Isuzu KB P190. Manual — part 1322

8A-350 ELECTRICAL-BODY AND CHASSIS

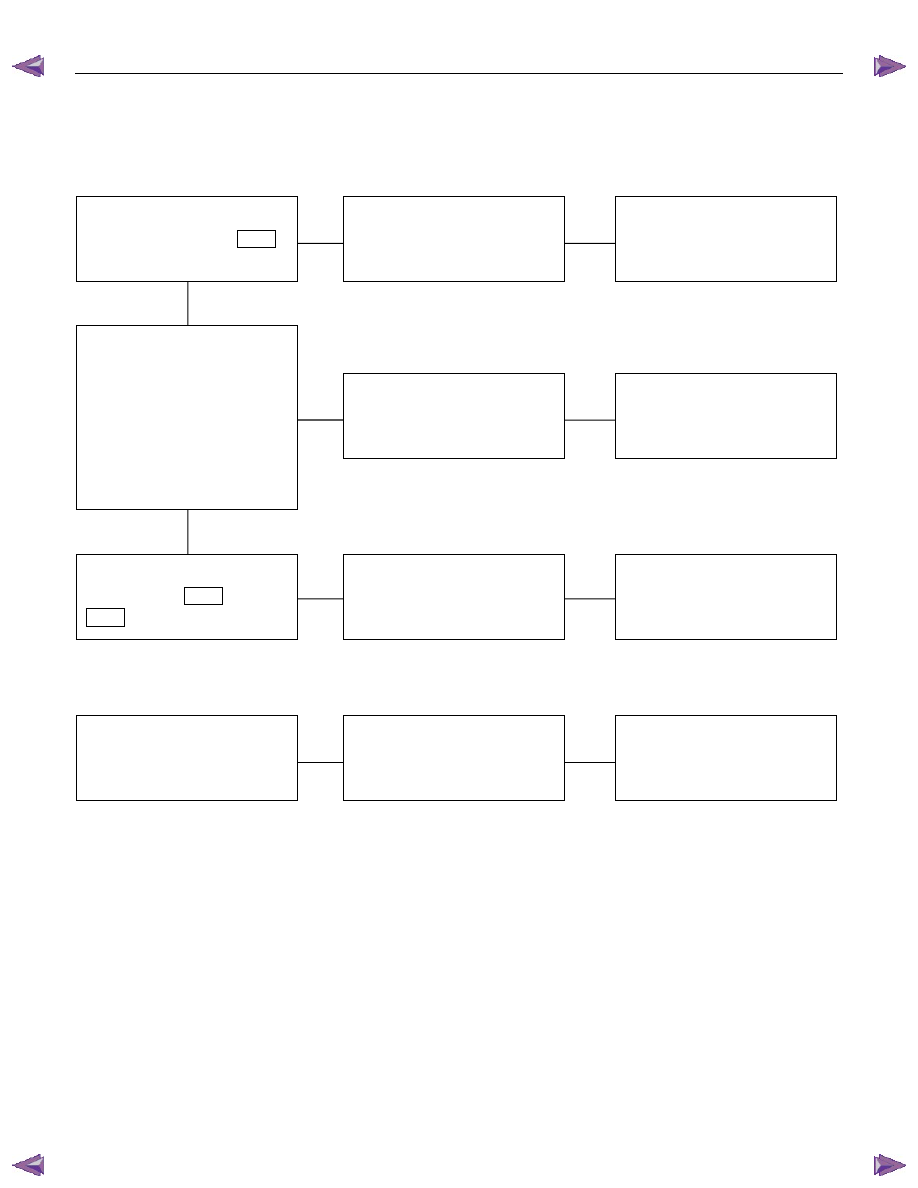

FUEL GAUGE AND FUEL TANK UNIT (HFV6)

1. No fuel level indicates at all

Checkpoint

Trouble

Cause

Countermeasure

Replace the tank unit

Open circuit inside the tank

unit

NG

Thermo unit malfunction

Replace the case baseboard

assy

Fuel gauge function

1. Disconnect the tank unit

connector then connect

3.4W bulb to wire harness

side

2. Check indicating point

when starter SW. is ON

position (Fuel level should

indicate)

Gauge malfunction

Repair open circuit or

connector contact

Continuity between

connectors 17

B23

and 17

B96

Open circuit or poor connector

contact

NG

NG

OK

OK

PIM (Tank unit) continuity

between connector 17

B96

and ground

2. Fuel gauge gives incorrect readings in all ranges

Replace the tank unit

Tank unit malfunction

NG

Tank unit resistance position

with the float at checking

points (Specified resistance

should indicate)

ELECTRICAL-BODY AND CHASSIS 8A-351

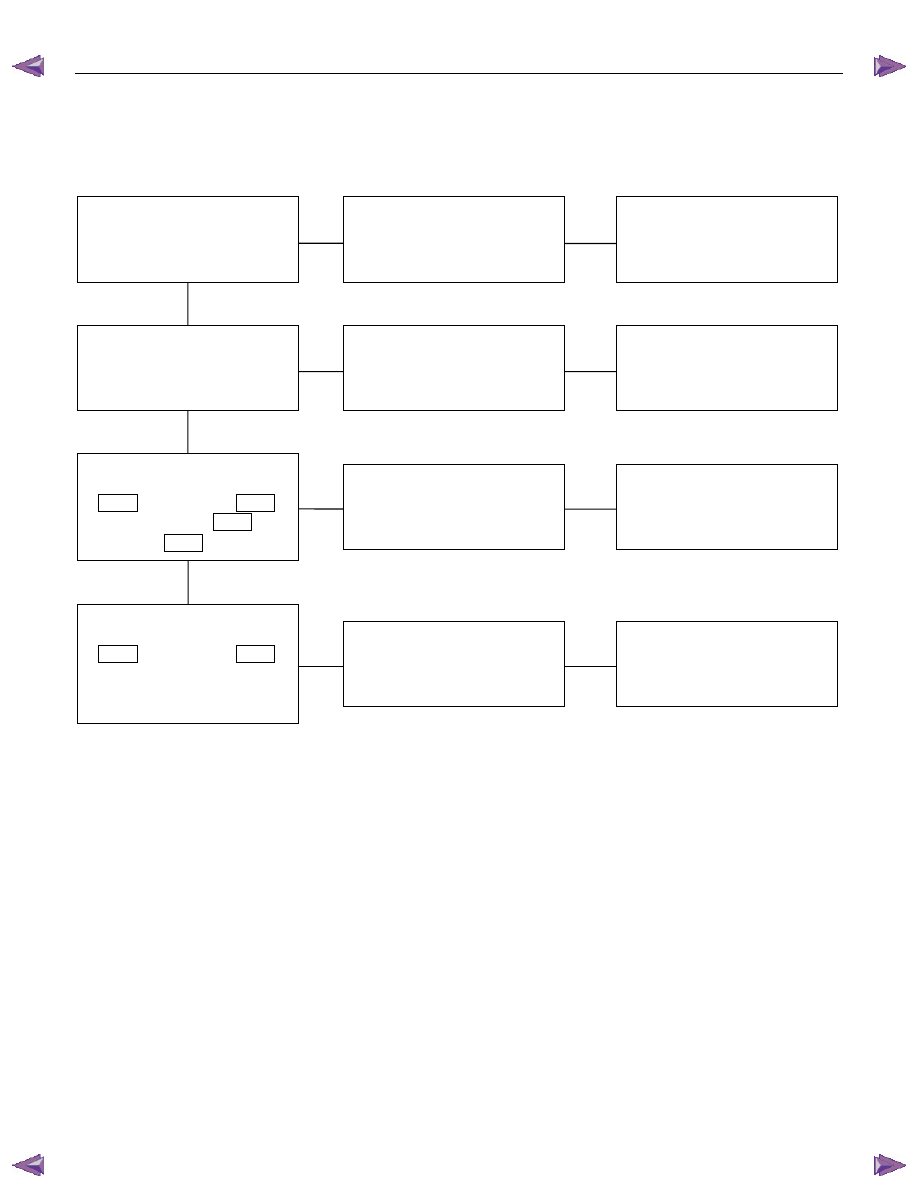

WARNING AND INDICATOR LIGHT

1. When the parking brake lever is pulled, the brake indicator light does not light up

Checkpoint

Trouble

Cause

Countermeasure

Replace or reinstall the bulb

Bulb burned out or loose

contact

NG

Adjust or replace the parking

brake SW.

Parking brake SW. installation

position and function

Incorrect SW. adjustment or

poor SW. point contact

Continuity between the

parking brake SW. connector

1

C39

(stick type), 1

R4

(lever type), and 4

B23

(C24SE : 9

B23

)

Repair open circuit or

connector contact

Open circuit or poor connector

contact

NG

NG

OK

OK

Brake indicator light bulb

continuity

NG

OK

Continuity between the

parking brake SW. connector

1

C39

(stick type), 1

R4

(lever type) and the ground

when the parking brake is

operated

Replace the parking brake

SW.

Parking brake SW.

malfunction

8A-352 ELECTRICAL-BODY AND CHASSIS

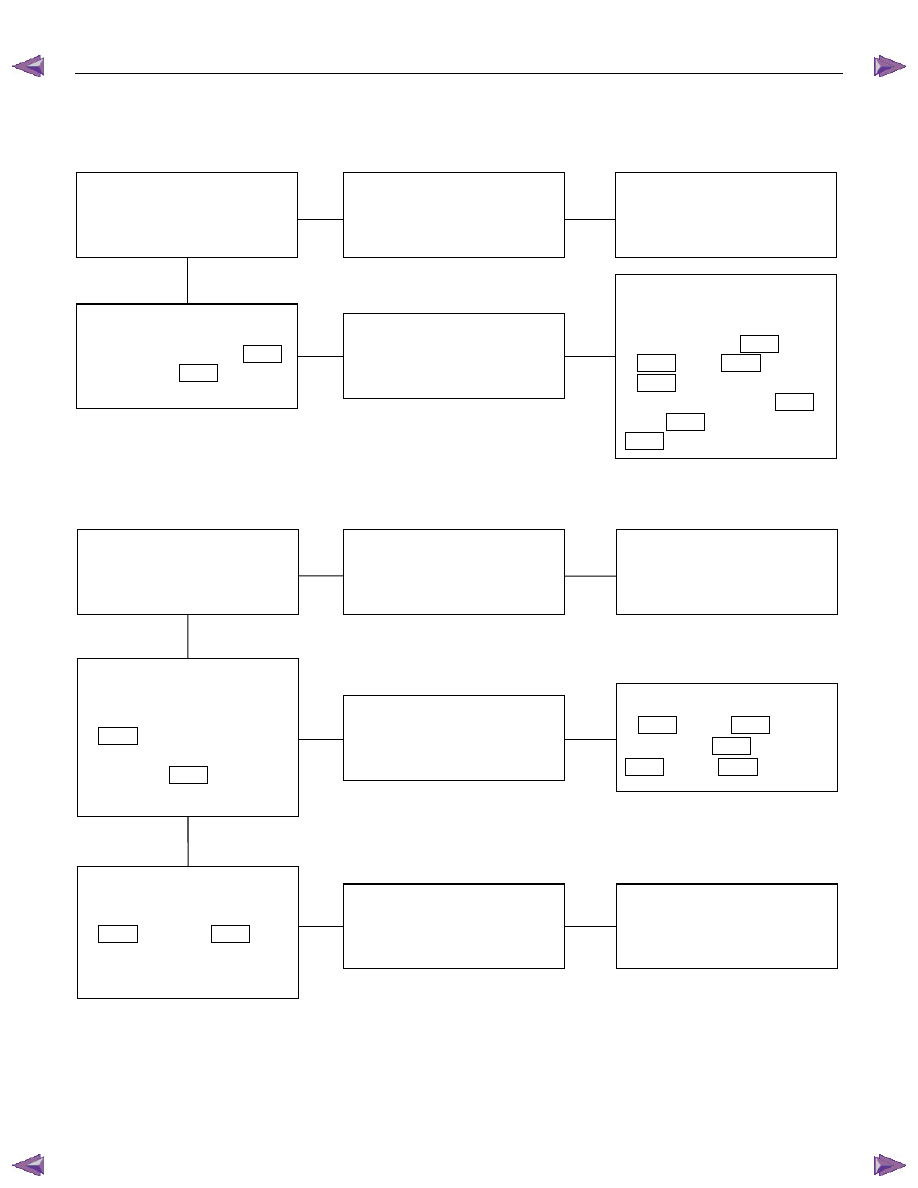

2. When the parking brake lever is released, the indicator light does not go off

Checkpoint

Trouble

Cause

Countermeasure

Adjust the SW. installation

position or replace the parking

brake SW.

Incorrect the parking brake

SW. adjustment or parking

brake SW. faulty

NG

Thermo unit malfunction

Replace the brake fluid level

SW., or repair a short circuit

between the parking brake

SW. connector 1

C39

,

1

R4

and 4

B23

(C24SE :

9

B23

) or the brake fluid

level SW. connector 2

C37

and 4

B23

(C24SE : 9

B23

)

Check to see if the indicator

light goes off when the parking

brake SW. connector 1

C39

(stick type), 1

R4

(lever

type) is disconnected

Brake fluid level SW. faulty or

short circuit

NG

OK

Parking brake SW. installation

position and function

3. Oil pressure warning light does not go off while engine is running

Refer to ENGINE Section

Refer to ENGINE Section

NG

Thermo unit malfunction

Check to see the warning light

goes off when the oil pressure

SW. connector

1

E1

is disconnected or

when the PIM (Oil pressure)

connector 6

B96

(HFV6) is

disconnected

Repair a short circuit between

1

E1

and 39

B23

(C24SE : 17

B24

) or 6

B96

and 39

B23

(HFV6)

Short circuit

NG

OK

Replace the oil pressure SW.

Continuity between the oil

pressure SW. connector

1

E1

(HFV6 : 6

B96

)and

the body ground when the

engine is operating

Oil pressure SW. faulty

NG

OK

Engine oil pressure

ELECTRICAL-BODY AND CHASSIS 8A-353

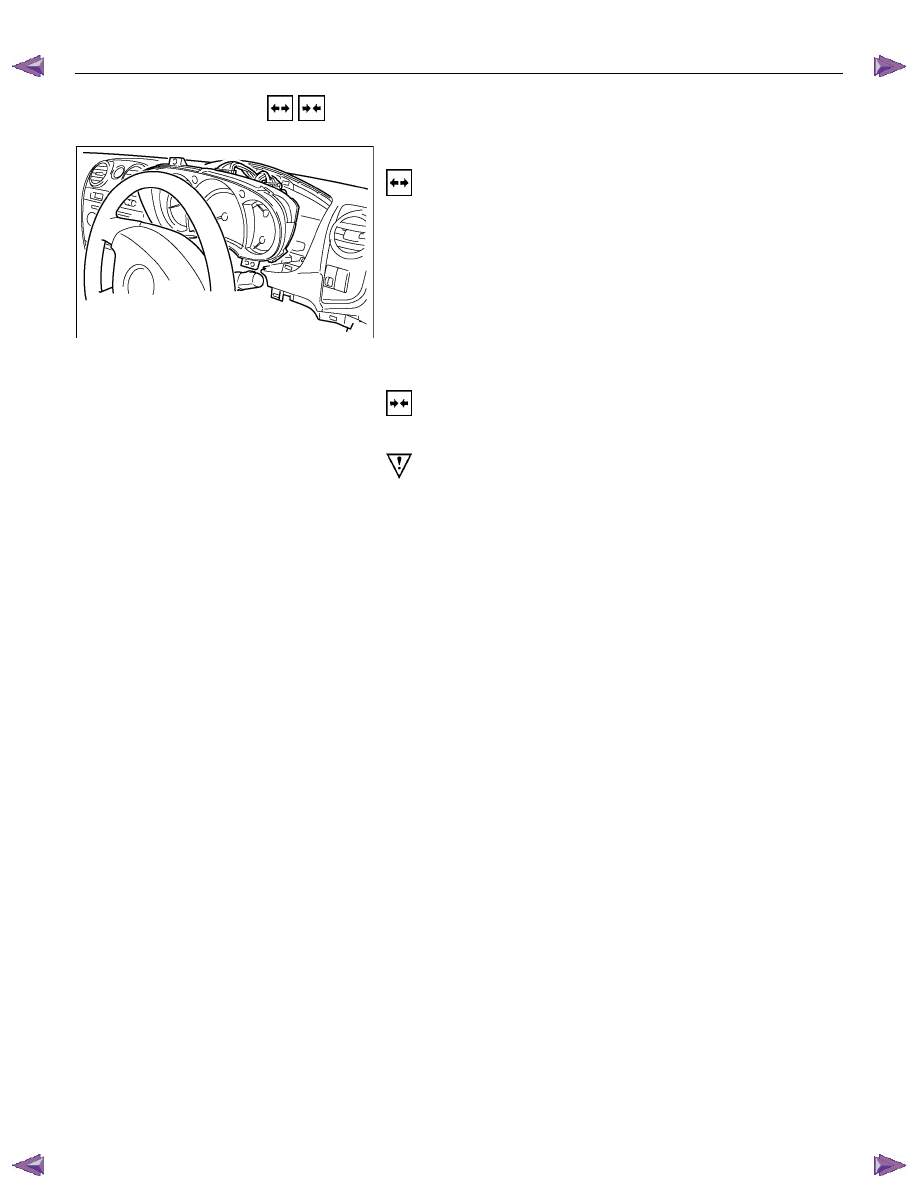

REMOVAL AND INSTALLATION

RTW780SH001701

This illustration is based on RHD model

METER ASSEMBLY

Removal

1. Meter Cluster Assembly

• Refer to the removal steps of “INSTRUMENT PANEL” in

Section 10 “CAB”

2. Meter Assembly

• Remove three screws of the meter assembly.

• Disconnect the meter connectors.

Installation

Follow the removal procedure in the reverse order to install the

meter.

Pay close attention to the important points mentioned in the

following paragraphs.

Connector

Be absolutely sure that the meter connectors are securely

connected.

This will prevent a poor contact and an open circuit.

Wire Harness

Do not pinch the wire harness between the cluster and the

meter hood during the meter assembly installation procedure.

Wire damage will result.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст