Isuzu KB P190. Manual — part 719

Engine Mechanical – V6

Page 6A1–99

Page 6A1–99

8

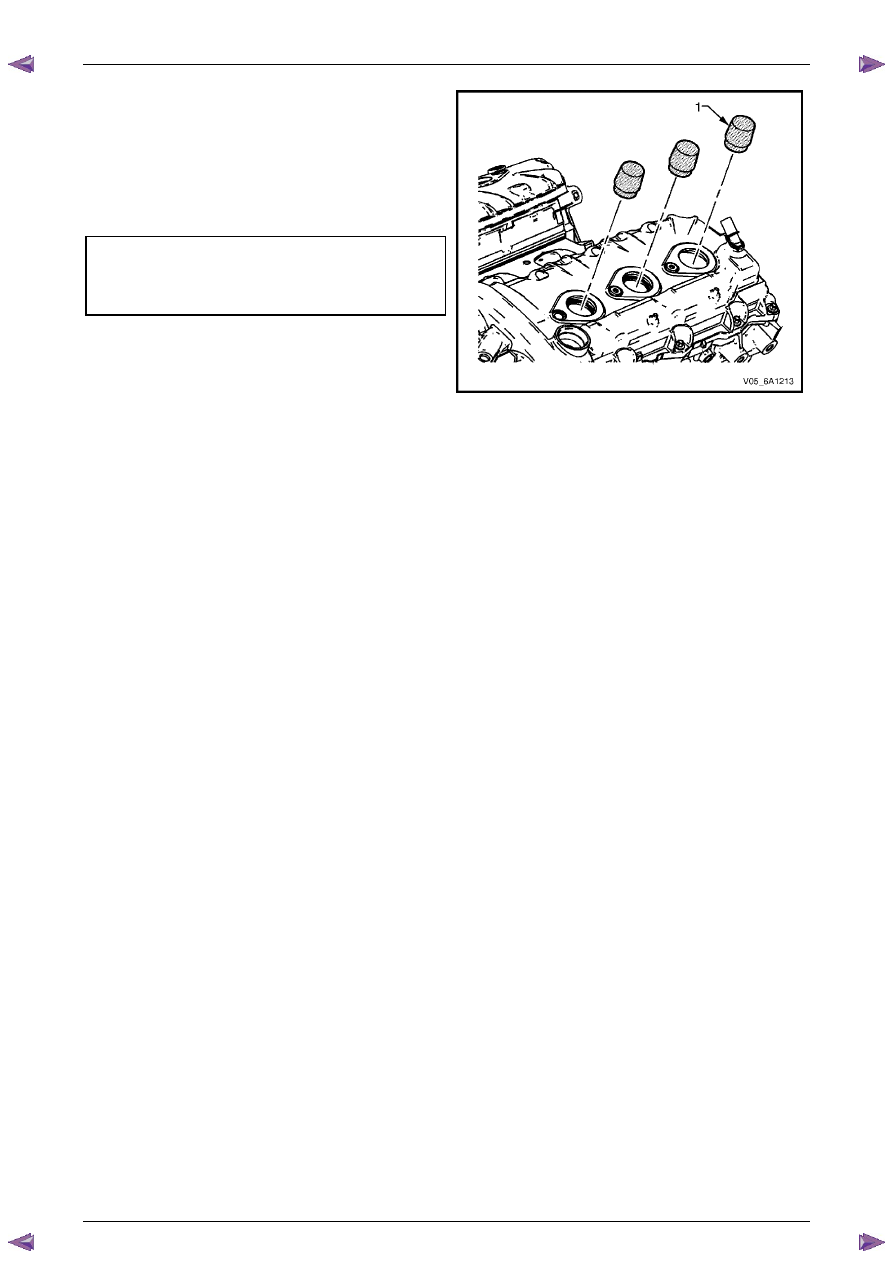

Remove Tool No. EN-46101 (1).

9

Tighten all remaining fasteners to the correct torque

specification.

Engine ground connector bolt

torque specification . . . . . . . . . . . 10.0 Nm

Engine wiring harness former attaching

bolt torque specification . . . . . . ..12.0 – 16.0 Nm

Figure 6A1 – 74

Engine Mechanical – V6

Page 6A1–100

Page 6A1–100

3.13 Crankshaft Balancer Assembly

Remove

1

Remove the accessory drive belt, refer to

3.5 Accessory Drive Belt

.

2

Remove the starter motor, refer to

Section 6D1-2 Starting System

.

3

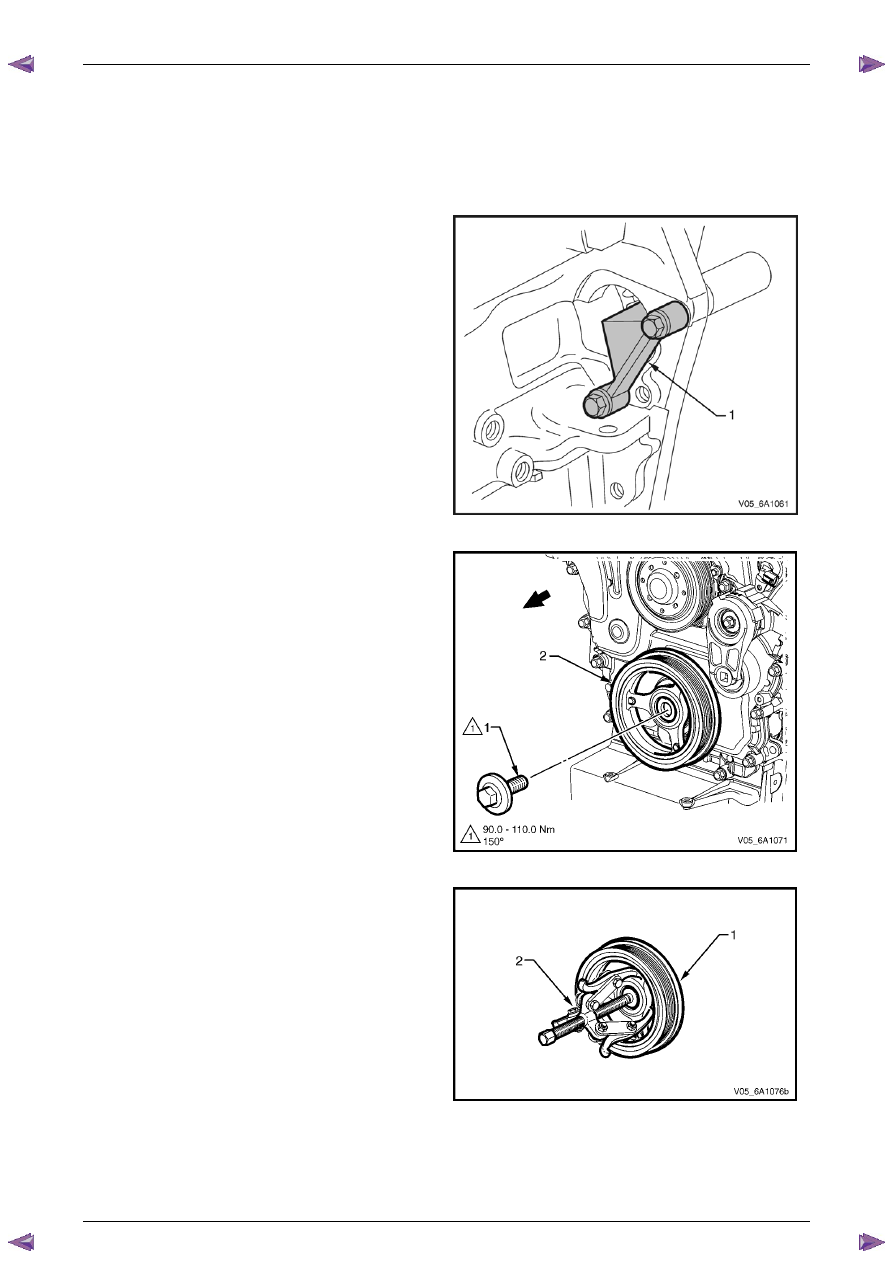

Install Tool No. EN-46106 (1) into the starter motor

opening to stop the camshaft from rotating.

Figure 6A1 – 75

4

Remove the bolt (1) attaching the crankshaft balancer

assembly (2) to the crankshaft.

Figure 6A1 – 76

5

Remove the crankshaft balancer assembly (1) from

the crankshaft using the appropriate tool:

Tool No. J-41816 (2) or equivalent.

Figure 6A1 – 77

Engine Mechanical – V6

Page 6A1–101

Page 6A1–101

Clean and Inspect

1

Using a suitable non-corrosive cleaning solvent and a soft bristled parts cleaning brush, clean the crankshaft

balancer assembly.

Safety glasses must be worn when using

compressed air.

2

Dry the crankshaft balancer assembly using compressed air.

3

Inspect the crankshaft balancer assembly for the following fault conditions:

•

Hub to crankshaft inner surface for wear or damage,

•

Sealing surface for wear, grooving or scoring,

•

Rubber ring between the hub and the pulley for wear, chunking and general deterioration, and

•

Drive belt ribs of the pulley for damage.

Reinstall

CAUTION

Do not lubricate the crankshaft front oil seal

or crankshaft balancer sealing surfaces. The

crankshaft balancer must be installed onto a

dry seal.

1

Lubricate the crankshaft balancer assembly hub bore.

2

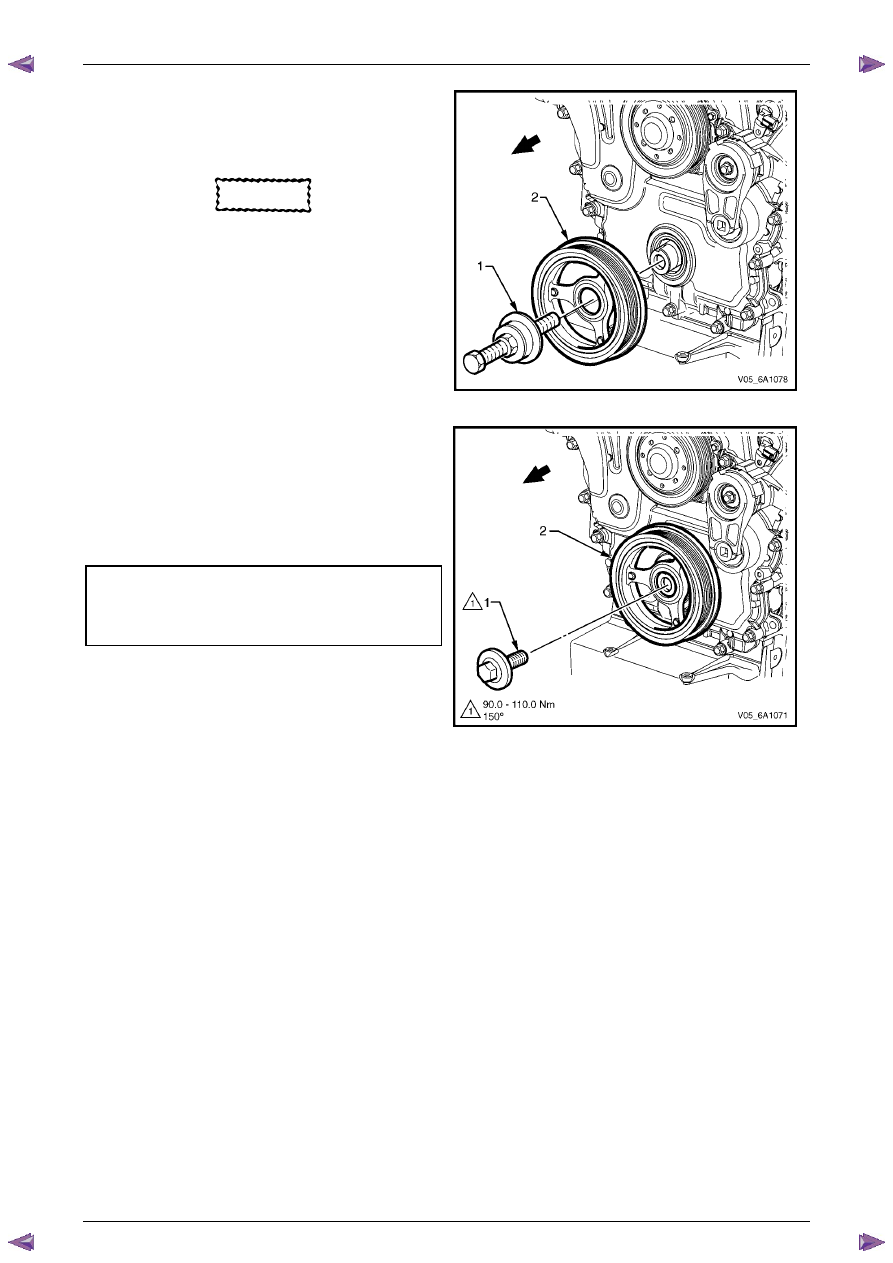

Partially install the crankshaft balancer assembly onto

the crankshaft.

Figure 6A1 – 78

Engine Mechanical – V6

Page 6A1–102

Page 6A1–102

3

Using crankshaft balancer installer, Tool No.

J-41998-B (1), fully install the crankshaft balancer

assembly into the crankshaft.

CAUTION

To prevent damage to the crankshaft

threads, fully install crankshaft balancer

installer, Tool No. J-41998-B (1) into the

crankshaft before pressing the pulley and

balancer assembly.

Figure 6A1 – 79

4

Apply Loctite 272 or equivalent to the thread of a new

crankshaft balancer assembly retaining bolt (1).

5

Install the crankshaft balancer assembly retaining bolt

and tighten to the correct torque specification.

Crankshaft balancer retaining

bolt torque specification:

Stage

1 . . . 90.0 – 110.0 Nm

Stage

2 . . . . . . . ...150

°

Figure 6A1 – 80

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст