Isuzu KB P190. Manual — part 634

Engine Mechanical – V6

Page 6A1–57

3.3

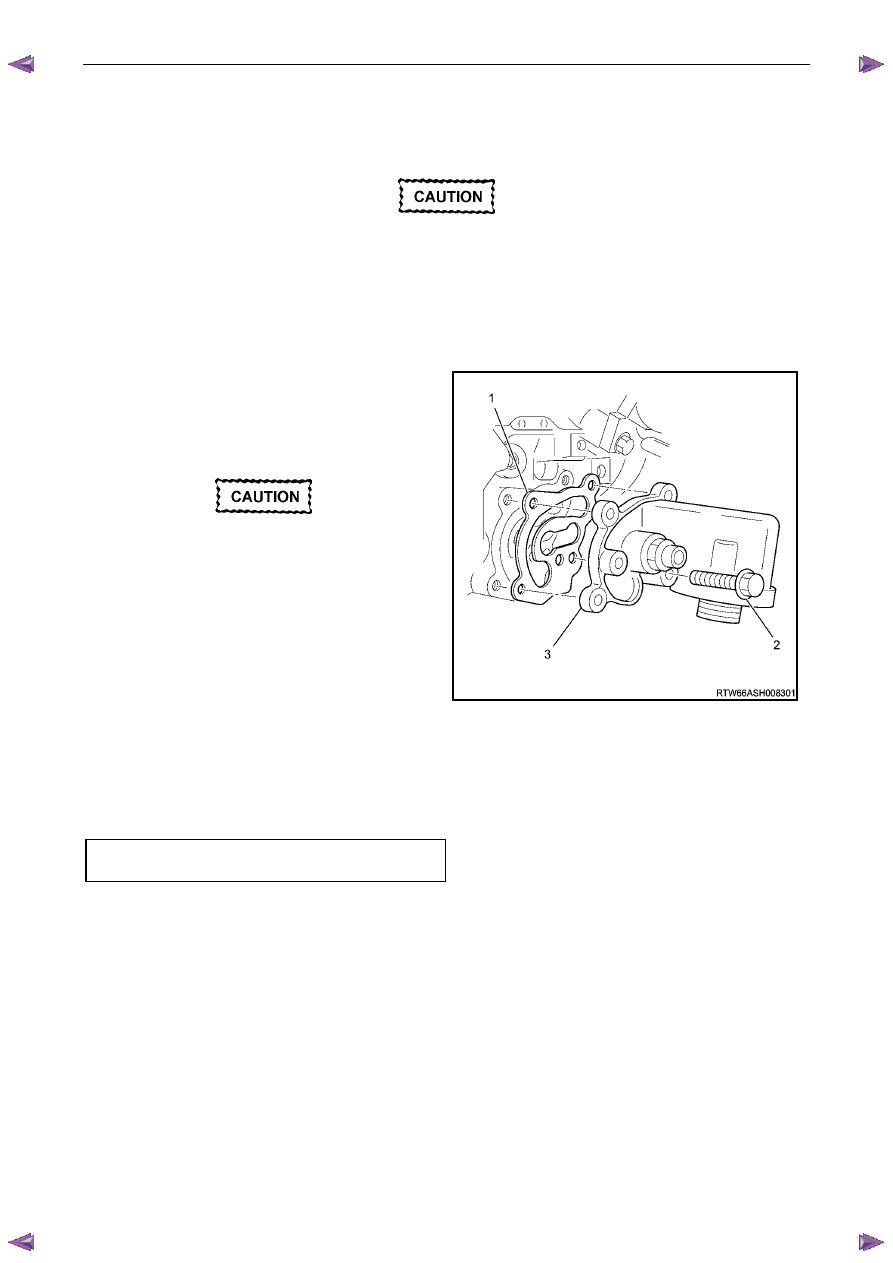

Oil Filter Adaptor

Remove

Disconnection of the battery affects certain

vehicle electronic systems, refer to 1.1

WARNING, CAUTION and NOTES before

disconnecting the battery.

1

Disconnect the battery negative terminal.

2

Disconnect the wiring harness connector from the oil pressure sender.

3

Remove the oil filter adaptor attaching bolts (2), four

places.

4

Remove the oil filter adaptor and discard the gasket

(3).

5

Clean the surfaces of the adaptor and cylinder block.

• Do not use a screwdriver or similar to

prise the oil filter adapter from the engine

as damage to the sealing surface may

occur.

• If required, use a rubber mallet to tap the

oil filter adapter to loosen the

components prior to separating.

Tapping should be done at bends,

corners or reinforced areas to prevent

distortion of parts.

Figure 6A1 – 27

Reinstall

Reinstallation of the oil filter adaptor is the reverse of the removal procedure, noting the following:

1

A new gasket must be used.

2

Loosely install the oil filter adaptor attaching bolts, then tighten all fasteners to the correct torque specification.

Oil filter adaptor attaching bolt

torque specification . . . . . . . . .. 20.0- 26.0 Nm

Engine Mechanical – V6

Page 6A1–58

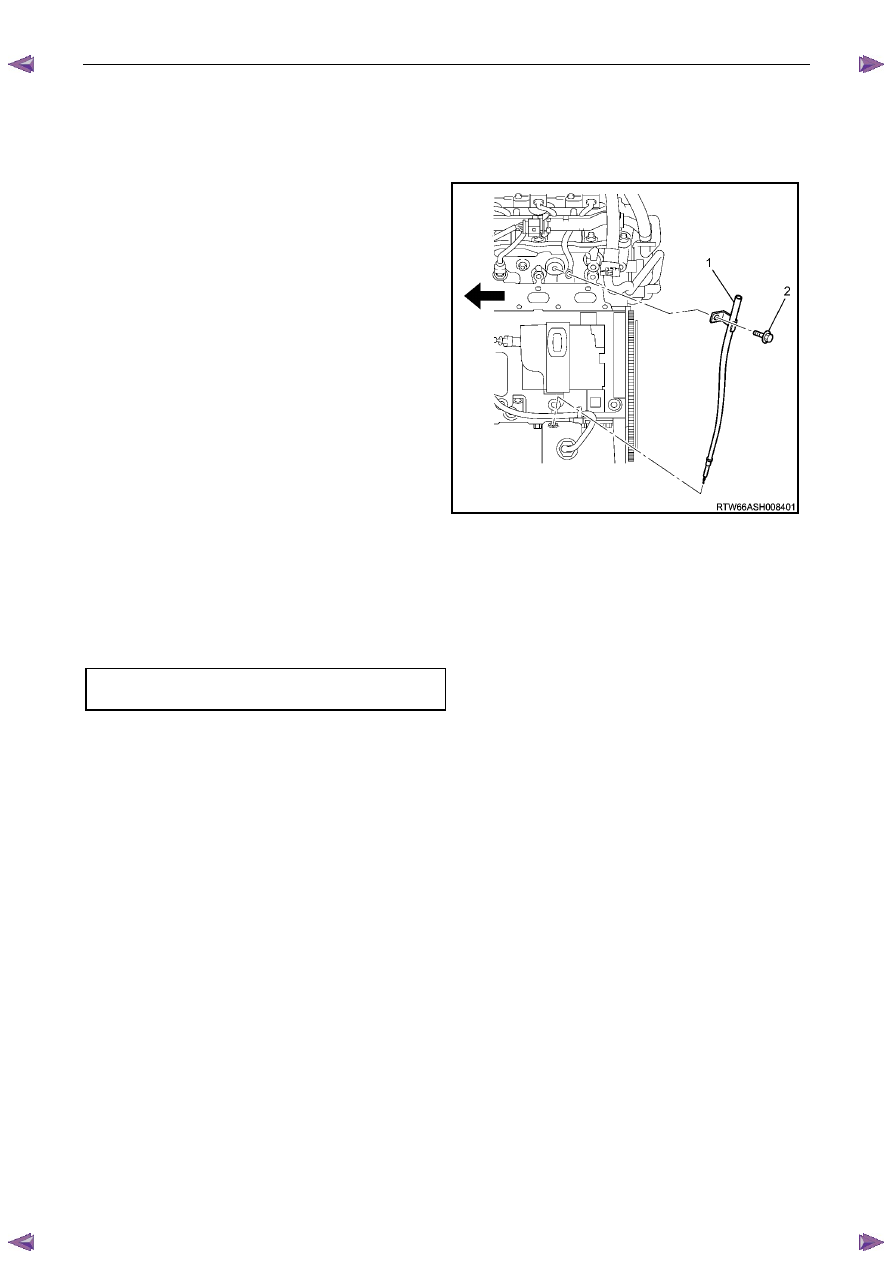

3.4

Oil Level Indicator Tube

Remove

1

Remove the oil level indicator from the oil level indicator tube.

2

Remove the bolt (2) attaching the oil level indicator

tube (1) and engine wiring harness retaining bracket.

3

Withdraw the oil level indicator tube from the oil pan.

4

Remove and discard the o-ring at the bottom of the oil

level indicator tube.

Figure 6A1 – 28

Reinstall

Reinstallation of the oil level indicator tube is the reverse of the removal procedure, noting the following:

1

Install a new oil level indicator o-ring.

2

Ensure the attaching bolt passes through the engine wiring harness retaining bracket.

3

Tighten bolt to the correct torque specification.

Oil level indicator tube attaching bolt

torque specification . . . . . . . . ...8.0 – 12.0 Nm

Engine Mechanical – V6

Page 6A1–59

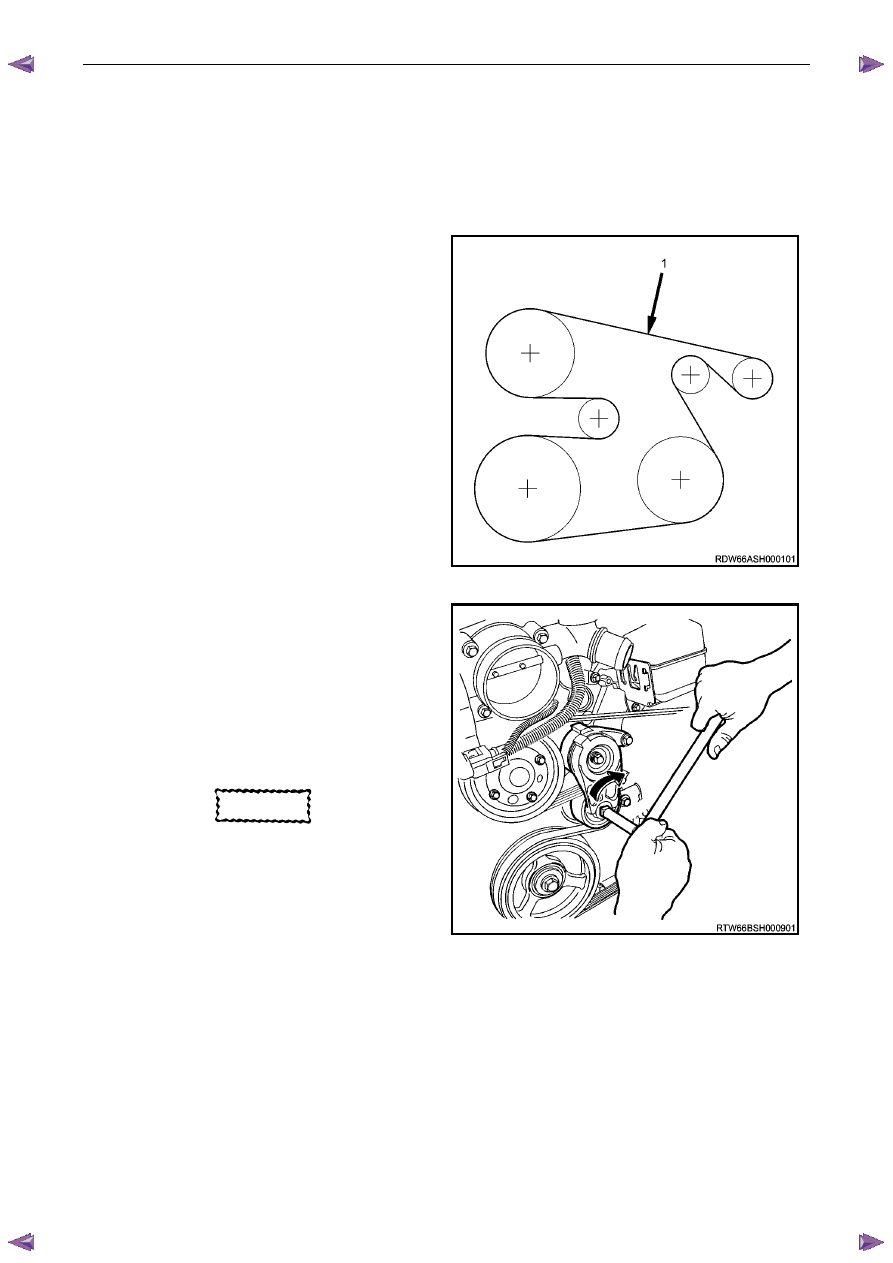

3.5

Accessory Drive Belt

RWD Vehicle

Remove

1

Remove the air intake duct from between the air flow meter and the throttle body, refer to 6C1-3 Engine

Management – V6 – Service Operations.

2

Note the accessory drive belt (1) routing.

Figure 6A1 – 29

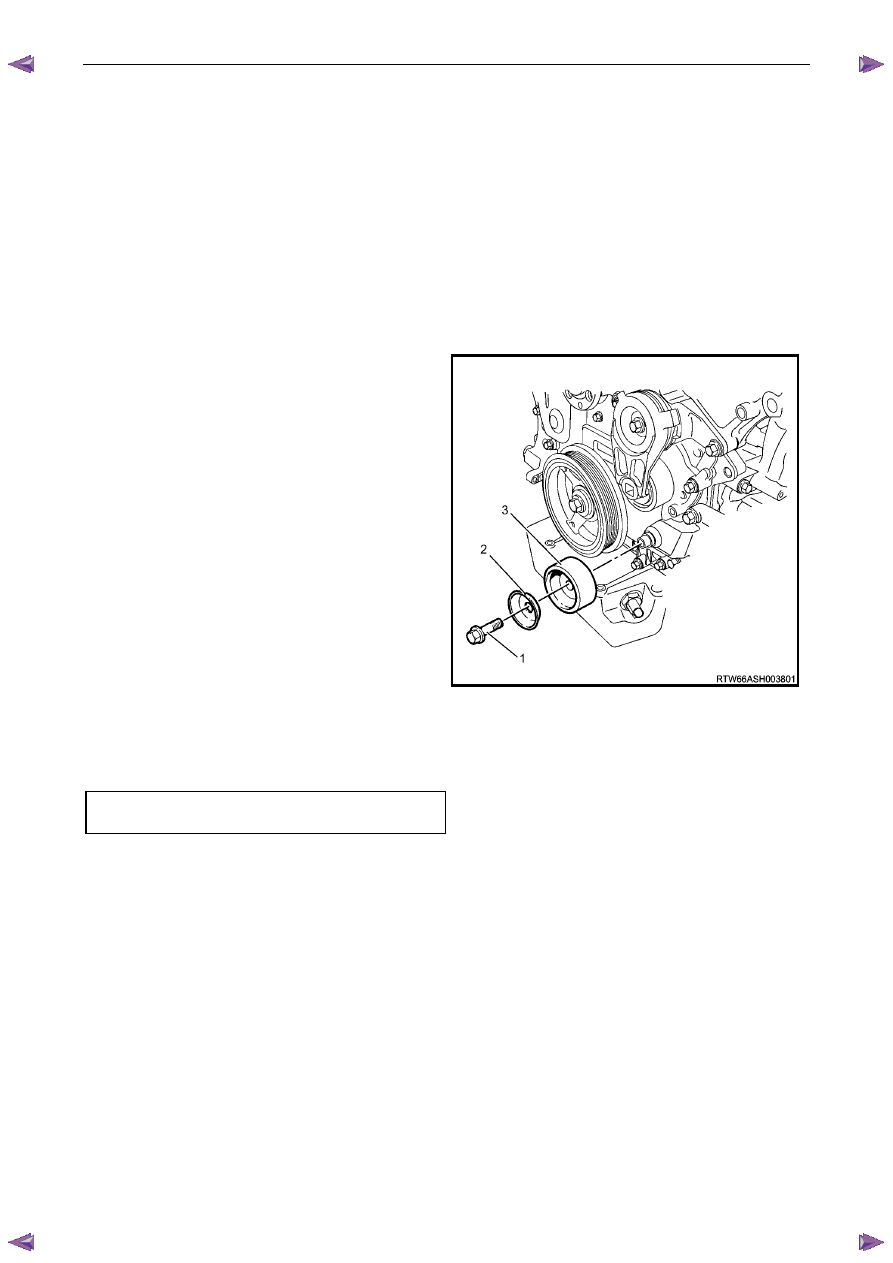

3

Using a suitable ½” drive socket bar (1), rotate the

drive belt tensioner (2) clockwise, to reduce belt

tension.

4

While holding the tensioner in the reduced tension

position, remove the accessory drive belt (3).

N O T E

If required use an assistant to maintain the

tensioner in the required position.

CAUTION

If running the engine with the accessory

drive belt removed, the coolant pump will

not be operating and the engine may

overheat if left unsupervised even for a short

period.

Figure 6A1 – 30

Reinstall

1

Install the drive belt over the A/C compressor, idler pulley, power steering pump, coolant pump, generator and

tensioner pulleys.

2

Using a suitable ½” drive socket bar (1), rotate the drive belt tensioner (2) clockwise, refer to Figure 6A1 – 30.

3

With an assistant holding the tensioner in the required position, feed the accessory drive belt (3) over the

crankshaft pulley.

4

Slowly release the drive belt tensioner mechanism.

Engine Mechanical – V6

Page 6A1–60

N O T E

Ensure the drive belt ribs are correctly aligned

with the grooves in the accessory drive pulleys or

damage to the drive belt and accessory drive

components and pulleys may occur.

5

Reinstall the air intake duct to the air flow meter and the throttle body, refer to 6C1-3 Engine Management – V6 –

Service Operations.

6

Run the engine to ensure correct operation.

3.6

Accessory Drive Belt Idler Pulley

Remove

1

Remove the accessory drive belt, refer to 3.5

Accessory Drive Belt.

2

Remove the accessory drive belt idler pulley attaching

bolt (1).

3

Remove the dished washer (2) and accessory drive

belt idler pulley (3).

Figure 6A1 – 31

Reinstall

Reinstallation of the accessory drive belt idler pulley is the reverse of the removal procedure. Tighten the bolt to the

correct torque specification.

Accessory drive belt idler pulley

attaching bolt torque specification. . . . . ..50.0 Nm

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст