Isuzu KB P190. Manual — part 852

Engine Management – V6 – Diagnostics

Page 6C1-2–130

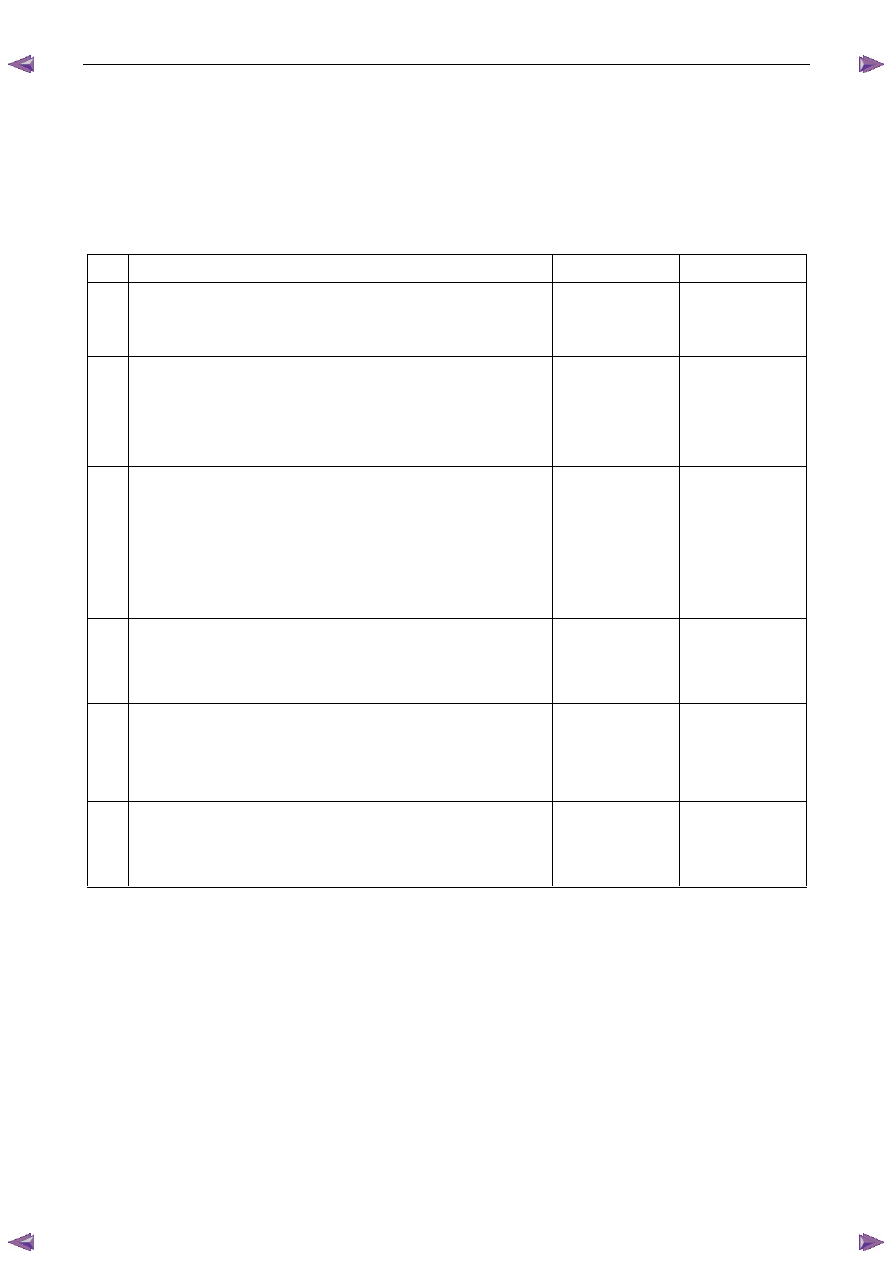

Step Action

Yes

No

8

Replace the ECM. Refer to 6C1-3 Engine Management – V6 –

Service Operations.

Was the repair completed?

Go to Step 9

—

9

1

Using Tech 2, clear the DTCs.

2

Switch off the ignition for 30 seconds.

3

Start the engine.

4

Operate the vehicle within the conditions for running the DTC.

Does any of the cooling fan relay control circuit DTCs fail this ignition

cycle?

Go to Step 2

Go to Step 10

10 Using Tech 2, select the DTC display function.

Does Tech 2 display any DTCs?

Go to the

appropriate DTC

Table in this Section

System OK

When all diagnosis and repairs are completed, check the system for correct operation.

7.27 DTC

P0500

DTC Descriptor

This diagnostic procedure supports DTC P0500 – Vehicle Speed Sensor Circuit Malfunction (Manual Transmission).

Circuit Description

Vehicle speed information is provided to the engine control module (ECM) by the vehicle speed sensor (VSS). The

ignition control relay applies ignition positive voltage to the VSS, and the ground circuit of the VSS is directly connected

to ground.

The VSS is a Hall effect switch. In conjunction with an 18 tooth reluctor wheel, the VSS provide a signal voltage to the

ECM. The ECM uses this signal voltage to determine vehicle speed.

If the ECM detects no vehicle speed, while other sensors indicate that the vehicle is moving, then DTC P0500 sets.

Conditions for Running the DTC

Runs once the following conditions are met:

•

The engine coolant temperature is greater than 40º C,

•

the ECM is in fuel shut-off mode, and

•

the engine speed is between 1,520 and 3,520 rpm

Conditions for Setting the DTC

The ECM detects a speed of less than 0 km/h for 8 seconds continuously, or 50 seconds cumulative.

Conditions for Clearing the DTC

The vehicle speed sensor circuit malfunction DTC is a Type C DTC. Refer to 1.4

Diagnostic Trouble Codes in this

Section, for action taken when Type C DTCs set and conditions for clearing Type C DTCs.

Additional Information

•

For an intermittent fault condition, refer to 5.2

Intermittent Fault Conditions in this Section.

•

Refer to 6C1-1 Engine Management – V6 – General Information for details on:

•

VSS operation, and

•

fuel shut-off mode.

Engine Management – V6 – Diagnostics

Page 6C1-2–131

•

Refer to 7B1 Manual Transmission – V6 for VSS replacement procedures.

•

Since a fault condition in a wiring connector may trigger DTCs, always test the connectors related to this

diagnostic procedure for shorted terminals or poor wiring connection before replacing any component. Refer to 8A

Electrical - Body and Chassis for information on electrical fault diagnosis.

•

To assist diagnosis, refer to 3 Wiring Diagrams and Connector Charts in this Section, for the system wiring

diagram and connector charts.

DTC P0500 Diagnostic Table

Step Action

Yes

No

1

Has the diagnostic system check been performed?

Go to Step 2

Refer to

4.4 Diagnostic

System Check in

this Section

2

1

Switch off the ignition for 30 seconds.

2

Operate the vehicle within the conditions for running the DTC.

3

Using Tech 2, select the DTC display function.

Does DTC P0500 fail this ignition cycle?

Go to Step 3

Refer to Additional

Information in this

DTC

3

1

Switch off the ignition.

2

Disconnect the wiring connector from the VSS.

3

Connect a test lamp between the ignition circuit of the VSS and

ground.

4

Switch on the ignition with the engine not running.

Does the test lamp illuminate?

Go to Step 5

Go to Step 4

4

Repair the high resistance or open circuit fault condition in the ignition

circuit of the VSS. Refer to 8A Electrical - Body and Chassis for

information on electrical wiring repair procedures.

Was the repair completed?

Go to Step 12

—

5

1

Connect a test lamp between the ground circuit and ignition

circuit of the VSS.

2

Switch on the ignition with the engine not running.

Does the test lamp illuminate?

Go to Step 7

Go to Step 6

6

Repair the high resistance or open circuit fault condition in the ground

circuit of the VSS. Refer to 8A Electrical - Body and Chassis for

information on electrical wiring repair procedures.

Was the repair completed?

Go to Step 12

—

Engine Management – V6 – Diagnostics

Page 6C1-2–132

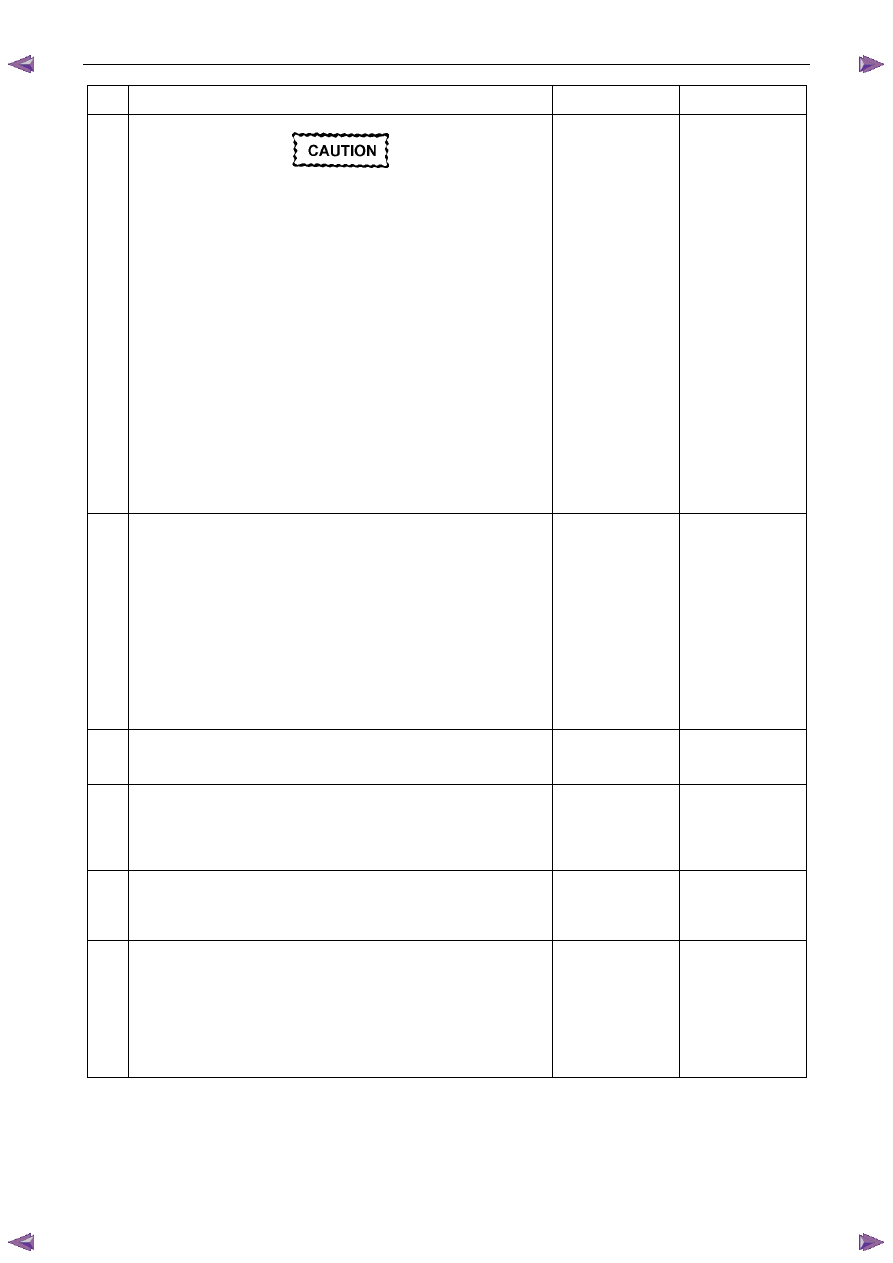

Step Action

Yes

No

7

To avoid damage to the drive axles, support the lower

control arms in the normal horizontal position. Do not

run the vehicle in gear with the wheels hanging down

at full travel.

1

Raise the vehicle and support the drive axles with safety stands.

Refer to 0A General Information for the location of jacking and

support points.

2

Connect a fused jumper wire between the ground circuit of the

connector and the ground circuit of the VSS.

3

Connect a fused jumper wire between the ignition circuit of the

connector and the ignition circuit of the VSS.

4

Using connector test adaptor kit J 35616-A, connect a digital

multimeter between the VSS signal circuit and ground.

5

Place the transmission in neutral.

6

Rotate the rear wheels by hand while observing the multimeter.

Does the multimeter indicate greater than 0.15 V AC?

Go to Step 10

Go to Step 8

8

Perform the following VSS inspection:

•

Inspect the VSS wiring harness for conditions that may induce

electromagnetic interference. Refer to 5.2

Intermittent Fault

Conditions in this Section.

•

Inspect the VSS for incorrect installation or incorrect attaching

bolt torque value. Refer to 6C1-3 Engine Management – V6 –

Service Operations.

•

Inspect the VSS sensor reluctor wheel for damage or conditions

that causes misalignment.

Was any fault found and rectified?

Go to Step 12

Go to Step 9

9

Replace the VSS. Refer to 7B1 Manual Transmission – V6.

Was the repair completed?

Go to Step 12

—

10 Test the VSS signal circuit for a high resistance, open circuit, short to

ground or short to voltage fault condition. Refer to 8A Electrical -

Body and Chassis for information on electrical fault diagnosis.

Was any fault found and rectified?

Go to Step 12

Go to Step 11

11 Replace the ECM. Refer to 6C1-3 Engine Management – V6 –

Service Operations.

Was the repair completed?

Go to Step 12

—

12 1

Using Tech 2, clear the DTCs.

2

Switch off the ignition for 30 seconds.

3

Start the engine.

4

Operate the vehicle within the conditions for running the DTC.

Does DTC P0500 fail this ignition cycle?

Go to Step 2

Go to Step 13

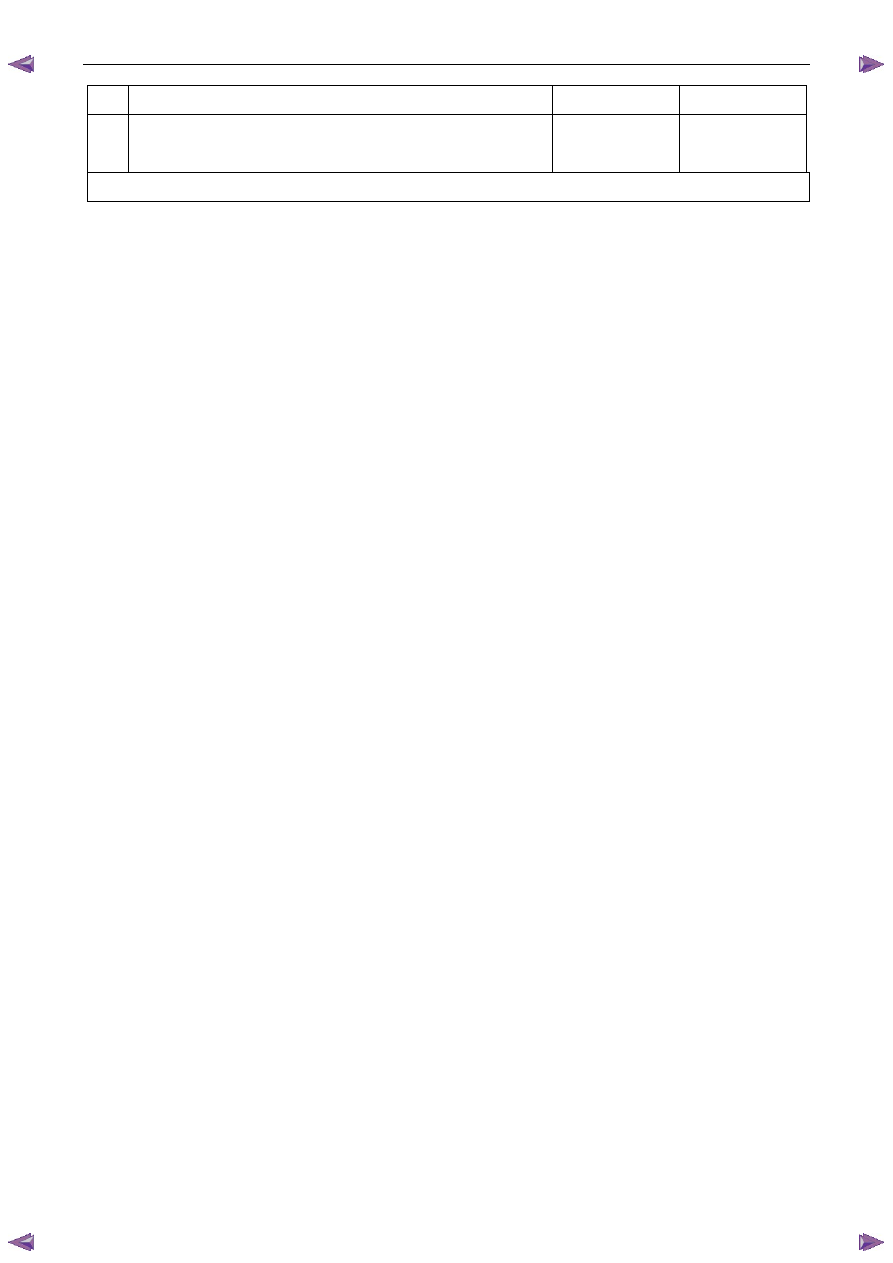

Engine Management – V6 – Diagnostics

Page 6C1-2–133

Step Action

Yes

No

13 Using Tech 2, select the DTC display function.

Are there any DTCs displayed?

Go to the

appropriate DTC

Table in this Section

System OK

When all diagnosis and repairs are completed, check the system for correct operation.

7.28 DTC P0504 or P0571

DTC Descriptor

This diagnostic procedure supports:

•

DTC P0504 – Brake Switch Circuit Malfunction.

•

DTC P0571 – Cruise Control Brake Switch Circuit

Circuit Description

The brake switch assembly is comprised of two individual switches, a stop lamp switch and cruise control cancel switch.

The ECM uses inputs from both of these switches for enabling cruise control, brake torque management etc. For further

information on the brake switch assemblies, refer to 6C1–1 Engine Management – V6 – General Information.

The ECM monitors both switches, and if the signals do not correlate, DTC P0504 will set. If the ECM determines that a

fault exists in the cruise control cancel circuit, DTC0571 will set.

Conditions for Running the DTC

Run continuously once the following conditions are met:

•

The ignition is switched on.

•

The ignition voltage is 10.0 – 16.0 V.

Conditions for Setting the DTC

The ECM detects one of the following conditions:

•

Only one switch signal is present when the vehicle accelerates or decelerates rapidly ten times.

N O T E

The ECM will count over several drive cycles.

•

A signal is seen from the stop lamp switch and cruise control cancel switch when the vehicle accelerates rapidly.

•

The ECM does not detect a signal from the switches during braking.

Conditions for Clearing the DTC

The brake switch circuit DTC is a Type B DTC. Refer to 1.4

Diagnostic Trouble Codes in this Section, for action

taken when Type B DTCs set and conditions for clearing Type C DTCs.

Additional Information

•

For an intermittent fault condition, refer to 5.2

Intermittent Fault Conditions in this Section.

•

Refer to 6C1-1 Engine Management – V6 – General Information for details of the brake switch operation.

•

Refer to 8C Cruise Control – HFV6 for brake pedal switch operation and testing.

•

Since a fault condition in a wiring connector may trigger DTCs, always test the connectors related to this

diagnostic procedure for shorted terminals or poor wiring connection before replacing any component. Refer to 8A

Electrical - Body and Chassis for information on electrical fault diagnosis.

•

To assist diagnosis, refer to 3 Wiring Diagrams and Connector Charts in this Section, for the system wiring

diagram and connector charts.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст