Isuzu KB P190. Manual — part 518

6A-58 ENGINE MECHANICAL (C24SE)

Clean

Plastigage from journals.

Lightly coat journals and bearings with engine oil.

Installation

Install bearing cap and shell using new bolts.

Torque - Angle Method

Main bearing cap bolt - 60 N

⋅m (6.1 kgf⋅m) +40° to 50°.

Con-rod bearing cap bolts - 35 N

⋅m (3.9 kgf⋅m) +45°.

2.Micrometer and gauge method.

Crankshaft removed.

Installation

1. Install caps and bearing shells to con-rods and cylinder

block.

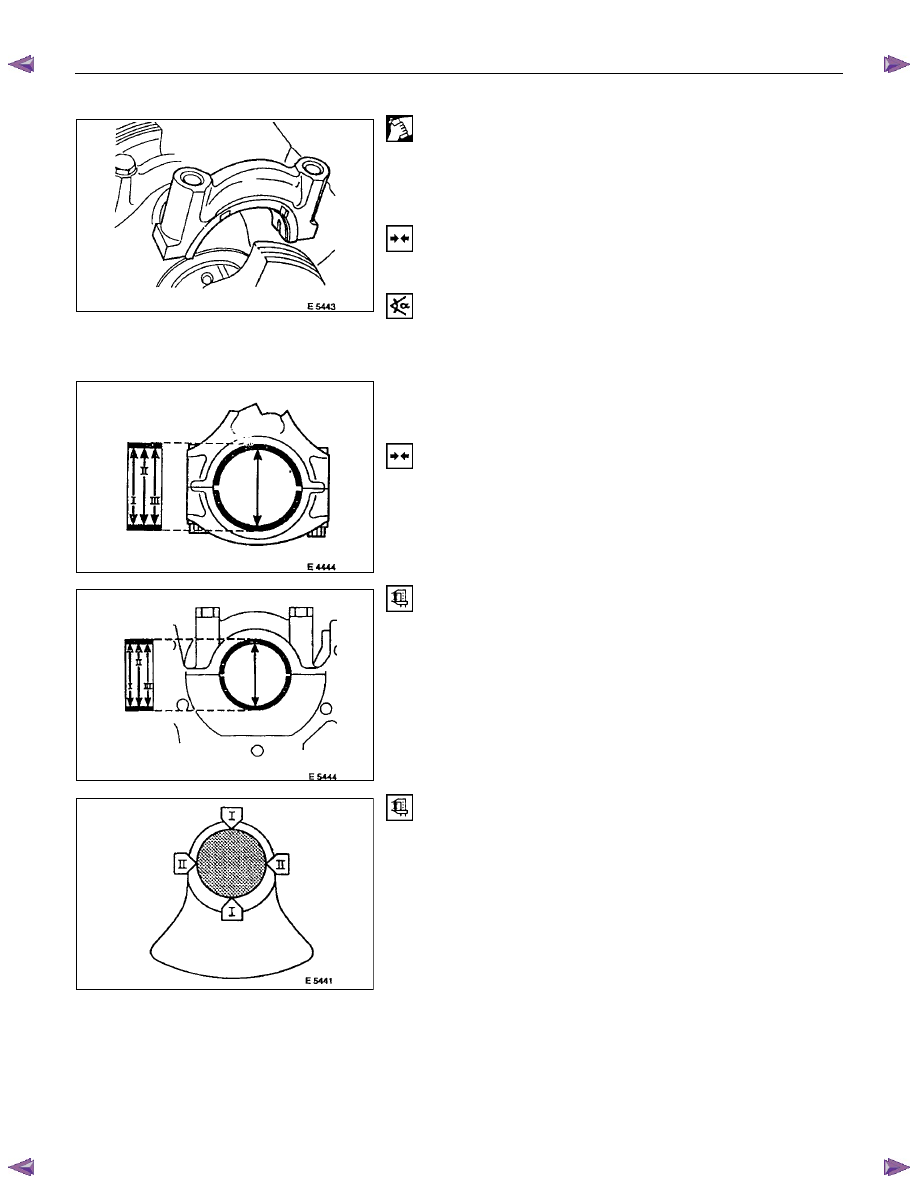

Measure

Con-rod and main bearing diameters at three points I, II, III

(arrowed).

Divide the sum of the three measurements by three to obtain a

mean diameter.

The top illustration shows con-rod measuring points.

The second illustration shows main bearing measuring points.

Measure

Crankshaft main and con-rod bearing journals at points I and

II. Divide the sum of both measurements to obtain a mean

diameter.

Crankshaft must be replaced if mean diameter of main or con-

rod journals is below specified limit - see "Technical Data".

If crankshaft is serviceable subtract crankshaft mean journal

diameters from corresponding shell bearing mean diameters to

determine bearing clearance.

Permissible main bearing clearance - 0.015 to 0.04mm/0.0006

to 0.002in.

Permissible con-rod bearing clearance - 0.006 to

0.031mm/0.002 to 0.001in.

ENGINE MECHANICAL (C24SE) 6A-59

Bypass Valve

Removal

1. Remove oil filter.

2. Remove bypass valve by cutting thread in locking disc

with M 10 tap (3rd stage), turning in M 10 bolt and taking

out bypass valve from seating.

Installation

1. Install bypass valve using drift (diameter approx.

15mm/0.6in.).

Oil Filter

Removal

1. Remove oil filter using commercially available tool.

Installation

1. Install oil filter by hand and oil seal ring.

2. Fill up engine oil while preventing overflow.

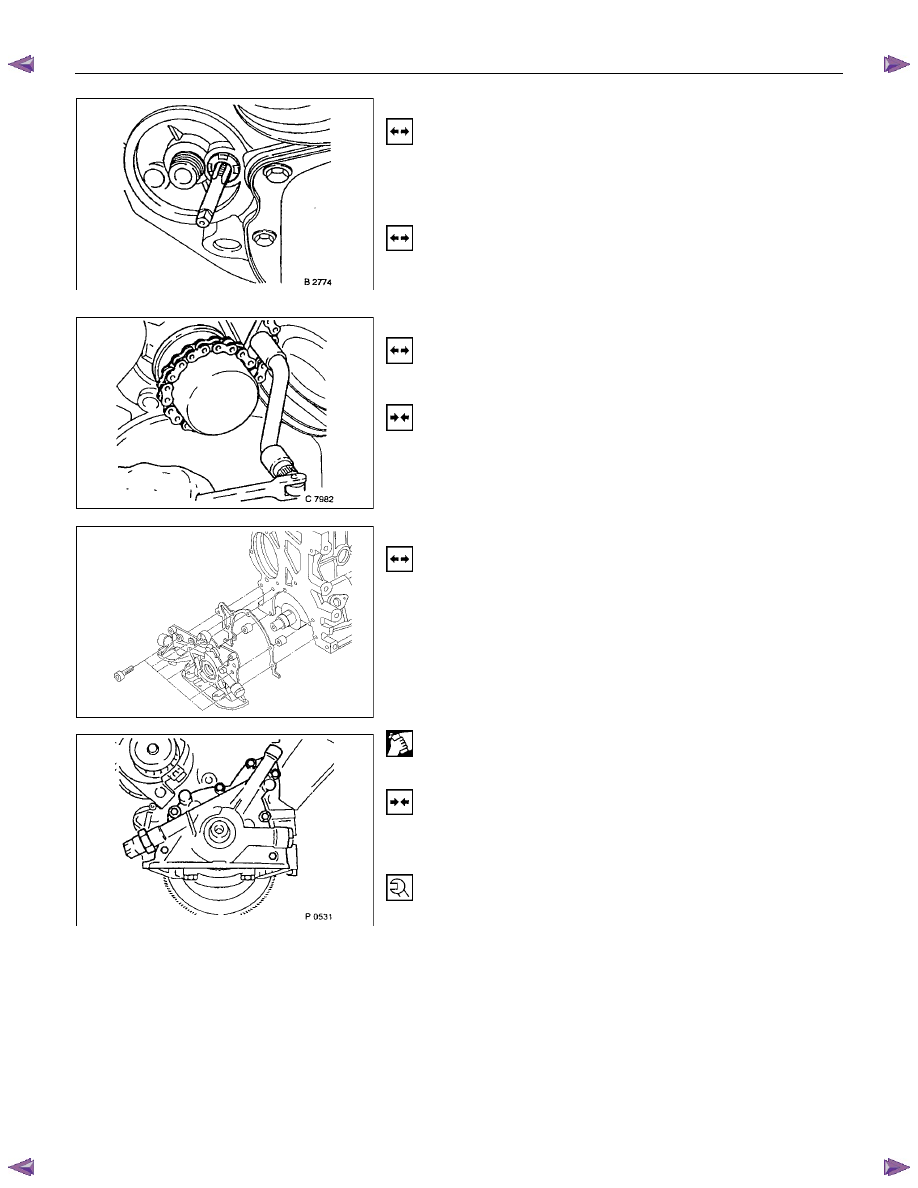

Oil Pump

Removal

1. Remove rear toothed belt cover, and oil pan according to

the corresponding operations.

2. Remove oil filter, wiring plug from oil pressure switch, oil

pump from cylinder block, and oil pressure switch from

oil pump.

Clean

Sealing surfaces

Installation

1. Install oil pressure switch to oil pump, oil pump to cylinder

block, oil pan, bearing bridge wiring plug, oil filter and

toothed belt cover.

Tighten (Torque)

Oil pressure switch to oil pump - 30 N

⋅m (3.2 kgf⋅m)

Oil pump to cylinder block - 6 N

⋅m (0.6 kgf⋅m)

Oil intake pipe to oil pump - 8 N

⋅m (0.8 kgf⋅m)

Intake pipe bracket to cylinder block - 8 N

⋅m (0.8 kgf⋅m)

*Insert bolts with Locktite (Refer to General Description

Recommended Liguid Gasket)

6A-60 ENGINE MECHANICAL (C24SE)

Oil Pump Safety Valve

Removal

1. Remove closure plug.

2. Remove seal ring.

3. Remove spring.

4. Remove piston.

Installation

1. Install piston (observe installation position).

2. Install spring.

3. Install seal ring.

4. Install closure plug.

Tighten (Torque)

Closure plug - 30 N

⋅m (3.0 kgf⋅m)

Oil Pump (Overhaul)

Removal

1. Remove oil pump according to the corresponding

operation.

2. Remove oil cover and pressure control valve.

Inspect

Clearance between gear pair and housing upper edge - see

“Technical Data”.

Check housing, cover and pressure control valve.

Installation

1. Install pump cover with Sealing Compound 15 03 166 (90

094 714).

2. Install oil pump safety valve according to the

corresponding operation.

3. Install oil pump according to the corresponding operation.

ENGINE MECHANICAL (C24SE) 6A-61

OPERATIONS ON OIL CIRCULATION

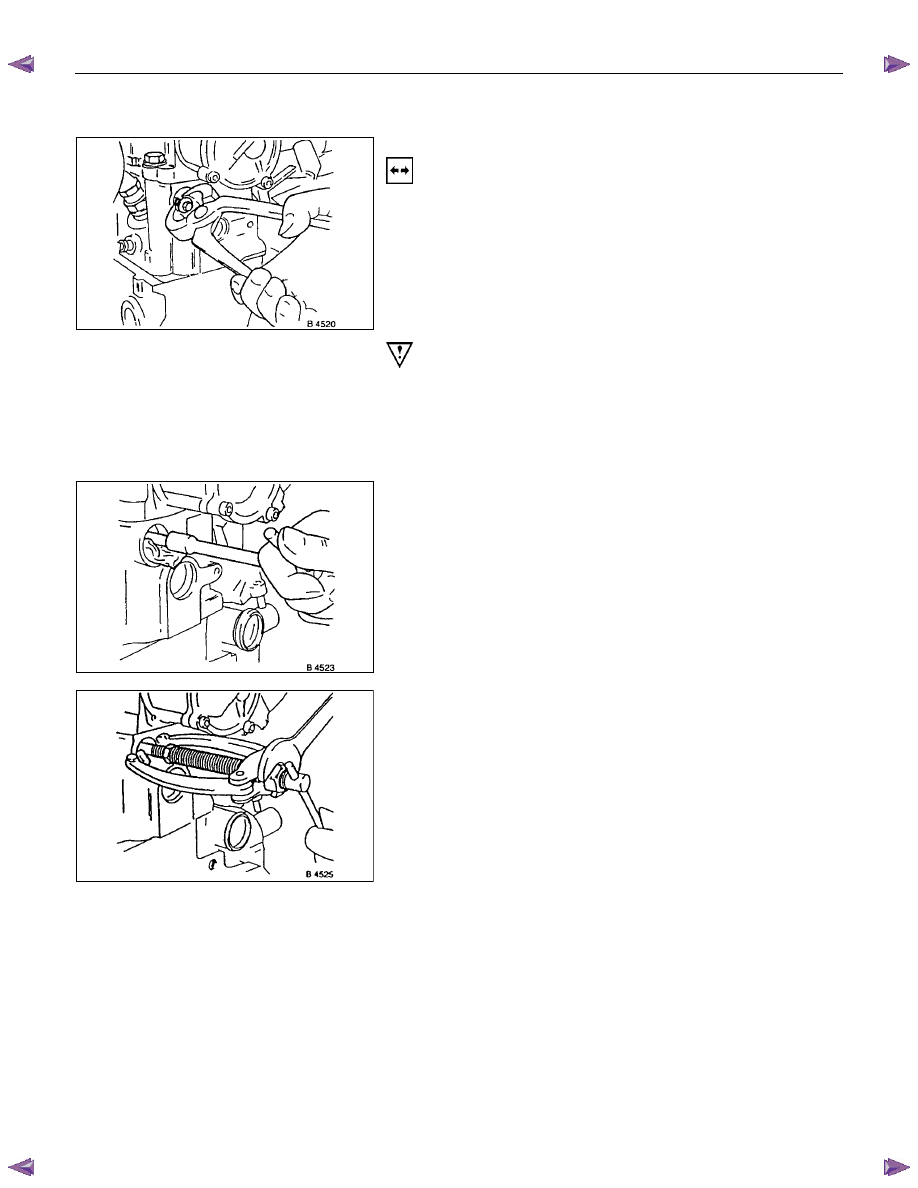

Cylinder Head Safety Valve

Removal

1. Remove cylinder head according to the corresponding

operation.

2. Make hole in core plugs with pointed drift, turn in self

tapping screw and edge out.

Important!

Cover oil duct in cylinder head with piece of cloth.

3. Pull out valve retainer, using commercially available tool.

4. Remove ball and spring.

5. Cut three threads in the ball seating with M 10 tap (3rd

stage).

6. Coat tap with grease.

7. Remove ball seating from cylinder head with

commercially available tool.

Do not damage cylinder head.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст