Isuzu KB P190. Manual — part 375

6A-140 ENGINE MECHANICAL (4JK1/4JJ1)

Lubrication System

Service Precautions

• During each disassembly, remove the old gasket

adhering to each part and mating part completely

using a scraper at the location, where the fluid

gasket is to be used, clean the traces of oil,

moisture, and dirt completely using waste cotton

and apply the specified new fluid gasket at each

location.

• Avoid excessive or insufficient coating volume.

Note that seizure may occur in case of excessive

coating due to clogging of the oil gallery and oil jet,

and oil and water leakage may occur if the coating

is insufficient.

• Always, the start and end of the application should

be overlapped.

Explanations on functions and operation

The lubrication system uses the filter element combined

with a full flow bypass, water-cooled oil cooler, and oil

jet for piston cooling.

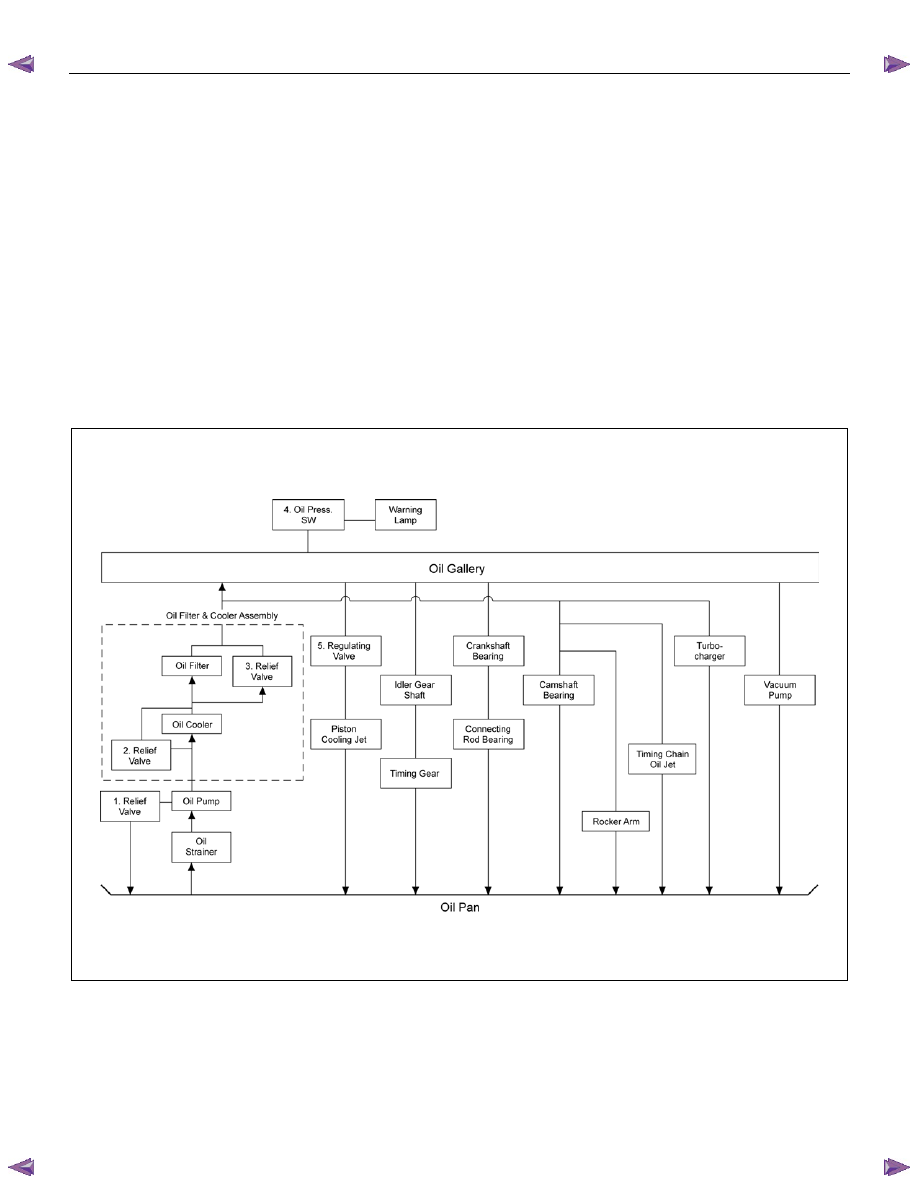

Lubricating system diagram

LNW76ALF000201

1. Oil Pump Relief Valve Operating Pressure: 490 – 686 kPa (5.0 – 7.0 kg/cm

2

/ 71 – 100 psi)

2. Oil Cooler Relief Valve Opening Pressure: 176 – 216 kPa (1.8 – 2.2 kg/cm

2

/ 26 – 31 psi)

3. Oil Filter Relief Valve Opening Pressure: 80 – 120 kPa (0.8 – 1.2 kg/cm

2

/ 11 – 17 psi)

4. Oil Pressure Switch Operating Pressure: 29.4 – 49.0 kPa (0.3 – 0.5 kg/cm

2

/ 4.3 – 7.1 psi)

5. Regulating Valve: 176 – 216 kPa (1.8 – 2.2 kg/cm

2

/ 26 – 31 psi)

ENGINE MECHANICAL (4JK1/4JJ1) 6A-141

Functional Check

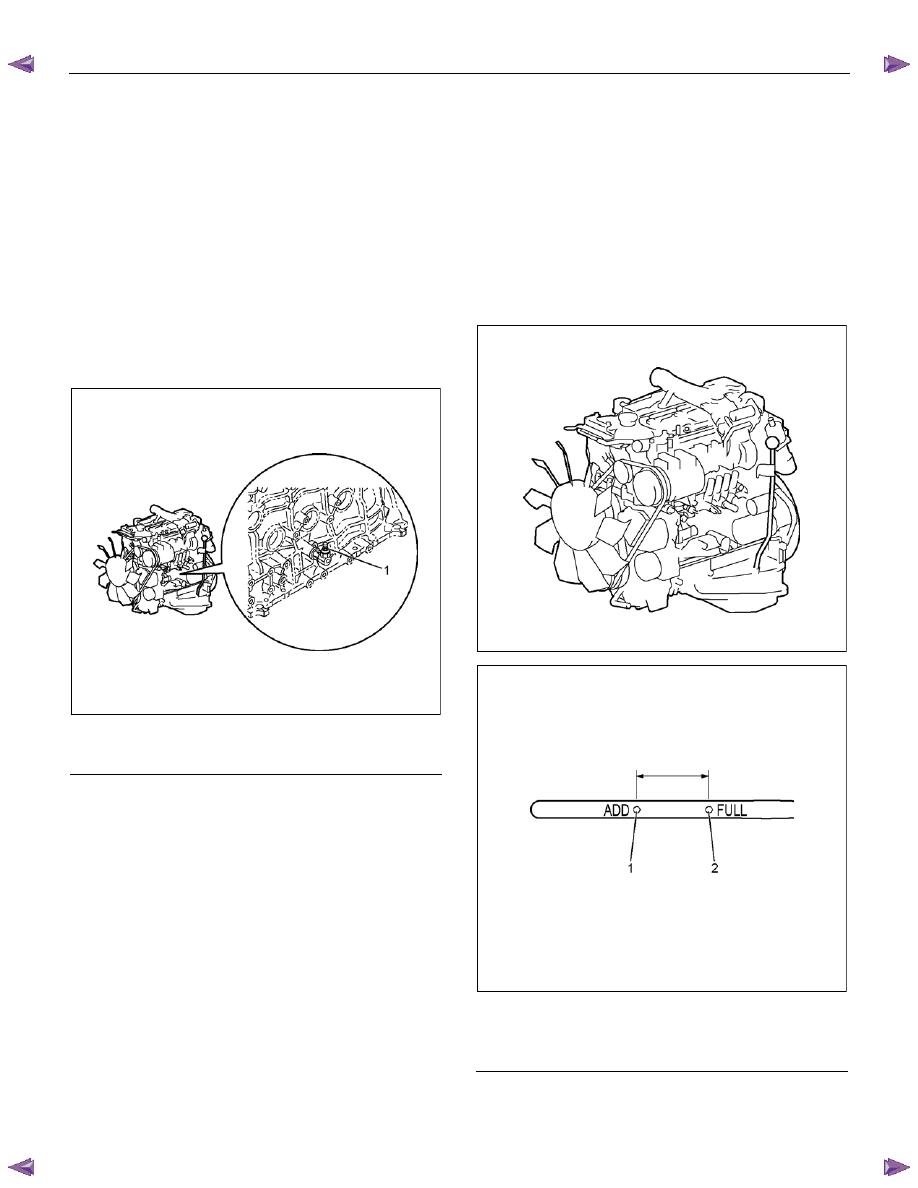

Oil pressure check

1. Check whether the engine oil is contaminated with

dirt, light oil, or water. If contaminated with dirt,

light oil, or water (after examining the cause and

taking the appropriate measures for light oil or

water contamination), replace the oil.

2. Check the engine oil level. The oil level should be

between the two holes of the level gauge. If the oil

level is insufficient, replenish it.

3. Remove the oil pressure switch on the nipple.

4. Install the oil pressure gauge on the nipple.

RTW56ASH015501

Legend

1. Oil Pressure Switch

5. Warm the engine.

6. Measure the oil pressure, to check whether it is

more than 400 kPa (4 kg/cm

2

/ 58 psi) at 3600

rpm.

7. Stop the engine.

8. Remove the oil pressure gauge.

9. Install the oil pressure switch.

10. Start the engine and check for oil leakage.

Engine oil

• Ensure the car is on level ground. Before starting

the engine or when 30 minutes or more have

elapsed after stopping the engine, check the

engine oil volume using the level gauge. The

volume is appropriate if the engine oil is between

the upper and lower limits of the level gauge.

Replenish the engine oil, if level is below the lower

limit. Also, check for contamination of the engine

oil.

RTW56ASH015601

RTW56ASH015701

Legend

1. Lower

Limit

2. Upper

Limit

6A-142 ENGINE MECHANICAL (4JK1/4JJ1)

Engine oil leakage

• In the lift up condition, confirm that there are no

leaks from the cylinder head cover and oil pan.

ENGINE MECHANICAL (4JK1/4JJ1) 6A-143

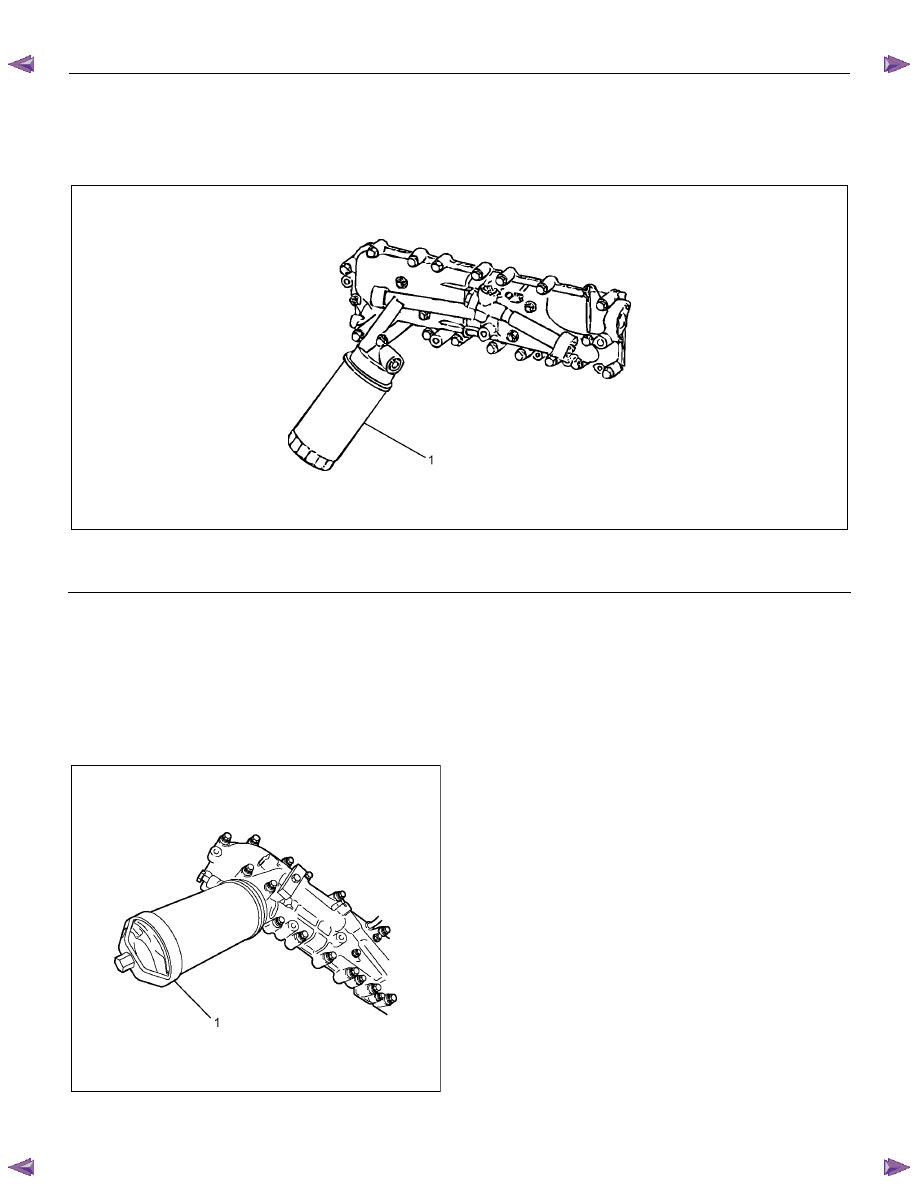

Oil Filter Cartridge

Components

RTW56ASF000101

Legend

1. Oil Filter Cartridge

Removal

1. Place a tray under the oil filter cartridge.

2. Remove the oil filter cartridge using the oil filter

wrench.

Special tool

Oil filter wrench: 5-8840-0203-0 (1)

RTW56ASH012501

Installation

1. Install the oil filter cartridge.

• Apply grease or engine oil to the seal in the

cartridge and install it using the oil filter wrench.

• Tighten the cartridge using the specified torque.

Tightening torque: 20 N·m (2.0 kg·m / 14 lb ft)

Or

After it comes in contact with the oil seal,

tighten it through an additional turn of 1 and

1/4.

Special

tool

Oil filter wrench: 5-8840-0203-0

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст