Isuzu KB P190. Manual — part 218

ENGINE MECHANICAL 6A – 67

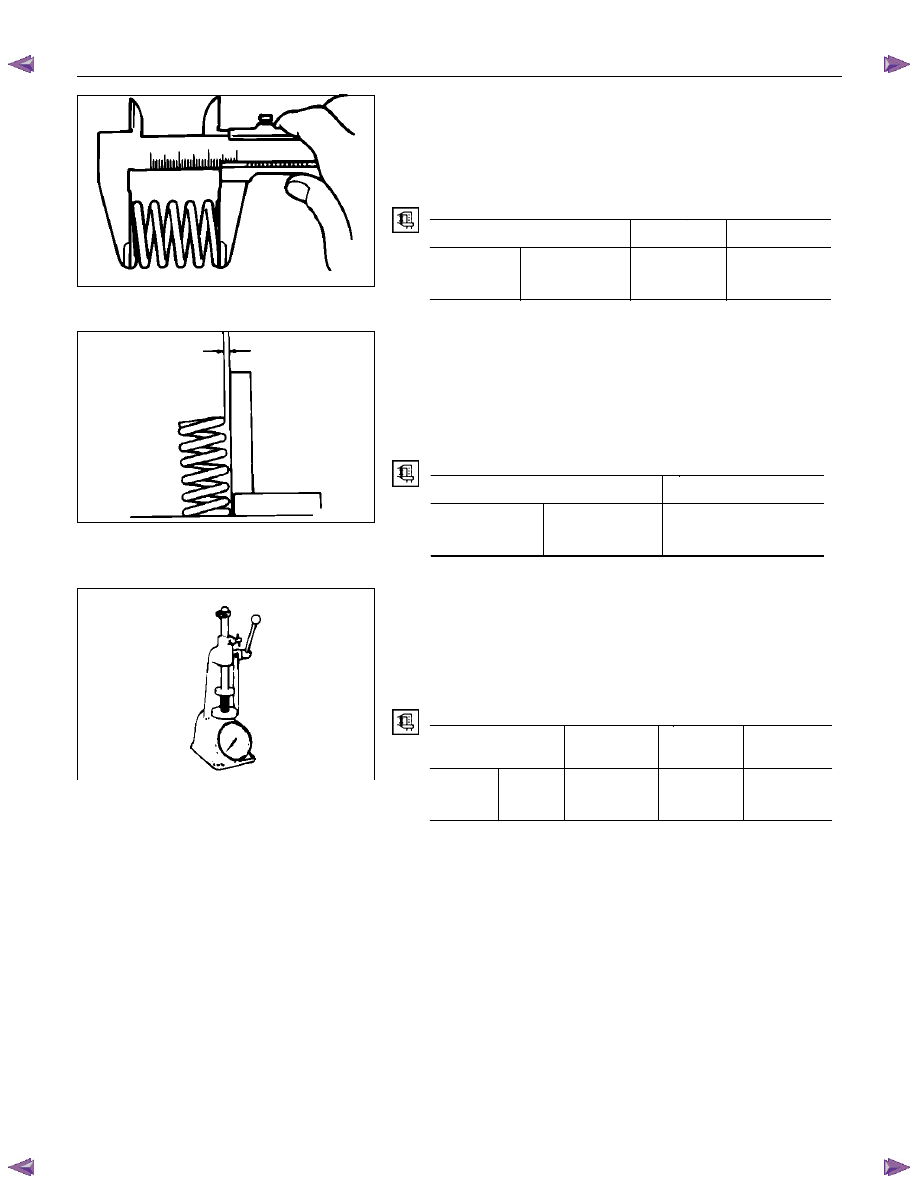

Valve Spring Free Height

Use a vernier caliper to measure the valve spring free height.

If the measured value is less than the specified limit, the valve

spring must be replaced.

Spring Free Height

mm (in)

Standard

Limit

4JA1T (L)

4JA1TC,

4JH1TC

Single spring

48.0 (1.89)

47.1 (1.85)

Valve Spring Squareness

Use a surface plate and a square to measure the valve spring

squareness.

If the measured value exceeds the specified limit, the valve

spring must be replaced.

Spring Squareness

mm (in)

Limit

4JA1T (L)

4JA1TC,

4JH1TC

Single spring

1.7 (0.070)

Valve Spring Tension

Use a spring tester to measure the valve spring tension.

If the measured value is less than the specified limit, the valve

spring must be replaced.

Valve Spring Tension

N (kg/lb)

Compressed

Height

Standard Limit

4JA1T (L)

4JA1TC,

4JH1TC

Single

spring

38.9mm

(1.53in)

296.0

(30.2/66.4)

257.7

(26.3/57.9)

011LX024

014RY00025

011LX026

6A – 68 ENGINE MECHANICAL

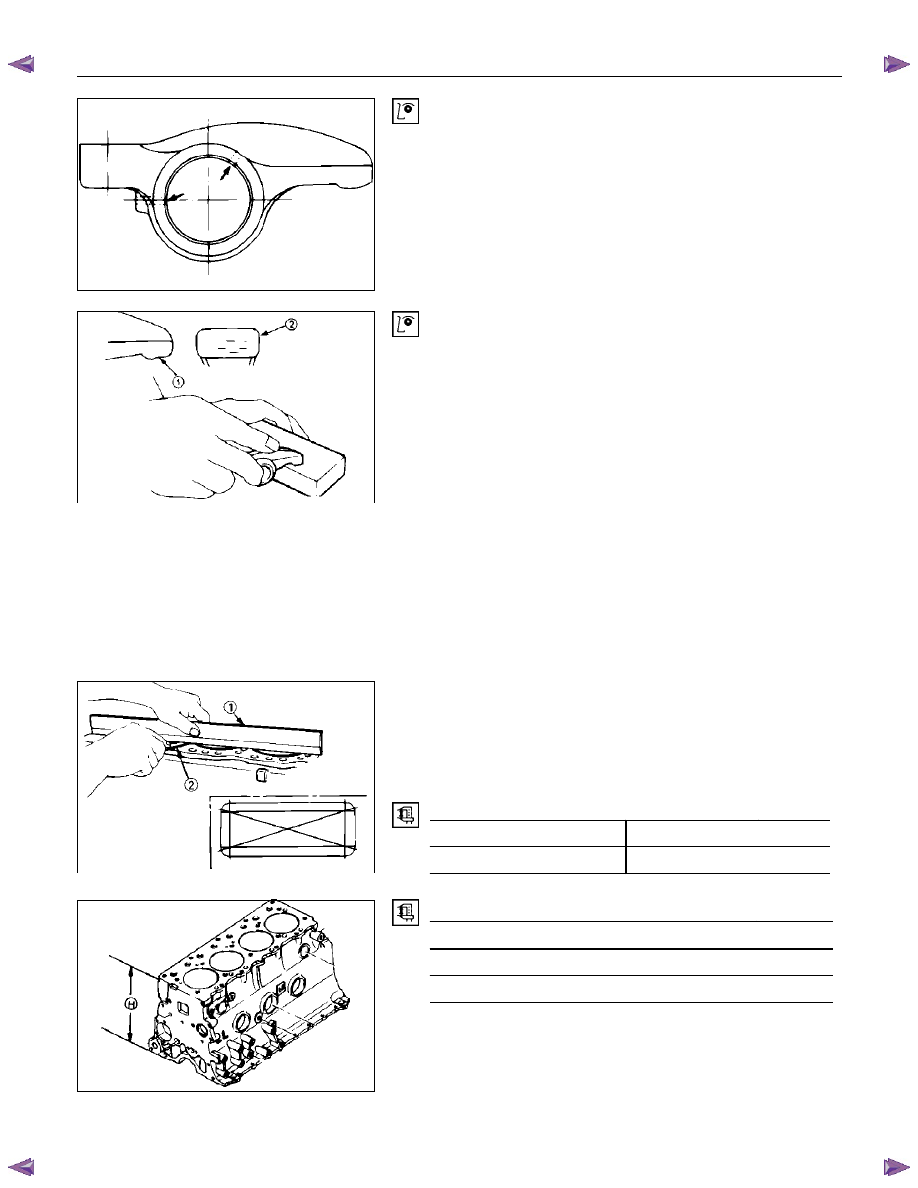

ROCKER ARM SHAFT AND ROCKER ARM

Rocker Arm Shaft Run-Out

1. Place the rocker arm shaft on a V-block.

2. Use a dial indicator to measure the rocker arm shaft

central portion run-out.

If the run-out is very slight, correct the rocker arm shaft

run-out with a bench press. The rocker arm must be at cold

condition.

If the measured rocker arm shaft run-out exceeds the

specified limit, the rocker arm shaft must be replaced.

Rocker Arm Shaft Run-Out

mm (in)

Limit

0.3 (0.012)

Rocker Arm Shaft Outside Diameter

Use a micrometer to measure the rocker arm fitting portion

outside diameter.

If the measured value is less than the specified limit, the rocker

arm shaft must be replaced.

Rocker Arm Shaft Outside Diameter

mm (in)

Standard Limit

18.98–19.00 (0.747–0.748)

18.90 (0.744)

Rocker Arm Shaft and Rocker Arm Clearance

1. Use either a vernier caliper or a dial indicator to measure

the rocker arm inside diameter.

Rocker Arm Inside Diameter

mm (in)

Standard Limit

19.010–19.030

(0.748–0.749)

19.100 (0.752)

2. Measure the rocker arm shaft outside diameter.

If the measured value exceeds the specified limit, replace

either the rocker arm or the rocker arm shaft.

Rocker Arm Shaft and Rocker Arm Clearance

mm (in)

Standard Limit

0.01–0.05

(0.0004–0.0020)

0.20 (0.008)

015LX009

014RY00024

015LX008

ENGINE MECHANICAL 6A – 69

3. Check that the rocker arm oil port is free of obstructions.

If necessary, use compressed air to clean the rocker arm

oil port.

Rocker Arm Correction

Inspect the rocker arm valve stem contact surfaces for step

wear (1) and scoring (2).

If the contact surfaces have light step wear or scoring, they

may be honed with an oil stone.

If the step wear or scoring is severe, the rocker arm must be

replaced.

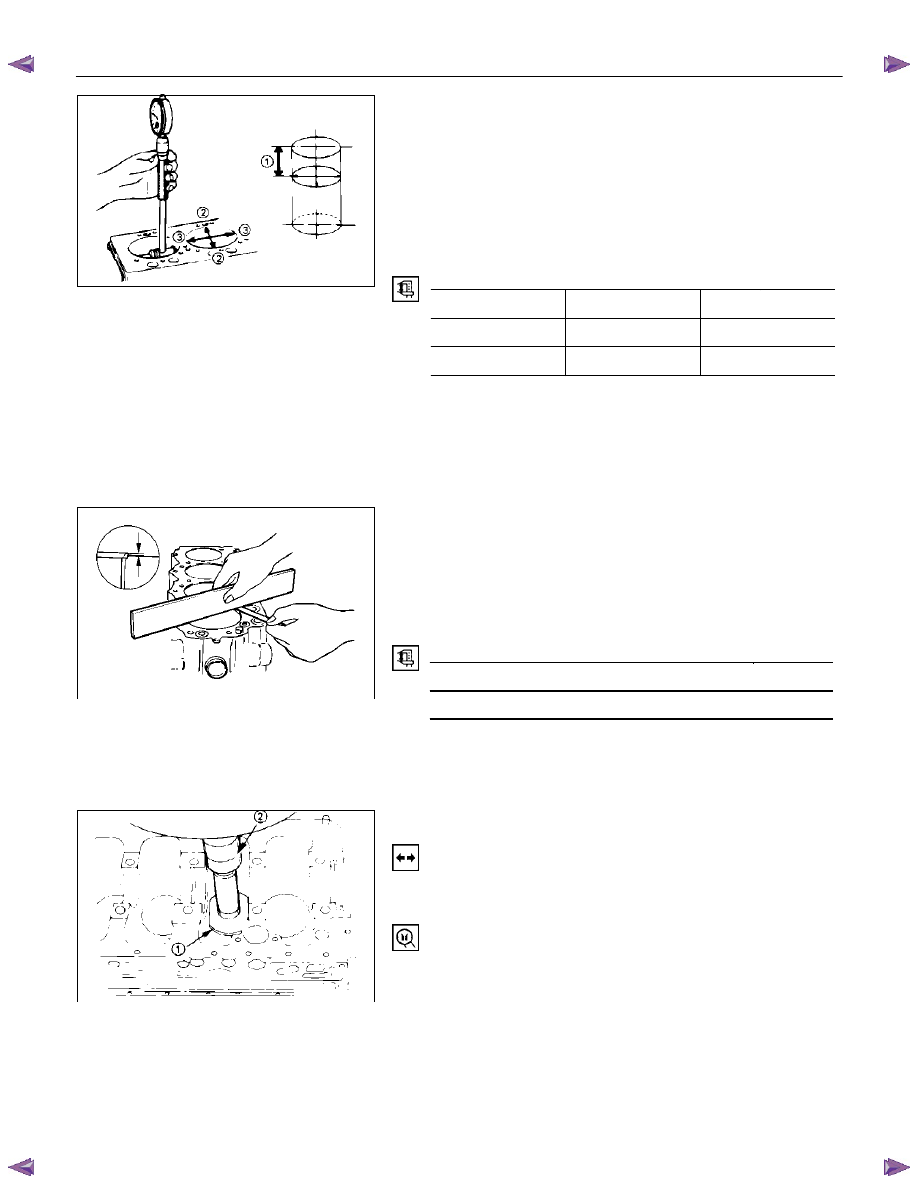

CYLINDER BODY

Cylinder Body Upper Face Warpage

1. Remove the cylinder body dowel.

2. Remove the cylinder liner.

Refer to "Cylinder Liner Replacement".

3. Use a straight edge (1) and a feeler gauge (2) to measure

the four sides and the two diagonals of the cylinder body

upper face.

If the measured values exceeds the limit, the cylinder body

must be replaced.

Cylinder Body Upper Face Warpage

mm (in)

Standard Limit

0.05 (0.002) or less

0.20 (0.008)

Cylinder Body Height (H) (Reference)

mm (in)

Standard

4JA1T(L), 4JA1TC : 244.945-245.055 (9.6435-9.6478)

4JH1TC : 269.945-270.055 (10.6277-10.6320)

4. Reinstall the cylinder liner.

Refer to "Cylinder Liner Replacement".

5. Reinstall the cylinder body dowel.

014RY00024

012R100001

012RY00009

014RY00023

6A – 70 ENGINE MECHANICAL

Cylinder Liner Bore Measurement

Use a cylinder indicator to measure the cylinder bore at

measuring point (1) in the thrust (2-2) and axial (3-3) directions

of the crankshaft.

Measuring Point (1): 20 mm (0.79 in)

If the measured value exceeds the specified limit, the cylinder

liner must be replaced.

Cylinder Liner Bore

mm (in)

Standard

Limit

4JA1T(L), 4JA1TC

93.00 (3.6614)

93.08 (3.6646)

4JH1TC

95.40 (3.7559)

95.48 (3.7590)

NOTE:

The inside of the dry type cylinder liner is chrome

plated. It cannot be rebored or honed.

If the inside of the cylinder liner is scored or

scorched, the cylinder liner must be replaced.

Cylinder Liner Projection Inspection

1. Hold a straight edge along the top edge of the cylinder liner

to be measured.

2. Use a feeler gauge to measure each cylinder liner

projection.

Cylinder Liner Projection

mm (in)

Standard

0-0.1 (0-0.004)

The difference in the cylinder liner projection height

between any two adjacent cylinders must not exceed 0.03

mm (0.0012 in).

Cylinder Liner Replacement

Cylinder Liner Removal

1. Insert the cylinder liner remover (1) into the cylinder body

(from the lower side of the cylinder body) until it makes firm

contact with the cylinder liner.

Cylinder Liner Remover : 5-8840-2039-0 (4JA1L/TC)

: 5-8840-2304-0 (4JH1TC)

2. Use a bench press (2) to slowly force the cylinder liner

from the cylinder body.

NOTE:

Take care not to damage the cylinder body upper face

during the cylinder liner removal procedure.

3. Measure the cylinder body upper face warpage.

Refer to "Cylinder Body Upper Face Warpage".

012RY00010

012LX016

012RY00012

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст