Isuzu KB P190. Manual — part 228

ENGINE MECHANICAL 6A – 107

RTW36ASH002001

11. Piston and Connecting Rod with Upper Bearing

12. Connecting Rod Bearing Cap with Lower Bearing

1. Apply a coat of engine oil to the circumference of each

piston ring and piston.

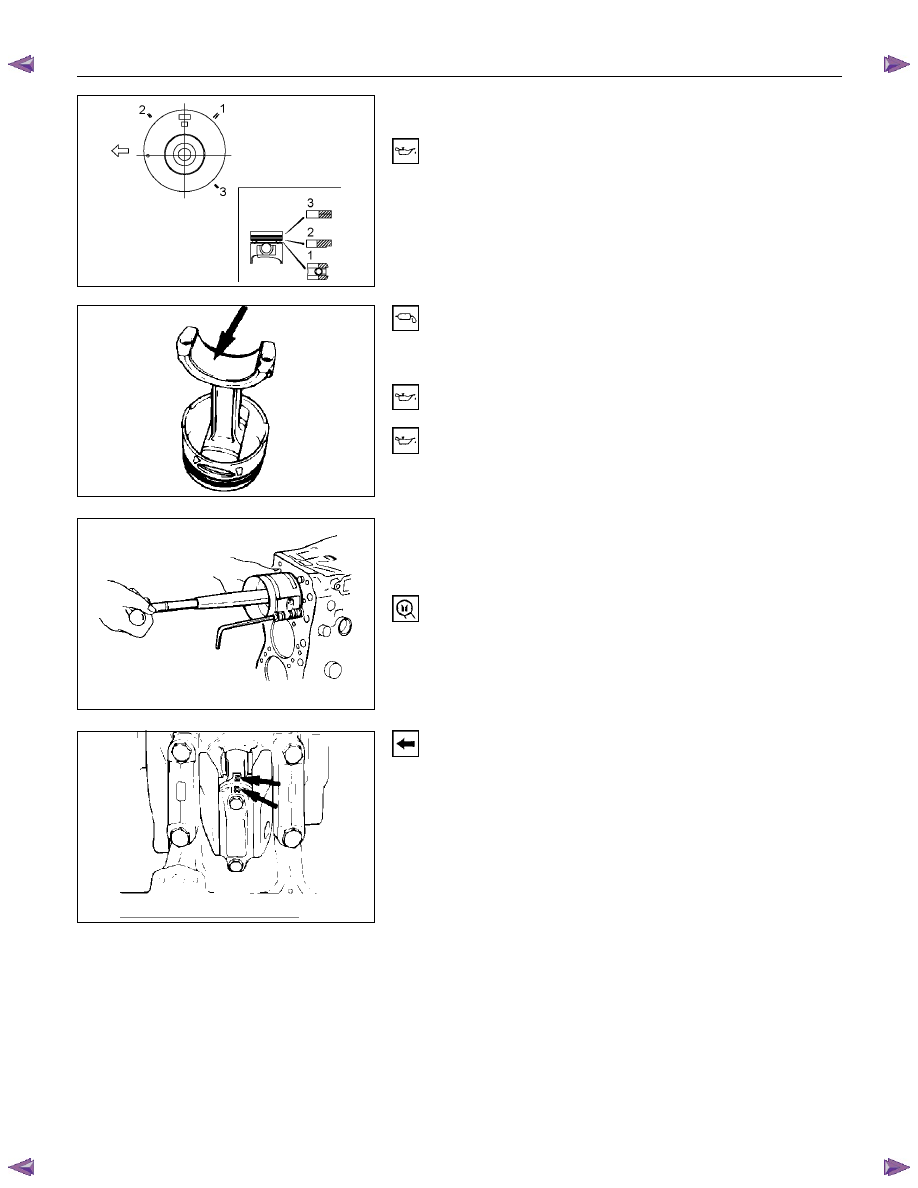

2. Position the piston ring gaps as shown in the

illustration.

1. Oil

ring

2. 2nd compression ring

3. 1st compression ring

3. Apply a coat of molybdenum disulfide grease to the two

piston skirts.

This will facilitate smooth break-in when the engine is

first started after reassembly.

4. Apply a coat of engine oil to the upper bearing

surfaces.

5. Apply a coat of engine oil to the cylinder wall.

6. Position the piston head front mark so that it is facing

the front of the engine.

7. Use the piston ring compressor to compress the piston

rings.

Piston Ring Compressor: 5-8840-9018-0

8. Use a hammer grip to push the piston in until the

connecting rod makes contact with the crankpin.

At the same time, rotate the crankshaft until the

crankpin is at BDC.

9. Align the bearing cap cylinder number marks and the

connecting rod cylinder number marks.

The cylinder number marks must be turned toward the

exhaust manifold.

015LX096

015R100007

015R100006

6A – 108 ENGINE MECHANICAL

10. Apply a coat of engine oil to the threads and setting

faces of each connecting rod cap bolt.

11. Tighten the connecting rod caps to the two step of

anglar tigthen method.

Connecting Rod Bearing Cap Bolt Torque

N·m (kg·m/Ib ft)

4JA1T (L),

4JA1TC

78-88 (8.0/57 – 9.0/65)

1st step; 29.0–29.2 (3.00/22.0–3.01/22.2)

4JH1TC

2nd step; 45

°-60°

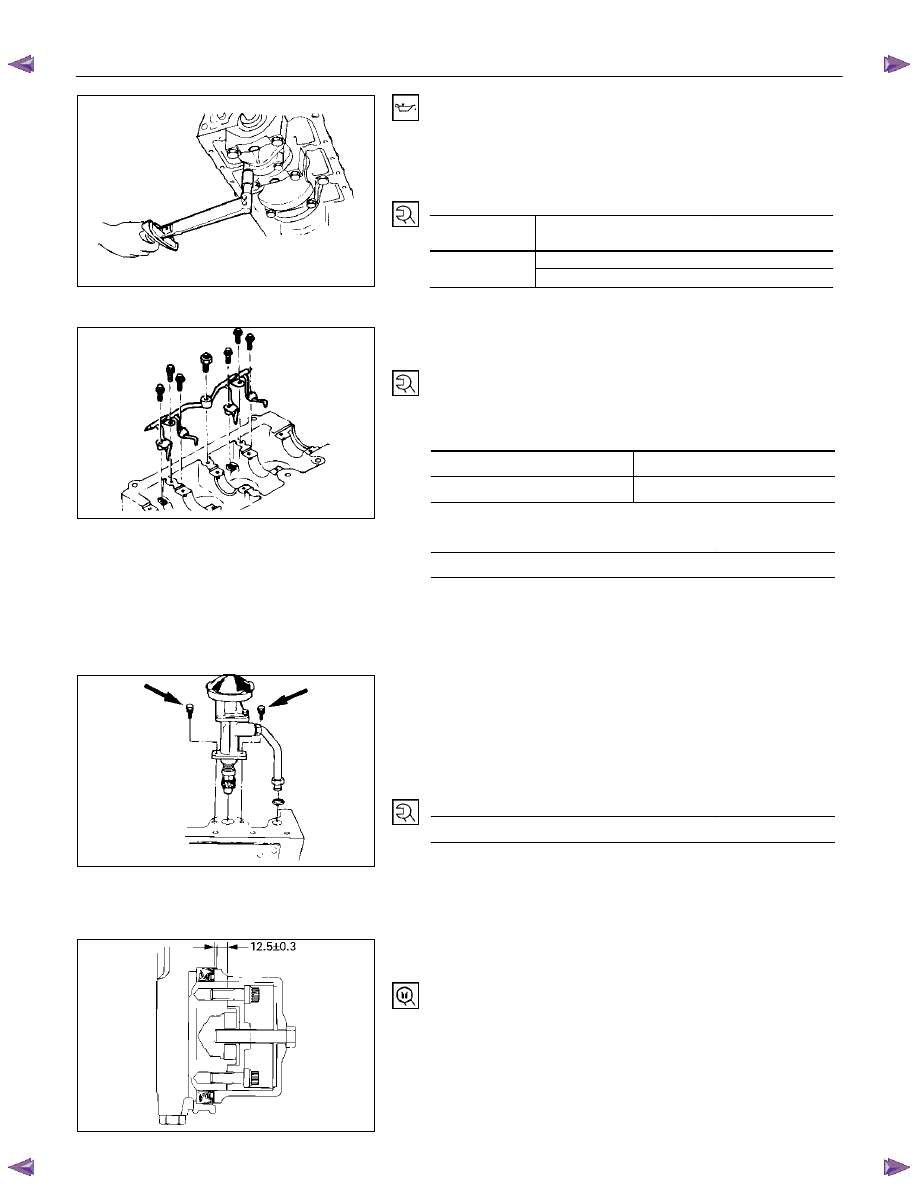

13. Piston Cooling Oil Jet

1. Install the piston cooling oil jet to the cylinder body.

2. Tighten the oil jet bolts and relief valve to the specified

torque.

Oil Jet Bolt Torque

N·m(kg·m/lb ft)

M8

× 1.25

19 (1.9/14)

M6

× 1.00

8 (0.8/6)

Relief Valve Torque

N·m(kg·m/lb ft)

29 (3.0/22)

NOTE:

Check that there is no interference between the piston

and the oiling jet by slowly rotating the crankshaft.

14. Oil Pump with Oil Pipe

Apply a coat of the molybdenum disul fide and engine oil

enough on the pinion gear.

Install the oil pump with the oil pipe and tighten the bolts to

the specified torque.

Oil Pump Bolt Torque

N·m(kg·m/lb ft)

19 (19/14)

NOTE:

Take care not to damage the O-rings when tightening

the oil pipe bolts.

15. Crankshaft Rear Oil Seal

Use a oil seal install to install the crankshaft rear oil seal.

Oil Seal Installer: 5-8840-2359-0

015LX130

015LX112

052LX010

051R100004

ENGINE MECHANICAL 6A – 109

16. Crank Case

1. Apply the recommended liquid gasket (Three bond

1207B) or its equivalent to arch gasket fitting surface

as shown in the illustration.

2. Install the crankcase front gasket (1) to the timing gear

case arches.

The gasket projection (2) must be facing forward.

NOTE:

ThreeBond 1207B is a fast-drying liquid gasket.

Install the arch packing to the crankcase immediately

aftter applying the gasket.

3. Install the rear arch gasket (2) to the No. 5 bearing

cap. Use your fingers to push the arch gasket into the

bearing cap groove.Take care not to scratch the arch

gasket outer surface.

Also apply the recommended liquid gasket (1207C) or

its equivalent to arch gasket fitting area as indicated in

the illustration.

4. Apply the recommended liquid gasket or its equivalent

to groove of the crankcase fitting surface as shown in

the illustration.

NOTE:

Be sure that the crank case fitting surface is

completely free of oil and dust before applying the

liquid gasket.

5. Install the crank case to the cylinder body.

6. Tighten the crank case bolts to the specified torque a

little at a time in the sequence shown in the illustration.

Crank Case Bolt Torque

N·m(kg·m/lbft)

19 (1.9/14)

013LV003

013RW012

013RW011

013R100001

6A – 110 ENGINE MECHANICAL

17. Cylinder Body Rear Plate

1. Align the rear plate with the cylinder body knock pins.

2. Tighten the rear plate to the specified torque.

Rear Plate Torque

N·m(kg·m/lbft)

82 (8.4/61)

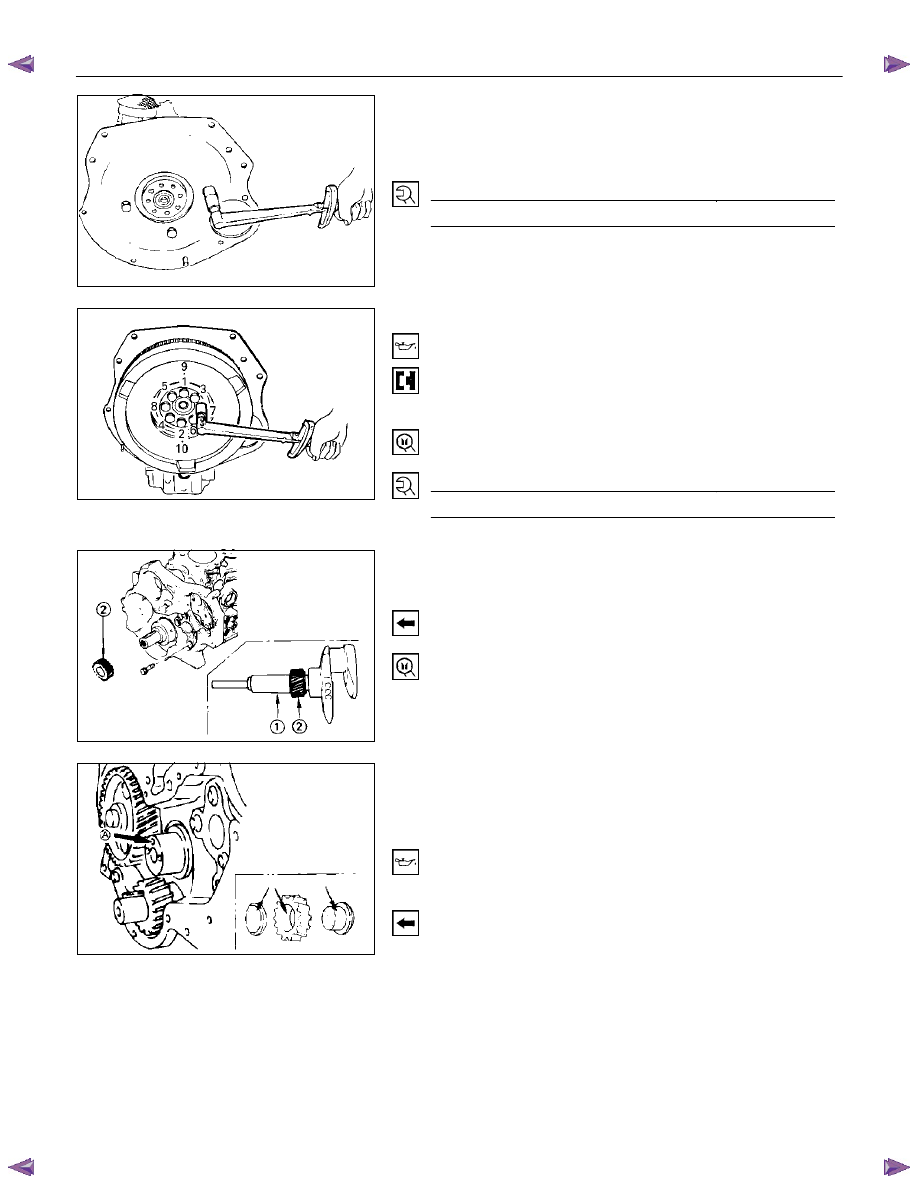

18. Flywheel

1. Apply a coat of engine oil to the threads of the flywheel

bolts.

2. Align the flywheel with the crankshaft dowel pin.

3. Tighten the flywheel bolts in the numerical order shown

in the illustration.

Gear stoper: 5-8840-0214-0

Flywheel Bolt Torque

N·m(kg·m/lbft)

118 (12/87)

19. Crankshaft Timing Gear

Use the crankshaft timing gear installer (1) to install the

crankshaft timing gear (2).

The crankshaft timing gear setting mark must be facing

outward.

Crankshaft Timing Gear Installer: 9-8522-0020-0

20. Idler Gear Shaft

21. Idler Gear "A"

1. Turn the crankshaft clockwise to set the DTC of the

No.1 piston.

2. Apply engine oil to the idler gear and the idler gear

shaft.

The idler gear shaft oil hole (A) must be facing up.

3. Position the idler gear setting marks so that they are

facing the front of the engine.

015LX113

020R100001

020RY00034

020RY00035

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст