Isuzu KB P190. Manual — part 110

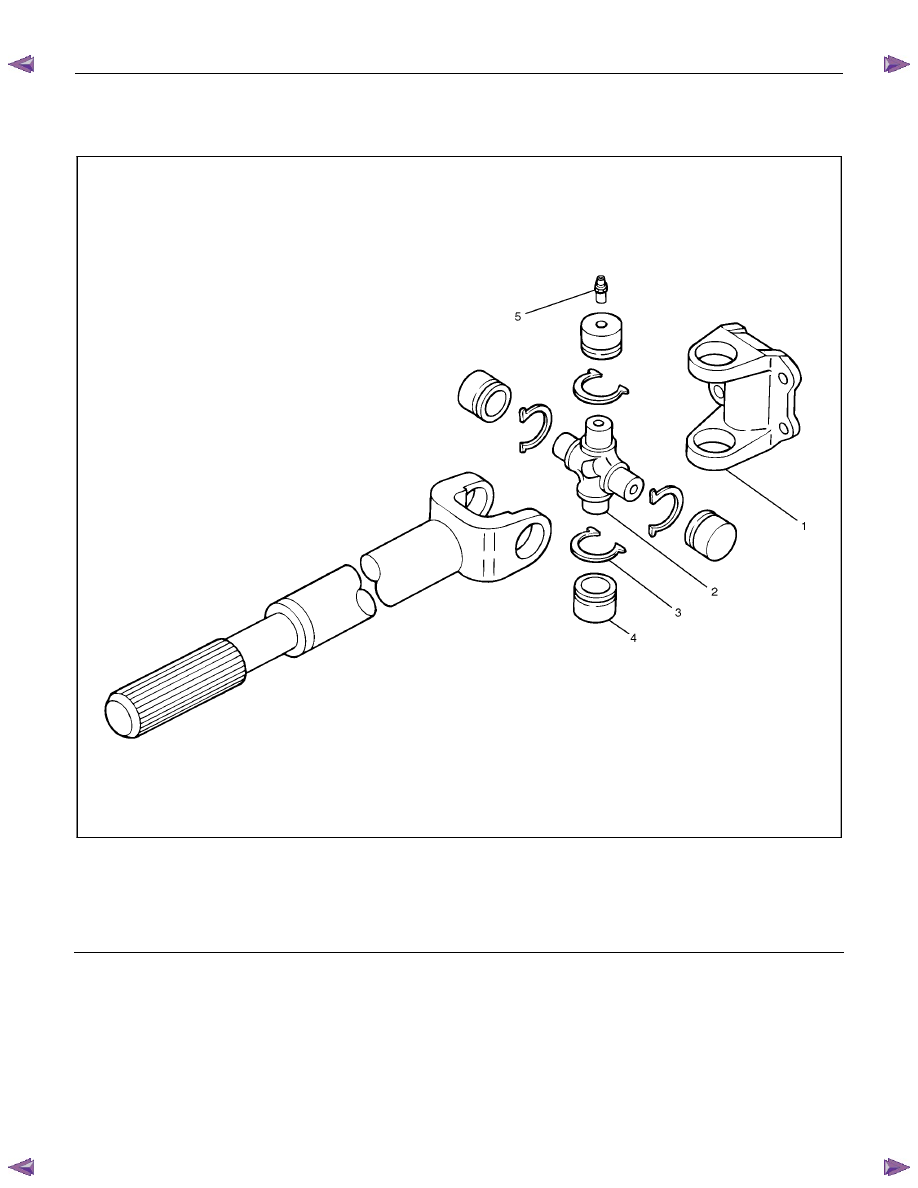

4A-24 PROPELLER SHAFT

Universal Joint Disassembly and

Reassembly

401RW055

Legend

1.

Flange

Yoke

2.

Spider

3.

Snap

Ring

4. Needle Roller Bearing

5.

Grease

Fitting

PROPELLER SHAFT 4A-25

401RS028

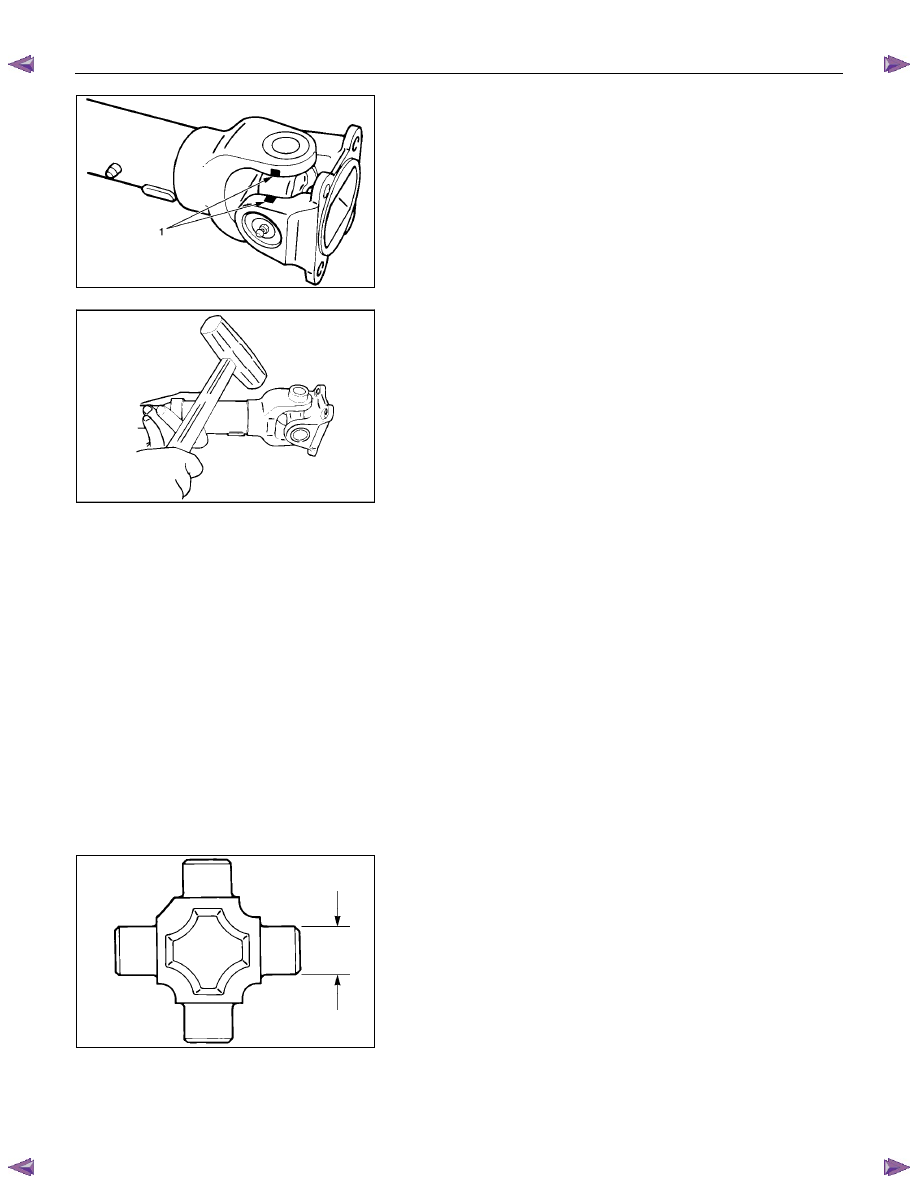

Disassembly

1. Apply alignment marks (1) on the yokes of the universal

joint, then remove snap ring.

401RS006

2. Tap out the needle roller bearing by gently striking the

shoulder of the yoke, using a mallet or a copper hammer.

3. Make sure of proper position for reinstallation by applying

setting marks, then remove spider.

Inspection and Repair

Make necessary correction or parts replacement if wear,

damage, corrosion or any other abnormal condition is found

through inspection.

NOTE:

When any part of the journal assembly (spider, needle roller

bearing) requires replacement, be sure to replace the entire

assembly.

Check the following parts for wear, damage, noise or any other

abnormal conditions:

1. Spider

2. Needle roller bearing

3. Yoke

4. Flange

5. Constant velocity joint

401RS007

Outside Diameter of Spider Pin

Standard: 17.00 mm (0.6693 in)

Limit: 16.99 mm (0.6689 in)

4A-26 PROPELLER SHAFT

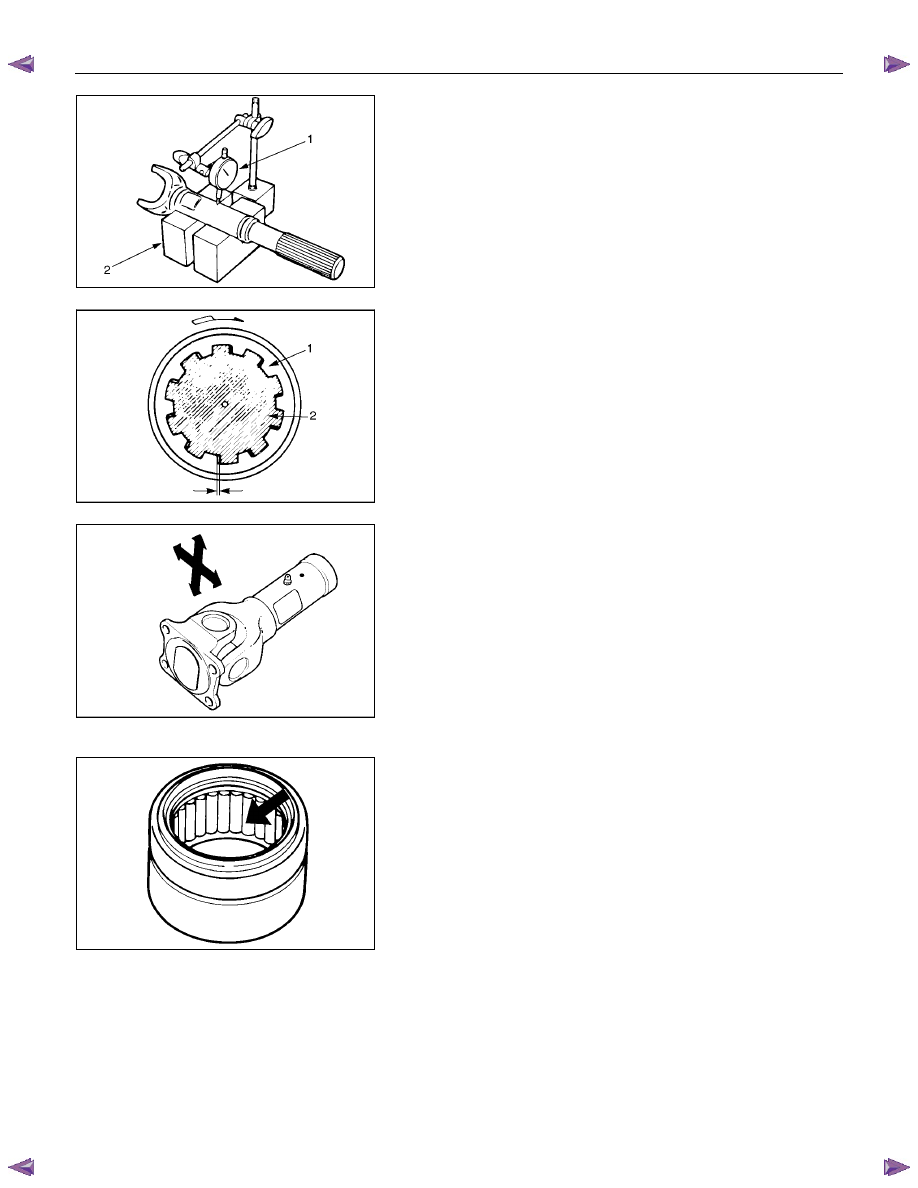

401RS027

Propeller Shaft Run-out

Support the ends of the propeller shaft on V-blocks (2) and

check for run-out by holding the probe of a dial indicator (1) in

contact with the center part of the shaft. If the amount of run-

out is beyond the standard value for assembly, correct with a

bench press or replace the shaft with a new propeller shaft

assembly.

Standard: 0.3 mm (0.012 in)

Limit: 0.5 mm (0.02 in)

401RS009

Play in Splines in Normal Direction of Rotation

Check the amount of play between the sleeve yoke (1) and the

propeller shaft spline (2) in the direction of rotation, using a

pointed feeler gauge.

Standard: 0.073-0.156 mm (0.003-0.006 in)

Limit: 0.3 mm (0.012 in)

401RS010

Play in Universal Joint

Limit: Less than 0.1 mm (0.004 in)

401RS011

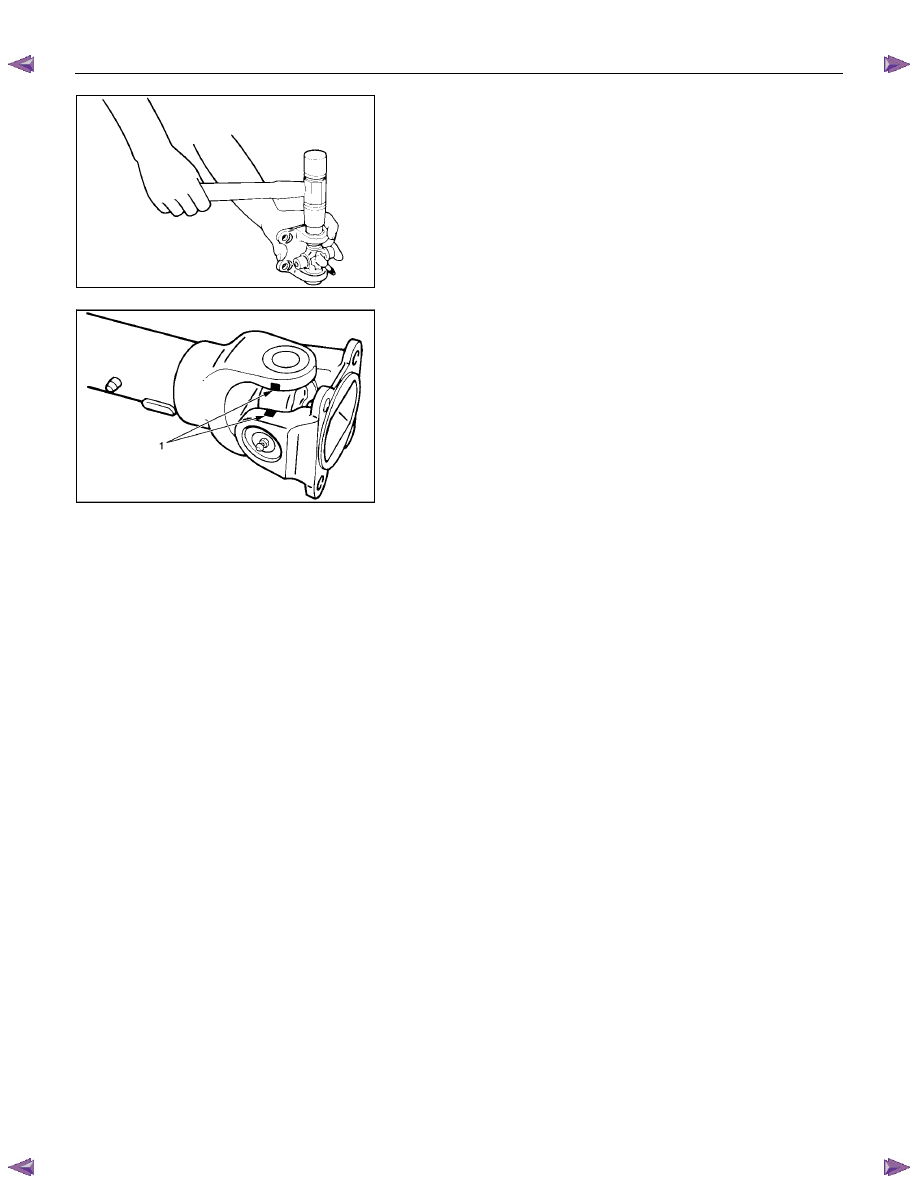

Reassembly

1. Install spider to flange yoke. Be sure to install the spider by

aligning the setting marks made during disassembly.

2. Apply a molybdenum-disulfide grease or multi-purpose type

grease NLGI No. 2 to inside of the bearing cap.

Grease Amount: Approx. 1.2 g (0.042 oz)

PROPELLER SHAFT 4A-27

401RS012

3. Using either a mallet (or copper hammer) or a press, install

the needle roller bearing into the yoke so that the snap ring

can be installed in its groove.

CAUTION:

The needle roller bearing cannot be installed smoothly if it

is set at an incorrect angle with the flange and excessive

hammering will damage the needle roller bearing.

401RS028

4. Align setting marks (1) and join the yokes.

5. Install snap ring.

NOTE:

Discard used snap rings and install new ones.

When the bearing cap is in position, select and attach a snap

ring of suitable thickness so that the end play of the spider pin

is held within 0.1 mm (0.004 in).

Snap ring thickness and Identification color

1.50 mm (0.059 in); Light Blue

1.53 mm (0.060 in); White

1.56 mm (0.061 in); Pink

1.59 mm (0.063 in); Yellow

1.62 mm (0.064 in); Green

1.65 mm (0.065 in); Brown

1.68 mm (0.066 in); Not colored

NOTE:

Be sure to use snap rings of the same thickness

on both sides.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст