Isuzu KB P190. Manual — part 662

Engine Mechanical – V6

Page 6A1–169

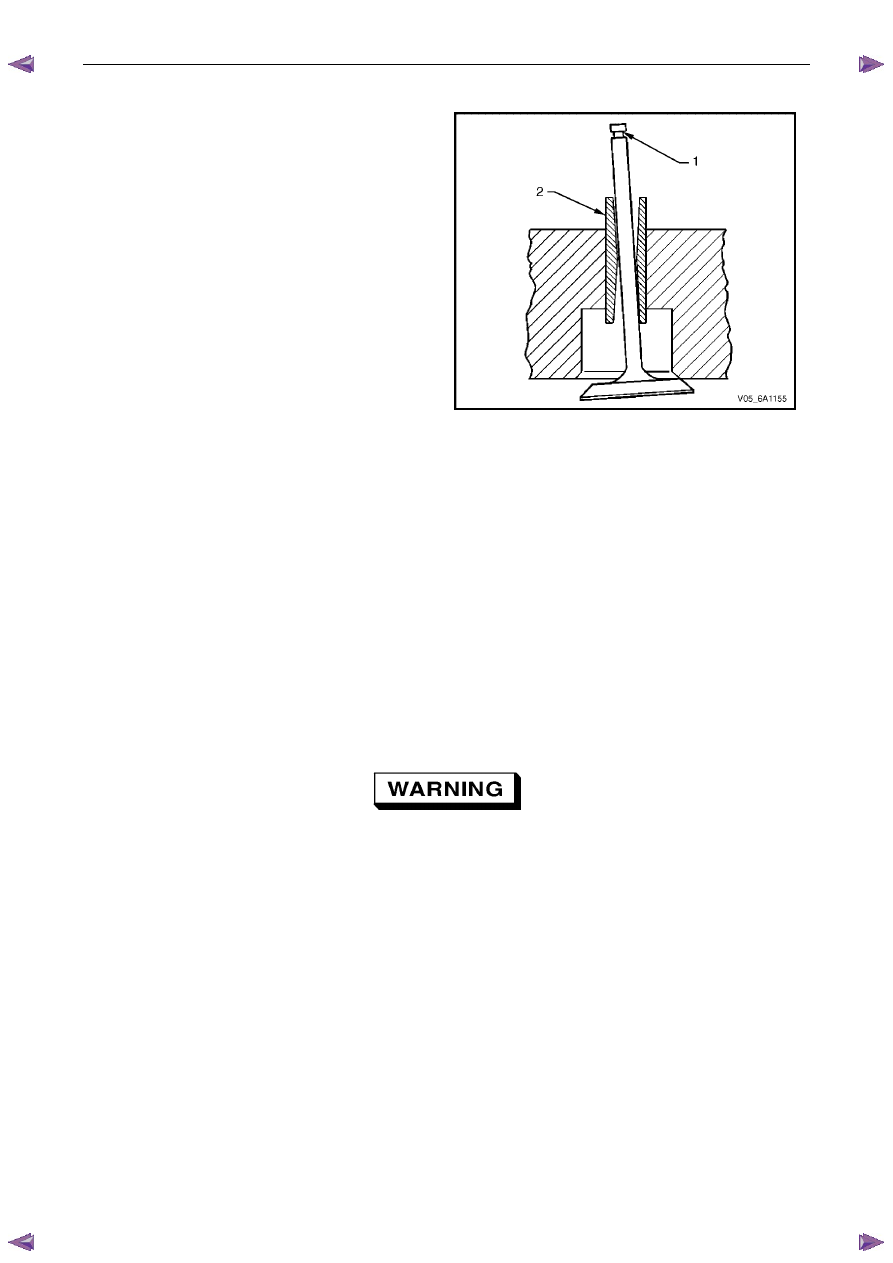

Valve Guide Measurement

1

Measure the valve stem (1) to-guide (2) clearance.

Excessive valve stem-to-guide clearance may cause

excessive oil consumption and may also cause a

valve to break. Insufficient clearance will result in

noisy and sticky functioning of the valve and will

disturb the engine assembly smoothness.

2

Clamp a dial indicator to the cylinder head at the

camshaft cover rail.

3

Locate the dial indicator so the movement of the valve

stem from side to side, crossways to the cylinder

head, will cause a direct movement of the indicator

stem. The dial indicator stem must contact the side of

the valve stem just above the valve guide.

4

Drop the valve head about 0.064 mm off the valve

seat.

5

Use light pressure when moving the valve stem from

side to side to obtain a clearance reading, refer to 5

Specifications.

•

If the clearance for the valve is greater than

specified and a new standard diameter valve

stem will not bring the clearance within

specifications, the valve guide may be oversized

by 0.075 mm using the valve guide reamer, Tool

No. J 42096 or by 0.375 mm using the valve

guide reamer, Tool No. EN-46120. Two sizes of

oversized valve stems are available for service.

•

Valve guide wear at the bottom 10 mm of the

valve guide is not significant enough to affect

normal operation.

•

If over sizing the guide does not bring the

clearance within specifications, replace the

cylinder head.

Figure 6A1 – 289

Valve Spring Inspection and Measurement

Inspection Procedure

1

Clean the valve springs in solvent.

Safety glasses must be worn when using

compressed air

2

Dry the valve springs with compressed air.

3

Inspect the valve springs for broken coils or coil ends.

Engine Mechanical – V6

Page 6A1–170

Measurement Procedure

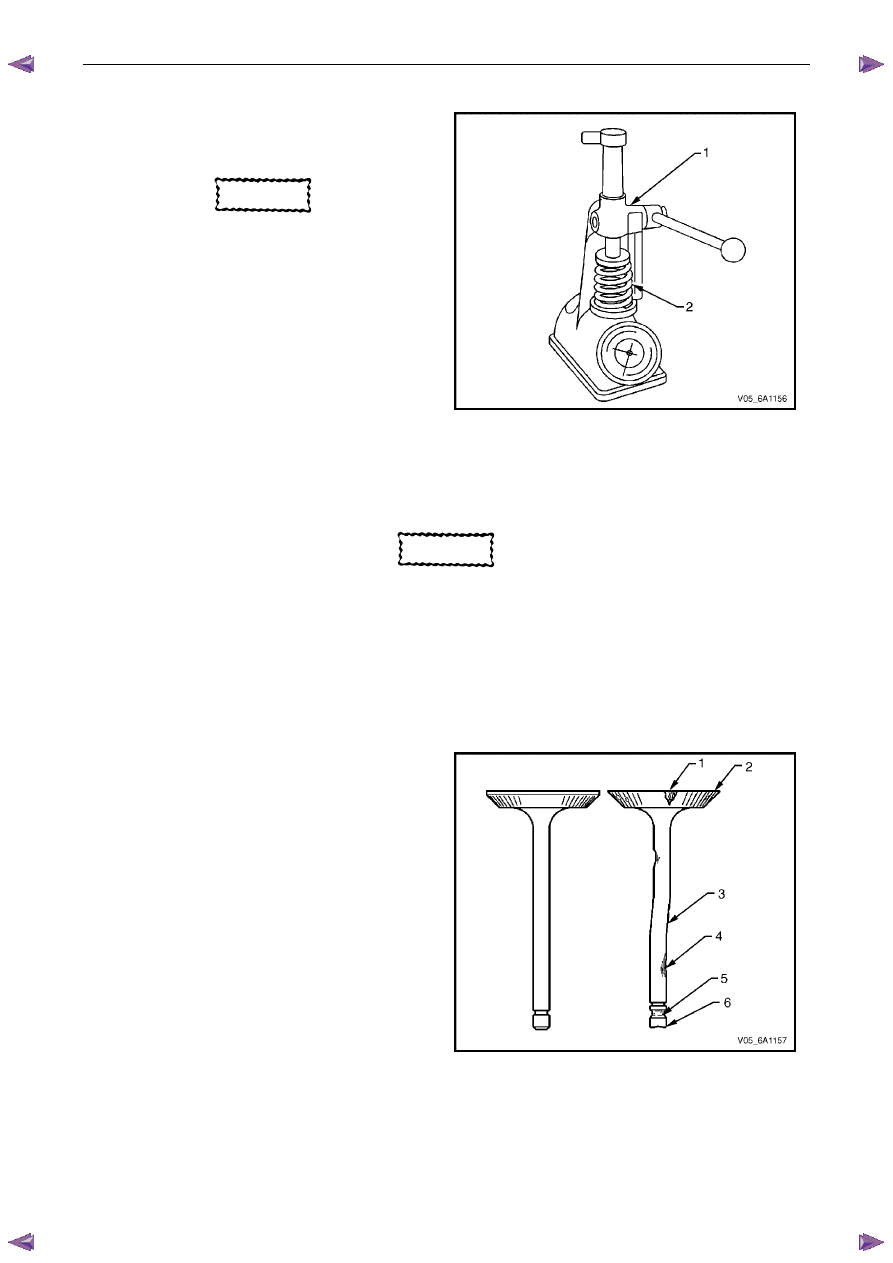

1

Use a commercially available valve spring tester to

measure the valve spring tension, refer to 5

Specifications.

CAUTION

Do not use shims to increase spring load.

The use of shims can cause the valve spring

to bottom out before the camshaft lobe is at

peak lift.

2

If low valve spring load is found, replace the valve

springs.

Figure 6A1 – 290

Valve and Seat Grinding

Valve Cleaning Procedure

CAUTION

Do not use a wire brush on any part of the

valve stem. The valve stem is chrome plated

to provide enhanced wear characteristics.

Wire brushing the stem could remove the

chrome plating.

1

Use soft bristle brush to clean any carbon build-up from the valve head.

2

Thoroughly clean the valve with solvent and wipe dry.

Valve Visual Inspection Procedure

1

Inspect the valve for damage from the head to tip for

the following conditions:

•

pitting in the valve seat area (1),

•

lack of valve margin (2),

•

bending in the valve stem (3),

•

pitting or excessive wear in the stem (4),

•

worn valve key grooves (5), and

•

worn valve tip (6).

2

Replace the valve if any of these conditions exist.

Figure 6A1 – 291

Valve Measurement and Reconditioning Overview

Correct valve service is critical to engine performance. Therefore, all detailed measurement procedures must be followed

to identify components that are out of specification. If the measurement procedures reveal the valve or valve seat must

be reconditioned, it is critical to perform the measurement procedures after reconditioning.

Engine Mechanical – V6

Page 6A1–171

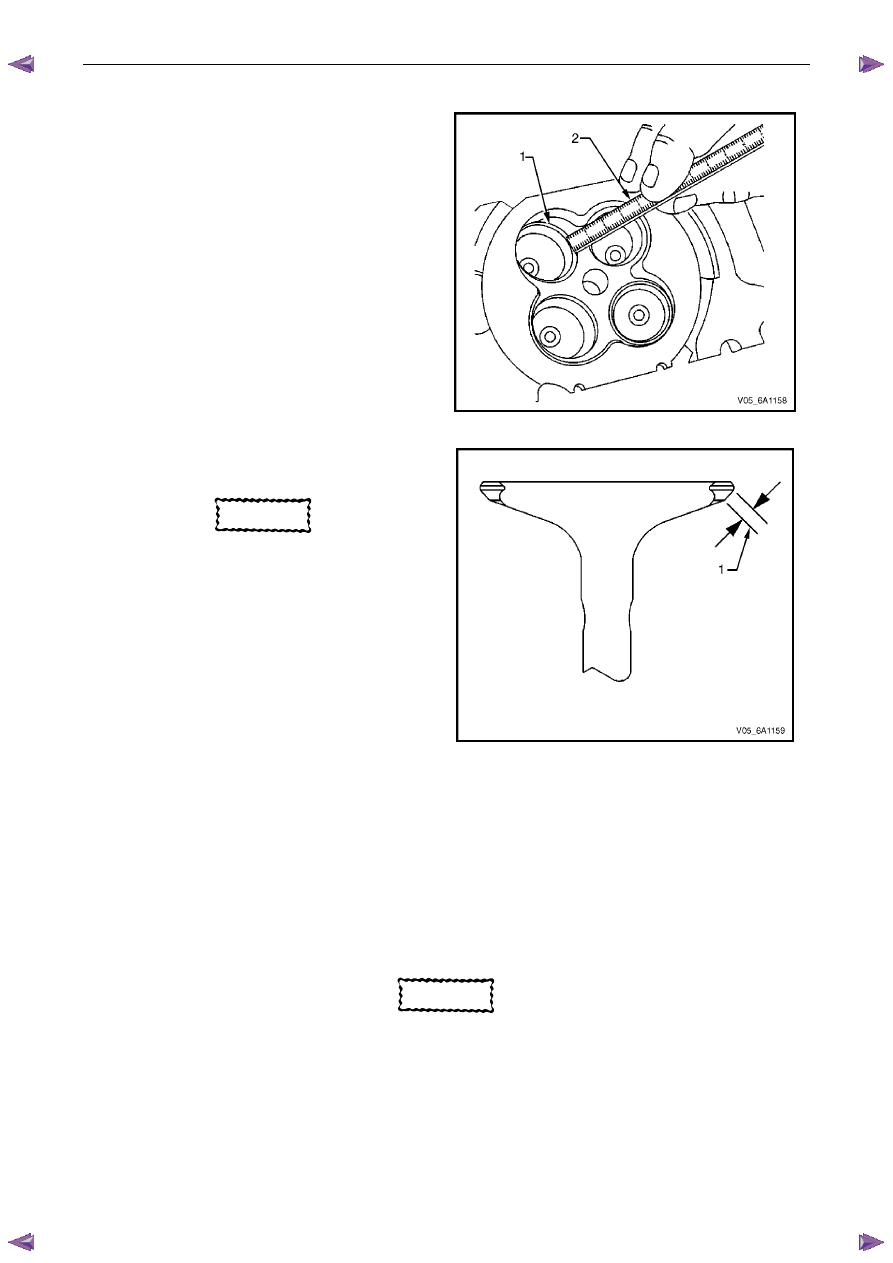

Valve Seat Width Measurement Procedure

1

Measure the valve seat (1) width in the cylinder head

using a scale (2).

Figure 6A1 – 292

2

Measure the seat width on the valve face (1) using a

correct scale.

CAUTION

The seat contact area must be at least

0.5 mm from the outer diameter (margin) of

the valve. If the contact area is too close to

the margins, the seat must be reconditioned

to move the contact area away from the

margin.

3

Compare the measurements with the specifications,

refer to 5

Specifications.

4

If the seat widths are acceptable, check the valve

seat roundness, refer to Valve Seat Roundness

Measurement Procedure in this Section.

5

If the seat width is not acceptable, grind the valve

seat to bring the width back to specification. Correct

valve seat width is critical to providing the correct

amount of valve heat dissipation, refer to Valve and

Seat Reconditioning Procedure in this Section.

Figure 6A1 – 293

Valve Seat Roundness Measurement Procedure

1

Measure the valve seat roundness using a dial indicator attached to a tapered pilot installed in the guide. The pilot

should have a slight bind when installed in the guide.

CAUTION

The correct size pilot must be used. Do not

use adjustable diameter pilots. Adjustable

pilots may damage the valve guides.

2

Compare your measurements with the specifications, refer to 5

Specifications.

3

If the valve seat exceeds the roundness specification, grind the valve and valve seat, refer to Valve and Seat

Reconditioning Procedure in this Section.

4

If new valves are being used, the valve seat roundness must be within 0.05 mm.

Engine Mechanical – V6

Page 6A1–172

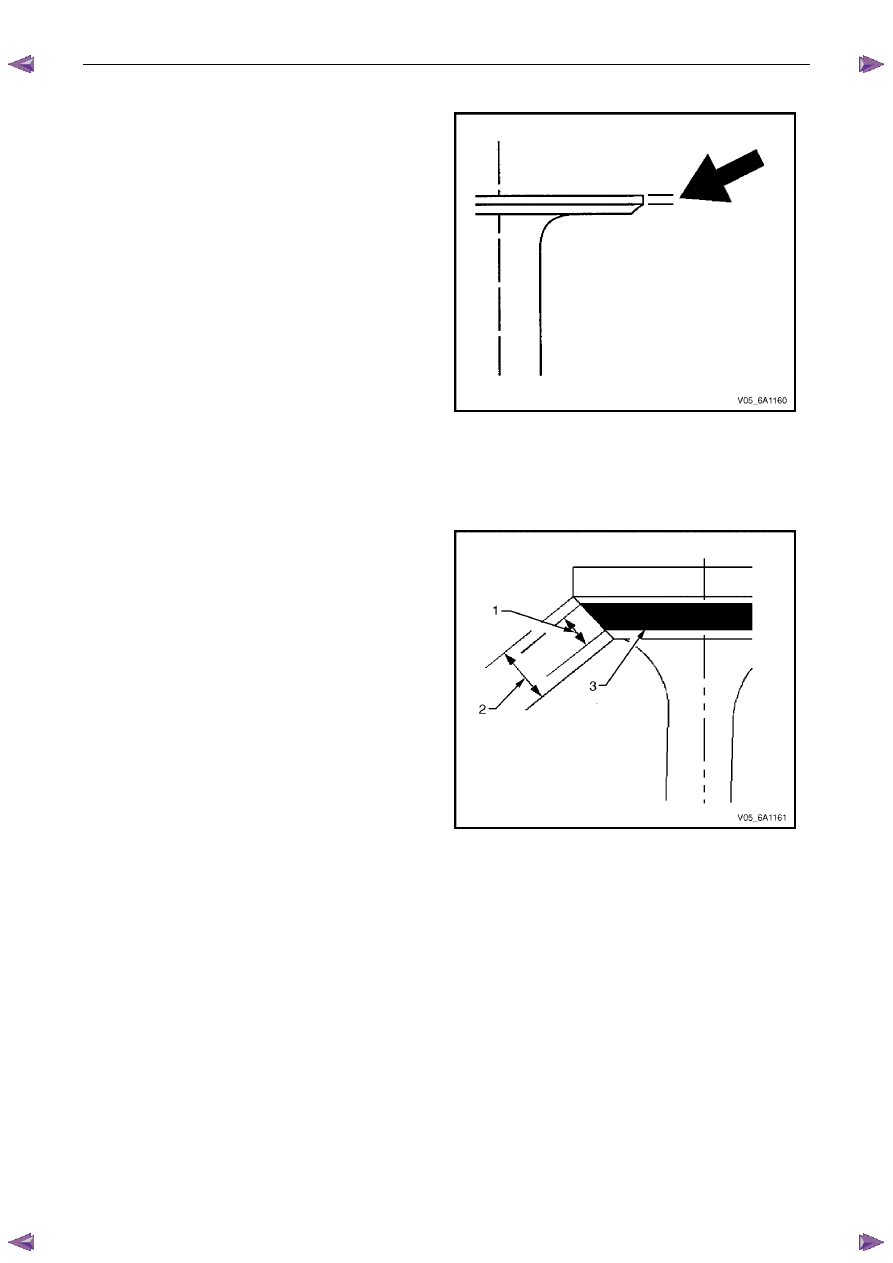

Valve Margin Measurement Procedure

1

Measure the valve margin using an appropriate scale.

2

Refer to 5 Specifications for minimum valve margin

and compare them to your measurements.

3

If the valve margins are beyond specification, replace

the valves.

4

If the valve margins are within specification and do

not require refacing, test the valve for seat

concentricity, refer to Valve-to-Seat Concentricity

Measurement Procedure in this Section.

Figure 6A1 – 294

Valve-to-Seat Concentricity Measurement Procedure

Checking the valve-to-seat concentricity determines whether the valve and seat are sealing correctly.

Measure the valve face and the valve seat to ensure correct valve sealing.

1

Coat the valve face lightly with blue dye (3).

2

Install the valve in the cylinder head.

3

Turn the valve against the seat with enough pressure

to wear off the dye.

4

Remove the valve from the cylinder head.

5

Inspect the valve face.

N O T E

•

If the valve face is concentric, providing a

correct seal, with the valve stem, a continuous

mark (1) will be made around the entire face (2).

•

The wear mark must be at least 0.5 mm from

the margin of the valve. If the wear mark is too

close to the margin, the seat must be

reconditioned to move the contact area away

from the margin.

•

If the face is not concentric with the stem, the

mark will not be continuous around the valve

face. The valve should be refaced or replaced

and the seat must be reconditioned, refer to

Valve and Seat Reconditioning Procedure in

this Section.

Figure 6A1 – 295

Valve and Seat Reconditioning Procedure

If the valve seat width, roundness or concentricity are beyond specifications, grind the seats in order to ensure correct

heat dissipation and prevent the build up of carbon on the seats.

If valve seat reconditioning is required, reface the valve face, unless a new valve is used.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст