Isuzu KB P190. Manual — part 1016

7A2-98 TRANSMISSION CONTROL SYSTEM (AW30–40LE)

Condition For Setting The DTC

The TCM detects following conditions for 0.5 seconds

continuously at shifting.

• Voltage at connector pin is 0V when solenoid is “ON”.

(DTC P0976)

• Voltage at connector pin is ignition voltage when

solenoid is “OFF”. (DTC P0977)

Action Taken When The DTC Sets

• No L-up control.

• No line pressure reduction control at gear change.

• No torque reduction control.

• No squat control.

• No slope control (keep mode).

• No line pressure reduction control at garage.

• No input revolution sensor failure detection.

• No shift solenoid failure detection.

• No L-up solenoid failure detection.

• Change to emergency mode.

• Check Trans “ON”.

• DTC stored.

• MIL request “ON”. (EURO 4 only)

Conditions For Clearing The DTC

• The DTC can be cleared from the TCM history by

using a scan tool.

• The DTC will be cleared from history when the

vehicle has achieved 40 warm-up cycles without a

failure reported.

• After more than 1 second has elapsed after the

ignition key has been turned “ON”, short between

No.11 and No.4 (ground) of DLC (Data Link

Connector). Then, after 1 second, but within 6

seconds, discontinue shorting.

Diagnostic Aids

• Inspect the wiring for poor electrical connection at the

TCM. Look for possible bent, backed out, deformed

or damaged terminals. Check for weak terminal

tension as well. Also check for a chafed wire that

could short to bare metal or other wiring.

Inspect for a broken wire inside the insulation.

• When diagnosing for a possible intermittent short or

open condition, move the wiring harness while

observing test equipment for a change.

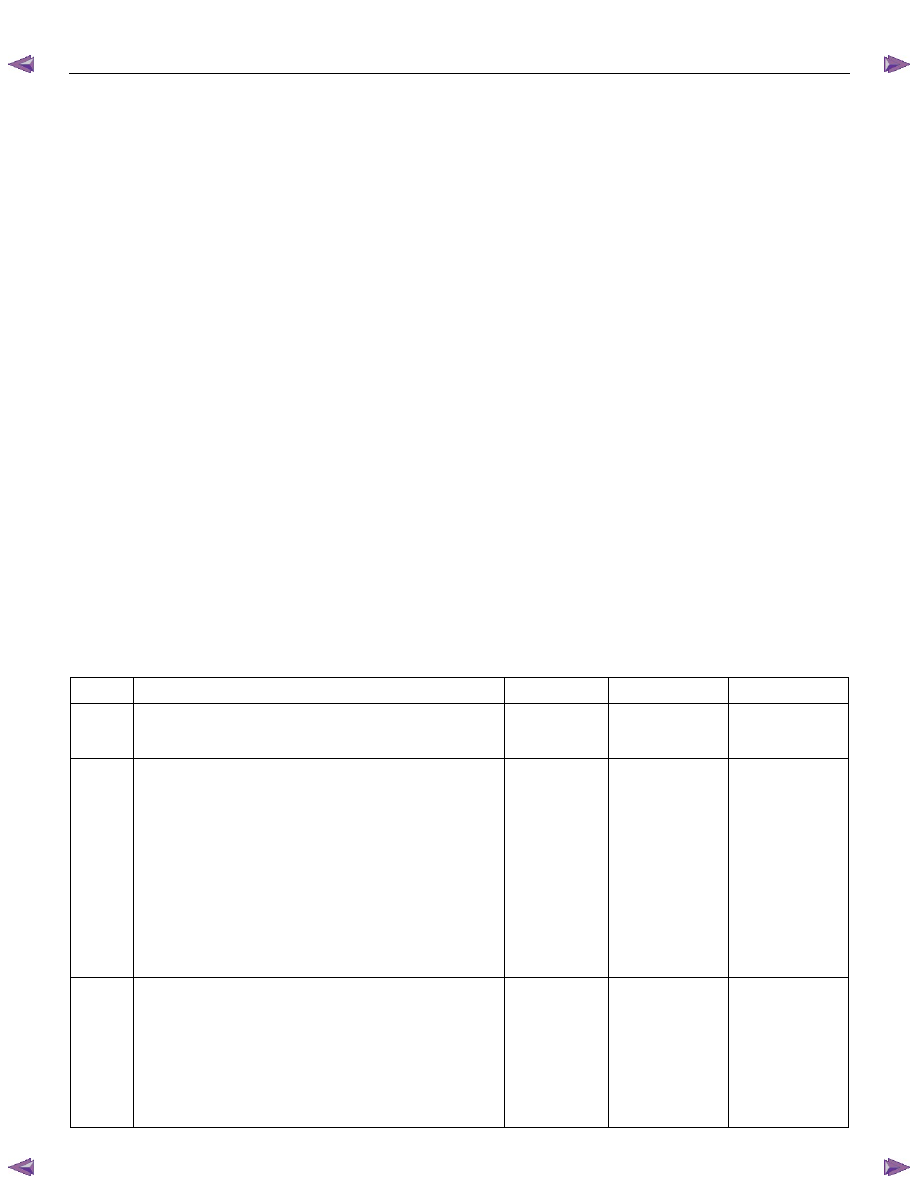

Circuit/System Testing DTC P0976 or P0977

Step Action Value(s)

YES

NO

1

Was the On-Board Diagnostic (OBD) System Check

performed?

— Go

to

Step 2

Go to OBD

System Check

2

1. Install a scan tool.

2. Start the engine.

3. Depress the brake pedal and place the select lever

in D position.

4. Press the 3rd start switch. (Turn the 3rd start

switch “ON”.)

5. Press the 3rd start switch again. (Turn the 3rd start

switch “OFF”.)

Does a scan tool indicate DTC P0976 or P0977?

— Go

to

Step 3

Refer to

Diagnostic Aids

3

1. Turn “ON” the ignition with the engine “ON”.

2. Place the selector lever in the “P” position.

3. Measure the voltage between terminal C94-15 and

terminal C94-1 on the TCM pigtail connector by 5-

8840-0285-0 DMM.

Is the voltage specified value?

8

∼

16V Go

to

Step 4

Go to Step 5

TRANSMISSION CONTROL SYSTEM (AW30–40LE) 7A2-99

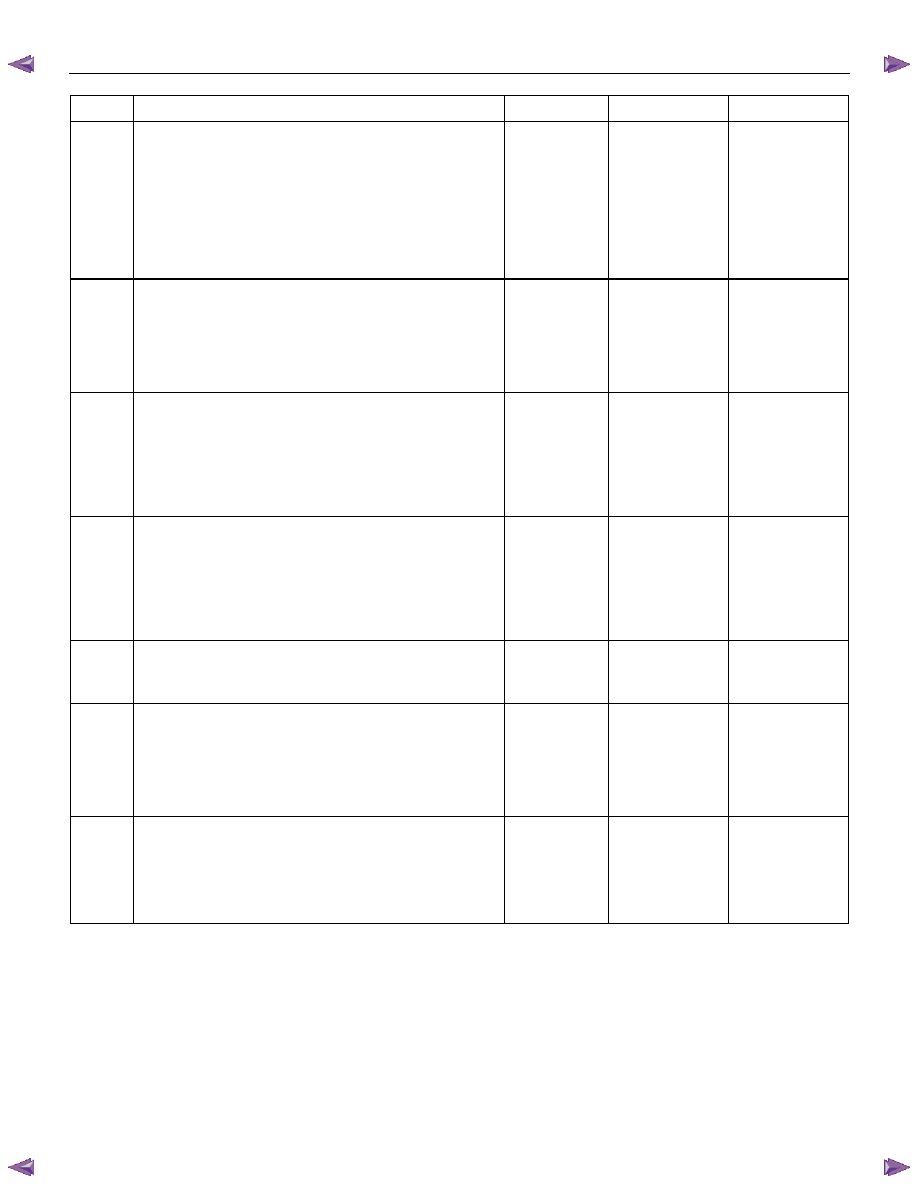

Step Action Value(s)

YES

NO

4

1. Turn “OFF” the ignition.

2. Disconnect the TCM connector (C-94).

3. Turn “ON” the ignition.

4. Measure the voltage between terminal C94-15 and

terminal C94-1 by 5-8840-0285-0 DMM.

Is the voltage specified value?

8

∼16V Go

to

Step 7

Go to Step 10

5

1. Turn “OFF” the ignition.

2. Measure the resistance between terminal C94-15

and body ground by 5-8840-0285-0 DMM.

Is the resistance specified value?

11

∼15Ω Go

to

Step 9

Go to Step 6

6

1. Disconnect the automatic transmission connector

(E-54).

2. Measure the resistance between terminal E54-8

and body ground by 5-8840-0285-0 DMM.

Is the resistance specified value?

11

∼15Ω Go

to

Step 7

Go to Step 8

7

1. Check for open or short in the wire between

terminal C94-15 and terminal E54-8.

2. Repair or replace the wire between terminal C94-

15 and terminal E54-8.

Is the action complete?

— Go

to

Step 11 —

8

Replace the S2 solenoid.

Is the action complete?

— Go

to

Step 11 —

9

1. Clear the DTC.

2. Perform the test-driving.

3. Check the DTC.

Was DTC P0976 or P0977 stored?

— Go

to

Step 10

Refer to

Diagnostic Aids

10

Replace the TCM.

Important: The replacement TCM must be

programmed (Refer to SPS for procedure).

Is the action complete?

— Go

to

Step 11 —

7A2-100 TRANSMISSION CONTROL SYSTEM (AW30–40LE)

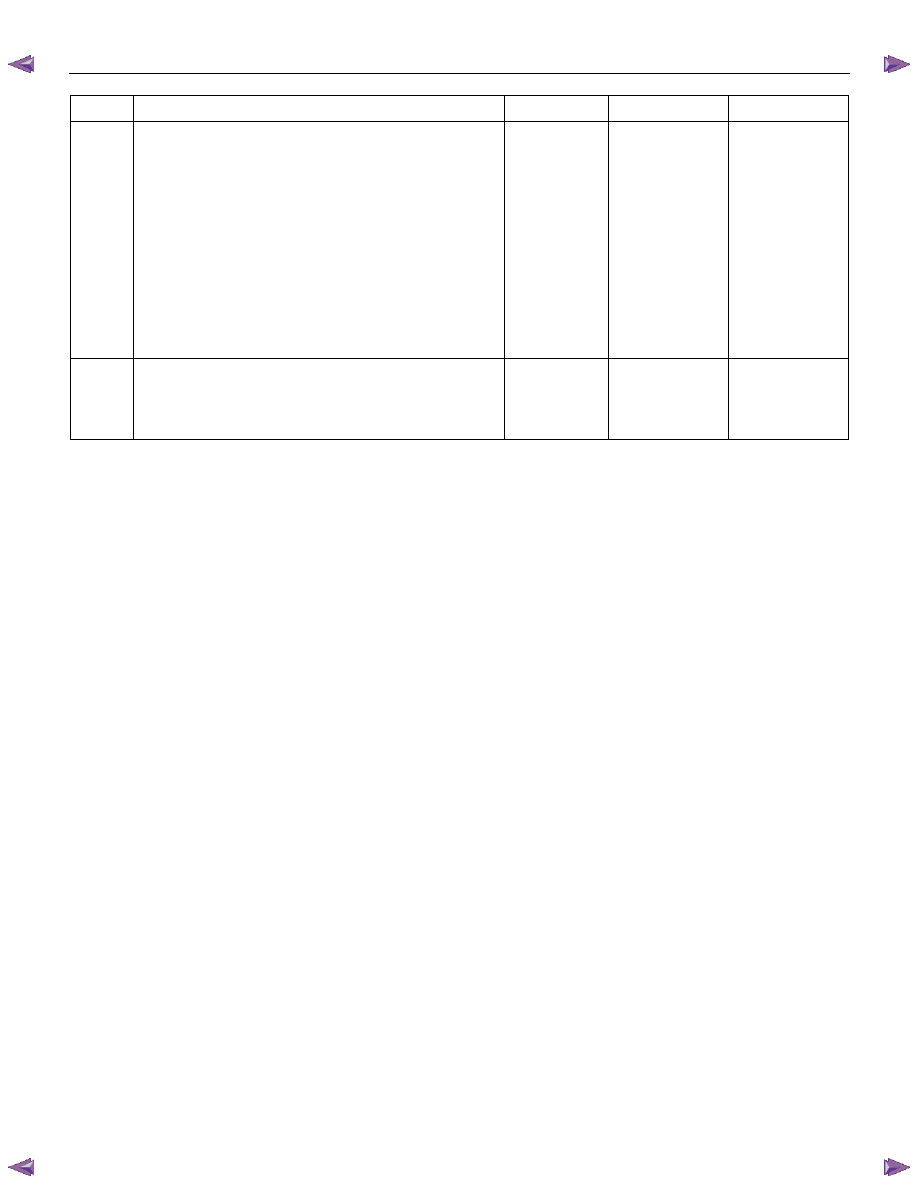

Step Action Value(s)

YES

NO

11

1. Reconnect all previously disconnected harness

connector(s).

2. Clear the DTCs with a scan tool.

3. Turn “OFF” the ignition.

4. Start the engine.

5. Operate the vehicle within the Conditions For

Running the DTC. You may also operate the

vehicle within the conditions that you observed

from the Freeze Frame/ Failure Records.

Did the DTC fail this ignition?

—

Go to Step 2 Go

to

Step 12

12

Observe the stored information, Capture info with a

scan tool.

Are there any DTCs that you have not diagnosed?

—

Go to

Diagnostic

Trouble Code

(DTC) List

Verify repair

TRANSMISSION CONTROL SYSTEM (AW30–40LE) 7A2-101

DTC P1790 (Flash Code 61)

Description

The electrically erasable programable read only

memory (EEPROM) is a permanent memory chip that is

physically solenoid within the TCM. The EEPROM

contans the program and the calibration information that

the TCM needs to control powertrain operation.

Unlike the PROM used in past applications, the

EEPROM is not replaceable. If the TCM is replaced, the

new TCM will need to be programmed. Equipment

containing the correct program and calibration for the

vehicle is required to program the TCM.

Condition For Running The DTC

ROM check sum calculation is completed.

Condition For Setting The DTC

Following condition is met twice since ignition “ON”.

• ROM check sum calculation result/check sum value

saved in ROM.

Action Taken When The DTC Sets

• Change to emergency mode.

• Check Trans “ON”.

• DTC

stored.

• MIL request “ON”. (EURO 4 only)

Conditions For Clearing The DTC

• The DTC can be cleared from the TCM history by

using a scan tool.

• The DTC will be cleared from history when the

vehicle has achieved 40 warm-up cycles without a

failure reported.

• After more than 1 second has elapsed after the

ignition key has been turned “ON”, short between

No.11 and No.5 (ground) of DLC (Data Link

Connector). Then, after 1 second, but within 6

seconds, discontinue shorting.

Diagnostic Aids

• Inspect the wiring for poor electrical connection at the

TCM. Look for possible bent, backed out, deformed

or damaged terminals. Check for weak terminal

tension as well. Also check for a chafed wire that

could short to bare metal or other wiring. Inspect for a

broken wire inside the insulation.

• When diagnosing for a possible intermittent short or

open condition, move the wiring harness while

observing test equipment for a change.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст