Isuzu KB P190. Manual — part 517

6A-54 ENGINE MECHANICAL (C24SE)

RTW46ASH002401

Installation

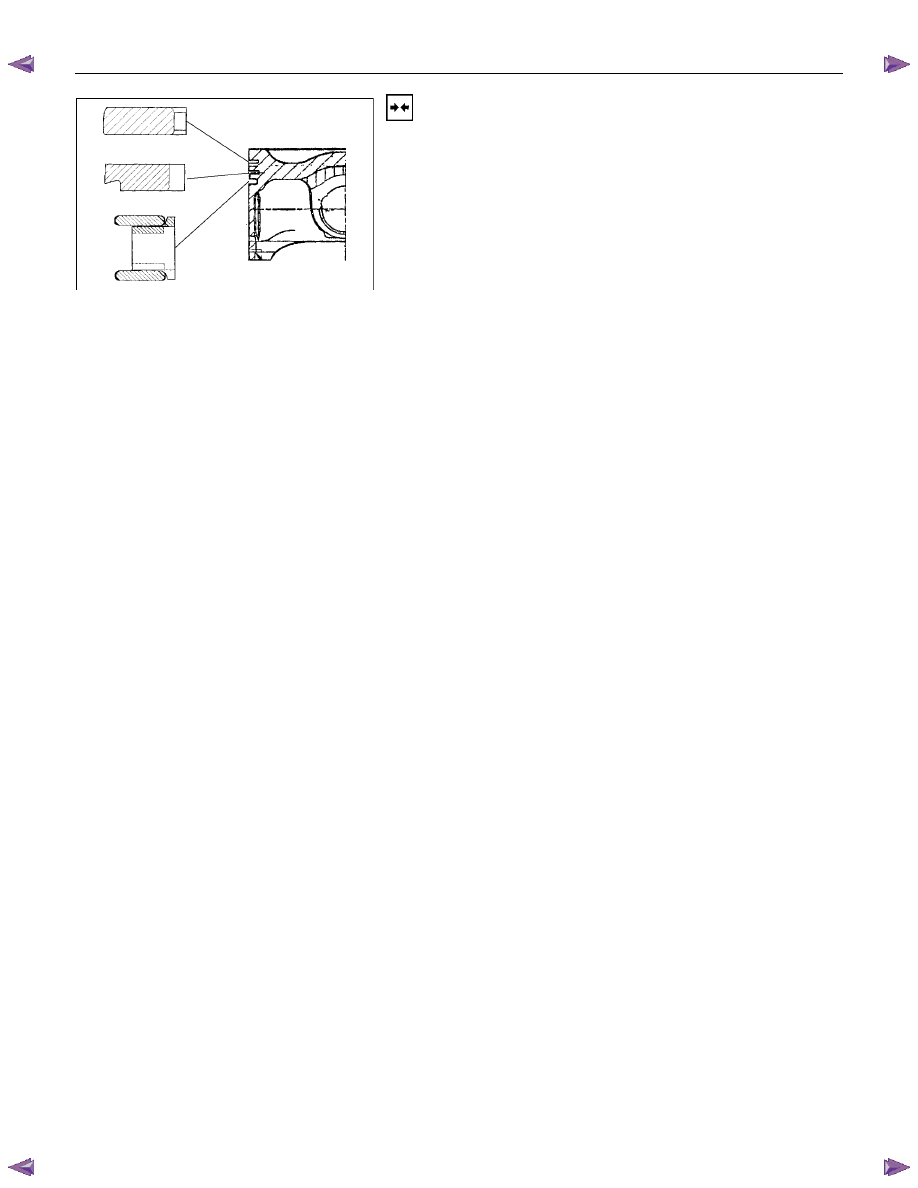

1. Install oil scraper ring.

2. Offset ring gaps of steel band rings each 25 to 50 mm/1

to 2in. to the left or right of the intermediate ring gap.

3. Install piston rings.

4. Offset ring gaps by approx. 180

°.

5. Install second piston ring with identification mark "TOP"

facing upwards.

6. Install piston with con-rod according to the corresponding

operation.

ENGINE MECHANICAL (C24SE) 6A-55

OPERATIONS ON REMOVED ENGINE

Crankshaft

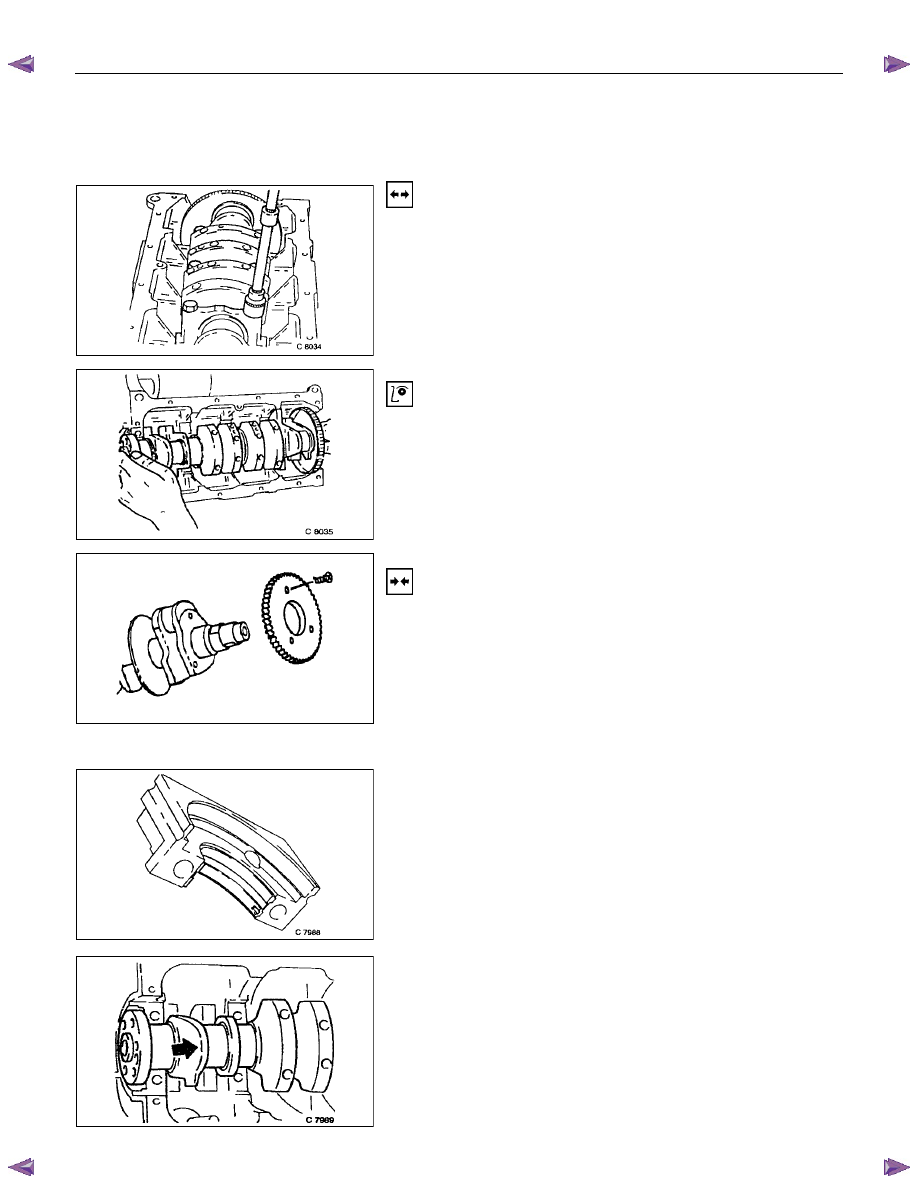

Removal

1. Mount the engine on an engine overhaul stand with

appropriate adapters.

2. Remove the aggregates, flywheel/drive disc, oil pan,

bearing bridge and oil pump according to the

corresponding operation.

3. Mark the con-rod bearing cover.

4. Remove the crankshaft bearing cover.

5. Remove the crankshaft from cylinder block.

Inspection

Remove and install all parts if necessary.

Crankshaft pulse pickup sensor rotor inspection and repair.

Inspect the crankshaft pulse pickup sensor rotor for excessive

wear and damage.

Replace the crankshaft pulse pickup rotor if the inspection

results exceed wear and damage limits.

Installation

1. Install the crankshaft pulse pickup sensor.

Torque: 13N

!!!!m (1.3 kgf!!!!m)

2. Install new bearing shells into the cylinder block and

bearing cover.

3. Coat the bearing shafts with engine oil.

For oversizes-see “Technical Data”

4. Install a new crankshaft into the cylinder block.

Note

The sealing of the crankshaft can be corrected with light

blows with a rubber hammer on the crank arm (arrowed).

6A-56 ENGINE MECHANICAL (C24SE)

5. Apply a bead of sealant (TB-1207C or equivalent) in the

grooves of both bearing shells.

Important!

After installation of bearing cover, press in sealing compound

again from above, until compound emerges at the joints.

Torque - Angle Method

Bearing cover to cylinder block - 50 N

⋅m (5.1 kgf⋅m) +40° to

50

°

Con-rod bearing cover to con-rod - 35 N

⋅m (3.5 kgf⋅m) +45° to

60

°.

Use new bolts.

6. Install oil pump, oil pan, bearing bridge rear crankshaft

sealing, flywheel/drive plate, and aggregates according to

the corresponding operations.

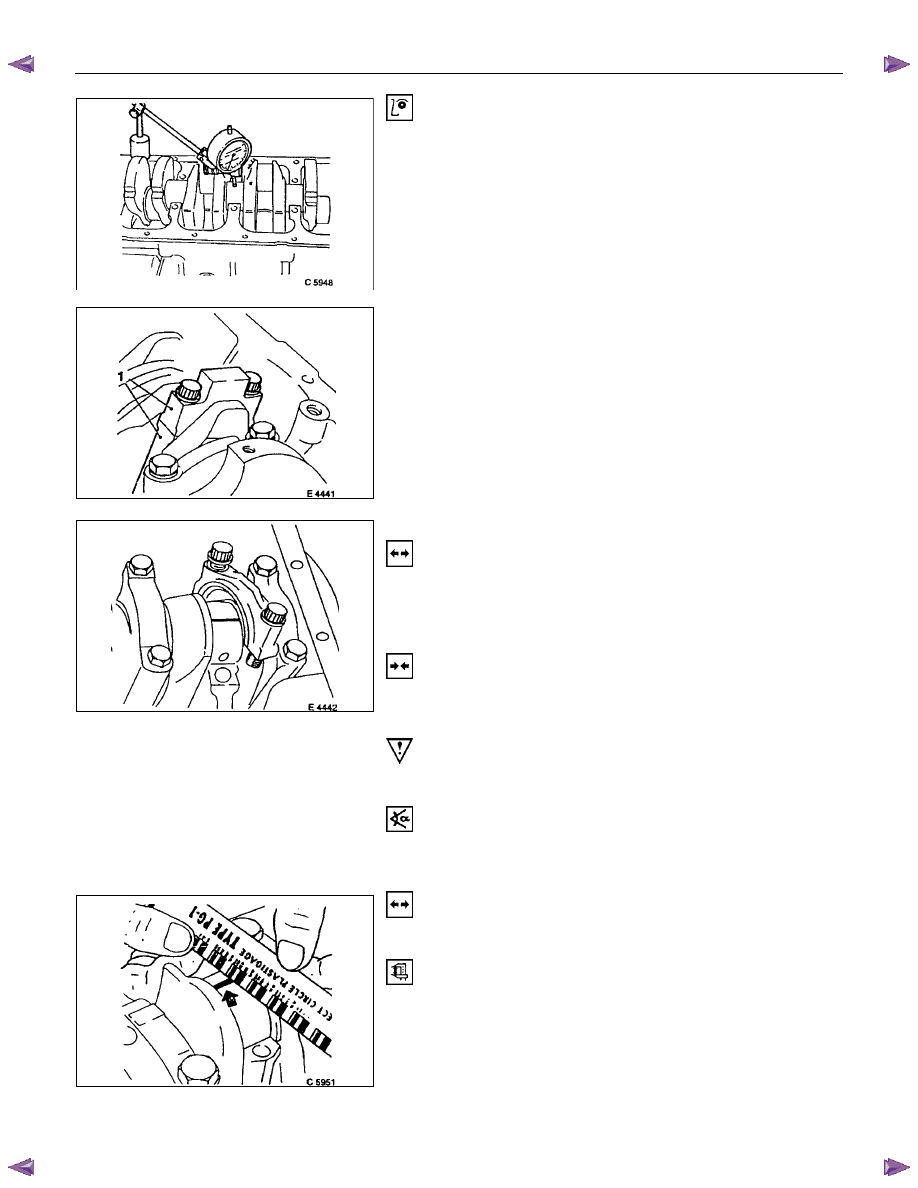

Inspection

Bearing play - bearing cover removed

Measure

With "Plastigage" (ductile plastic threads)

Cut threads to length of bearing width and lay axiaity between

crankshaft journal and bearing shell (arrowed).

Install bearing cover with correct torque.

Important!

Grease crankshaft journal and lubricate bearing shell slightly

so that the thread does not tear when the bearing cover is

moved.

Crankshaft

Inspection

End play when bearing shells are installed.

Front end contact surfaces of flywheel/flexible plate.

Permissible end play - see "Technical Data "

ENGINE MECHANICAL (C24SE) 6A-57

Inspection

Out-of-round (run-out)-middle bearing shell removed when

mounting on front and rear bearing.

Permissible out-of-round - see "Technical Data"

Bearing Free Play Measurement

Two methods for measuring bearing free play are described -

1. Plastigage method and 2. micrometer and gauge method.

The two procedures are suitable for measuring both con-rod

and main bearing free play.

For both methods ensure con-rod and main bearing caps are

identified (1) prior to removal as they are machine matched.

1.Plastigage Method

Removal

1. Remove bearing cap and shell.

2. Lightly coat journals and bearings with engine oil to

prevent Plastigage from tearing when cap is removed.

Installation

1. Lay a length of Plastigage across width of crank pin and

fit bearing cap and shell using old bolts at this stage.

Important!

Do not allow crankshaft to rotate.

Torque - Angle Method

Main bearing cap bolt - 60 N

⋅m (6.1 kgf⋅m) +40° + to 50°.

Con-rod bearing cap bolts - 35 N

⋅m (3.6 kgf⋅m) +45°.

Removal

1. Remove bearing cap and shell.

Measure

Width of Plastigage -use scale supplied with Plastigage.

If con-rod bearing clearance exceeds 0.031mm/0.001in or

main journal bearing clearance exceeds 0.04mm/0.02in. -

check crankshaft journal diameters - see corresponding

operation.

Replace bearing if crankshaft is within specification - see

"Technical Data"

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст