Isuzu KB P190. Manual — part 787

Engine Cooling – V6 Engine

Page 6B1–13

2.6

Coolant Filler Cap

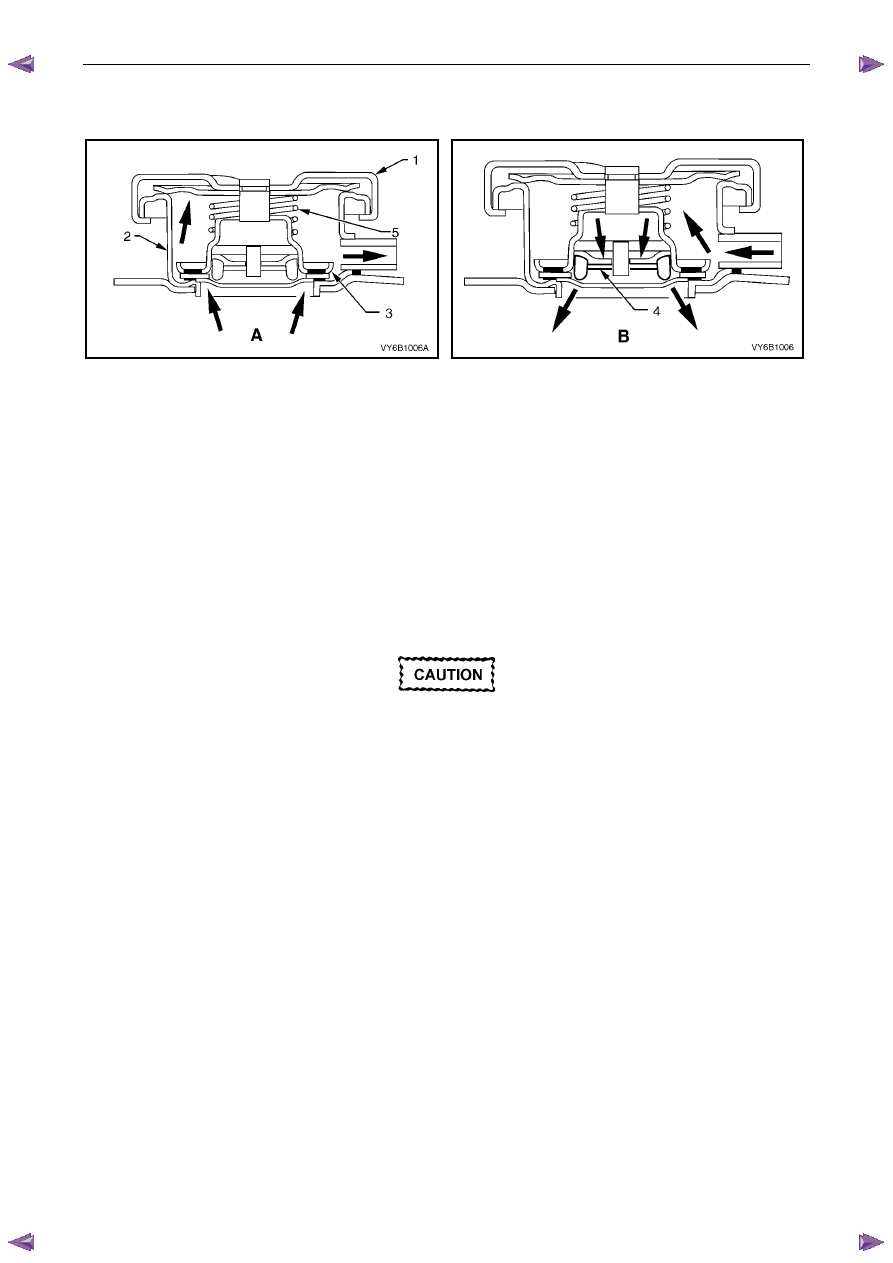

Figure 6B1 – 10

Figure 6B1 – 11

The pressurised coolant filler cap (1), fitted to the filler neck (2) on the coolant outlet housing, causes the cooling system

to operate at higher than atmospheric pressure. The higher pressure raises the boiling point of the coolant, resulting in

increased engine cooling efficiency. The coolant filler cap contains a pressure valve (3) and a vacuum (atmospheric)

valve (4).

Referring to view ‘A’, the pressure valve is held against its seat by a spring (5), which determines the maximum operating

pressure of the cooling system (120 kPa ).

Referring to view ‘B’, the vacuum valve (4) is held against its seat by a light spring and opens during cool down because

of the drop in pressure with contraction of the coolant volume. This pressure drop over-comes the spring force and the

vacuum valve is opened, preventing the radiator hoses from collapsing. In addition, coolant can also flow back into the

cooling system from the coolant recovery reservoir while this valve is open maintaining a full volume of coolant within the

engine and radiator.

Should the radiator pressure cap require

replacement, only fit the correct cap (with the

correct pressure-rating) for this engine. Refer

to the current release of Partfinder™ for this

information.

Engine Cooling – V6 Engine

Page 6B1–14

2.7

Coolant Recovery Reservoir

The coolant is maintained at the ideal level in the radiator by the coolant filler cap and the coolant recovery reservoir,

resulting in increased cooling efficiency.

The coolant recovery reservoir is located on the left-hand side front of the engine compartment, between the radiator

support panel and air cleaner assembly. The coolant recovery reservoir is connected to the radiator overflow connection

by a small diameter hose.

As the engine temperature rises, the coolant is heated and expands. The fluid displaced by expansion flows from the

radiator into the recovery reservoir.

When the engine is turned OFF, the coolant contracts as it cools. Coolant is then drawn back into the radiator through

the coolant filler cap atmospheric valve.

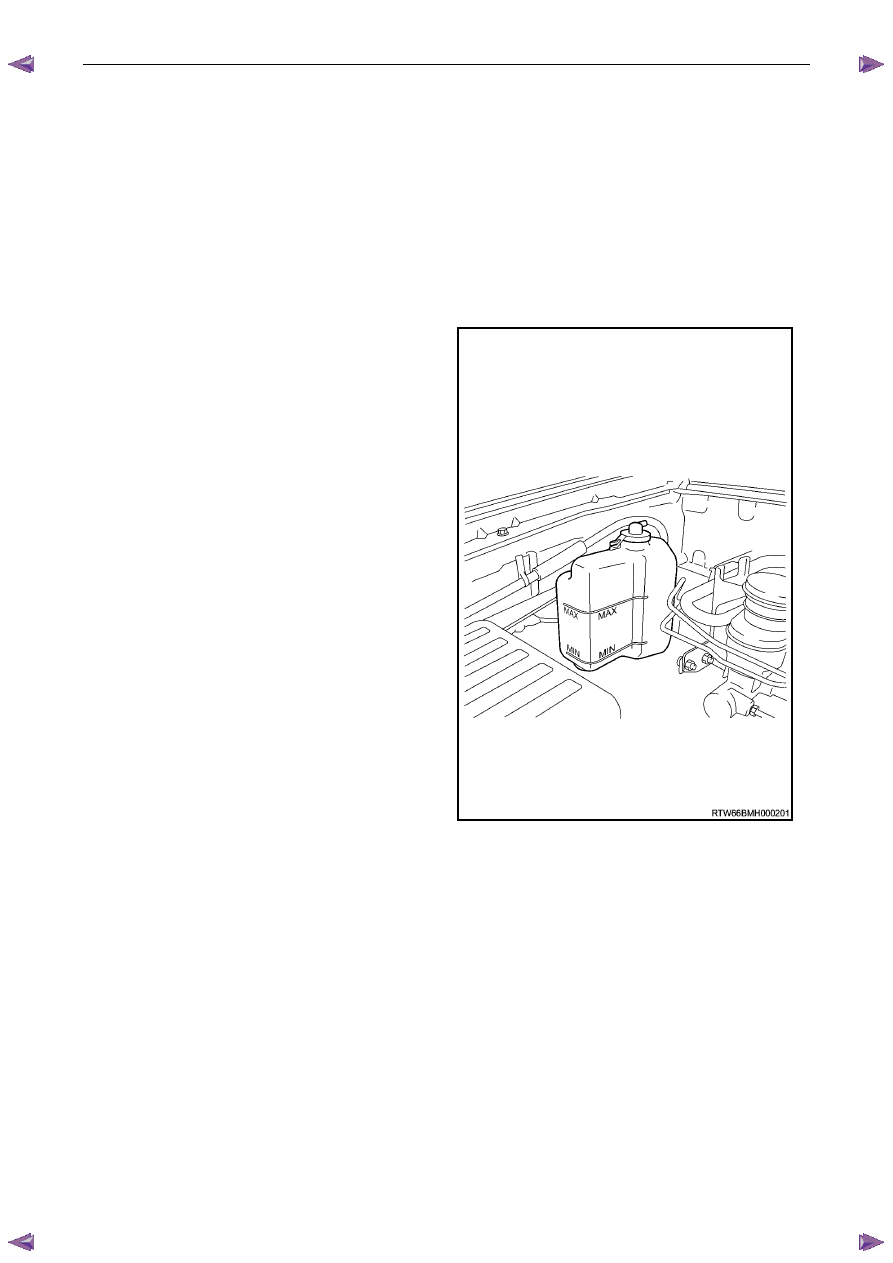

Coolant level should be maintained between the MAX and

MIN indicator lines on the coolant recovery reservoir, as

shown in Figure 6B1 – 12, when the engine is cold.

The cooling system is designed to use a coolant, DEX-

COOL® long-life coolant or equivalent to GM specification

6277M (a mixture of ethylene glycol antifreeze and

corrosion inhibitors and water), rather than plain water to

maintain the integrity of the cooling system, and to prevent

oxidation occurring within the engine.

N O T E

Some HFV6 Series vehicle markets call for

DEX-COOL® long-life coolant and others for

its equivalent, known as Extended Life Anti-

freeze Coolant, conforming to GM specification

6277M. If in doubt regarding the correct

coolant to be used, refer to the Owner’s

Handbook.

Figure 6B1 – 12

Engine Cooling – V6 Engine

Page 6B1–15

2.8

Engine Coolant Temperature Sensor

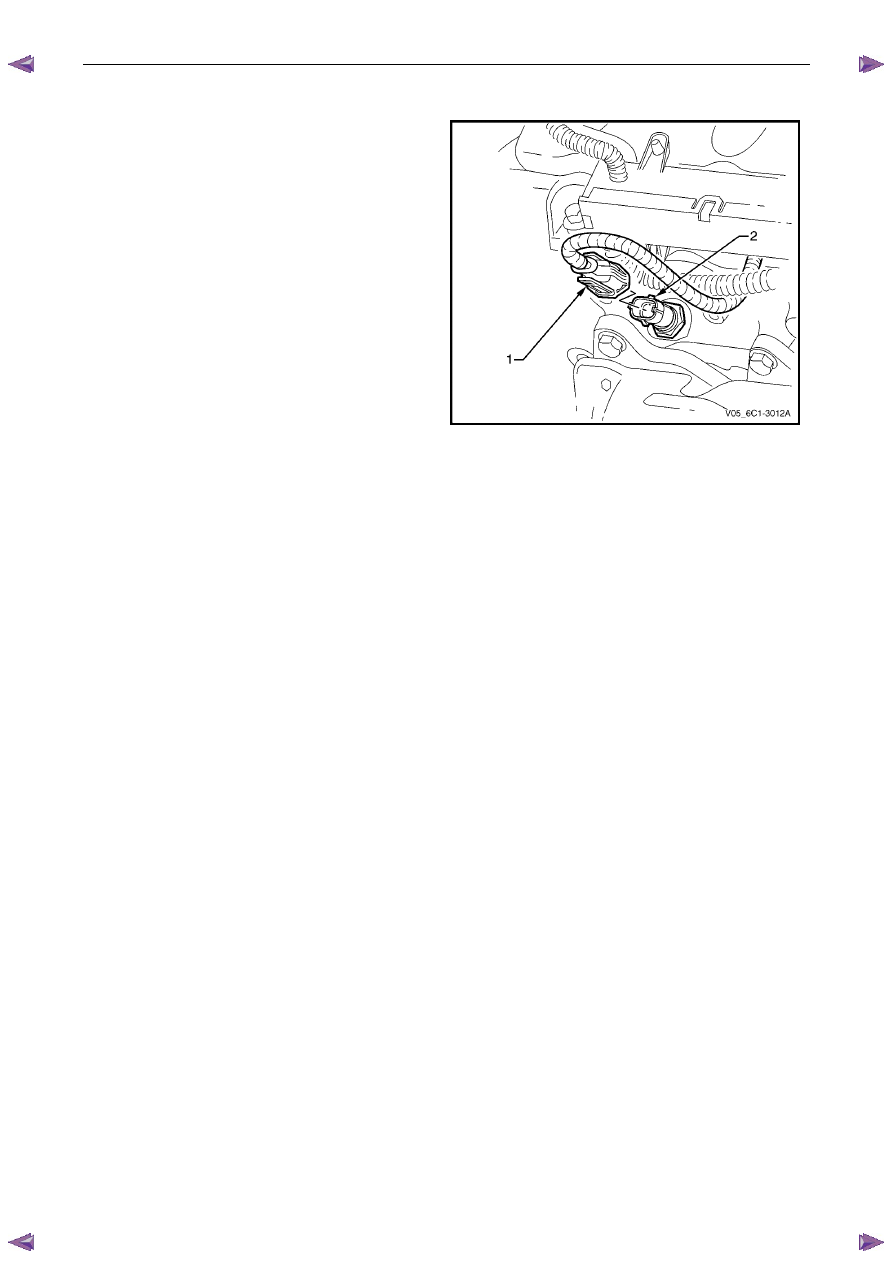

An Engine Coolant Temperature (ECT) sensor (2) is

mounted in the left-hand side cylinder head, just above

the exhaust manifold. The ECT sensor is used in

conjunction with the instrument panel temperature gauge.

The ECT sensor generates a signal, which is used by the

engine management system for calculation of the various

engine management functions.

Figure 6B1 – 13 shows the wiring harness connector (1)

and the ECT sensor (2).

Refer to 6C1-1 Engine Management General Information

for further information on the ECT sensor.

Figure 6B1 – 13

Engine Cooling – V6 Engine

Page 6B1–16

3 Service

Operations

3.1 Service

Notes

Safety

• To avoid serious personal injury, never

remove the coolant filler pressure cap on

the coolant outlet housing when the

engine is hot, even if the cooling system

should require filling. Sudden release of

cooling system pressure is very

dangerous.

• The vehicle is fitted with an electric

radiator cooling fan. When working around

the engine compartment, keep clear of the

fan as it may start without warning.

Before removing the coolant filler cap, allow the engine to cool, then place a shop rag over the coolant filler cap and then

slowly turn the cap anticlockwise, approximately 1½ turns, until the pressure relief position is reached. The pressure

relief position will allow any remaining pressure within the system to escape into the coolant recovery reservoir. Continue

to rotate the cap anticlockwise until the cap can be safely removed.

Periodic Servicing

The cooling system requires little attention except for maintaining the coolant to the correct level in the recovery reservoir

and periodic servicing at the time or distance intervals as outlined in 0B Lubrication and Service.

Periodic servicing includes:

1

Checking coolant level. Refer to 3.3

Draining and Filling Cooling System in this Section.

2

Checking coolant concentration. Refer to 3.2

Coolant Maintenance – Testing Coolant Concentration in this

Section.

3

Pressure test cooling system and coolant filler cap. Refer to 3.7 Pressure Testing in this Section.

4

Tighten hose clamps and inspect all hoses. Refer to 3.6 Coolant Hoses in this Section. Replace hoses if swollen

or deteriorated.

Always wear protective safety glasses when

working with spring type hose clamps. Failure

to do so could result in eye injury.

5

Clean out cooling system, refer to 3.4 Cleaning Cooling System – Cooling System Flush, in this Section and refill.

Refer to 3.3 Draining and Filling Cooling System in this Section.

Environmental Issues

To reduce environmental impact and maintenance cost, whenever the coolant is drained from any engine, the service

records are to be checked to determine when the coolant was last changed. If more than six months life is left before the

next coolant change, then the following procedure is to be followed:

1

When draining the coolant from the engine, use a clean container to hold at least 12 litres of coolant and ensure

that the coolant is not contaminated in the draining process.

2

After repairs have been completed, refill the engine cooling system with the drained coolant.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст