Isuzu KB P190. Manual — part 980

Automatic Transmission – 4L60E – On-vehicle Servicing

Page 7C4–7

N O T E

This will also flush the cooler hose/line

assemblies and cooler with transmission fluid.

7

If the flow rate is satisfactory, reconnect the cooler inlet line to the transmission, refer to

3.17

Transmission Cooler Line/Hose Assemblies.

8

Lower the vehicle, check and top up the transmission fluid to the correct level as required, refer to

2.1 Transmission Fluid.

Flow Rate Test

Do not run the engine any longer than

absolutely necessary, as a fluid level too low

can cause aeration and foaming.

1

Ensure the transmission fluid is at the recommended level or slightly above, refer to 2.1

Transmission Fluid.

2

Disconnect the cooler inlet line at the transmission quick-connect fitting, refer to 3.17 Transmission Cooler

Line/Hose Assemblies.

3

Place a suitable size container underneath the disconnected cooler inlet line.

4

With the selector lever in the P position, start the engine and observe the fluid flow into the container after all the air

bubbles have ceased and a steady flow is evident. Measure the flow rate over 20 seconds and ensure it is within

the specification.

Transmission fluid flow rate specification per 20 Seconds:

Temperature:

Ambient. . . . . . . . . . . . . . . 0.7 Litres

86° – 93° C . . . . . . . . . . . . . .. 1.2 Litres

5

If the flow rate is less than the specification, the cause of the low flow rate must be located and rectified.

Possible cause could include:

•

restricted cooler within the radiator tank,

•

kinked or damaged transmission cooler hose/line assemblies, or

•

internal transmission fault such as a faulty pump.

6

Reinstall the cooler inlet line to the transmission quick-connect fitting, refer to 3.17

Transmission Cooler

Line/Hose Assemblies.

Automatic Transmission – 4L60E – On-vehicle Servicing

Page 7C4–8

3 Service

Operations

3.1

Fluid Change and Filter Replacement

To avoid personal injury take note of the

following:

• Avoid accidental hot oil spillage by

performing fluid change only when the

transmission fluid is cold.

• Wear safety glasses and gloves when

using compressed air and cleaning fluids.

Remove

1

Raise the vehicle and support in a safe manner, refer to 0A General Information.

2

Clean all dirt from around the oil pan and the transmission case.

3

Place a suitable sized drain tray under the

transmission.

4

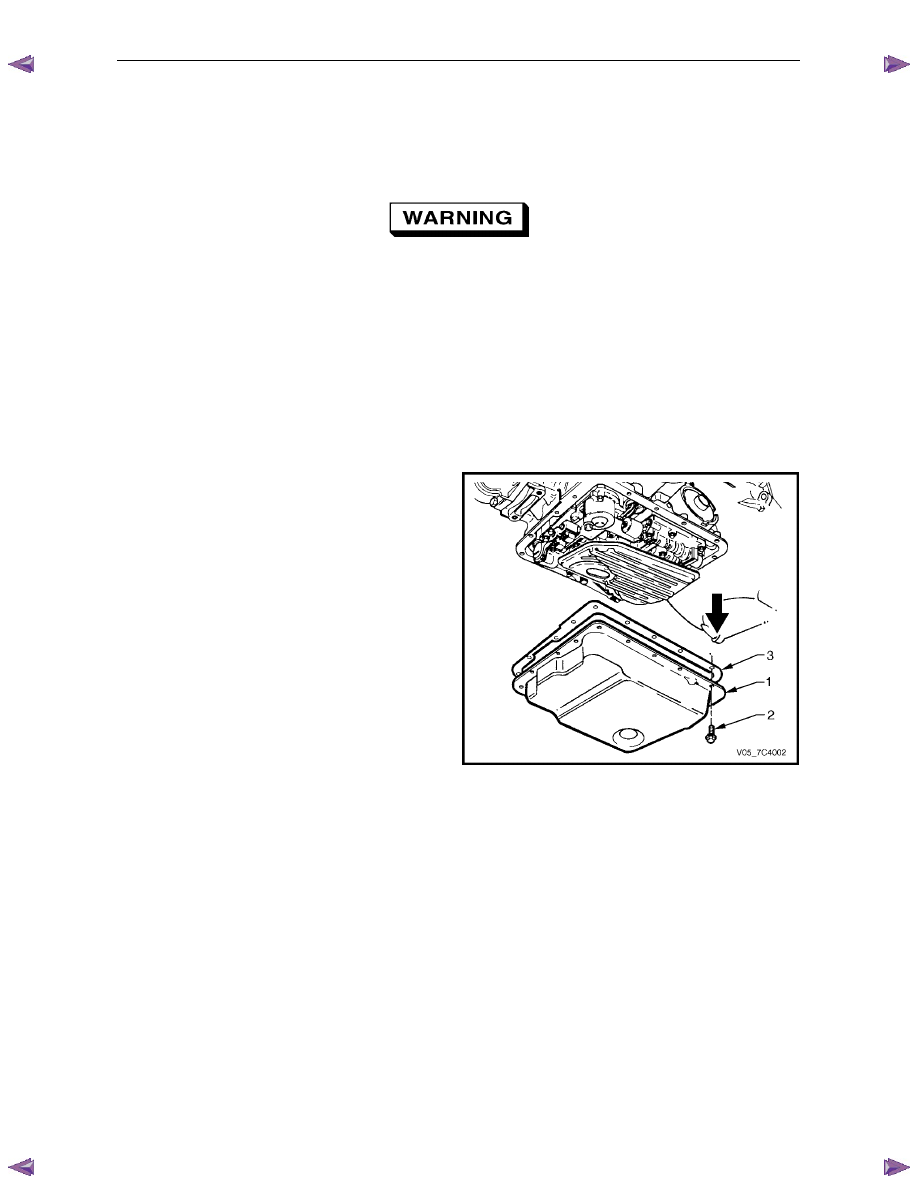

Hold the oil pan (1) in place and remove the oil pan

bolts (2) from the front and both sides.

N O T E

Leave the three rear oil pan bolts in place.

5

Loosen the three rear oil pan bolts by about 4 turns

each. While still supporting the oil pan, lightly tap the

sides with a rubber hammer to break the gasket (3)

seal.

6

Lower the front of the oil pan and drain the fluid into a

suitable container.

7

Remove the three remaining rear bolts and the oil pan

from the transmission.

8

Remove the oil pan gasket and discard.

Figure 7C4 – 2

Automatic Transmission – 4L60E – On-vehicle Servicing

Page 7C4–9

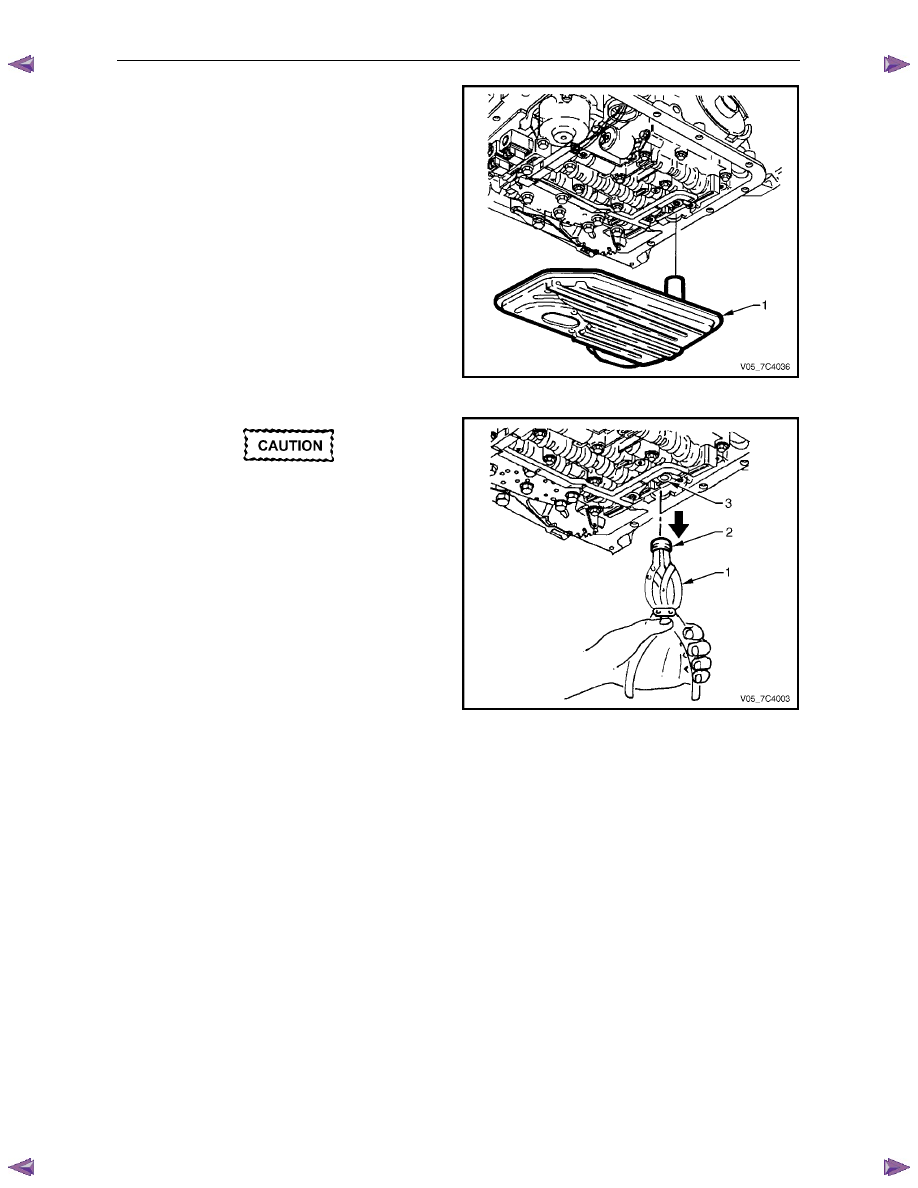

9

Remove the oil filter (1) by pulling down while twisting

the filter and remove it from the transmission.

10

Open the filter by prising the metal crimping away from

the top of the filter and pull it apart.

11

Inspect the filter material for particles that may indicate

evidence of a potential transmission problem.

Examples of the type of material are:

•

clutch friction material,

•

bronze slivers, indicating bush wear and

•

steel particles.

Figure 7C4 – 3

Take care not to scratch the oil pump bore,

as fluid leakage could occur from this point

or the pump may suck in air, causing the

fluid to aerate.

12

Using suitable circlip pliers (1) or a two legged puller

and slide hammer, remove the oil filter seal (2) taking

care not to scratch the oil pump bore (3) during the

process. Discard the seal.

Figure 7C4 – 4

Reinstall

1

Clean the oil pan in a commercially available cleaning fluid and blow dry using compressed air.

N O T E

Ensure all traces of the old gasket are removed

from the transmission and oil pan.

2

Wipe the transmission case gasket mating surface with a clean lint free cloth.

Automatic Transmission – 4L60E – On-vehicle Servicing

Page 7C4–10

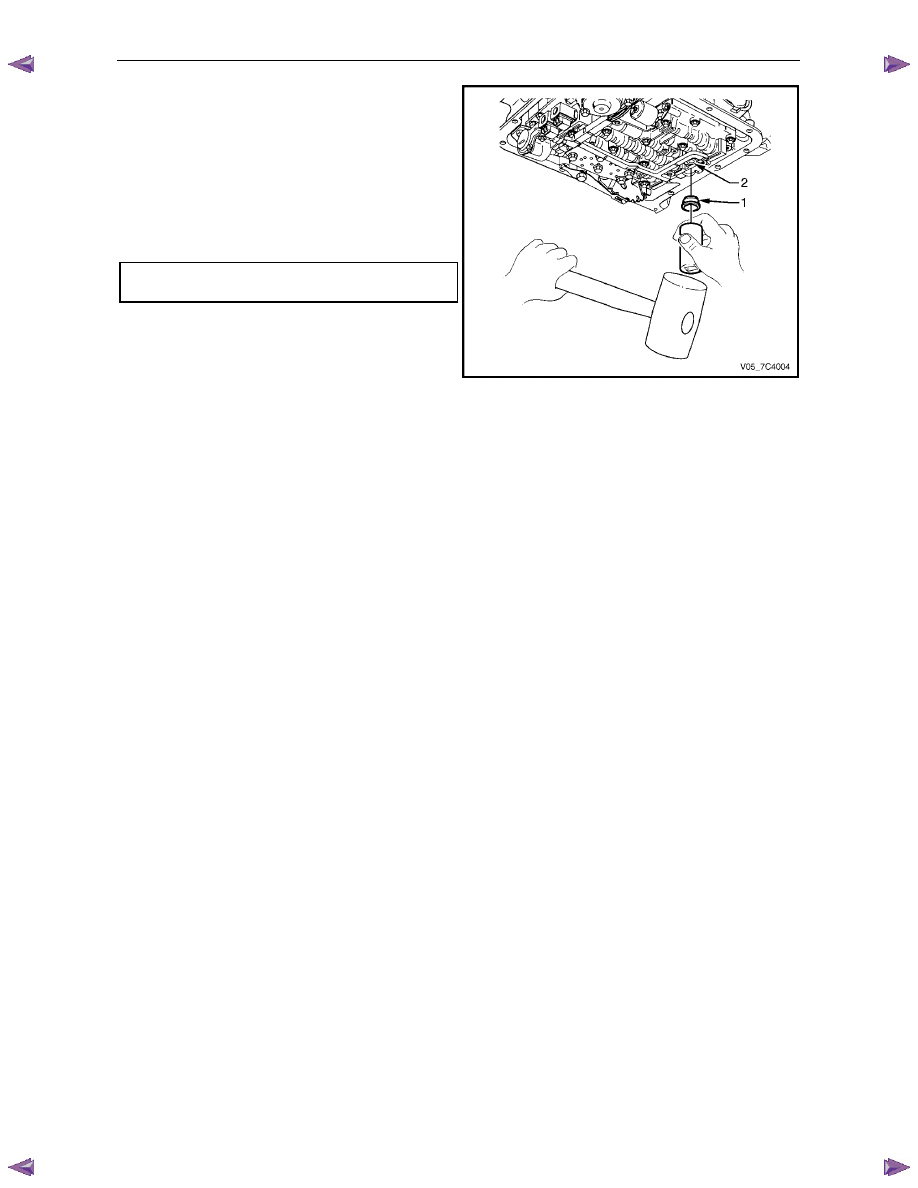

3

Lubricate a new oil filter seal (1) with clean

transmission fluid and install into the oil pump bore (2)

using a suitable sized socket or piece of tubing.

4

Install a new filter into the transmission case.

5

Check if the magnet is functional and located in the

designated position in the oil pan. Install a new gasket

and reinstall the oil pan.

6

Tighten the bolts attaching the oil pan to the correct

torque specification.

Oil pan attaching bolt

torque specification . . . . . . . . . . . 12.0 Nm

Figure 7C4 – 5

7

Lower vehicle and add approximately 4.8 litres of automatic transmission fluid.

8

Operate the vehicle for about 24 km or until normal transmission operating temperature is reached, refer to

2.1 Transmission Fluid.

9

Ensure there are no fluid leaks from the oil pan area, rectify as required.

10

Check and top up the transmission fluid to the correct level as required, refer 2.1

Transmission Fluid.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст