Suzuki Grand Vitara JB627. Manual — part 271

7A-16 Heater and Ventilation:

Installation

1) Reverse removal procedure, noting the following.

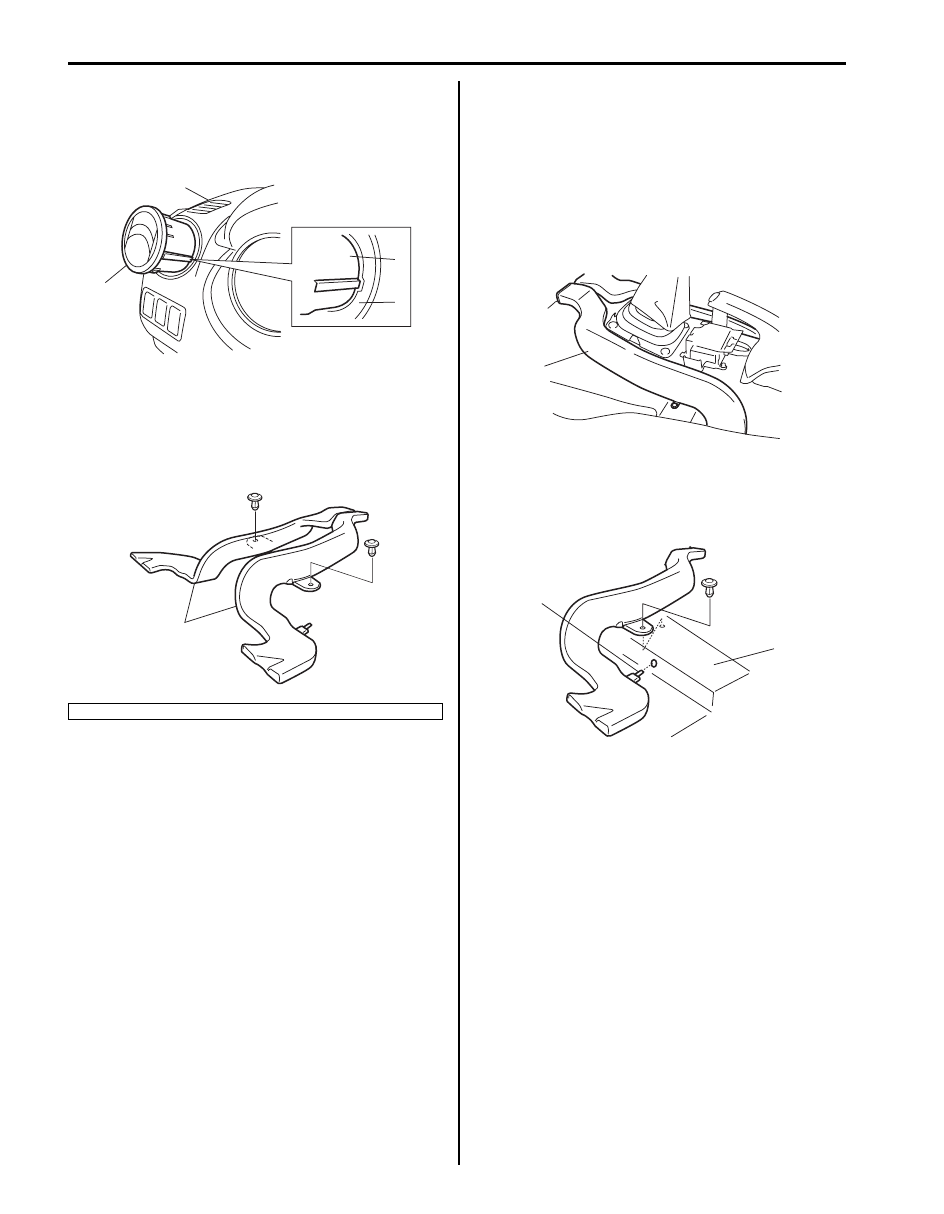

• Install side ventilation louver (1) to instrument

panel (2) as shown in figure.

• When installing defroster duct to instrument panel,

put claws of defroster duct into hole of ventilator

duct surely.

Rear Duct Components

S6JB0B7106022

Rear Duct Removal and Installation

S6JB0B7106023

Removal

1) Disconnect negative (–) cable at battery.

2) Remove front seats.

3) Remove console box.

4) Take off carpet till rear ducts is totally exposed.

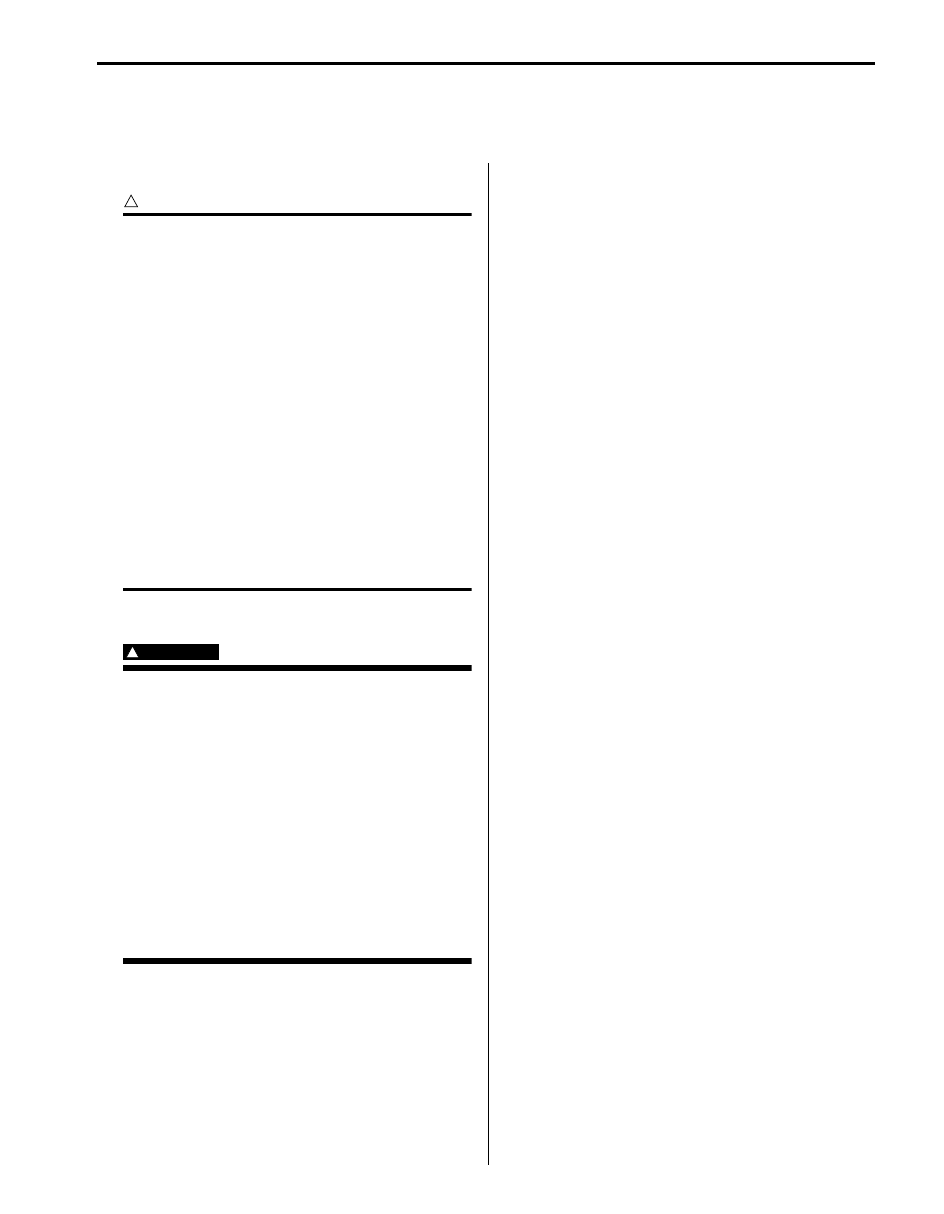

5) Remove rear ducts (1).

Installation

Reverse removal procedure noting the following.

• Insert boss (1) of duct into hole of floor member (2).

1. Rear duct

1

2

1

2

I5JB0A710024-02

1

I5JB0A710025-02

1

I5JB0A710026-01

2

1

I5JB0A710027-01

Air Conditioning System: 7B-1

HVAC

Air Conditioning System

Precautions

A/C System Caution

S6JB0B7200001

CAUTION

!

The air conditioning system of this vehicle

uses refrigerant HFC-134a (R-134a).

None of refrigerant, compressor oil and

component parts is interchangeable between

two types of A/C: one using refrigerant HFC-

134a (R-134a) and the other using refrigerant

CFC-12 (R-12).

Be sure to check which refrigerant is used

before any service work including inspection

and maintenance. For identification between

these two types, refer to “A/C Refrigerant

Type Description”.

When replenishing or changing refrigerant

and compressor oil and when replacing

parts, make sure that the material or the part

to be used is appropriate to the A/C installed

in the vehicle being serviced.

Use of incorrect one will result in leakage of

refrigerant, damage in parts or other faulty

condition.

Precautions on Servicing A/C System

S6JB0B7200002

WARNING

!

Should refrigerant HFC-134a (R-134a) is

exposed to your eye(s), consult a doctor

immediately.

• Do not use your hand to rub affected

eye(s). Instead, use fresh cold water to

splash it over affected area to thus

gradually raise its temperature above the

freezing point.

• Obtain proper treatment as soon as

possible from a doctor or eye specialist.

Should liquid refrigerant HFC-134a (R-

134a) is exposed to your skin, such

affected part should be treated in the same

manner as when skin is frostbitten or

frozen.

Precautions in Diagnosing Trouble

S6JB0B7200003

• Do not disconnect connector from HVAC control

module, battery cable from battery, or main fuse

before reading diagnostic information stored in HVAC

control module memory.

• When diagnosing vehicle indoors, sunload sensor has

to be lighted over vertically with an incandescent light.

Otherwise, DTC is detected even if sunload sensor is

normal.

• Diagnostic information (diagnostic trouble code)

stored in HVAC control module can be checked by

display of HVAC control module. Also, it can be

checked by using SUZUKI scan tool. Before checking

diagnostic information (diagnostic trouble code), read

this manual and operator’s manual for SUZUKI scan

tool to know how to read diagnostic information

(diagnostic trouble code).

• When trouble is diagnosed using diagnostic

information (diagnostic trouble code) on display of

HVAC control module, keep in your mind that each

diagnostic information (diagnostic trouble code) has

priority, and only diagnostic information (diagnostic

trouble code) which has the highest priority is

indicated. Therefore, after troubleshooting the

malfunction, make sure if there exists any other

diagnostic information (diagnostic trouble code).

• After troubleshooting some trouble, DTC can be

stored in HVAC control module memory as history

DTC.

• Be sure to read “Precautions for Electrical Circuit

Service” before inspection.

Precautions on Handling Refrigerant HFC-134a

(R-134a)

S6JB0B7200004

• When handling refrigerant, always wear goggles to

protect your eyes.

• Avoid you direct contact to liquid refrigerant.

• Do not heat refrigerant container higher than 40

°C

(104

°F).

• Do not discharge refrigerant into atmosphere.

• Do not allow liquid refrigerant to touch bright metals.

Refrigerant combined with moisture is corrosive and

will tarnish surfaces of bright metals including chrome.

• After recovering refrigerant from system, the amount

of compressor oil removed must be measured and the

same amount added to the system.

7B-2 Air Conditioning System:

Precautions on Servicing Refrigerant Line

S6JB0B7200005

• When connecting hoses and pipes, apply a few drops of compressor oil (refrigerant oil) to seats of coupling nuts

and O-ring.

• Never use heat for bending pipes. When bending a pipe, try to make its bending radius as slight as possible.

• Keep internal parts of air conditioning free from moisture and dirt. When disconnecting any line from system, install

a blind plug or cap to the fitting immediately.

• When tightening or loosening a fitting, use two wrenches, one for turning and the other for support.

• Tighten bolts to specified torque.

Tightening torque

Refrigerant line bolt: 12 N·m (1.2 kgf-m, 9.0 lb-ft)

• Route drain hose so that drained water does not make any contact to vehicle components.

Precautions on Refrigerant Recovery

S6JB0B7200006

When discharging refrigerant out of A/C system, always

recover it by using refrigerant recovery and recycling

equipment. Discharging refrigerant HFC-134a (R-134a)

into atmosphere would cause adverse effect to

environments.

NOTE

When handling recovery and recycling

equipment, be sure to follow the instruction

manual for the equipment.

Precautions on Refrigerant Charge

S6JB0B7200007

Charge a proper amount of refrigerant to A/C system

according to charging procedure described in recovery,

evacuation and charging. Refer to “Charge” in

“Operation Procedure for Charging A/C with

Refrigerant”.

Precautions on Replenishing Compressor Oil

S6JB0B7200008

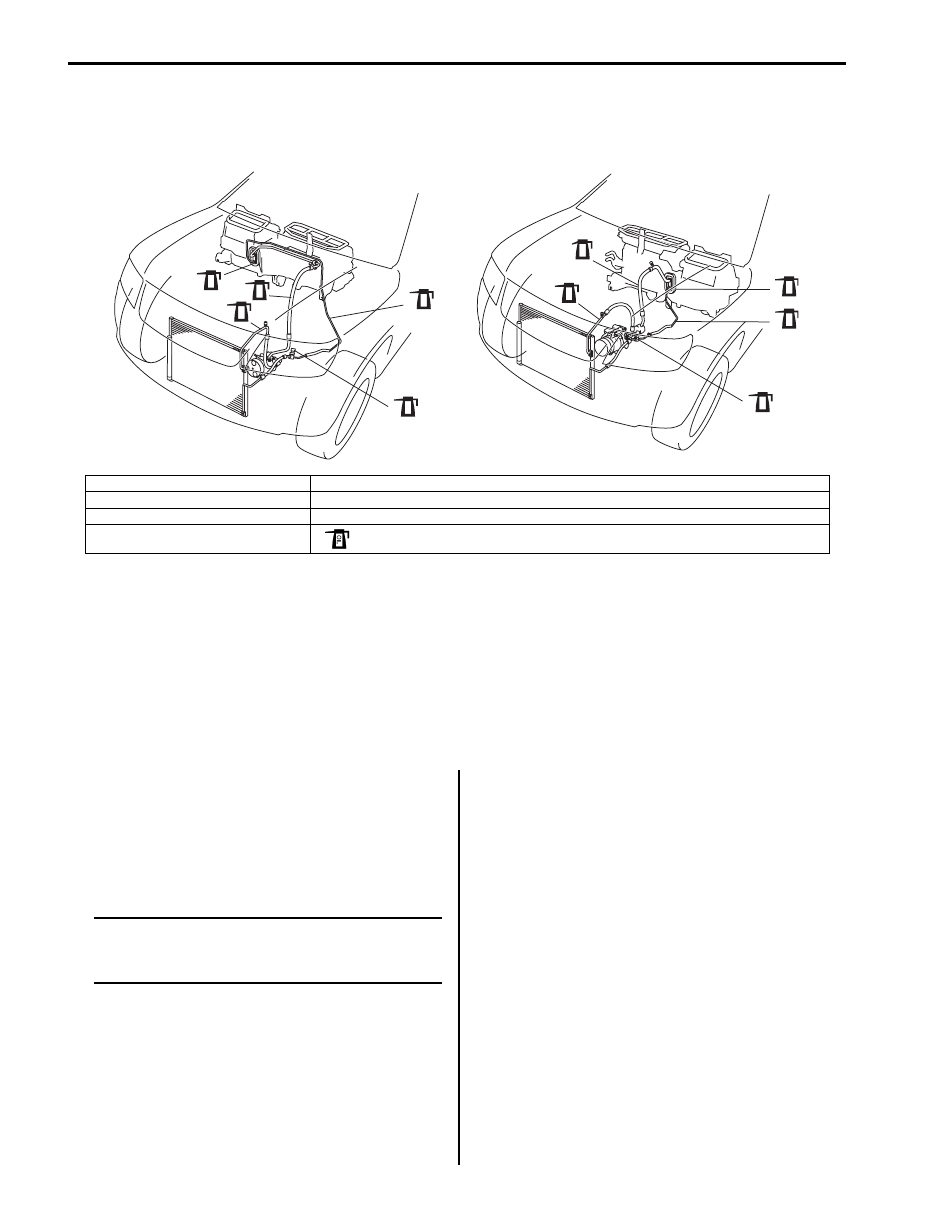

When replacing air conditioning parts with new ones, it is

necessary to replenish oil by the amount supposedly

remaining in each part.

4

OIL

1

OIL

2

OIL

3

OIL

5

OIL

[A]

1

OIL

2

OIL

4

OIL

3

OIL

5

OIL

[B]

I6JB0B720003-02

[A]: LHD model

3. Liquid pipe

[B]: RHD model

4. Expansion valve

1. Suction hose

5. Pressure sensor

2. Discharge hose

: Apply compressor oil (refrigerant oil) to O-ring.

Air Conditioning System: 7B-3

When Charging Refrigerant Only

When charging refrigerant without replacing any

component, replenish the same amount of measured oil

when recovering refrigerant (if not measure, replenish 20

cm

3

(20 cc) oil).

When Replacing Compressor

CAUTION

!

Be sure to use specified compressor oil or an

equivalent compressor oil.

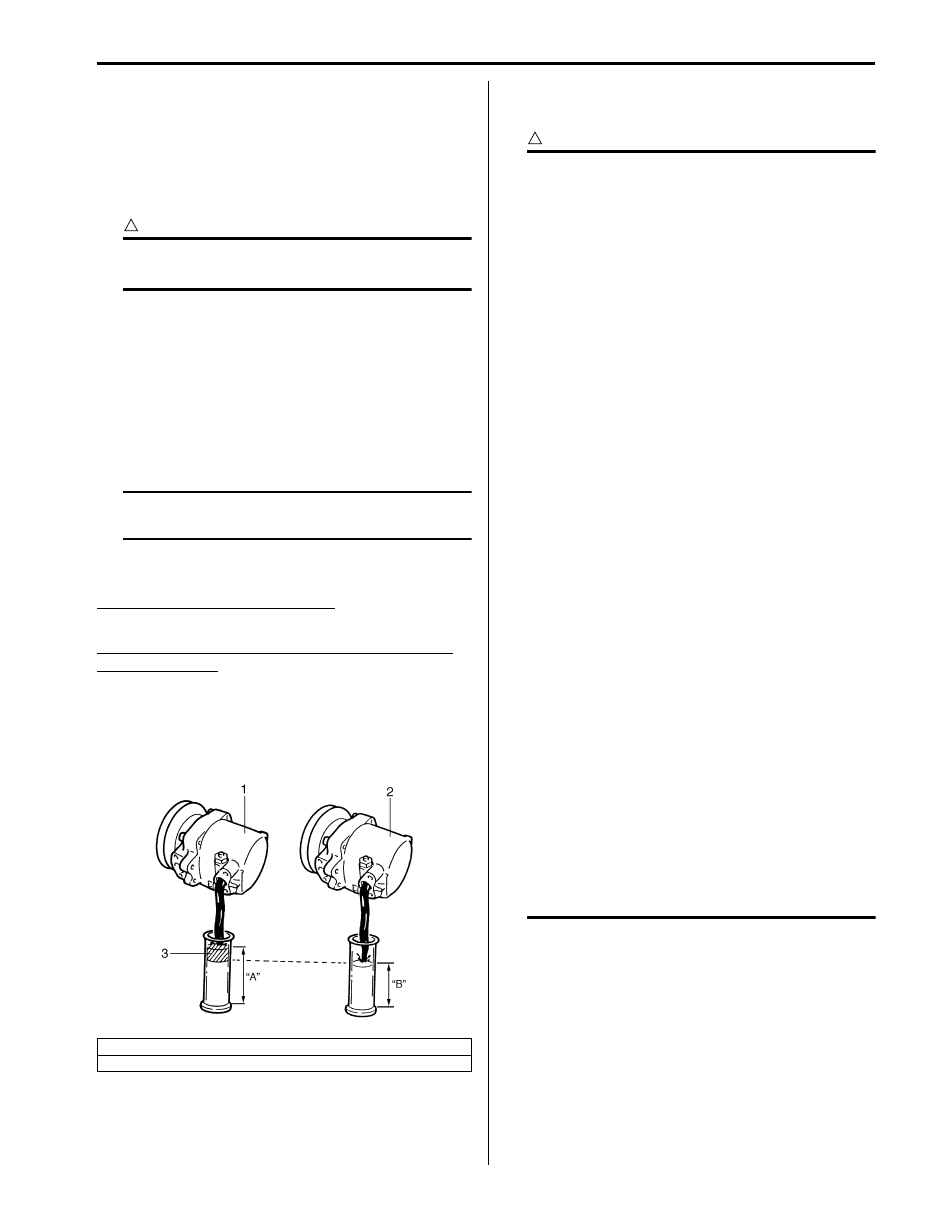

Compressor oil is sealed in each new compressor (1) by

the amount required for air conditioner cycle. Therefore,

when using a new compressor for replacement, drain oil

from it by the amount calculated as follows.

“C” = “A” – “B”

“C”: Amount of oil to be drained

“A”: Amount of oil sealed in a new compressor

“B”: Amount of oil remaining in removed

compressor

NOTE

Compressor assembly supplied from factory

is filled up with the following amount of oil.

: Compressor oil 99000–99022–00E (Compressor oil

(DH-PS, 250cc))

Amount of oil in new compressor

: 150 (+20, –0) cm

3

(150 (+20, –0) cc)

Amount of compressor oil to be replenished after

part replacement

Evaporator: 50 cm

3

(50 cc)

Condenser: 30 cm

3

(30 cc)

Receiver/dryer: 10 cm

3

(10 cc)

Hoses: 10 cm

3

(10 cc)

Pipes: 10 cm

3

(10 cc)

Precautions on Servicing Compressor

Assembly

S6JB0B7200009

CAUTION

!

• None of refrigerant, compressor oil and

component parts is interchangeable

between two types of A/C: one using CFC-

12 (R-12) and the other using HFC-134a (R-

134a).

For identification between these two types,

refer to “A/C Refrigerant Type

Description”.

When replenishing or changing refrigerant

and compressor oil and when replacing

parts, make sure that the material or the

part to be used is appropriate to the A/C

installed in the vehicle being serviced. Use

of incorrect refrigerant or compressor oil

will result in leakage of refrigerant, damage

in parts or other faulty condition.

• When servicing the compressor, keep dirt

or foreign material away from getting on or

into the compressor parts and system.

Clean tools and a clean work area are

important for proper service.

The compressor connection and the

outside of the compressor should be

cleaned before any “On-vehicle” repair or

before removal of the compressor. The

parts must be kept clean at all times and

any parts to be reassembled should be

cleaned with trichloromethane, naphtha,

kerosene or equivalent solvent and dried

with dry air. Use only lint free cloths to

wipe parts.

• When compressor is removed from the

vehicle for servicing, the oil remaining in

the compressor should be discarded and

new refrigerant oil added to the

compressor.

Minor repair procedures may be done on

the vehicle without discharging the

system. Major repair procedures require

that the system be discharged of

refrigerant.

2. Removed compressor

3. Excess oil (A – B)

I5JB0A720003-01

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст