seal (5 and 6) at each end

of the converter prevents exhaust gases from fouling and

eroding the mat.

Surfaces of the ceramic monolith that are exposed to

exhaust gases are coated with a catalytic material. This

material contains rhodium and platinum, which act to

facilitate the chemical reactions necessary to oxidise carbon

monoxide and hydrocarbons into harmless carbon dioxide.

Figure 6F– 1

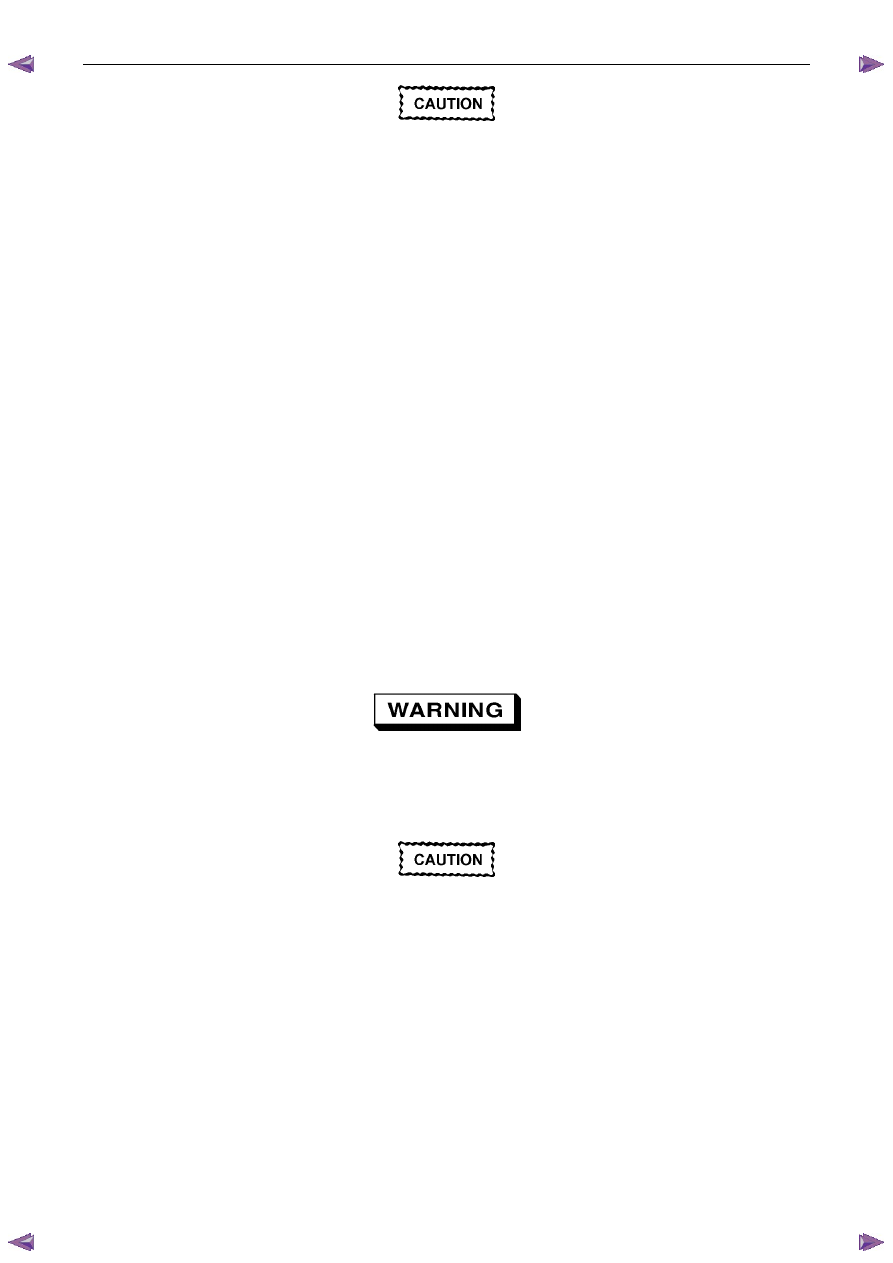

The catalytic converter is a substance that accelerates a chemical reaction without itself being changed. Engine exhaust

gases contain carbon monoxide (CO), hydrocarbons (HC) and oxides of nitrogen (NO

x

). When the exhaust gases flow

through the monolith, reactions with the catalytic converter occur. CO and HC are converted by oxidation with oxygen

(O

2

) in the exhaust gases to produce carbon dioxide (CO

2

) and water vapour (H

2

O). NO

x

is converted by reduction with

CO to produce nitrogen (N

2

) and CO

2

. The converter is called a three-way type because it simultaneously converts three

components of exhaust gas (CO, HC and NO

x

) to harmless natural gases, refer to Figure 6F– 2

Figure 6F– 2

Exhaust System – V6

Page 6F – 3

The Catalytic converter can be damaged or

rendered ineffective, if:

• operated outside the limits of the closed

loop mixture control system

• the engine burns excessive amount of oil

• the exhaust temperature at the converter

is too high (exceeds 840°C).

The catalytic material is very sensitive to the effects of a rich or lean fuel mixture, which may cause the temperature of

the converter to rise rapidly. The catalytic converter normally operates at approximately 600

°C.

The catalytic converter is also sensitive to the use of leaded petrol. Using leaded fuel can cause deposits to form in the

converter, which restrict exhaust flow and prevent the catalyst from working. This will result in an increase in exhaust

backpressure and converter temperature.

N O T E

The use of unleaded petrol results in black

tailpipe deposits rather than the grey colour that

some people may normally associate with an

acceptable combustion condition. This black

colour resulting from the use of unleaded fuel

does not necessarily indicate a state of poor

engine tune. For V6 engines, Refer to: 6C1 – 1

Engine Management General Information.

Euro 3 Emissions Standards

The Euro 3 emissions standard is a European standard which aims at setting vehicle emissions targets to encourage

vehicle manufacturers to reduce harmful vehicle emissions such as Carbon Monoxide (CO), Hydrocarbons (HC) and the

various oxides of Nitrogen (NOx).

This vehicle is fitted with a supplemental

restraint system (SRS). Refer to section 9A

Restraints, in order to determine whether you

are performing service on or near the SRS

components or the SRS wiring.

Always use the correct fastener in the proper

location. When you replace a fastener, use

ONLY the exact part number for that

application. Isuzu will identify those fasteners

that require a replacement after removal and

fasteners that require thread lockers or thread

sealant. Unless otherwise specified, do not

use supplemental coatings (Paints, greases

or corrosion inhibitors) on thread fasteners or

fastener joints. Generally such coatings

adversely effect the fastener torque and the

joint clamping force, and may damage the

fastener. When you install fasteners, use the

correct tightening sequence and torque

specifications.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст