Isuzu KB P190. Manual — part 374

6A-136 ENGINE MECHANICAL (4JK1/4JJ1)

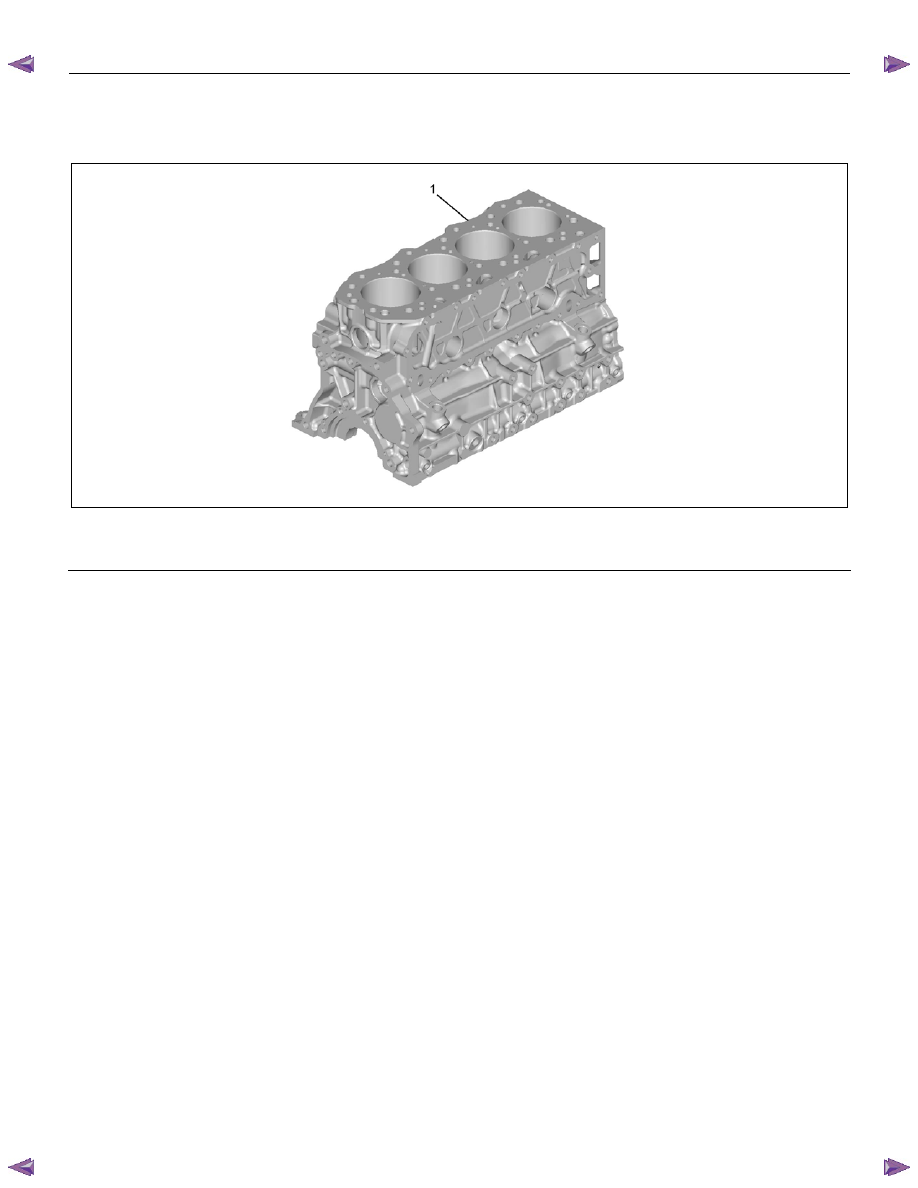

Cylinder Block

Components

RTW76ASF000101

Legend

1. Cylinder

Block

Removal

1. Demount the engine assembly.

Refer to "Engine Assembly".

2. Remove the cylinder head cover.

Refer to "Cylinder Head Cover".

3. Remove the camshaft assembly.

Refer to "Camshaft Assembly".

4. Remove the cylinder head.

Refer to "Cylinder Head".

5. Remove the fuel supply pump and fuel rail

assembly.

Refer to "Fuel Supply Pump" and "Fuel Rail

Assembly" in FUEL SYSTEM Section.

6. Remove the oil filter assembly and oil cooler.

Refer to “Oil Filter Assembly and Oil Cooler”.

7. Remove the crankshaft front oil seal.

Refer to "Crankshaft Front Oil Seal".

8. Remove the crankshaft rear oil seal.

Refer to "Crankshaft Rear Oil Seal".

9. Remove the oil pan.

Refer to "Oil Pan".

10. Remove the water pump.

Refer to "Water Pump" in Cooling System Section.

11. Remove the front cover.

Refer to "Front Cover".

12. Remove the timing gear train.

Refer to "Timing Gear Train".

13. Remove the oil pump.

Refer to "Oil Pump".

14. Remove pistons and connecting rods.

Refer to "Piston and Connecting Rod".

15. Remove the crankshaft.

Refer to "Crankshaft".

ENGINE MECHANICAL (4JK1/4JJ1) 6A-137

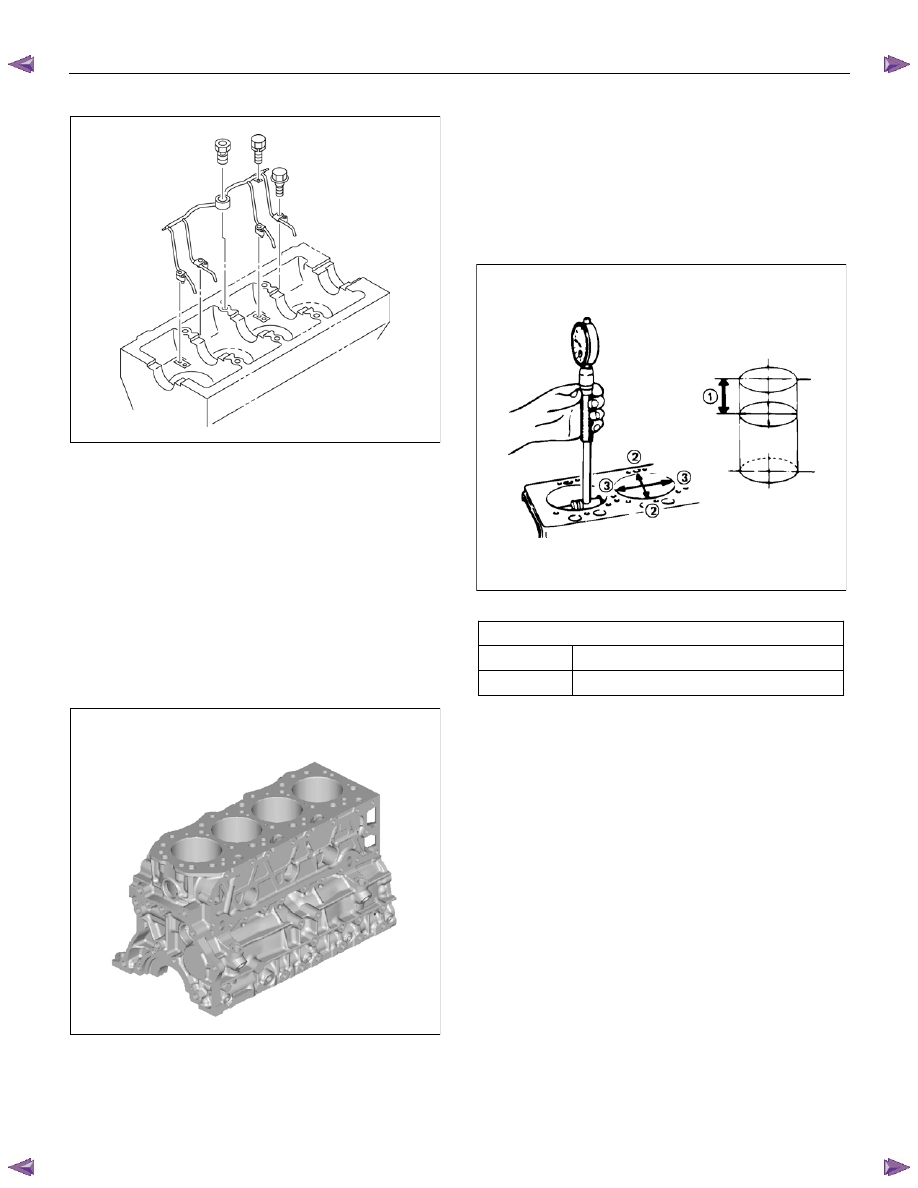

16. Remove the piston cooling pipe.

RTW76ASH001101

Inspection

1. Carefully remove water stains or other foreign

matters on the surface of the cylinder block.

• Be careful not to damage the cylinder block.

2. Carefully remove the liquid gasket on the

crankcase mounting surface.

3. Clean up the cylinder block.

4. Visually inspect the cylinder block.

• Conduct color check and hydraulic (or

pneumatic) test and if you find a crack or other

damage, replace the cylinder block.

RTW76ASH000801

5. Cylinder block wear measurement.

• Use a cylinder indicator to measure the cylinder

bore at measuring point (1) in the thrust (2-2)

and axial (3-3) directions of the crankshaft.

• Measuring Point (1): 20 mm (0.79 in)

If the measured value exceeds the specified

limit, the cylinder block must be replaced or

rebored.

012RY00010

Cylinder block bore diameter

mm (in)

Standard 95.421

− 95.450 (3.7567 − 3.7579)

Limit 95.48

(3.7590)

6A-138 ENGINE MECHANICAL (4JK1/4JJ1)

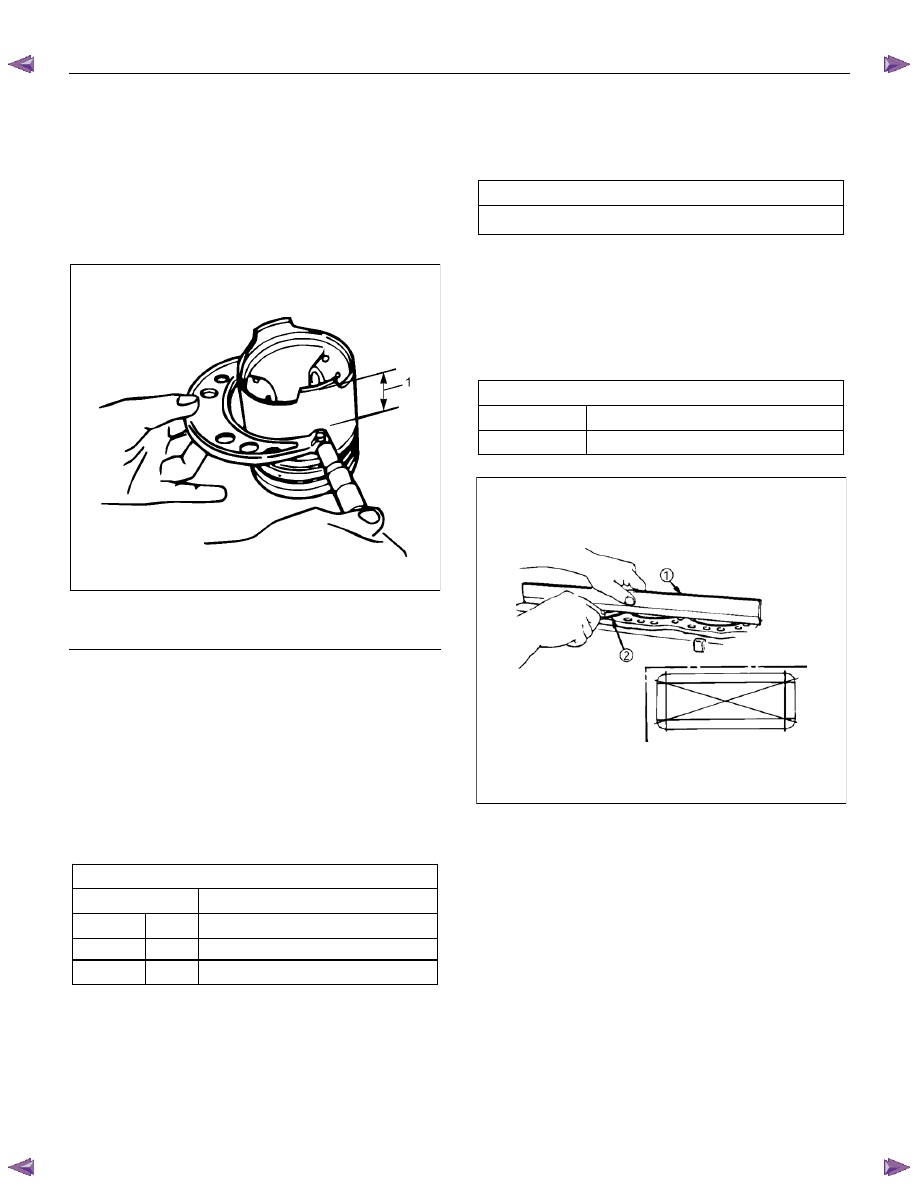

6. Cylinder Reboring.

• Select oversize pistons to fit the largest cylinder

bore (previously measured).

• At a point 11 mm (0.43 in) above the lower

edge of the piston skirt, measure the piston

diameter at a right angle to the piston pin.

Calculate the additional cylinder boring required

for each cylinder.

RTW56ASH023101

Legend

1. 11mm

(0.43in)

• Formula

Boring inside diameter = D + C - H ± E

D = Piston outside diameter

(Measured Oversize Piston)

C = Piston and cylinder bore clearance

0.082 - 0.100 mm (0.0032 - 0.0039 in)

H = Honing allowance

0.03 mm (0.0012 in) or less

E = Boring machine error

Piston size

mm (in)

Standard

95.330 - 95.359 (3.7531 - 3.7543)

Oversize (0.25) 95.580 - 95.609 (3.7629 - 3.7641)

(0.50) 95.830 - 95.859 (3.7728 - 3.7739)

(0.75) 96.080 - 96.109 (3.7826 - 3.7838)

• Bore and hone the individual cylinders as

required.

• Once again, measure the individual cylinder

bores.

Each cylinder bore remainder

mm (in)

0.02 (0.0008) or less.

7. Cylinder block upper face warpage.

• Use a straight edge (1) and a thickness gauge

(2) to measure the four sides and the two

diagonals of the cylinder block upper face.

• If the measured values exceeds the limit, the

cylinder block must be replaced.

Cylinder block upper face warpage

mm (in)

Standard

0.05 or less (0.002 or less)

Limit 0.20

(0.0080)

012R100001

ENGINE MECHANICAL (4JK1/4JJ1) 6A-139

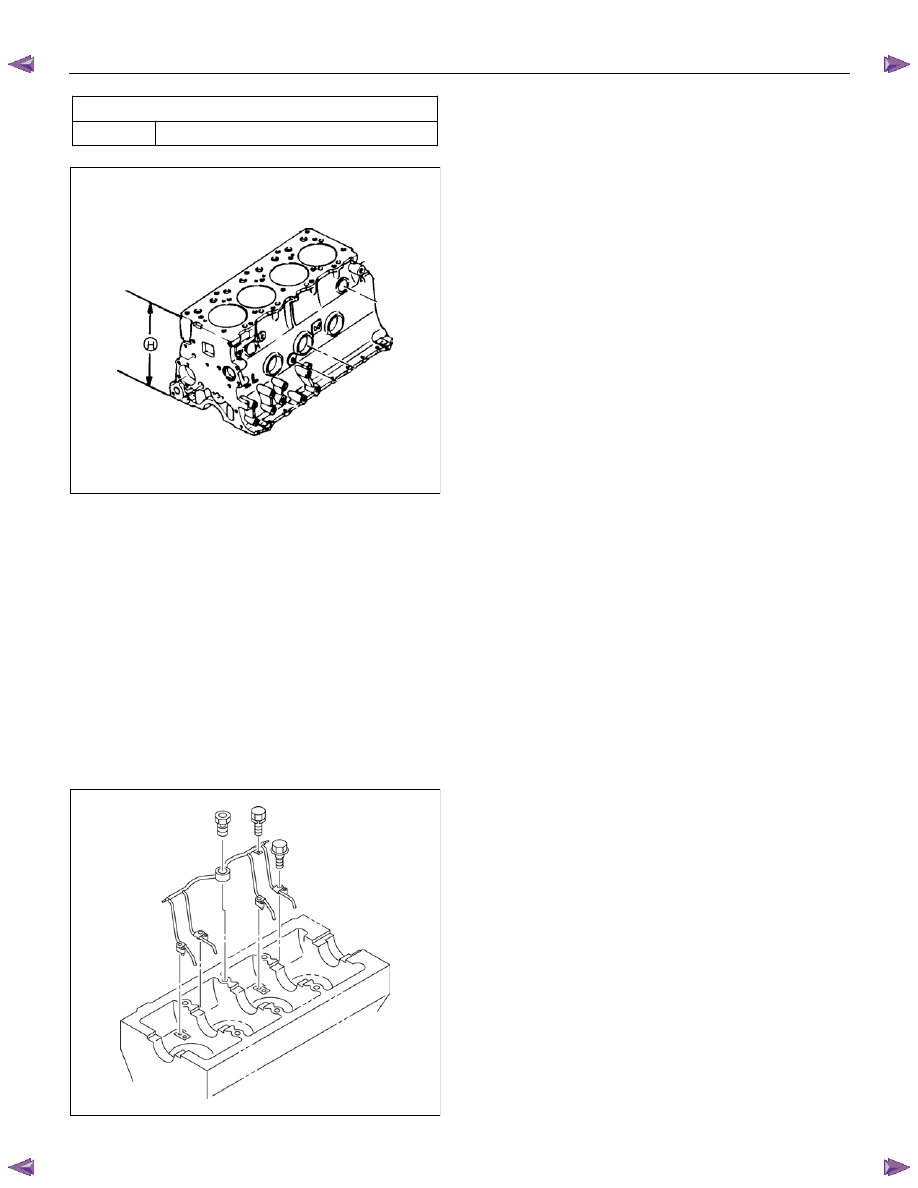

Cylinder block height (H) (Reference)

mm (in)

Standard

259.945 – 260.055 (10.2340 – 10.2384)

012R100009

Installation

1. Install the piston cooling pipe.

• Align the dowel pin of the piston cooling pipe

with the pin hole on the cylinder block and

tighten with the relief valve.

Tightening torque:

Relief valve 30 N

⋅⋅⋅⋅m (3.1 kg⋅⋅⋅⋅m / 22 lb ft)

bolts M8

25 N

⋅⋅⋅⋅m (2.5 kg⋅⋅⋅⋅m / 18 lb ft)

bolts M6

8 N

⋅⋅⋅⋅m (0.8 kg⋅⋅⋅⋅m / 69 lb in)

Note:

Be careful not to deform or damage the piston cooling

pipe nozzle.

RTW76ASH001101

2. Install the crankshaft.

Refer to "Crankshaft".

3. Install pistons and connecting rods.

Refer to "Piston and Connecting Rod".

4. Install the oil pump.

Refer to "Oil Pump".

5. Install the timing gear train.

Refer to "Timing Gear Train".

6. Install the front cover.

Refer to "Front Cover".

7. Install the water pump.

Refer to "Water Pump" in Cooling System Section.

8. Install the oil pan.

Refer to "Oil Pan".

9. Install the crankshaft rear oil seal.

Refer to "Crankshaft Rear Oil Seal".

10. Install the crankshaft front oil seal.

Refer to "Crankshaft Front Oil Seal".

11. Install the oil filter assembly and oil cooler.

Refer to "Oil Filter Assembly and Oil Cooler".

12.

Install the fuel supply pump and fuel rail

assembly.

Refer to "Fuel Supply Pump" and "Fuel Rail

Assembly " in Fuel System Section.

13. Install the cylinder head.

Refer to "Cylinder Head".

14. Install the camshaft assembly.

Refer to "Camshaft Assembly".

15. Install the cylinder head cover.

Refer to "Cylinder Head Cover".

16. Mount the engine assembly on the chassis.

Refer to "Engine Assembly".

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст