Isuzu KB P190. Manual — part 646

Engine Mechanical – V6

Page 6A1–105

11

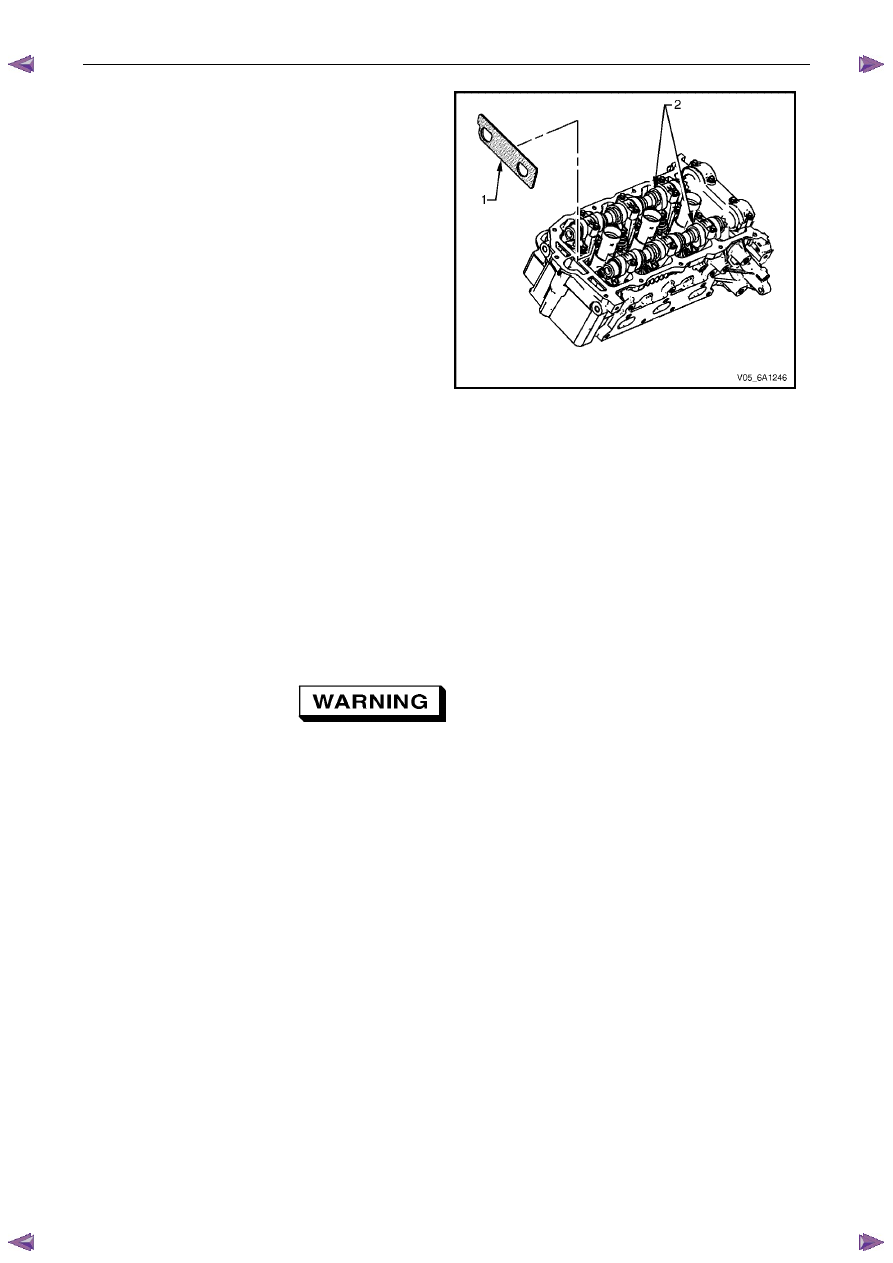

Remove Tool No. EN 46105-1 (1) from the right-hand

cylinder head camshafts (2).

Figure 6A1 – 127

Clean

1

Clean all the following components with a suitable solvent:

•

crankshaft sprocket,

•

primary timing chain,

•

primary timing chain guide,

•

primary timing chain tensioner,

•

secondary timing chains,

•

secondary timing chain shoes,

•

secondary timing chain guides,

•

secondary timing chain tensioners, and

•

bolts.

Safety glasses must be worn when using

compressed air.

2

Dry all the components with compressed air.

Engine Mechanical – V6

Page 6A1–106

Inspect

Timing Chains

1

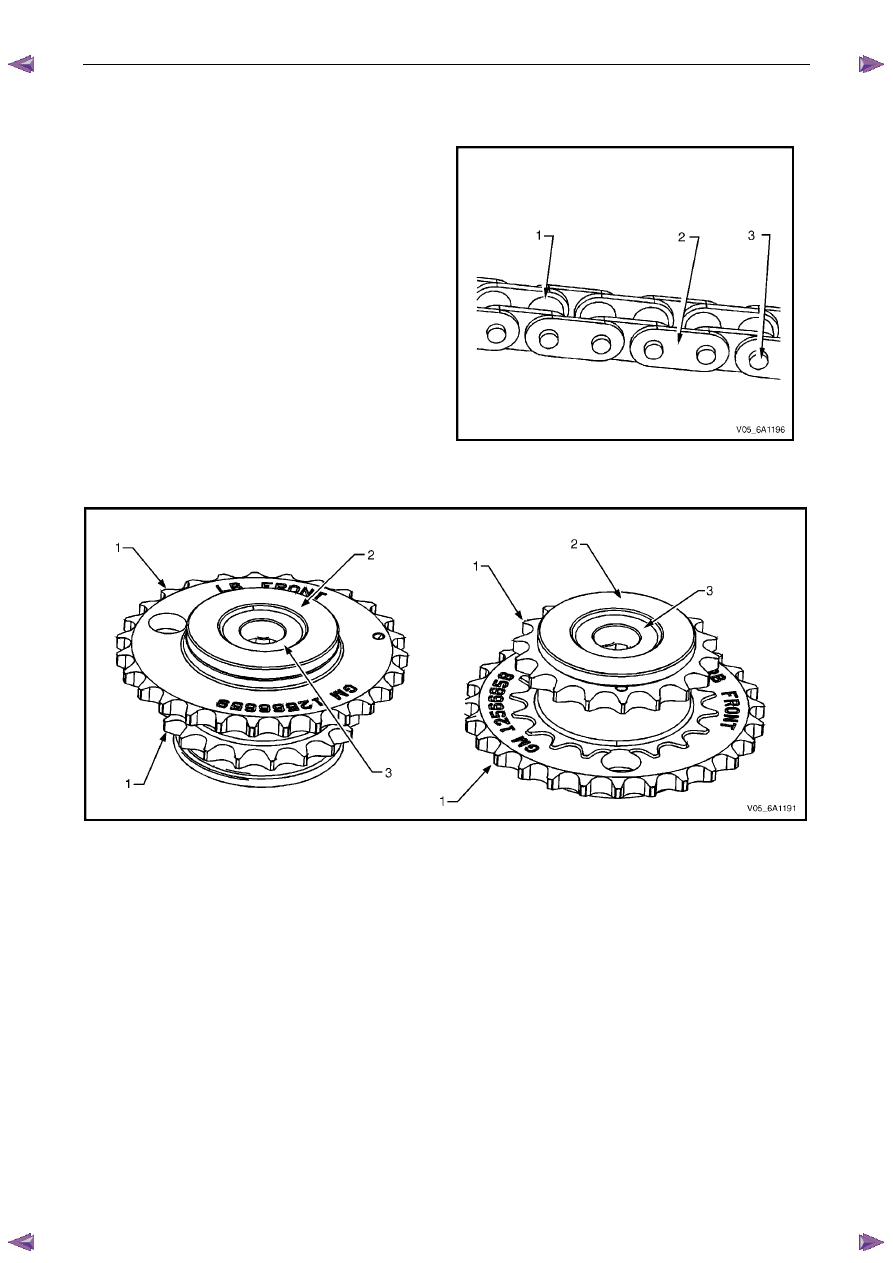

Inspect the primary and/or secondary timing chains

for the following:

•

binding or worn rollers (1),

•

loose links (2), and

•

loose pins (3).

2

Replace a damaged timing chain as required.

Figure 6A1 – 128

Camshaft Intermediate Driveshaft Sprockets

Figure 6A1 – 129

1

Inspect the camshaft intermediate driveshaft sprockets for the following:

•

Damage to the primary and secondary timing chain sprocket (1), refer to Figure 6A1 – 129.

•

Damage to the hub bearing (2). Ensure the hub bearing spins freely. If the hub bearing wobbles, is noisy or

feels rough when rotated replace the camshaft intermediate sprocket, and

•

Damage to the bolt flange seating / sealing surface (3).

•

Damage to the bearing hub-to-engine block sealing surface.

Inlet and Exhaust Camshaft Sprocket

Inspect the camshaft sprocket assemblies, refer to 3.18

Camshaft Sprocket.

Engine Mechanical – V6

Page 6A1–107

Crankshaft Sprocket

1

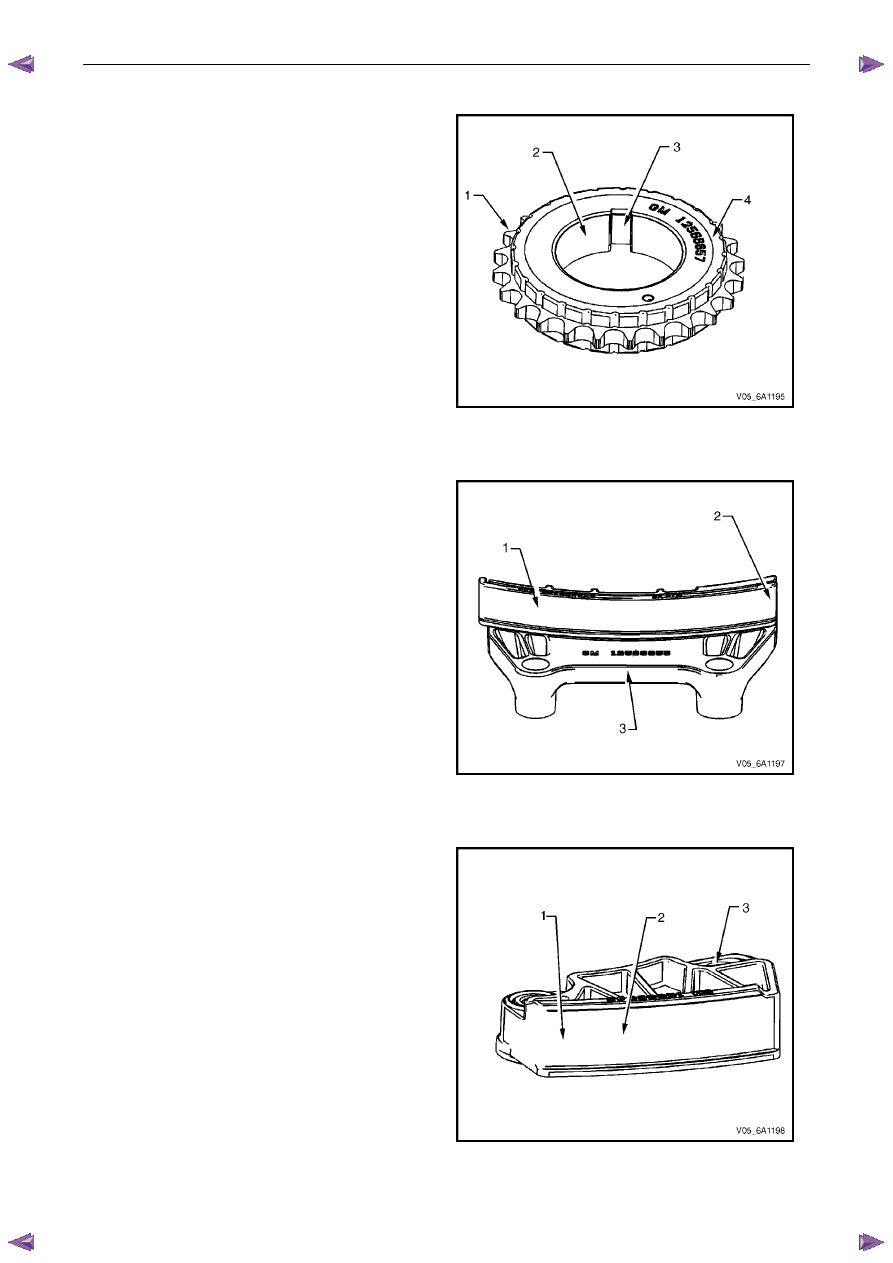

Inspect the crankshaft sprocket for the following:

•

sprocket damage (1),

•

bore damage (2),

•

keyway damage (3), and

•

damage to the cushion material (4).

2

Replace a damaged sprocket as required.

Figure 6A1 – 130

Primary Timing Chain Upper Guide

1

Inspect the primary timing chain upper guide for the

following:

•

worn guide surface (1),

•

cracked or broken guide surface (2), and

•

cracked or damaged guide base (3).

2

Replace a damaged guide as required.

Figure 6A1 – 131

Primary Timing Chain Lower Guide

1

Inspect the primary timing chain lower guide for the

following:

•

worn guide surface (1),

•

cracked or broken guide surface (2), and

•

cracked or damaged guide base (3).

2

Replace the primary timing chain lower guide by

replacing the oil pump assembly, refer to 3.17 Oil

Pump Assembly.

N O T E

The primary timing chain lower guide is not

serviced separately and is part of the oil pump

assembly.

Figure 6A1 – 132

Engine Mechanical – V6

Page 6A1–108

Primary Timing Chain Tensioner

Figure 6A1 – 133

1

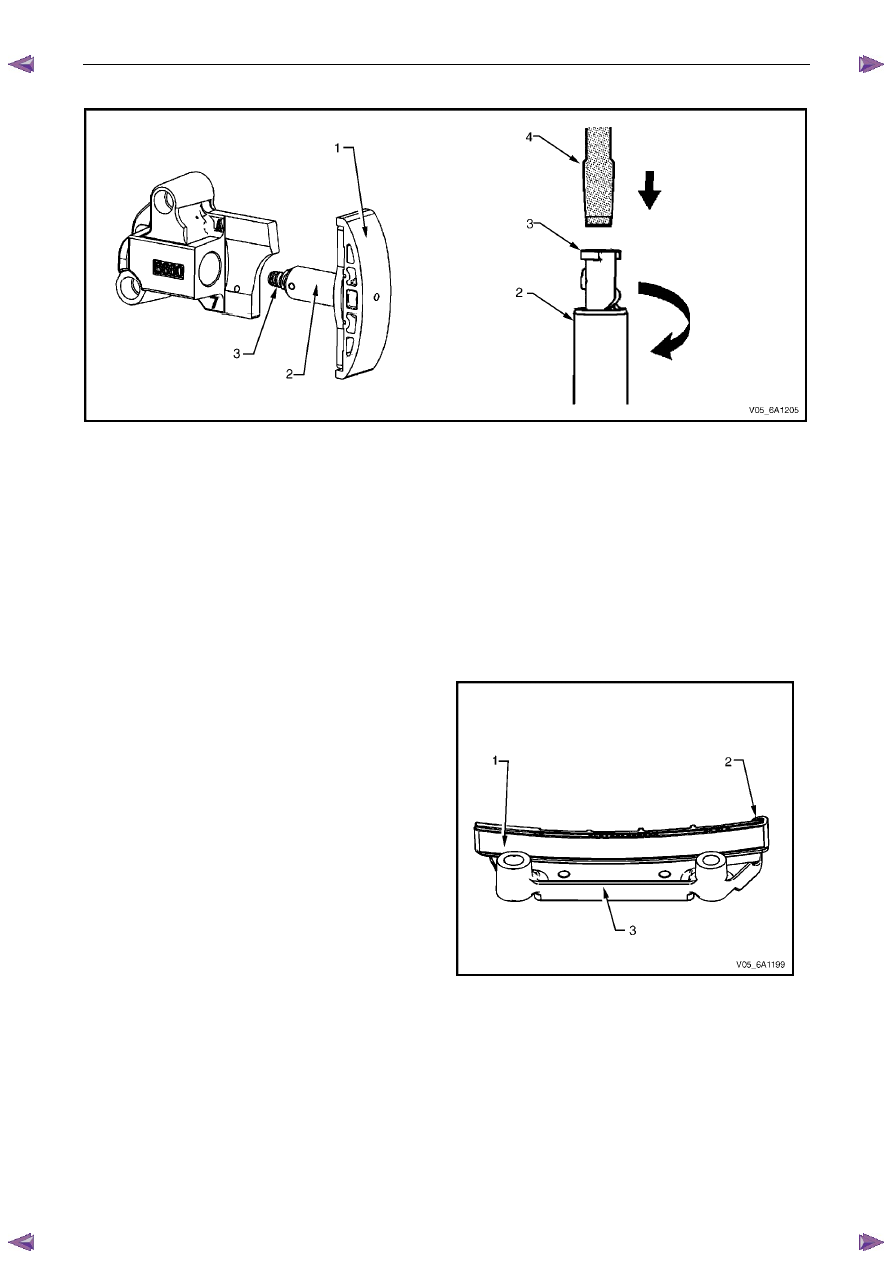

Inspect the primary timing chain tensioner for worn shoe surface (1), refer to Figure 6A1 – 133.

2

Inspect the tensioner for a locked or binding tensioner shaft (2). Reset the plunger (3) and ensure the tensioner

shaft moves freely in and out of the body of the tensioner.

N O T E

To reset the tensioner, use a suitably sized flat

blade screwdriver or Tool No. J 45027 (4) to wind

the plunger in a clockwise direction, into the

tensioner shaft.

3

Replace a damaged tensioner as required.

Left-hand Secondary Timing Chain Guide

1

Inspect the left-hand secondary timing chain guide for

the following:

•

worn guide surface (1),

•

cracked or broken guide surface (2), and

•

cracked or damaged guide base (3).

2

Replace a damaged guide as required.

Figure 6A1 – 134

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст